|

|

|

|

|

|

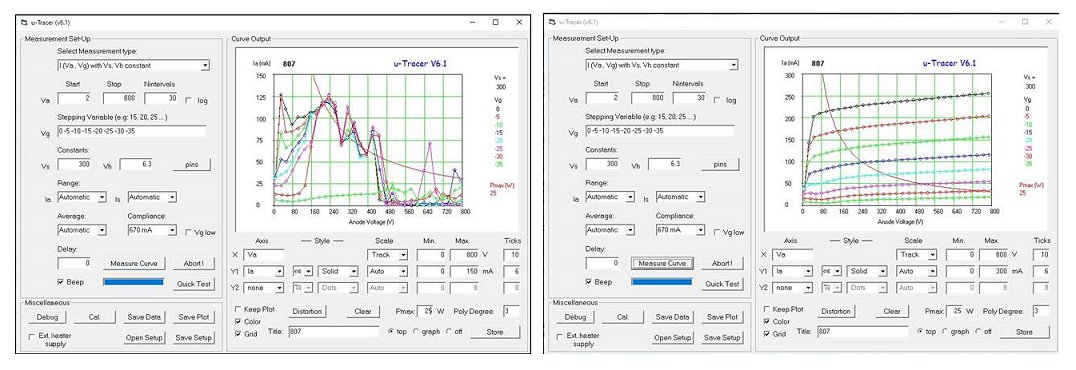

I think that I am not exaggerating when I write that the uTracer3+ has been an unexpected and enormous success. At the moment of writing these lines in excess of 1550 uTracer3+ are in service in 55 countries! The uTracer3+ is a compromise between simplicity and performance and was originally intended for my private use only. It was designed to trace and test the majority of the tubes that are being used in amplifiers, radios and televisions. Nevertheless, over the years people have continuously asked me for a tester/tracer with extended capabilities, especially towards higher voltages.

Sense and Simplicity

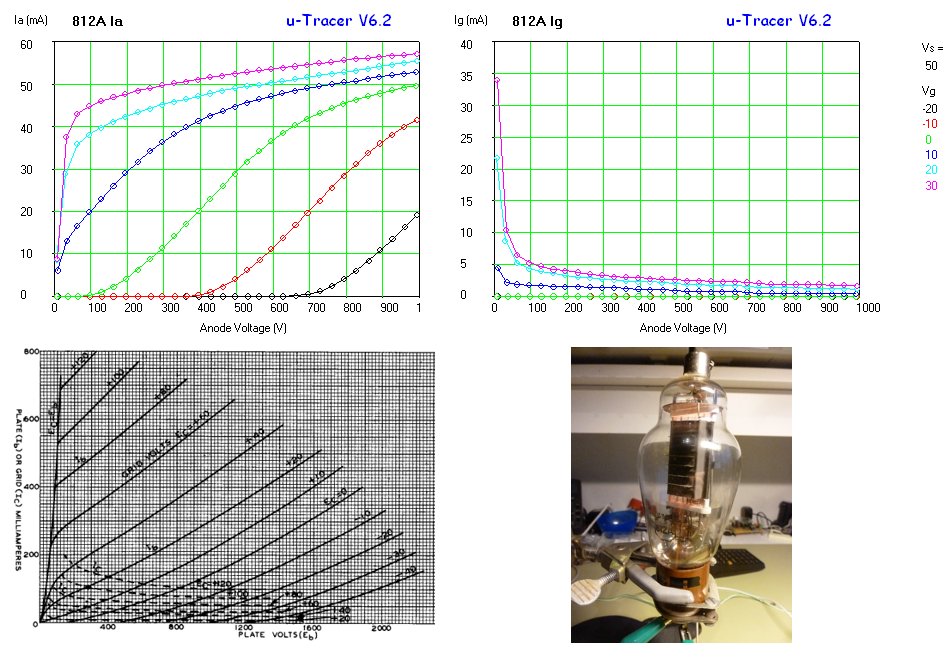

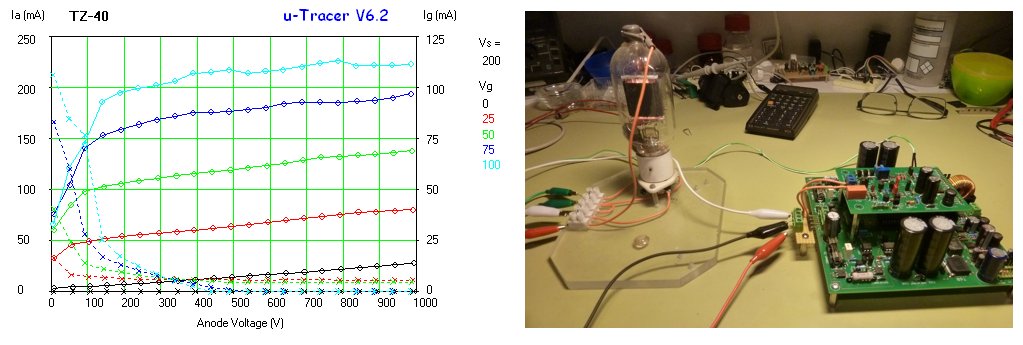

Personally I rather doubt the need for testing/tracing at higher anode and screen voltages. It is true that in some audio amplifiers supply voltages as high as 800 V are used, but I think that most of the interesting tube parameters can be well characterized at voltages between 0 and 400 V, while for higher voltages the curves can simply be extrapolated. Nevertheless, I agree that especially for RF transmitter tubes higher voltages would be welcome. With higher voltages comes “in one breath” the wish for higher currents. A uTracer for higher voltages and currents doesn’t make much sense if not also the grid bias range is being revised, and not only to more negative values, but for transmitter tubes also to positive grid biases. With positive grid biases also comes the need to measure the grid current …..

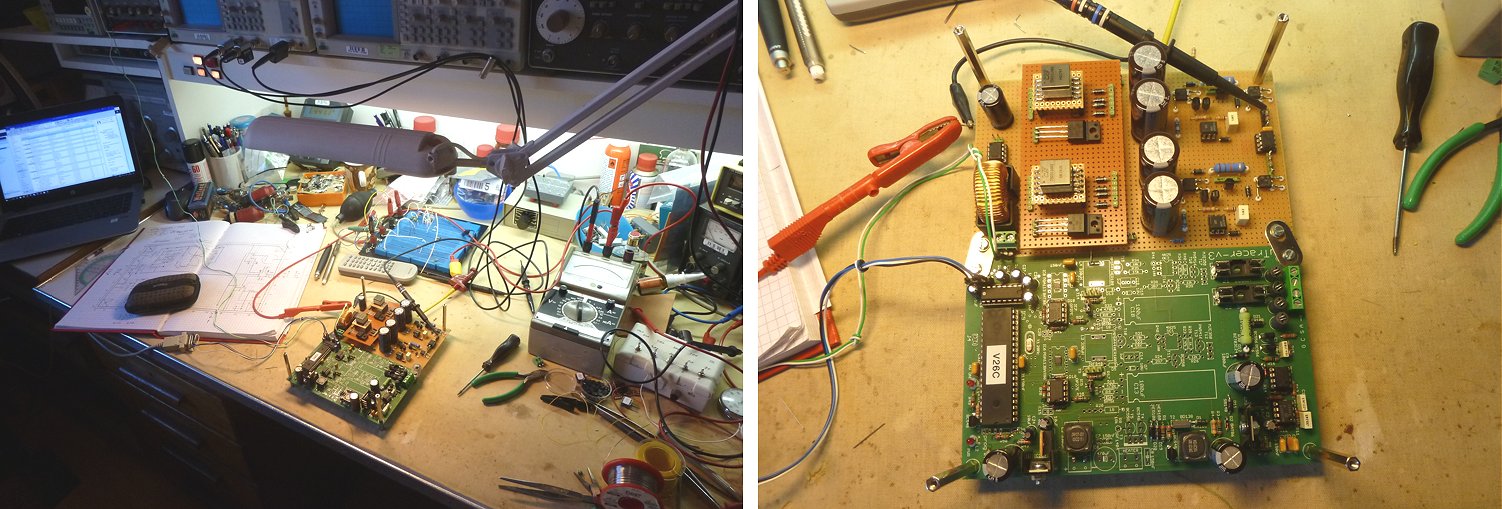

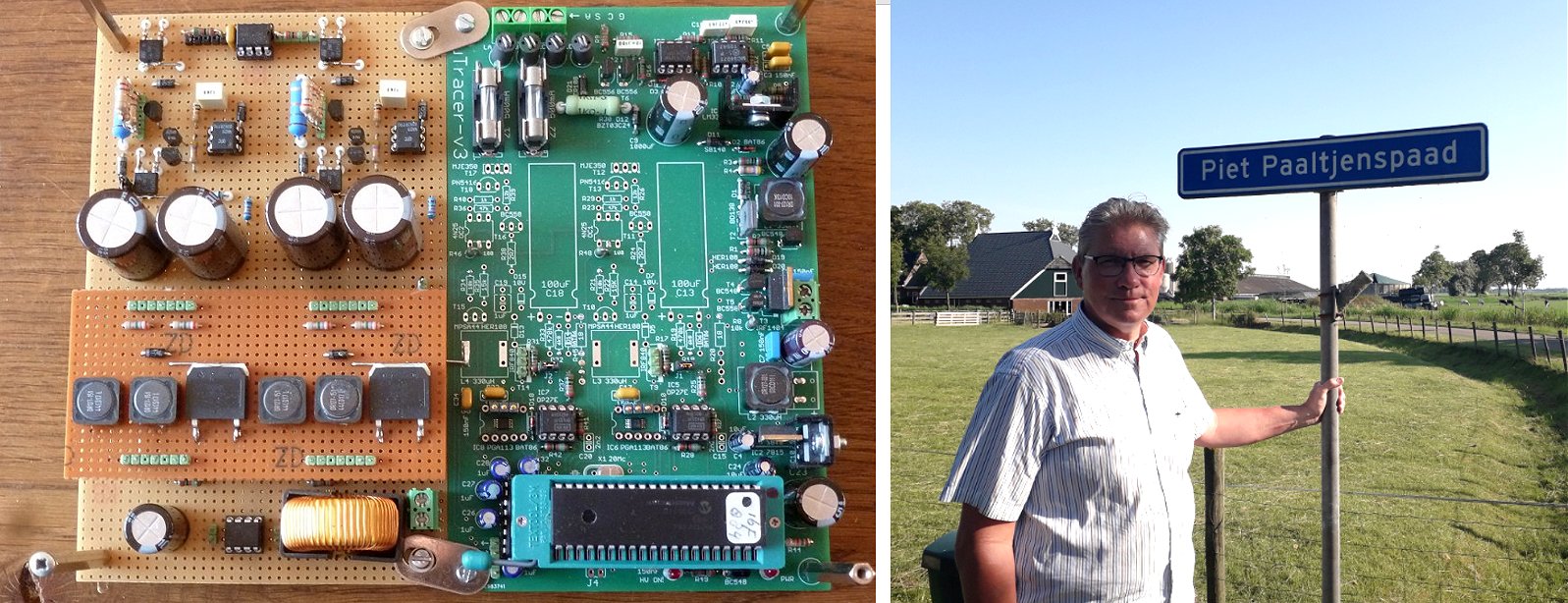

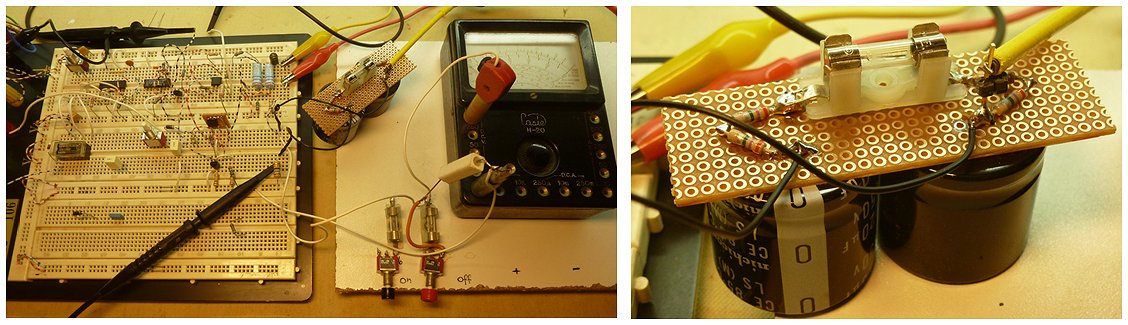

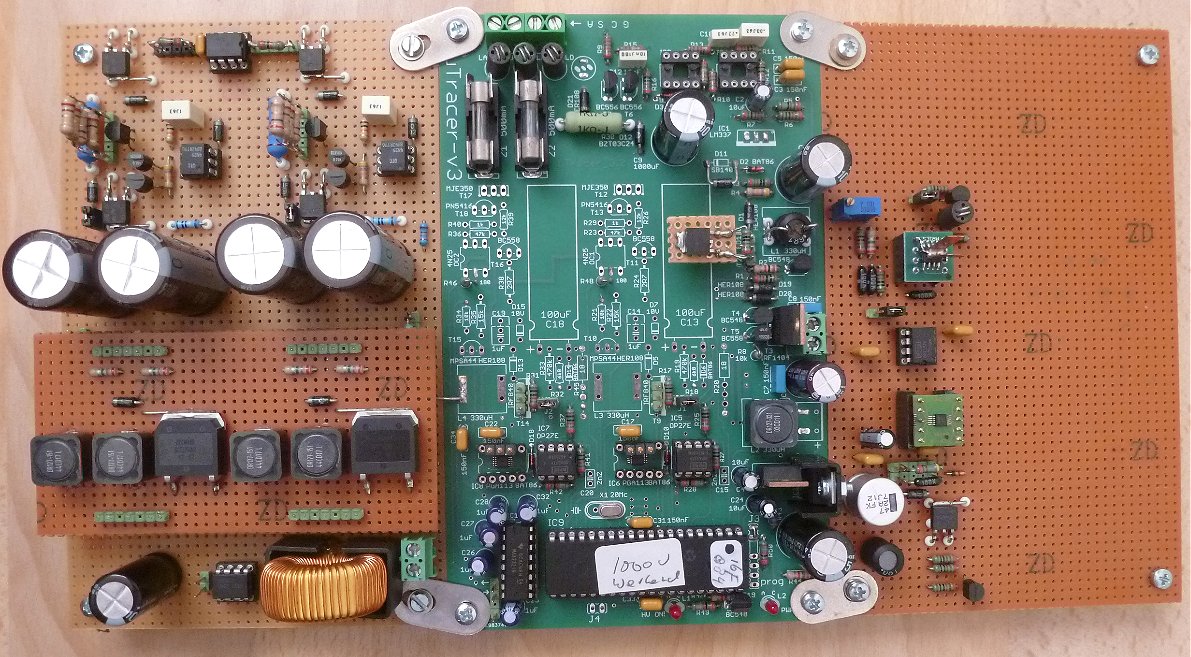

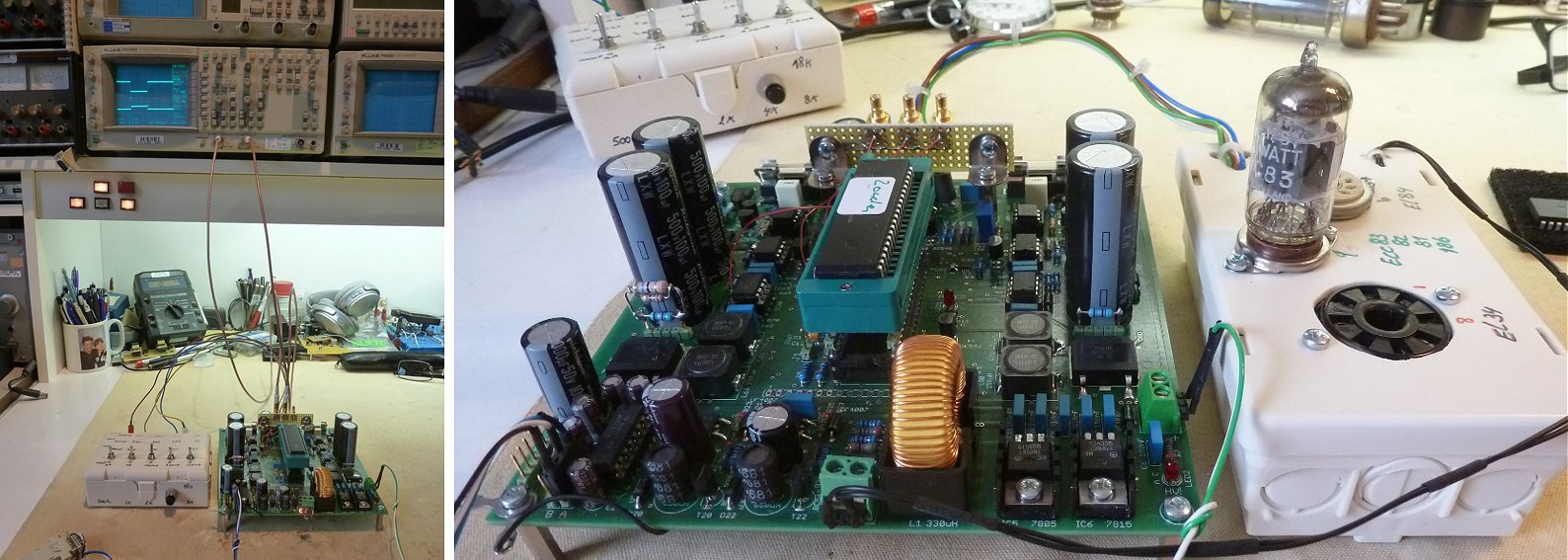

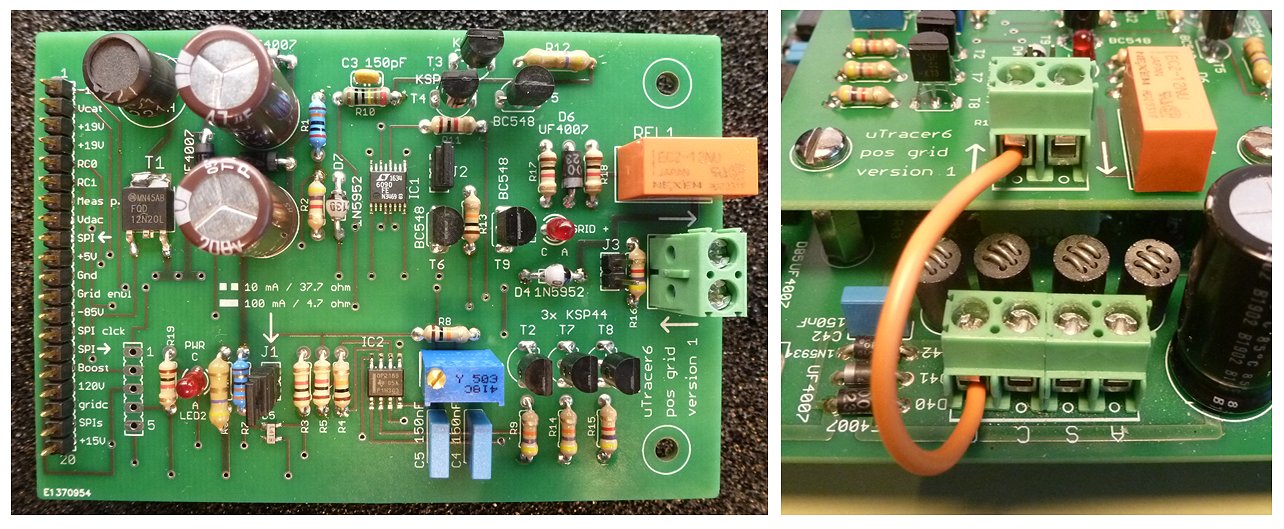

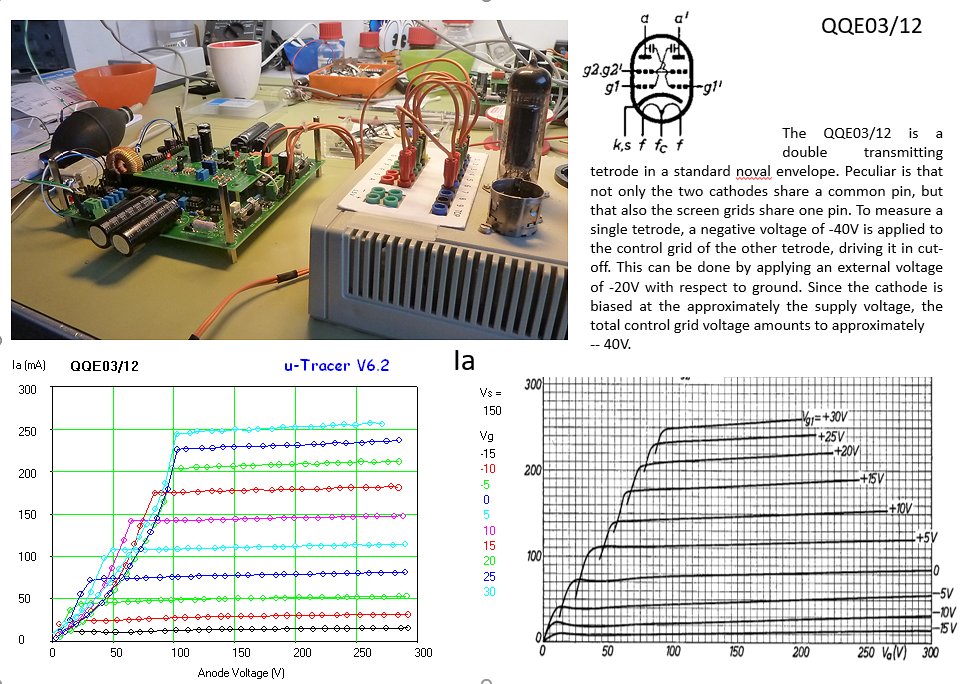

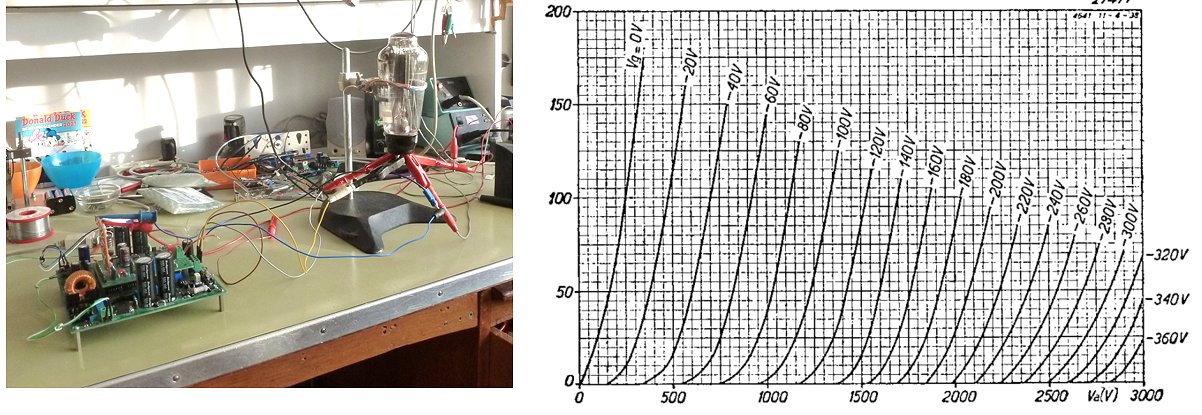

Figure 1.1 Studies for a new uTracer that on their way ended up in “the valley-of-death.” Left, prototype for the high voltage supply/switch of the uTracer5 (never published).

Center, perfboard version of the uTracer5. Right, prototype for the high voltage supply/switch of the uTracer4.

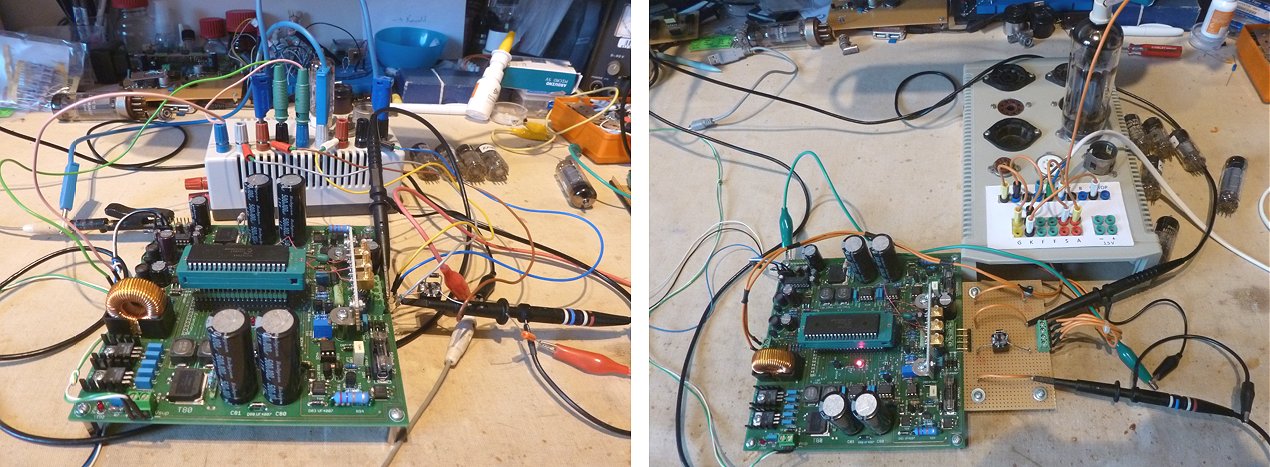

When one starts thinking about the requirements for a next generation uTracer, before you know it you end up with a monster that is designed to do everything, but that has lost all the “Sense and Simplicity” of the original uTracer3. This problem has been hampering me over the past years in developing a new uTracer. Figure 1.1 shows some of the attempts for a new uTracer that I have been working on during the past years. Some of these attempts were published, such as the uTracer4, while other attempts never reached my webpages. Most of these attempts failed because the design became unmanageable complex losing all the charm of the original uTracer. Hoping to have learned from all these failed attempts, I decided to have a new go at a uTracer that offers improved performance, but still has the simplicity and elegance of the uTracer3.

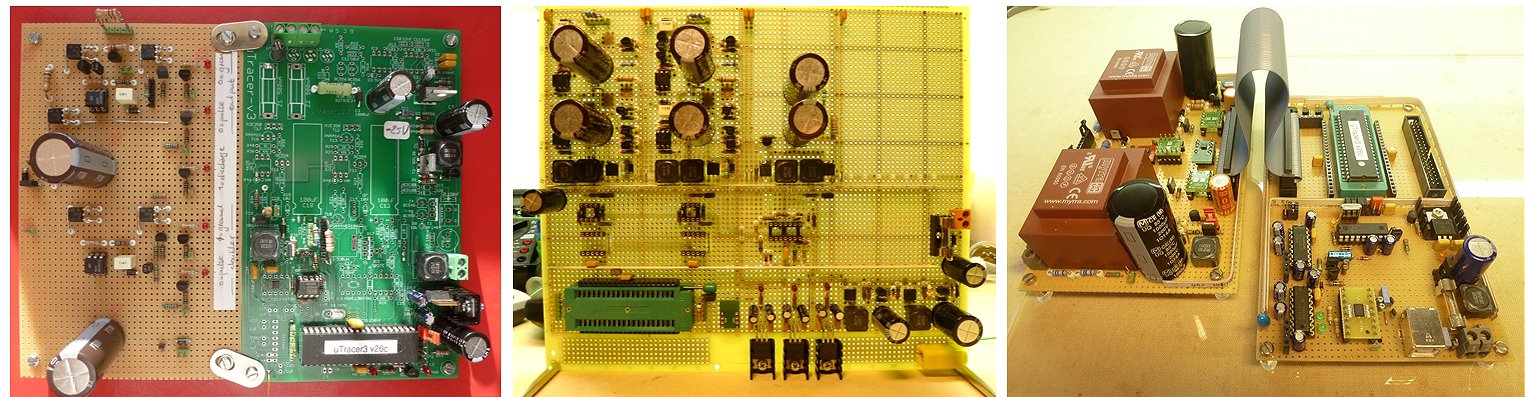

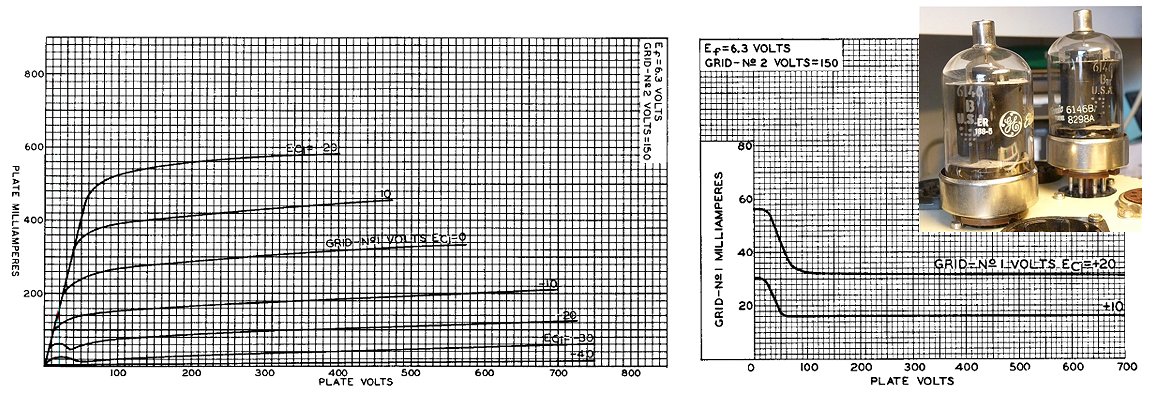

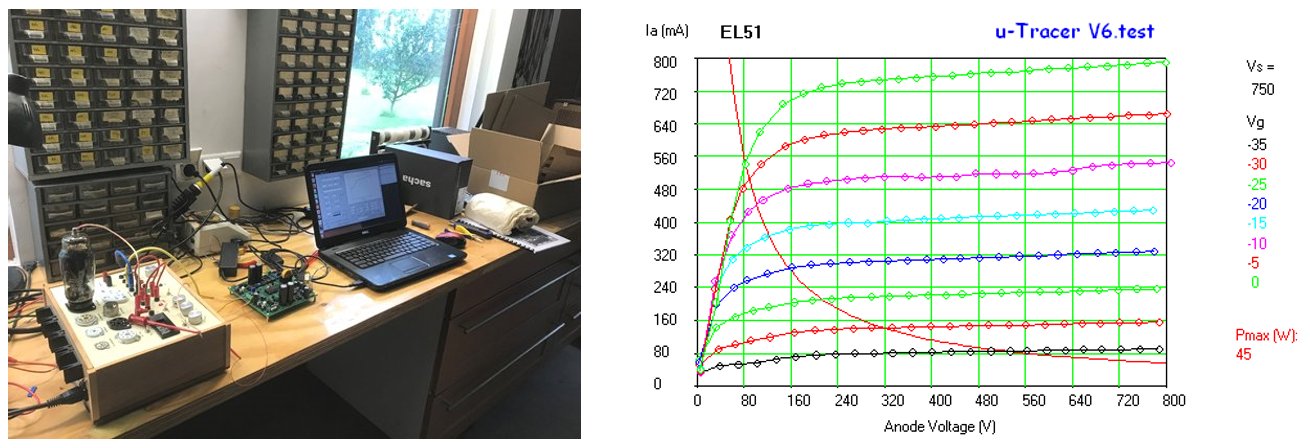

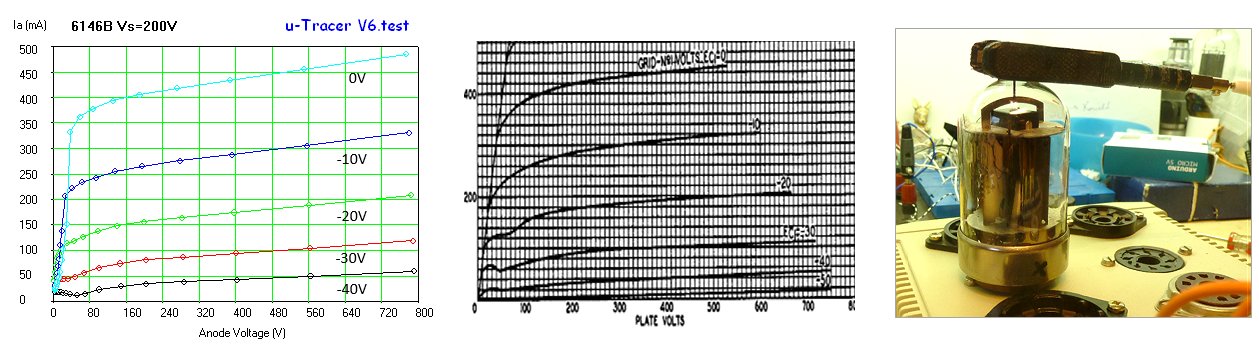

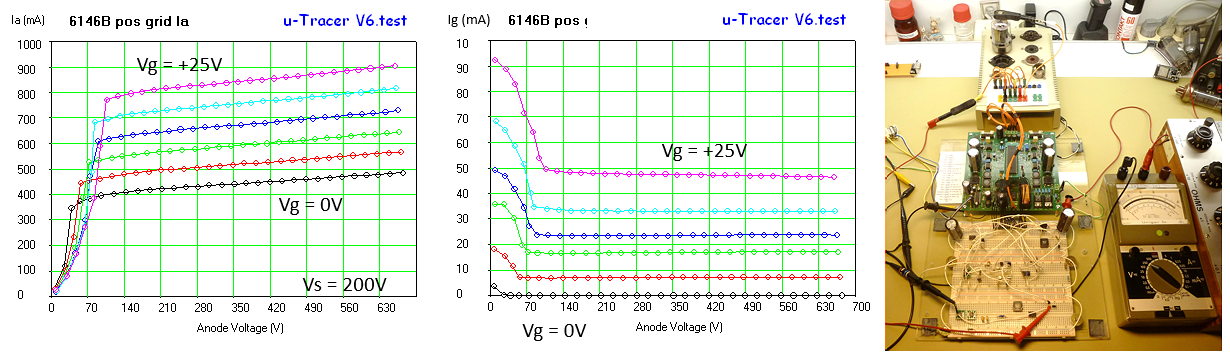

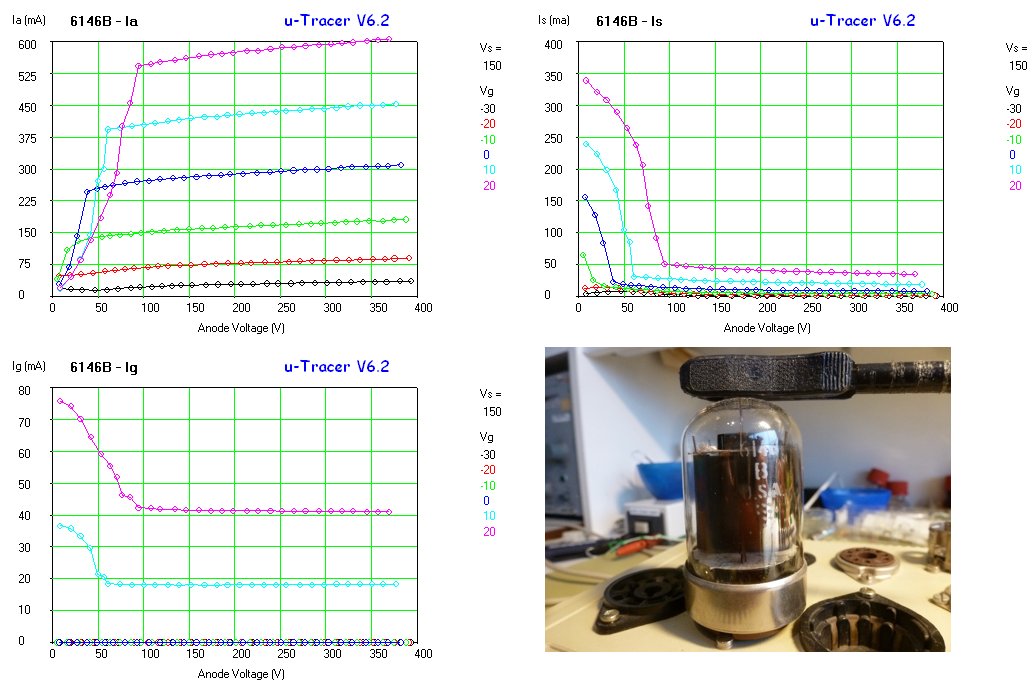

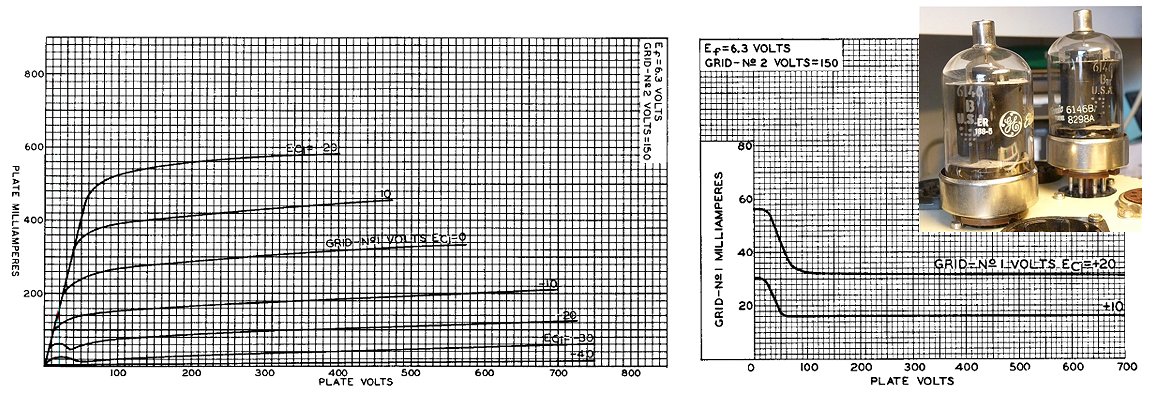

Figure 1.2 The 6146B is a popular tube amongst radio amateurs. I made it the “target tube” for the uTracer6.

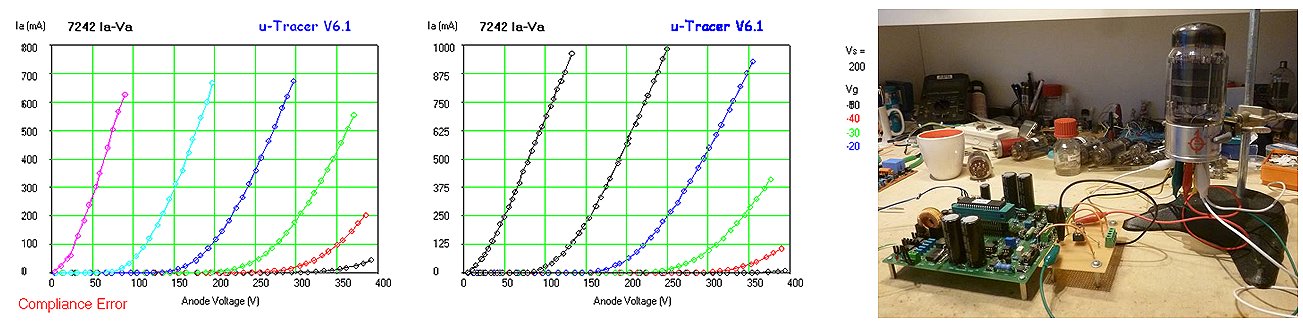

Sometime ago somebody gave me a couple of 6146B beam power tubes. Searching the internet I discovered that the 6146B is a very popular transmitting tube used by radio amateurs. On studying the 6146B data sheet I found that this is the kind of tube that would really need all the new features I have in mind for a possible uTracer6! Voltages up to 800 V, currents in excess of 500 mA, and both positive and negative grid biases. So I decided to take the set of curves of Fig. 1.2 as a kind of target for the uTracer6 specifications.

Based on the experience with the uTracer3, the never finished concepts for the uTracer4 and 5, as well as the experiments published in the Lab Notebook page, I think I have a feeling of what is reasonably possible, and from this I come to the following tentative uTracer6 specifications:

In the following pages we will investigate how realistic these specifications are. One thing that I have learned the past years is to make incremental steps. So both for the hardware, but especially also for the software I will stay as closely as possible with what is there for the uTracer3. As usual I will include some “personal memorabilia” in these pages, mainly for myself since these pages primarily serve as my own documentation and I like to be remembered of happy personal events that happened concurrent to the experiments/writing of this work.

| to top of page | back to uTracer homepage |

Increasing the anode and screen voltages of the uTracer is not so easy. First of all, because the maximum working voltage of electrolytic capacitors is fundamentally limited to around 450 V. Secondly, boost converters are not really ideal for generating very high voltages. This is because the maximum voltage that can be applied over an inductor is limited, but more importantly, boostconverters require a switching transistor that has both a very low on-resistance as well as a very high working voltage, which are conflicting requirements.

More suitable are flyback converters. Flyback converters use a transformer to generate the high voltage. A very nice property of the flyback converter is that the switching transistor on the primary side “does not see” the high voltage on the secondary side, but only a voltage that is scaled down according to transformation ratio of the transformer. This makes the selection of the switching transistor much easier since on-resistance and output voltage now basically have been decoupled. If you want to know more about the basics of flyback converters have a look at a page that I wrote ages ago.

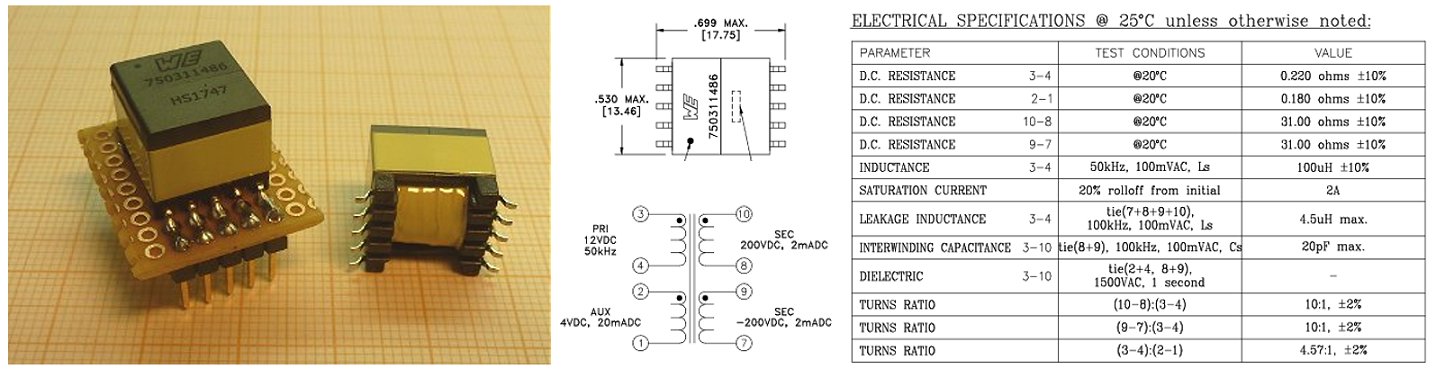

Unfortunately, flyback converters have one, for hobbyists, huge drawback: they require a transformer. Among hobbyists, including myself, transformers are not very popular. Either you have to make them yourself (…) or you have to rely on what is commercially available, which is usually not that much. However, some time ago I uncovered a cute little transformer that at first side might be perfectly suitable for experimenting with higher voltages for the uTracer. The transformer in question is manufactured by Würth with type number 750311486, and is available from Mouser with type number 710-750311692.

Figure 2.1 The 750311486 flyback transformer from Würth.

This little gem, which measures something less than a cube centimetre has four windings. A primary winding with an inductance of 80 uH, and two secondary windings, each with 10 times more windings than the primary winding. My idea was to use both secondary windings in series to generate voltages towards 1000 V. Figure 2.2 shows a simple first test circuit to see if a flyback converter around this transformer would fit into the uTracer concept. The circuit consists of an oscillator that generates 10us wide pulses at a repetition frequency of 10 kHz. On the secondary side, the two secondary windings feed two 100 uF / 450 V capacitors in series. A tricky pitfall of this circuit is the isolation between the two secondary windings. According to the specifications, the isolation between the primary and secondary windings is specified at 1500 V. However, this is the isolation between primary side and secondary side. It says nothing about the isolation between the two secondary windings. To make it for the transformer as easy as possible, I made an elaborate construction with D1 … D4 that ensures there is no DC potential between the two secondary windings. Only during the flyback phase, there is a very short moment when all diodes are conducting, and where there can be up to 900 V between the two windings.

Figure 2.2 Circuit used to test the 750311486 flyback transformer from Würth under conditions resembling the uTracer topology.

The circuit worked like a dream. In less than six seconds, the circuit charged the capacitors to 900 V! There was no sign of dielectric breakdown between the secondary windings. Note that at the primary side a simple IRFI540 transistor was used that is specified at 77 mOhm on resistance with a breakdown voltage of only 100 V.

Figure 2.3 Full blown test circuit that I use(d) to study circuit concepts to increase the working voltage of the uTracer.

On the perfboard there is a second “piggyback” perfboard that allows me to test different inductor/transformer configurations.

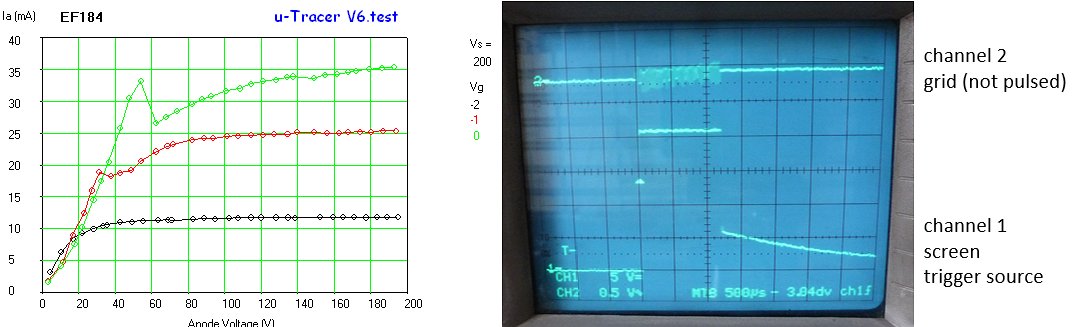

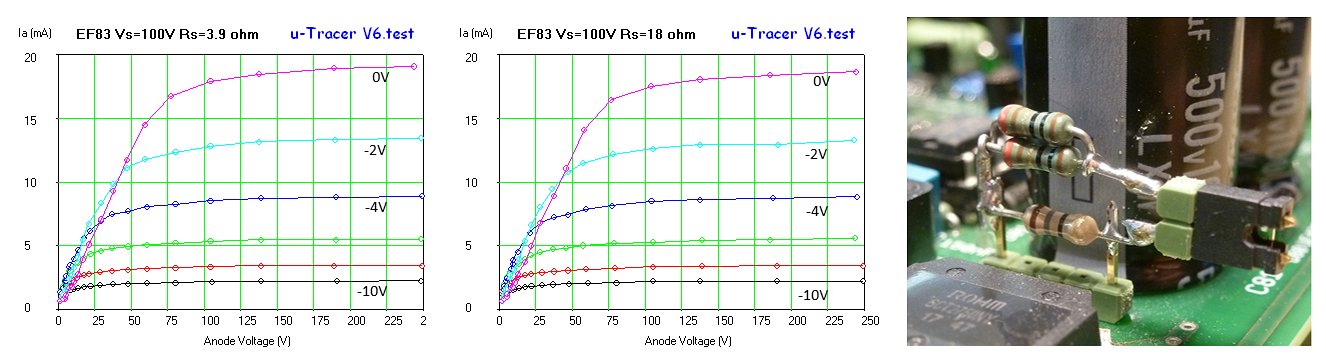

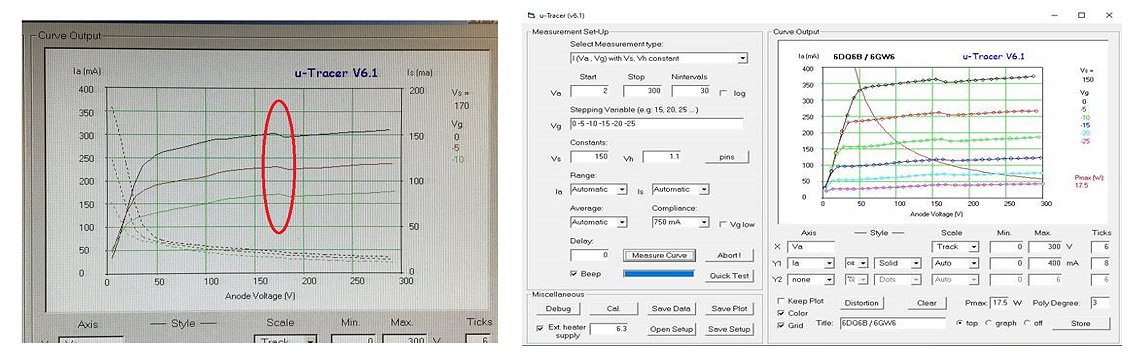

The next step was to try the flyback transformer in an actual uTracer setup. Figure 2.3 shows a hacked uTracer where the high voltage section has been replaced by a breadboard flyback implementation. The breadboard contains the high voltage section in a flexible and reconfigurable configuration, and a new high voltage switch (more about that in a future write-up). Because I don’t want to completely change the uTracer’s firmware, the flyback converter is driven in the same way as the standard uTracer, so with pulses of a variable length (0 to 50 us) with a repetition frequency of 10 kHz. The uTracer measures the voltage and stops pulsing when the voltage reaches the set point value. To my surprize and disappointment the circuit worked less well than I expected. The curves were raged, especially for voltages below 150 V. Considerable time was spent on debugging the circuit. At first I suspected the oscillations that are common to flyback converters and that are caused by the charge stored on the drain of the MOSFET that cause oscillations after the transformer has delivered its charge to the load capacitor. Adding snubbers and diodes did give some improvement, but the circuit still continued to perform unsatisfactory.

I sometimes have the bad habit to start experimenting straight away without thinking too much or making calculations/simulations first. I plead guilty! After the initial disappointment I made some basic calculations that gave some clues as to why things didn’t work as expected. The most basic equation for any boost or flyback converter is given in Fig. 2.4A. It gives the current in an inductor with inductance L when it is applied to a voltage source Vsupl for t seconds. It basically says, when an inductance is connected to a voltage source, the current through the inductor increases linearly with time and at a rate inversely proportional to the inductance. Let’s take the flyback transformer as an example (Fig. 2.4B). If we apply 20 V during 15 us to the 100 uH primary winding, the current in the primary winding will rise to 2 A, the maximum current before the core starts to saturate.

Figure 2.4 Basic equation(s) governing working of a flyback converter.

When T1 is opened, the magnetic energy stored in the transformer will be dumped in the capacitor. The initial current flowing in the secondary side simply follows from the fact that the energy initially stored on the primary side of the transformer, is now transferred to the secondary side (Fig. 2.4D). So with a ratio in turns of a factor 10, the initial current on the secondary side is 2*sqrt(0.1)= 0.63 A. Here we see one of the reasons why the circuit is not working as expected. The secondary current causes a large voltage drop over the secondary winding amounting to 0.63*62= 39 V! This not only interferes with the proper flyback operation at low output voltages, but it also gives rise to substantial dissipation as could also be felt by the temperature of the transformer.

Back to the good old boost converter

After a lot of playing and tweaking of the flyback circuit, some improvement in the performance of the circuit was obtained, but it was too much of a hassle; the elegance of the circuit was lost.

Playing with the flyback converter, I realized however, that in the boost converter concept the problem of a too high voltage over a single inductor could be solved by using two inductors in series! From the uTracer3 we know that this type of inductors can easily handle 450 V across their terminals. By placing two inductors with half the inductance value in series, the current will flow through both inductors and consequently the generated voltage, which is proportional to dI/dt, will by definition be equally divided over the two inductors, potentially boosting the voltage up to 900 V

Anode and screen voltages up to 900 V would be great of course, but the problem of a switching transistor that can handle 1000 V with a sufficiently low on-resistance and acceptable price and availability remained a problem. Fortunately it appeared that since the uTracer3 the industry has made significant progress. Silicon Carbide transistors with incredible specifications have now become available at very acceptable prices. An example is the SCT2750NY from ROHM that is available from Mouser under part number

755-SCT2750NYTB. This 1x1cm “monster” has a breakdown voltage of 1700 V, and an on-resistance of only 0.75 Ohm. It can handle currents up to 6 A, a power dissipation of 57 W, and comes at a price of around 6 euros. Apart from its large TO-268-2L package, the only other drawback that I can think of is that for the device to handle substantial currents, a gate voltage of around 15 V is required.

Figure 2.5 900 V Boost converter module.

Figure 2.5 shows the basic circuit of the high voltage boost converter. The circuit is pretty straightforward. The gate of the SiC fet is driven by a dual gate driver circuit. I used an IR25600, but many other gate driver ICs (like the MIC4427) will do just as well. The 8 pin package contains two driver circuits so that one can be used for the anode section and the other for the screen section. Resistor R1 limits the gate current during switching to a safe value. The filter consisting of L1 and C1 smooths out the high current boost pulses, which helps to reduce noise in the system. Finally, the two 2.7 M resistors R2 and R3 ensure that the output voltage is equally divided over C3 and C4 even when is a small difference in leakage current in these capacitors.

Figure 2.6 To the left the modular test uTracer now with the boost converter installed. Note the large size of the SiC transistor! The picture on the right is just a small souvenir for myself of the holiday spent in Friensland in the North of Holland where we visited Foudgum, a tiny village in the North of Holland where the Dutch writer and poet Piet Paaltjens lived (summer 2019).

Figure 2.6 shows the same test board as in Fig. 2.3, but now equipped with the boost converter. The circuit worked like a dream, without any hitches! Note the enormous size of the SiC SCT2750 in comparison to the inductors! An added benefit of the circuit is that the saturation current of the 150 uH inductors is much higher than the 330 uH inductors in the uTracer3: 3 A vs 1.5 A. By simply increasing the length of the boost converter pulses to 35 us, this current is reached. Since the energy stored in an inductor is proportional to the current squared, this means that per boost converter cycle 4 times the amount of energy (charge) is transferred to the capacitor(s). In plain English, they charge much faster, especially for voltages in the lower range.

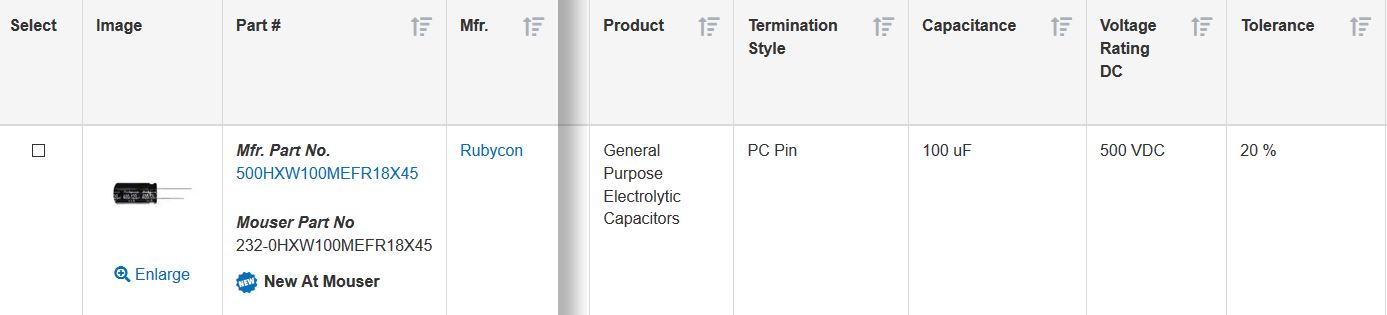

Figure 2.7 The new 100 uF / 500 V capacitors from Rubicon (datasheet).

I had just finished writing this article when I found that Rubycon is now offering 100 uF capacitors at a working voltage of 500 V! There are more 100 uF / 500 V capacitors available, but they are of the bulkier snap-in type. The new Rubycon capacitors have the same diameter (18 mm) and pin spacing (7.5 mm) as the capacitors used in the uTracer. Using 2 of these capacitors in series would in principle make a 1000 V uTracer possible! Unfortunately these capacitors have a very long lead time of 20 weeks (!!) and Mouser does not have then on stock. Still, I ordered a bunch of them, and they will be delivered in April.

After I published this section, Georg Grossmann sent me a few considerations that I find valuable enough to reproduce below:

A uTracer for 1000V and 1000 mA ( and +/- 100V grid!) is a formidable goal. I'm looking forward to see your approach to solve the numerous challenges ahead.

Studying your elaboration on HV generation, a few concerns have come to my mind. As you have stated yourself, the classical boot converter seems to have come to its limits. Using a flyback transformer looks much more elegant. When I tried to understand why you couldn't get it to work well enough, a few learnings from own (unsuccessful) experiences came to my mind.

The current in the primary coil should stay safely below saturation. In your example, (100 uH, 20V) you have an initial rise in current of 200mA/us. Since effective inductivity falls with higher currents, this rate increases a lot nearing saturation. That implies that saturation is probably reached earlier than assumed in your example, leading to much higher peak currents than intended in the primary coil.

I'm not so sure about your assumption regarding the voltage loss in the secondary windings. The benefit of the transformer is of course that it increases the voltage by the ratio of secondary to primary windings. Currents are decreased by the inverse of this ratio. The last line of Formula 2.4 D is suggesting that the inductivities of transformer coils are proportional to the number of windings, which is not correct. A simple approach gives a secondary peak current in both secondary coils of Ipr/20, about 100mA at saturation and 3.1 V loss in each coil.

A possible cause for the unstable behaviour of the flyback design at lower voltages could be that the design requires the magnetic flux in the transformer to be zero before each new pulse. Otherwise the current in the primary coil will not start at zero, leading to an even earlier saturation and unwanted dramatic increase of current. At lower voltages, the time needed for the secondary current to fall to 0 can be longer than the 100us given by the 10kHz pulse frequency. The combined inductivity of both coils in series should be about 40 mH. To fall from 100mA to zero in less than 100us a voltage of at least 40V is needed.

Maybe the flyback design deserves a second try. Adapting both the primary switch-on time and the pulse frequency to avoid saturation could do the trick. That would allow the use of standard MOSFETs directly driven by the MCU and promises also a higher conversion efficiency.

I hope to see more of your very interesting experiments and design concepts soon.

Generating the required high voltages is of course only one part of the story of a higher voltage uTracer. We also need a high voltage switch that can handle 900V, or with a safety margin 1000V, and that can operate in a floating mode. The uTracer3 uses a simple PNP switch. As it turns out, it is very difficult to find affordable PNP or PMOS devices for such high voltages. However, NPN and NMOS devices for these voltages are readily available. In general N-type devices require a more complex driver circuit because the gate voltage has to be controlled with respect to the source that is floating. The gate voltage even has to become higher than the high side voltage rail when the device is fully on! As it turns out, for this application, also the P-type solution would require a special driver scheme to galvanically isolate the high voltage switch from the rest of the circuit, so in complexity there is not much difference. Having decided for an N-type device we still have to make the choice between an NPN bipolar transistor or an N-Channel MOSFET. Given the fact that for the MOSFET we don’t have to bother with a static gate current and that suitable high-voltage NMOS transistors are relatively cheap, the choice was easy. At first sight suitable transistors are the FQD2N100 from Fairchild or the STD2NK100Z from ST Microelectronics. These transistors have an on resistance of resp. 9 and 6 ohm, more or less independent of the drain current, so that it is quite straightforward to compensate for the voltage drop over the transistor after the measurement.

Figure 3.1 Circuit configurations for the high voltage switch.

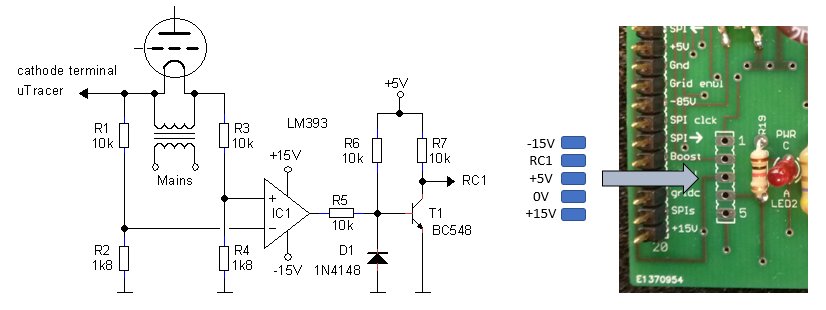

Just like in the uTracer3, the gate driver circuit is powered from a capacitor that is charged immediately before the measurement pulse. Figure 3.1A schematically shows the idea. Before each measurement pulse T2 is briefly closed, which charges C1 to 15V. Next T2 opens again leaving the high voltage switch circuit completely floating and only connected to the high-voltage source.

We should almost forget that also a means to discharge the capacitors needs to be implemented to discharge the capacitors when e.g. a new curve is measured of when the measurement is finished. The simplest way to implement this is to use a simple discharge resistor and tranistor in the same way as this is done in the uTracer3 (Fig. 3.1B) However, it seems rather a waste to use an additional transistor for that while we have another high voltage switch in almost the same “position” doing nothing most of the time: transistor T1 only needs to be closed a few milliseconds just before a measurement pulse! With a simple “OR” circuit consisting of diodes D2 and D3 we can have T2 perform the two tasks of discharging the reservoir capacitors and the grounding of high side driver circuit to charge the boots-trap capacitor.

Figure 3.1D shows a first attempt to an implementation of the high side gate driver circuit: R3 keeps T1 open when the transistor in the

opto-coupler is off. Transistor T3 and R2 form a simple current limiting circuit that is also used in the uTracer3, while C2 suppresses potential oscillations.

In the remainder of this section the high voltage switch will be analysed and tested to find out its operating limits.

Figure 3.2 Test circuit for the NMOS high voltage switch

Analzing and testing an “high-side” circuit like the high voltage switch is not that easy. All the components are at a high potential with respect to ground and complicated differential probes have to be used to measure e.g. the gate-source voltage of the switching transistor. Fortunately, since the control input of the switch is basically isolated from the rest of the circuit through the use of an opto-coupler (the bias diode D2 Fig. 3.2 is normally off), it is possible to exchange the position of the load and the switch with respect to ground so that the circuit can be tested using ground as a reference.

Figure 3.2 shows the test circuit used in this section. Going from left to right we first find a pulse generator which simulates the measurement pulse normally issues by the PIC. It consists of a de-bounce circuit around N1 and N2, the pulse generator consisting of C1, R3, D1 and N3, and a buffer that eventually drives the LED in the opto coupler consisting of N4-N7 and T1. The pulse length is determined by C1 and R3.

A 150 nF capacitor results in a pulse length of approximately 1 ms, the normal measurement pulse length. A 1 nF capacitor generates a 10 us wide pulse which is approximately the pulse width when the processor interrupts the measurement because an over-load condition has been detected. The reservoir capacitor consists of two 220 uF / 450 V capacitors in series. Resistors R6 and R7 ensure that the high voltage is distributed evenly over both capacitors. The current is measured over Rsense, which causes a negative voltage drop over the resistor. The reservoir capacitor is charged via R9 by my (very) high voltage supply consisting of three stacked delta E0300-0.1-L 0 – 300 V power supplies, capable of generating 0 – 900 V. The voltage over the high voltage switch is measured with a 10:1 voltage divider (and a 10:1 scope probe). The zener diode is used for Ron measurements to prevent overloading of the scope input.

The operation in detail

The high voltage switch can operate in three different modes:

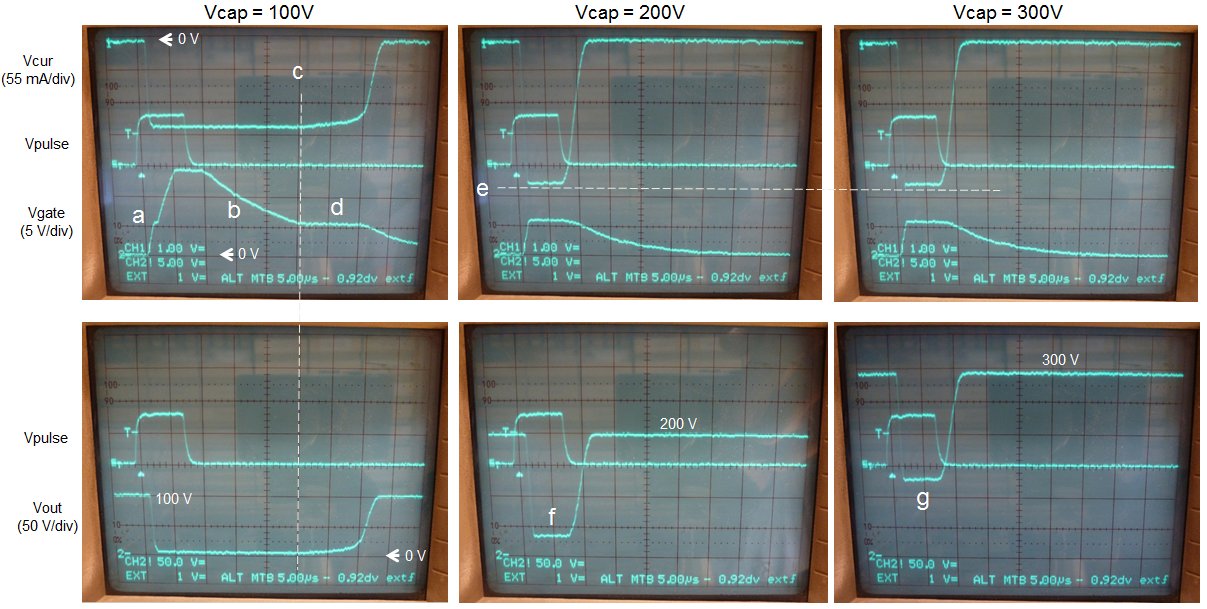

Figure 3.3 Analysis of the waveforms in the NMOS high voltage switch (see description below).

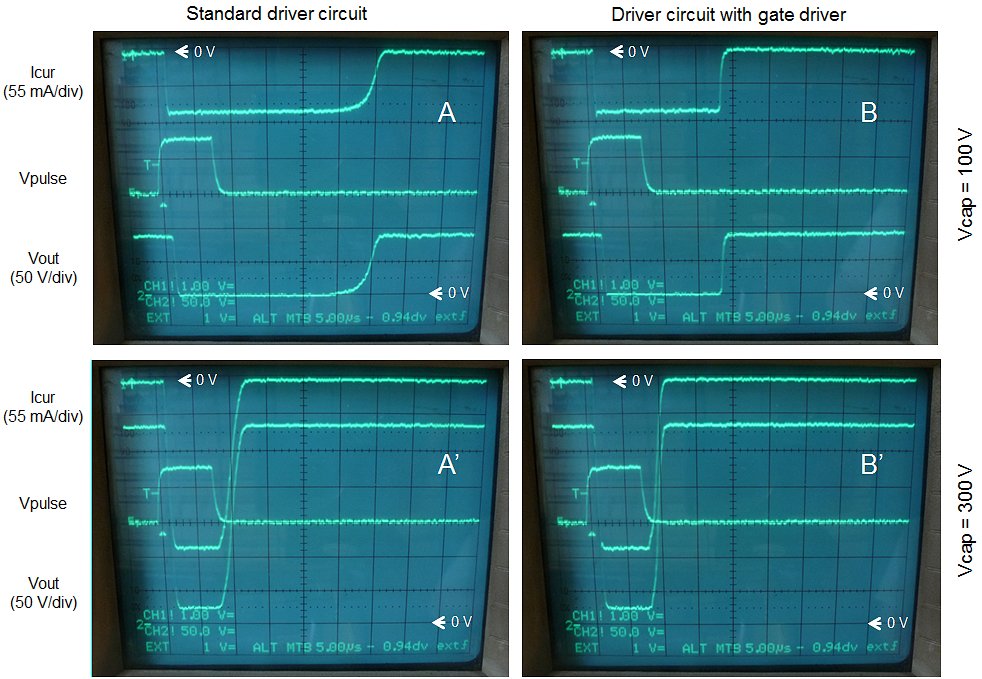

In Figure 3.3 the working of the switch in modes 2 and 3 is analyzed. For safety reasons the voltage is not pushed to the limit, but a maximum voltage of 300 V is used. The figure shows in three columns three different voltage setting: 100 V, 200 V and 300 V. The pictures in one column show different signals during the same measurement. The center trace in both pictures is the pulse signal that is also used to trigger the scope. In this case the pulse width is ca. 8 us. The upper trace in the top pictures shows Vcur which is the voltage drop over Rsense. The lower trace in the top pictures shows the gate voltage of the NMOS. The bottom trace in the lower picture shows the output voltage. Because the switch circuit has been shifted to ground level, the output voltage is high in the off-phase and should approach zero in the on-phase.

As load a resistor of 800 ohm is used. This means that with increasing voltage and the hardware current limit set at 250 mA (Rcur = 2.7 ohm), the hardware current limit protection will kick in at around V = R*I = 800*0.25 = 200 V. For 100 V the hardware current limit circuit is not yet activated. After the start of the measurement pulse, the photo transistor in the opto-coupler is switched on, and the gate voltage rises. The rise time is limited by the current the photo transistor can generate and the gate capacitance of the MOSFET. At Around 5 to 6 V gate voltage, the MOSFET switches on (Fig. 3.3a) and the output voltage drops. The sharp decrease of the anode voltage counter acts (through the drain-gate capacitance) the charging of the gate resulting in the kink in the gate voltage. Eventually the gate voltage rises to 15 V and the MOSFET is fully on. After the measurement pulse has been switched off, the gate is discharged by resistor R9 resulting in a logarithmic decay of the gate voltage (Fig. 3.3b). Since during that time the gate voltage is higher than the threshold voltage, the MOSFET remains fully on. At point c the gate voltage approaches the threshold voltage and the MOSFET starts being switched off causing an increase in anode voltage. The increasing drain voltage, again through the drain-gate capacitance, counter acts the discharging of the gate and actually stabilizes the gate voltage on a plateau value around the threshold voltage (Fig. 3.3d). At a certain point this balance situation can no longer be maintained and the MOSFET is finally switched off.

At 200 V the hardware current limit circuit has kicked in (Fig. 3.3 middle column). Note that the drain voltage in rest is 200 V, and but that during the measurement pulse the drain voltage is no longer zero but has increased to approximately 80 V (Fig. 3.3f). This is because the hardware current limit circuit has regulated the conduction of the MOSFET in such a way that it is now dropping these 80 V so that the current through the load remains constant at 250 mA. As a result, the gate voltage is adjusted to a value slightly above the threshold. Since the gate voltages is already around the threshold voltage, and the drain voltage is no longer zero, the switch-off time is drastically reduced. For 300 V the current remains constant (Fig. 3.3e), which is only possible by allowing for a higher voltage drop over the MOSFET (Fig. 3.3g).

Figure 3.4 Switching characteristics at Vgate = 15 V (left column) and Vgate = 10 V (right column).

Figure 3.4 shows a similar set of curves as in Fig. 3.3 for a voltage of 100 V and a load resistor of 800 ohm (current limit circuit not activated). In the left column a gate voltage of 15 V is compared to a gate voltage of 10 V in the right column. By decreasing the gate voltages the discharging of the gate is significantly reduces (comp. a1 to a2 in Fig. 3.4) However, the plateau time remains the same (comp. b1 and b2). A gate voltage of 10 V seems optimal.

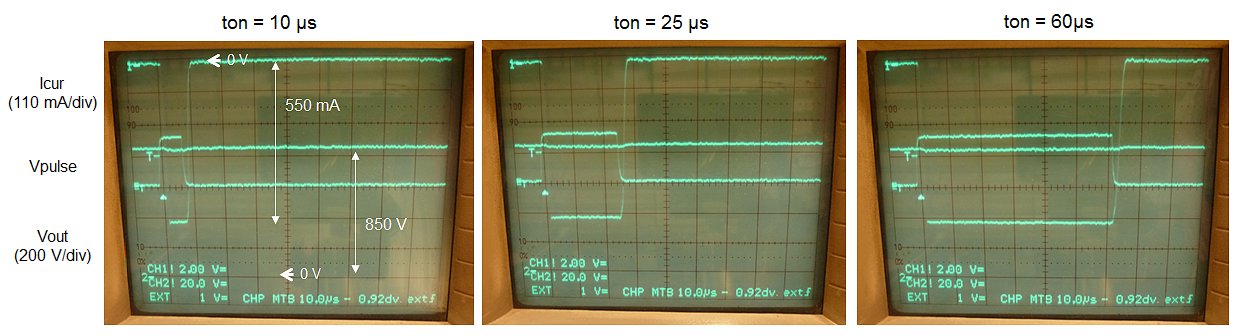

Pulse testing @ 550 mA

During the first tests it appeared that the NMOS high voltage switch easily passed all load and short circuit tests with the hardware current limit set to 250 mA. The hardware current limit was therefore set to 550 mA by lowering Rcur to 1.189 ohm (2.7//2.7//10).

Figure 3.5 Mode 1 testing at 550 mA (load = 1k5).

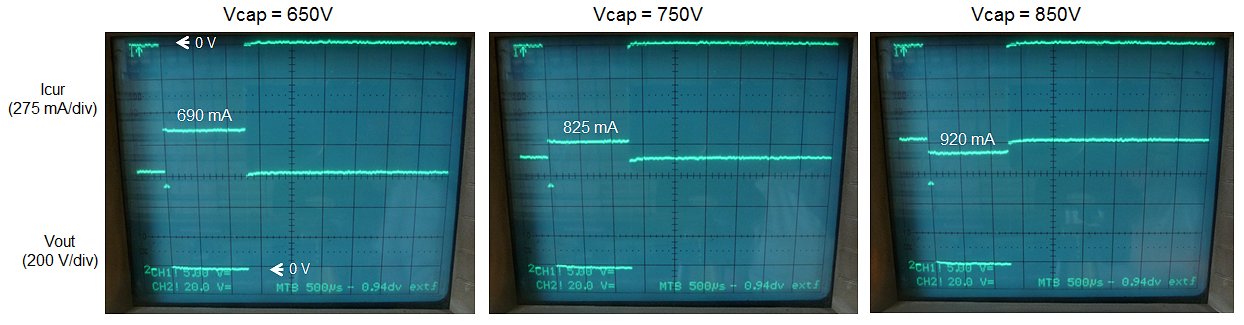

The first test was for normal operation with a measurement pulse length of 1 ms. Figure 3.5 shows the current as well as the drain voltage of the switch connected to a load resistor of 1k5. The load resistor was chosen such that the current limit circuit would just come into action between 750 and 850 V. The graphs show a perfect switching behaviour even for the highest voltage and current combination.

Figure 3.6 Mode 2 & 3 testing around 550 mA (load 1k5)

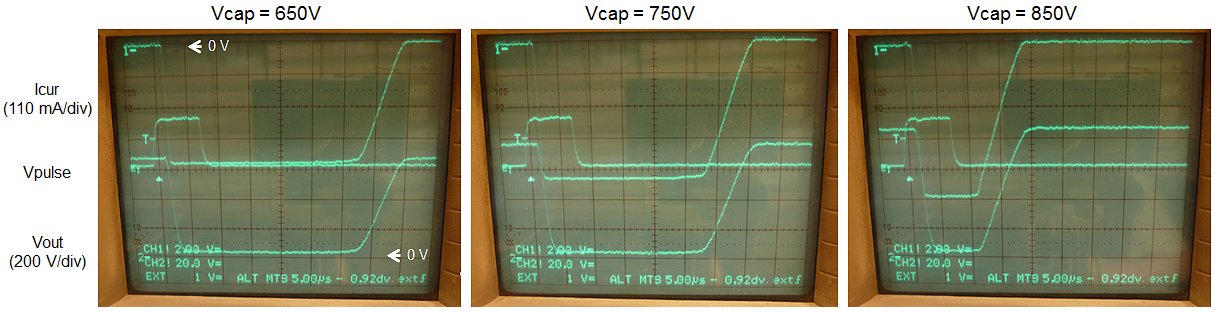

In the second test Mode 2 and 3 operation is simulated with a mesurment pulse length of 10 us. A load of 1k5 is connected and the voltage is increased from 650 to 850 V (Fig. 3.6). At 650 V the hardware current limit circuit is not yet activated, the gate voltage of the MOSFET of 15 V, and the turn-off time is relatively long. At 750 V the current limit circuit is just activated and the pulse length is decreasing. At 850 V the current limit circuit is fully activated, the gate voltage is around the threshold and the turn-off time is minimal. The current is 550 mA.

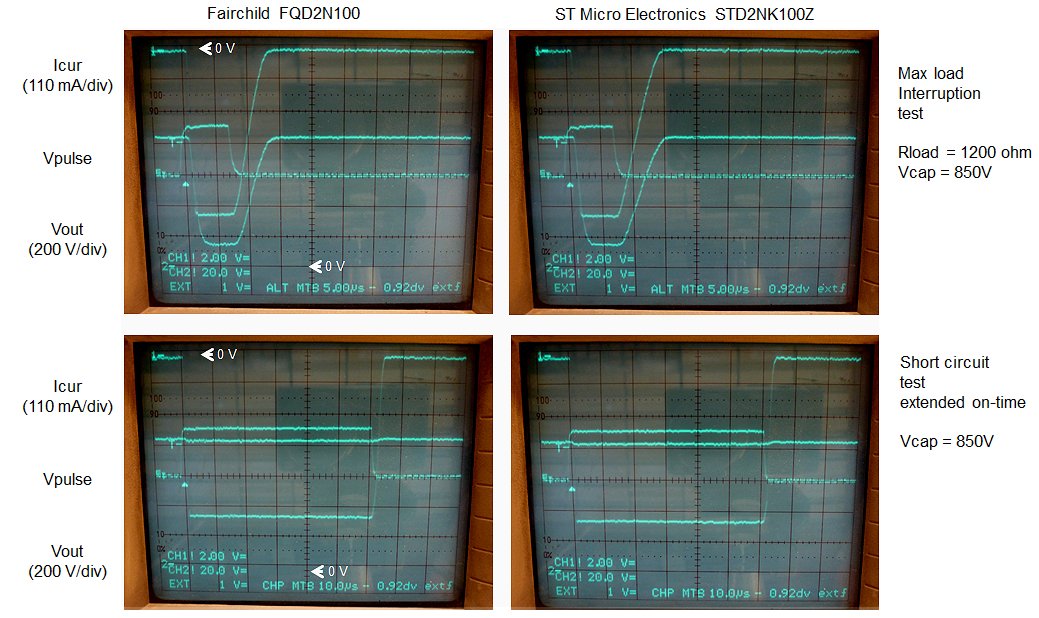

Figure 3.8 Full short circuit test at maximum voltage (850 V) and 550 mA! The tiny MOSFET in DPAK package is capable of handling an instantaneous dissipation of 425 W!

Finally a full short circuit test at maximum voltage (850 V) and maximum current (550 mA). Figure 3.8 shows how the tiny MOSFET handles an instantaneous dissipation of 425 W repeatedly without problems.

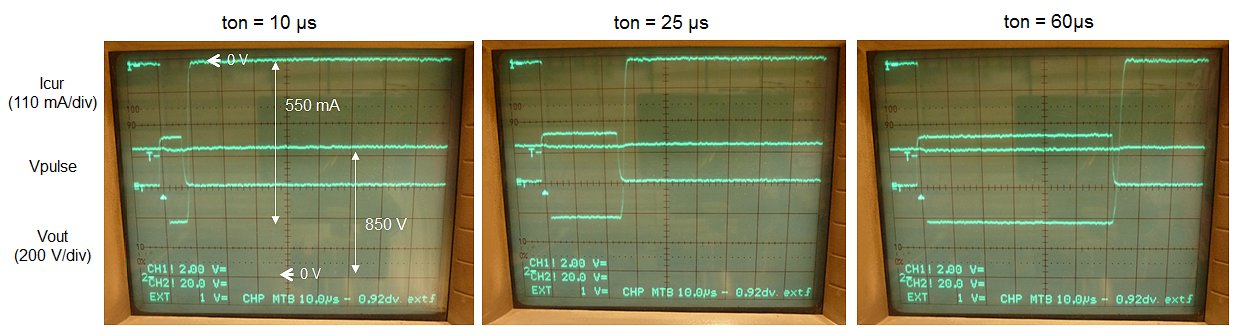

Figure 3.8 Exploring the safety margin

To investigate the safety margin we have with this switch circuit, the pulse length was increased in steps at maximum voltage (850 V) and full short circuit conditions (Fig. 3.8). It appeared that the pulse length could be increased to at least 60 us – 6 times the pulse length in reality – without problems. Most likely I could have gone further, but since this is evidence enough to convince me of the robustness of the circuit, and since I don’t like pushing buttons and waiting for a bang, I didn’t push it any further.

Figure 3.9 The FQD2N100 compared to the STD2NK100Z.

There are two 1000V MOSFETs that are readily available and reasonably priced: The FQD2N100 from Fairchild, and the STD2NK100Z from ST Micro Electronics. Their datasheets are pretty similar. The main difference is their price: the STD2NK100Z is about double the price of the FQD2N100. Under the assumption that more expensive also implies better performance all experiments so far were carried out using the STD2NK100Z. However, the comparison of the two in Fig. 3.9 shows that both transistors show almost identical behaviour and that FQD2N100 even shows slightly better turn-off characteristics.

Figure 3.10 Voltage drop over the MOSFETs as a function of drain current.

The voltage drop over a bipolar transistor in saturation is usually more-or-less independent of the current, and usually amounts to 100 to 200 mV. A MOSFET in the on-state in contrast behaves as a resistor with the on-resistance a function of the gate voltage. The voltage drop over the MOSFET will therefor depend on the current. This is not a problem, since – just as with the uTracer3 – the plotted current can be corrected for this voltage drop. To measure the on-resistance of the MOSFET, the voltage drop over the MOSFET (+ 2.7 ohm resistor) was measured for different currents taking care that the current limit circuit was not activated. To measure the Ron, the output voltage of the output voltage divider was limited to 2.7 V by means of zener diode D3 (Fig. 3.2). This allows for zooming into the low voltage drop when the MOSFET is on, while the input voltage is clipped when the MOSFET is off so that the amplifier of the oscilloscope is not saturated. The Ron (corrected for the 2.7 ohm resistor) has been plotted versus the current for both type MOSFETs in Fig. 3.10. The on-resistances for both types are indeed more or less constant and correspond well to the values specified in the datasheets.

A small personal souvenir of a fantastic holiday in the Yorkshire Dales: a panoramic view on Middleham from William’s Hill.

Tackling dV/dt breakdown

While playing with the HV-switch test circuit (Fig. 3.1) a rather startling incident/accident occurred. I had the load resistor connected with two (isolated) clips, and at a certain moment I disconnected the load while the reservoir capacitor was charged to 900 V and T3 was not conducting. The moment I opened the clip, there was a big bang and the MOSFET, Rcur, Rsense, and a fuse I had in series with the capacitor were blown to pieces (Fig. 4.2)! What on earth had happened, and how can opening of a circuit result in such a violent event?

The most likely explanation is a dV/dt breakdown. Such a breakdown can occur when the rate of increase of the drain voltage exceeds a certain value. What happens is that the drain-gate capacitance causes a positive transient on the gate which not only momentarily opens the MOSFET, but which also may very well destroy the gate oxide causing the MOSFET to permanently fail. When I opened the clip I must have accidentally touched the lead resulting in a dV/dt breakdown.

One of the most effective measures to prevent dV/dt breakdown is to lower the impedance of the circuit that is driving the gate of the switching transistor. In the driver circuit shown in Fig. 4.1 the gate of the MOSFET in the off-state is connected to ground via a relatively high value 10k resistor. The lower the resistor value, the smaller the voltage spike on the gate. A simple push-pull buffer will drastically lower the impedance level and significantly reduce the sensitivity to dV/dt breakdown.

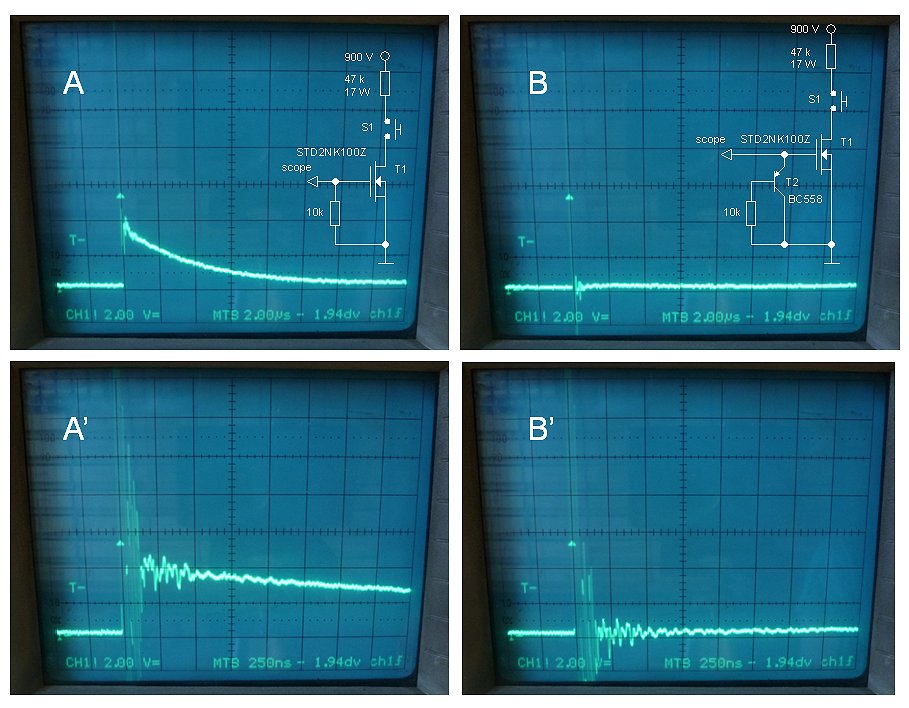

Figure 4.1 dV/dt testing without gate driver circuit (AA’) and with push-pull gate driver (BB’).

A simple experiment was used to get an qualitative idea of the impact of a buffer circuit on the dV/dt fenomenon. In Fig. 4.1A the drain of the MOSFET is connected via a push button and a current limiting resistor to a 900 V power supply. The signal on the gate of the MOSFET is monitored with a memory scope. When the switch is closed a transient appears om the gate. Figure 4.1A’ shows the same event on a different time scale. An extra transistor acting as an emitter follower almost completely suppresses the transient (Fig. 4.1B and B’). At t=0 there is in all cases a very large and very short spike that doesn’t decrease in amplitude when a buffer is used. I think is has nothing to do with the dV/dt effect but is just a measurement artifact.

Figure 4.2 A) Original HV-switch circuit, B) collateral damage as a result of a dV/dt breakdown, C) new HV-switch circuit with gate driver.

Figure 4.3 Switching behavior of the new HV-switch circuit compared to the standard circuit. Rload = 1 kohm

In the HV-switch circuit shown in Fig. 4.2C, a push-pull buffer circuit has been added to provide a low impedance drive circuit for the gate of the MOSFET. This does add some complexity to the circuit, but it greatly suppressed dV/dt related problems, while it also improves the switching speed of the circuit especially the turn-off time. This is illustrated in Figure 4.3. Here the switching behavior of the standard circuit (left two phortos) is compared to the circuit with the buffer stage (right two photos). In the top two photos the hardware current limit is not activated, while it is activated in the bottom two measurements. Especially in the case when the current limit is not active the reduction of the switch-off time is significant because the discharge of the gate-source capacitor is faster (Figure 3.3 part a1). However, the typical MOSFET turn-off behavior/time when the gate voltage passes through the Vt (Fig. 3.3 part b1) still remains.

Pulse testing @ 1 A!

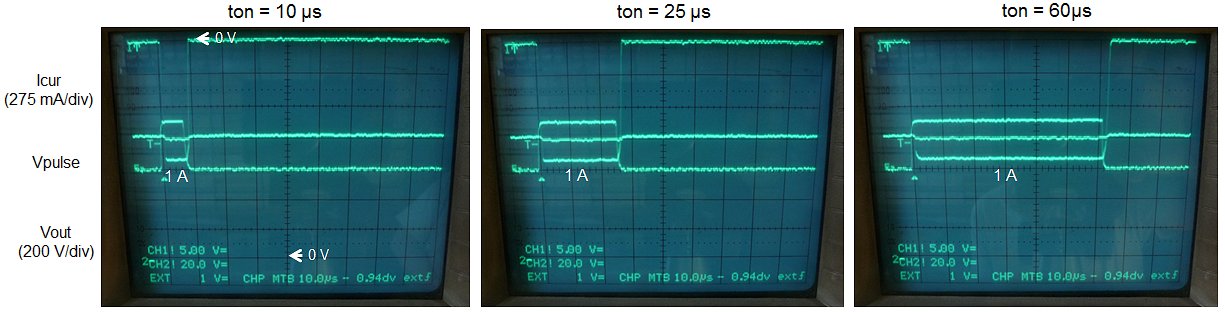

Figure 4.4 Standard 1 ms test. Rload = 900 ohm (1k//10k), Rsense = 2.7/4 = 0.65 ohm

During experiments with the HV-switch with the push-pull gate driver it was observed that the new circuit was much more stable in the current limiting regime. The 470 pF capacitor could be omitted without any problems and only for very low voltages oscillations were observed which readily disappeared for voltages higher than 100 V. It was therefore decided to again test the circuits up to currents of 1 Ampere! To set the hardware current limit to 1 A , Rsense was replaced by four 2.7 ohm resistors in parallel. Figure 4.4 shows the one millisecond Mode 1 test for voltages and currents around the maximum values. With a load resistor of 900 ohm and a voltage of 850 V, the circuit is tested at maximum voltage and maximum current. At the highest current the discharging of the reservoir capacitor is clearly visible

Figure 4.5 Full short circuit test extended times. Rsense = 2.7/4 = 0.65 ohm

Figure 4.5 Shows the high-speed switching behavior around the current limit region. The switching of 1 Amp at 900 V is no problem at all for the circuit. The switching speed is very fast, and the total on-time is very much determined by the control pulse width.

Finally, the robustness of the circuit was tested under full short circuit conditions at maximum voltage for extended times. The circuit easily managed to cope with repeated blasts at 60 us without problems!

Figure 4.6 First version of a 1000 V/1 A anode & screen supply

Figure 4.6 Shows a first draft of the new anode/screen supplies. After the previous sections the circuit holds no surprizes. On the left hand side the circuit around T1 forms the 1000 V boost converter, assuming that in the end 500 V capacitors are used. The current sense resistor has been dimensioned to give a voltage drop of 4.7 V at a current of 1 A. The high voltage divider also (approximately) outputs 4.7 V at the maximum voltage of 1000 V. Note that for R3 a 1000 V type needs to be used. In contrast to the uTracer3, the high voltage feedback is not only fed directly into the ADC input of the PIC, but also to the free input of the PGA. I am considering to use the PGA during the setting of the voltage to increase the resolution especially at lower voltages. The BAT86 diodes that were used in the uTracer3 have been replaced by a single Schottky overvoltage protection pair D3 because under certain circumstances the output of the IC1 can swing to -15 or +15 V. The high voltage switch around T6 is identical to the circuit discussed in this section. As explained in Fig. 3.1D T2 has the double function to discharge C1 and C2 when needed, but also to charge C3 immediately prior to a measurement. Finally, not shown in this schematic, T1 and T2 need to be driven by a separate driver buffer because their gate voltages are not compatible with the output voltages of the processor.

Although the grid bias circuit of the uTracer3 - considering its simplicity - works quite well, I nevertheless wanted to revise the circuit for the uTracer6. Over the years many people have expressed wishes or made suggestions for improvements. I have summarized the most commonly made suggestions below:

Obviously, I have been thinking about a circuit that would be able cover the complete wish list stated above. However, unavoidably every time I ended up with a complex circuit that completely spoilt the concept of the uTracer: an elegant circuit designed to balance the thin line between complexity and performance. A circuit covering all the requirements would add excessive complexity and cost, while 95% of the users only need the basic functionality.

In the end I decided on a circuit that realizes only the basic requirements: range 0 to -100 V, high accuracy over the complete bias range, and current sinking capability. However, the specials such as an extended negative bias range or positive biases can be realized by the addition of an optional extension circuit to be realized as a “shield” that can be simply clicked onto the main board by users that require the additional functionality.

The basic circuit

A complicating factor in the grid bias circuit is that, just as in the uTracer3, the cathode of the tube is referenced to the positive power supply voltage, nominally 19.5 V. This implies that also the grid voltage needs to be referenced to the positive power supply voltage. Just as in the uTracer3 this is done by using an OpAmp configured as a subtraction circuit. Figure 5.1A shows the OpAmp subtraction circuit in its most general form. In most versions of this circuit R1=R2 and R3=R4, while R3=A*R1 (Fig. 5.1B). The result is a circuit that amplifies the voltage difference between the two terminals A times. Not so often used is the variant shown in Fig. 5.1 C. Here R1=R4 and R2=R3, while R2=A*R1. In this case the output voltage is the voltage on the positive input minus A times the voltage on the negative input. When the positive input is connected to the cathode and the output of the OpAmp to the grid, a voltage Vadc on the input will result in a grid bias of –A*Vadc.

Figure 5.1 The OpAmp subtraction circuit in its general from (A), and two special cases (A & B).

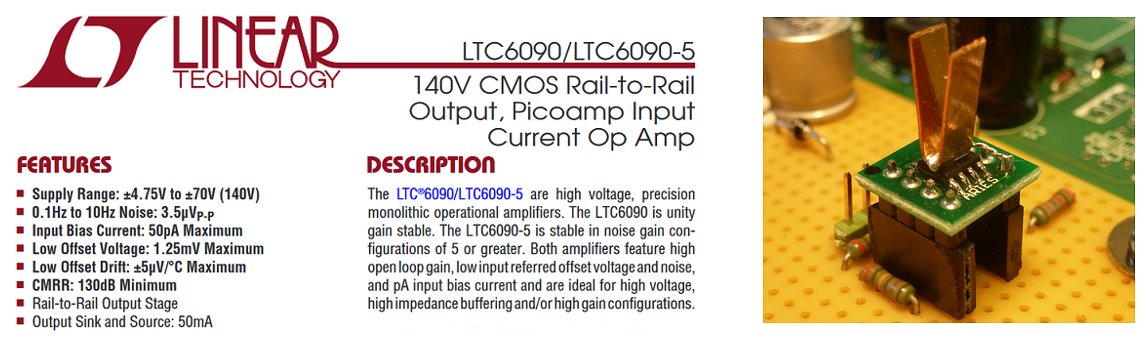

The trick is that for the uTracer6 a very special OpAmp is used: the LTC6090 from linear technology, now Analog Devices I believe. This remarkable device has a supply voltage range of 140 V! It has a rail-to-rail output, is unity gain stable, has on chip temperature protection and an output disable input and it comes in a small SO8 package. By connecting the positive supply voltage input to the 19.5 V supply voltage and the negative supply voltage input to a voltage of at least -80 V, a grid voltage range of 0 to -100 V with current sinking capability can be realized. Figure 5.2 depicts the circuit in its elementary form. An AD converter controlled by the PIC generates a voltage of 0 to 5V. By setting the gain of the subtraction circuit to 200/10 = 20, a 0 V ADC output voltage corresponds to 0 V grid voltage while a 5 V ADC voltage corresponds to a grid voltage of -20*5 = -100 V.

Figure 5.2 The principle of the grid bias circuit of the uTracer6.

Offset voltages

One thing to consider is the offset voltage of the LTC6090. From the datasheet of the LTC6090 we learn that the typical input offset voltage of the device is specified as 0.33 mV, while it can be as high as 1.2 mV. With a gain of 20 this can result in an offset voltage at the output ranging from 6.6 mV to 24 mV, excluding offsets introduced by tolerances in the resistors, the ADC and other preceding stages. Unfortunately, the LTC6090 is not provided with an input to compensate for the offset voltage. However, it appears possible to compensate for the input offset by deliberately creating a small imbalance in the resistors of the subtraction circuit:

The imbalance in the resistors can easily be created for instance by tweaking R4. Taking a peek forward to Figure 5.3, we see that placing a high value resistor in parallel to R4 first lowers its value slightly which can then be compensated for with a low value potentiometer. Placing a 2M7 resistor over the 10 kohm resistor and using a 10 turn 100 ohm potentiometer makes the resultant resistance variable between 9.963 kohm and 10.063 kohm. Inserting these values in the equations above results in a δ of approximately ± 0.005. With a supply voltage of 19.5 V this will result in offset correction range at the output of the OpAmp of approximately ± 100 mV.

The complete circuit

Figure 5.3 shows the complete grid bias circuit as I have it in mind for the uTracer6. Going from the left to the right, we first find the inverting boost converter that is used to generate the -85 V voltage that is used for the negative supply voltage of the LTC6090. The circuit is based on the inverting boost converter of the uTracer3, but in this case the pnp BC138 transistor has been replaced by the readily available 100V PMOS transistor IRFR9120. Just like the other boost converters in the circuit, also this boost converter is controlled by the PIC microcontroller. The firmware was originally designed so that it can handle up to 8 boost converters simultaneously (read

here and

here). This not only greatly simplifies the circuit, but it also gives the PIC total control over the boost converters. One of the “tricks” in the uTracer is that all boost converters are shut down during the 1 ms measurement interval, thereby greatly eliminating the noise in the circuit.

Figure 5.3 The complete “basic version” grid bias circuit.

For the DA converter I selected the DAC8562 from Texas Instruments. The DAC8562 houses in a tiny MSOP package two independent 16-bit DA converters, a voltage reference and an SPI control. I have used one of the two DA converters for the negative grid supply, while the other DA converter is reserved for the positive grid supply. Since a 16 bit word is used to control the grid voltage, positive and negative, this implies that both converters will be used in 15 bit mode. With 15 bits the resolution is then set to 100V/2^15 = 100V/32768 = 3.1 mV. The “zero code error” of the DAC8562 is specified as typically 1 mV (max 4 mV). However, when the DAC was directly connected to the subtraction circuit, the zero code output voltage appeared to be much higher since the DAC output had to sink the current through R9 (approximately 100 uA). To completely decouple the DAC from the subtraction circuit, buffer IC2 was added.

The subtraction circuit itself has already been discussed, however there are a few particulars worth mentioning. From the beginning I was a bit worried about the dissipation in the LTC6090. With such high supply voltages already a small current either in the form of current used by the OpAmp itself, or current supplied to the output can result in a relatively high dissipation and associated temperature increase. For this reason, the package has been supplied with a thermal pad on the backside that can be used to transfer heat from the chip inside to the PCB. For hobbyists not in the possession of SMD soldering equipment, handling a package with a thermal pad can be a bit of a nuisance. Therefore I wanted to avoid the use of the thermal pas all together. The idea was to activate the output of the LTC6090 only during the actual measurement pulse, while I hoped that the dissipation of the LTC6090 itself would be low enough to avoid excessive heating of the package.

The LTC6090 has an output disable input on pin 8. When this pin is pulled low, the output of the LTC6090 basically goes into tristate mode. Normally the output disable input is tied to the temperature flag output (pin 5). This open drain output pulls the output disable pin low when the internal temperature of the LTC6090 reaches a certain critical point. In the grid bias circuit, the collector of transistor T3 is or-tied to the output disable input. This transistor is controlled by the PIC, and only switches the output of IC3 on during the actual measurement. T3 is connected to the output disable pin with a jumper. The jumper can be removed so that the output is switched on continuously to facilitate testing and calibration. In practice it turned out that the dissipation in the LTC6090 is not a problem at all.

Figure 5.4 During the experimental phase of the circuit development the thermal pad of the LTC6090 (here lying on its back) was provided with a small copper heatsink. This turned out to be not necessary.

Diodes D2, D3, D4 as well as C5 and R12 protect the circuit in the case of a flashover from anode to grid or cathode (read more here). When a flashover occurs the excess amount of charge is stored in C5. As a result, the voltage over C5 will increase. Diode D2 now isolates the cathode from the rest of the circuit. In case the potential rises above 24V, diode D3 will start to conduct and short circuit the charge to ground. Diode D4 directs flash overs to the grid to the cathode. Resistor R12 serves the purpose to maintain a constant current through D2, while it also discharges C5 during/after a flash over. Notice that the positive power supply voltage of the LTC6090 has been taken from the anode side of D2. Although the OpAmp is advertised as rail-to-rail, in reality there is (as with most OpAmps) always a few hundred millivolts of difference between the maximum output voltage and the positive supply voltage. The 0.6 V voltage drop over the permanently forward biased diode neatly compensates for this so that the grid voltage can be really adjusted to zero volt.

Figure 5.5 The complete grid bias circuit on perf board.

Obviously the new grid circuit does require necessary but not very exciting modifications to the firmware in the PIC, as well as to the GUI. For the calibration the DAC is loaded with zero which should result in a zero-volt grid voltage with respect to the cathode. With the potentiometer the output can now be set to exactly zero. It appears that during the first 20 min after switch on of the circuit there is a small drift in the grid voltage (about 20 mV), it is therefore recommended to wait at least 20 min before performing the zero grid voltage calibration. The full scale calibration is performed during the final calibration of the uTracer in the GUI.

Few aspects of the uTracer3 have been such a point of discussion as the heater supply and the “old fashioned” RS232 interface. I am afraid that for the uTracer6 I am going to stick with the same concepts, but with a big improvement in the heater supply. In this section a motivation and an explanation.

The Heater supply (alternatives)

During the design of the original uTracer, I added the heater supply as a “nice to have add-on.” I had one PWM output on the PIC left and thought it would be a nice idea to use it to make a simple PWM controlled heater supply. Readers who are interested in the full story of the heater supply and its short comings can read up here and here. On this page I will just suffice with a short summary.

The heater is driven by a PWM circuit that switches the heater output at a high frequency between the supply voltage (19.5 V) and ground. Because of the thermal inertia of the heater, the effective voltage on the heater settles to the rms value of the PWM signal. The energy supplied to the heater can simply be regulated by varying the duty cycle of the PWM signal. In principle this is a nice and elegant idea, however, unfortunately in the uTracer3 the repetition frequency of the PWM signal was rather high namely 19.5 kHz. The reason for this is that the other PWM module in the PIC processor is used to generate the grid bias. Here a high frequency makes it easier to low-pass filter the signal to get a DC voltage. The problem now is that as a result of the high PWM frequency, the PWM pulses become very short for low heater voltages. These narrow pulses in combination with (parasitic) inductances in the wiring degrade the rectangular shape of the short pulses (see measurements below), which results in a somewhat lower effective heater voltage than expected.

The problem in short is not that the circuit concept is not sound, but rather that the PWM frequency is too high. In the uTracer6 there is no need for that anymore. Since the grid bias is no longer generated by the second PWM output but by a proper DAC, a much lower frequency for the PWM repetition frequency for the heater can be chosen. The result is much wider PWM pulses that are far less sensitive to parasitic inductances.

Over time I have collected quite en extensive wish list for the heater circuit of a new uTracer. The list includes: higher voltages (up to 100 V), higher currents, higher accuracy, the possibility to monitor the heater current, etc. Apart from the whish for a higher accuracy, I have to disappoint everybody. I have thought about it quite a lot and even experimented with modern buck converter solutions. However, I have found that it really is impossible to compete with the many ready-made power supply solutions that are on the market today.

|

|

|

|

Figure 6.1 Some ready-made power supply modules that depending on your wishes and budget can be an attractive alternative for the built in heater supply of the uTracer6. Click on a picture to execute a search for the specific module.

Quite a few users of the uTracer3 who found that the internal heater supply of the uTracer3 didn’t satisfy their needs have discovered the world of cheap and ready-made power supply solutions. Albert Valiente made his own 35 V / 9 A heater supply from a display module, a pre-assembled buck converter and a ten-turn potentiometer. Read his description here. Other users have combined the uTracer with a completely ready-made power supply module

(e.g.

Example1

,

Example2

,

Example3

,

Example4

,

).

A Google search on “variable power supply module,” yields pages full of all kinds of power supplies that can be ordered for only a few euro. Figure 6.1 shows some of the more prominent results at the time of writing of this page. To be honest, it simply doesn’t make sense to try to compete with this with an elaborate programmable heater supply for the uTracer6. So there we have it, I think that the improved heater circuit of the uTracer6 will serve the needs of 80% of the users; the other 20% are far better served with a ready-made solution that additionally offers the possibility to pre-heat tubes without the necessity of a computer connection.

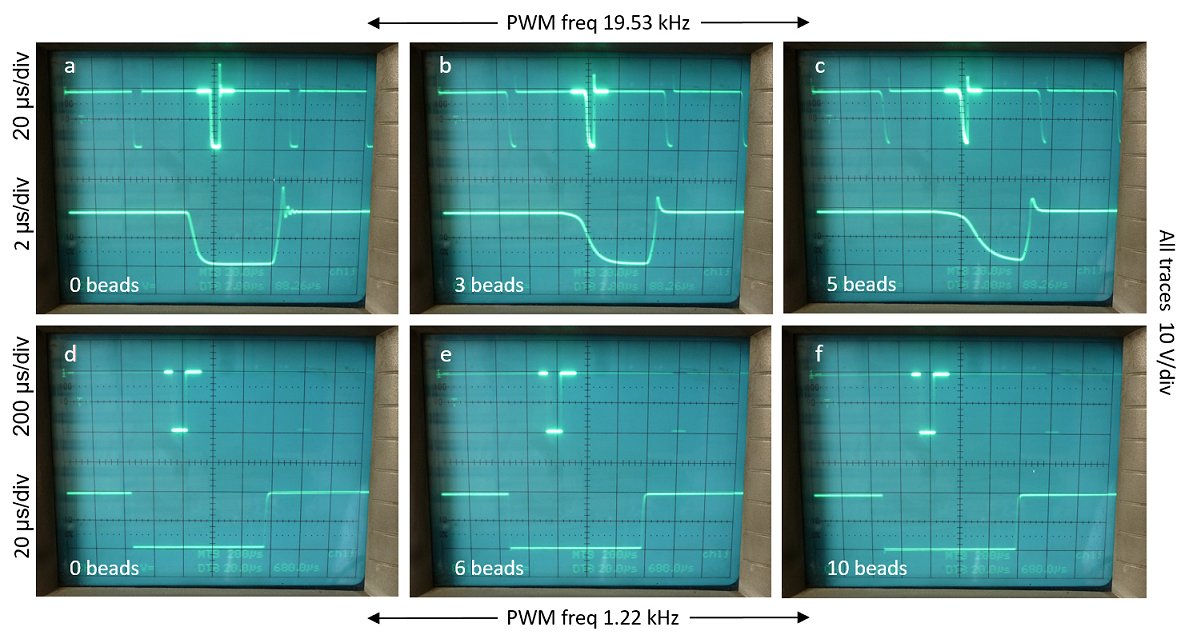

Evaluation of the improved heater circuit

Now that the second PWM output is no longer used to control the grid bias, we can choose any frequency for the heater PWM. The frequency of the PWM generators is controlled by Timer 2 of the PIC. With a crystal frequency of 20 MHz it is possible to set the frequency of the PWM generator to 1.22 kHz, 4.90 kHz, 19.53 kHz by changing the setting of the clock prescaler to 16, 4, 1 respectively. For the uTracer6 I choose to go down to 1.22 kHz.

In the uTracer3 the gate of the MOSFET is driven by a bipolar push-pull pair in order to obtain as steep as possible gate pulse, to reduce switching losses. At a 10 times lower frequency, the switching losses are negligible so it was possible to eliminate the complete push-pull stage and even to introduce a gate series resistance to limit the gate current.

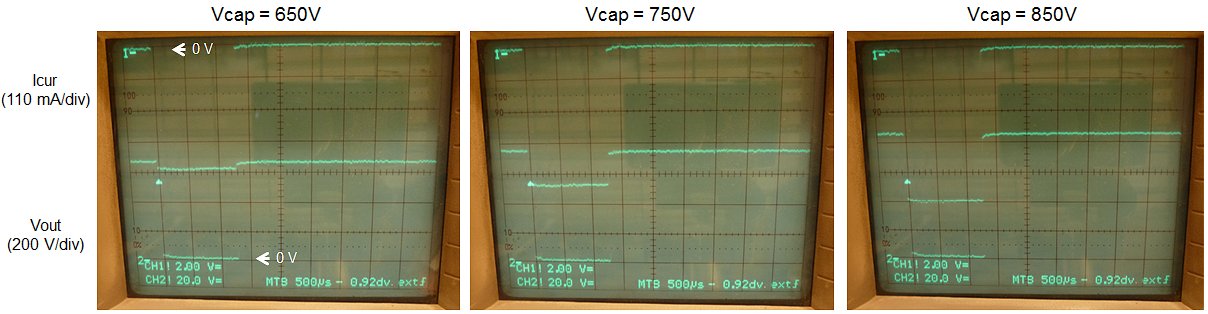

The first thing to check is if the lower PWM frequency indeed makes the heater supply less sensitive (or even insensitive) to parasitic inductances in the wiring.

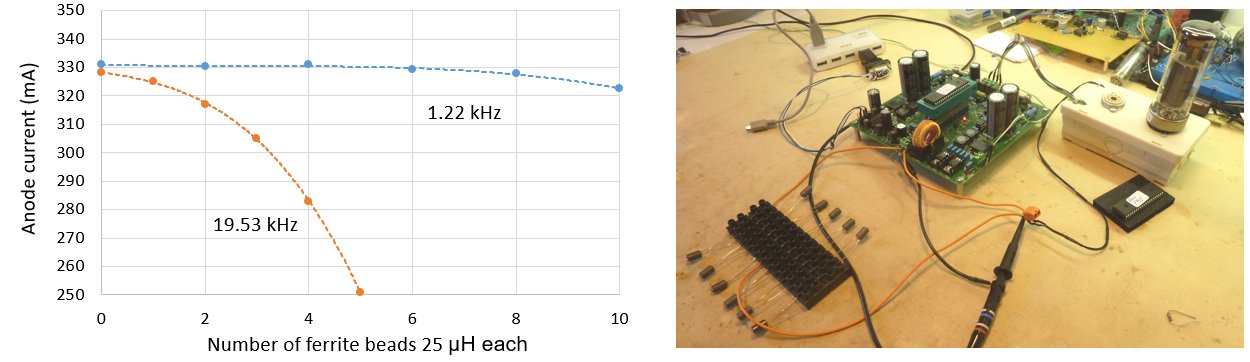

The first thing checked was the shape of the PWM pulses. The top row of figures in the Fig. 6.2 depicts the shape of the PWM pulses applied to an EL34 heater at a PWM frequency of 19.53 kHz. Note that the reference of the oscilloscope is connected to the positive power supply voltage, so that a low signal means that the voltage is applied to the heater. Going from left to right, respectively 0, 3 and 5 RFI suppressions beads were inserted in series with the heater leads, each RFI bead adding 25 uH (test setup in Fig. 6.5 right). Observe that with only a little bit of inductance the square pulse shape is heavily distorted, resulting in a too low effective rms heater voltage. In the bottom row graphs the PWM frequency is lowered to 1.22 kHz. Obviously also in this case the trailing and leading edges of the PWM pulses are distorted, however, because the frequency is so much lower that has little to none effect on the total pulse shape. Even with 10 bead in series the pulse wave shape is nearly perfectly rectangular.

Figure 6.2 Comparison of the effect of parasitic series inductance on the pulse shape of the PWM heater supply for two different PWM frequencies. Each bead introduces 25 uH.

It is not at all straightforward to directly measure the equivalent rms voltage generated by the heater supply. Even multimeters that that can provide true rms AC measurements fail to give accurate results. The problem is the very high “crest factor” of PWM signals for either very low or very high duty cycles. The crest factor is defined as the peak amplitude of a waveform divided by its rms value. For a PWM signal with fixed amplitude and 10 bits resolution, the crest factor can be as high as sqrt(1000)=30! I own a professional Keithley model 2000 multimeter that is capable of true rms measurements, but even for this instrument the accuracy is not even specified for crest factors higher than 5! No wonder it produces absolute nonsense for high and low duty cycles. The best accuracy can be expected when the duty cycle is approximately 50%.

Figure 6.3 Effect of parasitic heater series inductance on the anode current of an EL34 at fixed bias conditions for two different PWM frequencies (left). Test setup with a first peek preview of an experimental uTracer6 (right).

The easiest way to quantify the rms heater voltage is to measure the effect on the anode current for fixed anode, screen and grid voltages. Figure 6.3 left shows the anode current of an EL34 at Vg = -1 V, Va = 300 V, and Vs = 275 V for the two PWM frequencies with different number of 25 uH inductors beads in series with the heater leads. The graph clearly shows that except for very large series inductances, the anode current and thus the effective heater voltage is more or less independent of parasitic inductances.

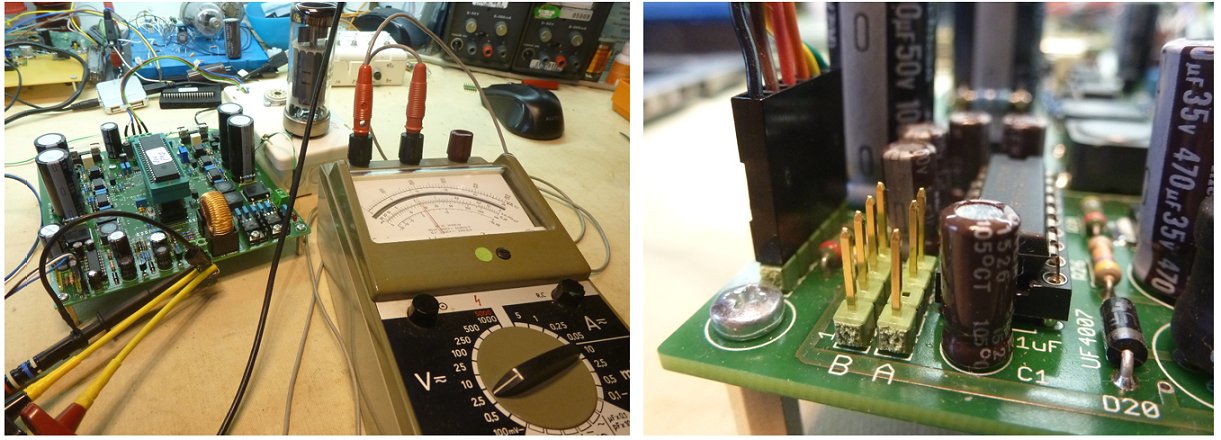

As long as the PWM pulses are nicely rectangular and not distorted, there is a simple way to directly measure the rms value of the heater supply, provided that you own a good old analog multimeter! Analog multimeters measure the average voltage of an AC signal, and when the waveform is known - in this case a PWM signal with nice rectangular pulses - there is a direct relation between the average voltage of the signal and its rms value. To understand that we need a little bit of theory.

Figure 6.4 The rms voltage of a PWM modulated signal.

The formulas on the left hand side of the equal sign in Fig 6.4 give the effective power delivered to a resistor R by a PWM supply with duty cycle δ and amplitude Vmax. This should be equal to the power supplied to the same resistor by a DC supply with an equivalent voltage Vrms. The bottom equation then shows the relation between the rms voltage of the PWM supply and its parameters Vmax and duty cycle.

Figure 6.5 The rms voltage of a perfect PWM signal as a function of average voltage and maximum voltage.

The average value of a PWM signal as measured by an “old fashioned” multimeter is simply Vmax times the duty cycle δ (Fig. 6.5). Substituting δ into the equation of Fig. 6.4 yields Vrms as a function of the average voltage and Vmax, the supply voltage. The table in Fig. 6.5 lists the in this way measured rms heater voltage for three different GUI settings delivered to a 100 ohm resistor. The values are slightly higher that the set points, but that is due to the fact that I never bother to calibrate my experimental uTracers.

Figure 6.6 Left, I own two UNIGOR multimeters from the 60’s / 70’s. They are in perfect working order, indestructible and I use them for everything! Right, FDTI TTL-232R-5V cable interface on an experimental uTracer6.

The RS232 interface

I fully realize that everybody these days is used to appliances and applications that you can just plug into your USB port, and that simply make a connection and then work (most of the times). Unfortunately, that is not so simple for amateur and semi-professional projects and products. I started this sections three times over trying to explain why, but in the end I decided to just give a list of arguments why I want to stick to the “good old (fashioned)” RS232 interface:

A small enhancement I will make is that I will provide for a connector that also provides a +5 V power supply voltage to accommodate Bluetooth modules etc. and a connector that can be used to directly connect a TTL-232R-5V cable from FDTI (Fig.6.6).

Large part of this section was written during a weekend out to The Hague.

There we visited a memorable exhibition of the Dutch painter Louis Apol at the panorama Mesdag museum.

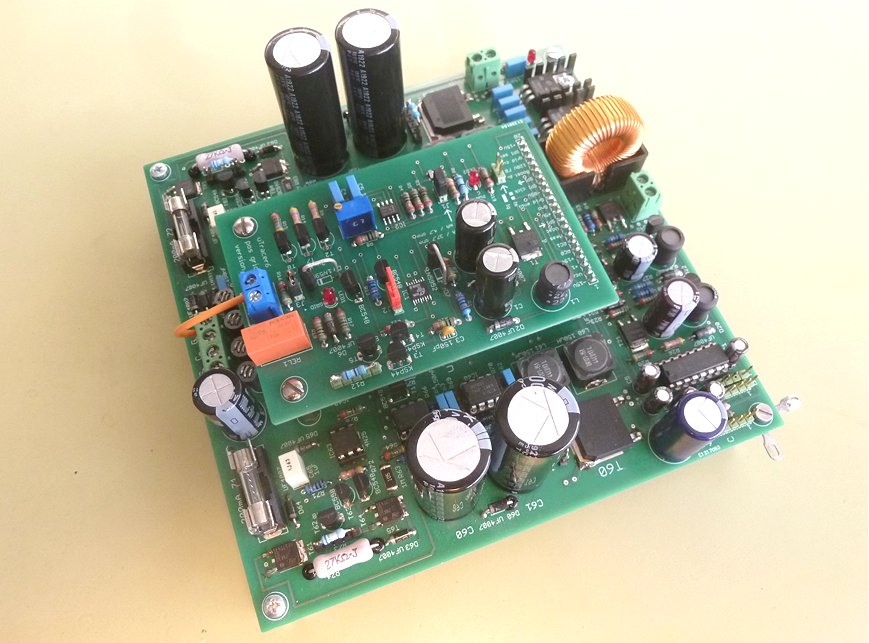

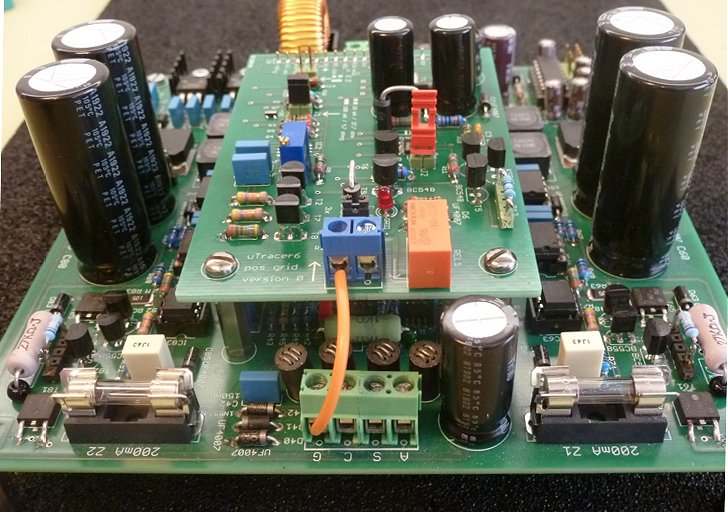

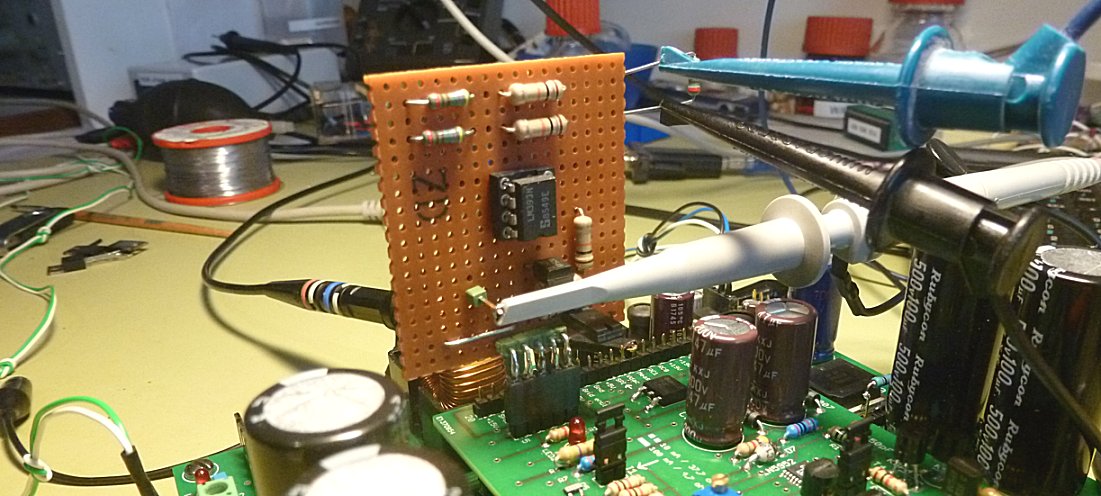

Reading through these sections it might perhaps seem that this has been a single straight path adventure. That is obviously not the case. There have been many trials and errors and considerations whereby the most difficult part has been to find the balance between something that is “doable” for the amateur and that at the same time gives unprecedented performance. I have already mentioned that after a few “wild” experiments with the uTracer4 and the never published uTracer5, I decided to stay close to home and use the uTracer3 as the skeleton to build on the uTracer6. This is nicely illustrated by Fig. 7.1. Eurocircuits my trusted supplier of PCBs from time to time sends me some extra PCB’s. These come in very handy in experiments! The half populated uTracer3 PCB in combination with the perfboard PCB on the left of Fig. 7.1 first was used to test the different high voltage boost and flyback converter ideas using the original grid bias supply. Next, the perfboard to the right was added with the new grid bias circuit. Finally, the new negative supplies and new heater supply were implemented and tested.

Figure 7.1 Very first test version of the uTracer6. click here to view the bottom side of the PCB.

Figure 7.2 shows the analog circuitry of the uTracer6 while Fig. 7.3 shows the microcontroller and some miscellaneous circuitry. Let’s go through the circuit diagram section by section to start with the most interesting part, the analog circuit. To make it easier to trace a certain component in the circuit diagram and on the PCB, the components have been numbered into groups. Components numbers 1-19 belong to the general section, components 20-39 are part of the negative power supply, components 40-69 belong to the grid bias supply while numbers 60-79 belong to the anode supply. Finally, components 70-99 are part of the screen supply.

Starting at the lower left corner of the Fig. 7.2 we first find the heater supply which has been reduced to a single transistor T4. With the lower PWM frequency (see section 6), the gate driver stage included in the uTracer3 was no longer necessary. The IPD048N06L3 that was selected for T4 has a low enough Vt so that is can be directly driven from the PIC. Moving to the right we find two almost identical circuits that generate the negative supply voltages in the circuit, -15 V and -85 V. The circuits are pretty much similar to the negative supply circuit of the uTracer3 except for the fact that the pnp transistor has been replaced by a modern PMOS transistor the IRFR9120. Whereas in the uTracer3 an LM337 was used to regulate the -15V, in the uTracer6 this voltage is directly regulated by the inverting boost converter itself. Moving even further to the right we find the power supply input. A so called “fools diode” D1 shortens the power supply input to protect the circuit when the plus and minus of the power supple are accidentally interchanged. Next the power supply is split into a “clean part” that e.g. feeds the grid section, and a “dirty branch” that feeds all the switch mode power supplies. The dirty branch is filtered by a heavy choke L1 and C15.

Moving one row up, R5 and R6 form a voltage divider that reduce the supply voltage to a level so that it can be sampled by one of the PIC’s ADCs. The software uses this information amongst others to calculate the correct duty cycle for the heater supply. Moving to the right we find the positive power supplies consisting of two standard linear regulators. Note that the input voltage from the +5 V regulator is taken from the output of the +15 V regulator to distribute the dissipation over the two regulators. Compared to the uTracer3 the +5 V regulator does not heat up noticeably.

Moving further to the right we find the grid bias supply. Compared to the uTracer3 this part of the circuit has been completely redesigned. Central to the grid supply is the DAC8562 DA converter. The DAC8562 houses two independent 16 bit DAC converters and a voltage reference. The whole chip is controlled through a standard SPI interface. For the uTracer6 really a 14 bit DA would have been sufficient, but is appears that the DAC8562’s 14 bit sister (the DAC8162) is more expensive than the 16 bit version (!). The outputs of the DAC8562 are practically rail to rail with 0 V output for code 0000H programmed. During experiments it appeared however that the modest load of the IC42 output stage is enough to lift the zero code output voltage of the DAC8562 by a few millivolts, enough to cause a few tens of millivolts of offset at the grid output. Since this time I really wanted to have a consistent grid supply that would really go to 0 V, buffers IC41 a and b were inserted to isolate the DAC from the output stage. Of the two DACs inside the DAC8562 one is used for the negative grid bias supply, while the other one is reserved for the positive grid supply so it is routed to the extension connector.

Figure 7.2 Analog section of the uTracer6.

For an extensive description of the grid output stage the reader is referred to the one of the previous sections. Identical to the uTracer3, the cathode of the tube is connected to the positive power supply (through diode D40). This means that the 0 to 5 V output voltage of the DAC has to be translated to a 0 to -100 V grid voltage with respect to cathode (positive power supply). For the output stage the LTC6090 is used. This high voltage OpAmp can be used with a differential supply voltage of up to 140 V. In this circuit the positive supply voltage is connected to the cathode (positive power supple voltage), while the negative power supply voltage is connected to the -85 V power supply. The difference of 20 – (-85V) = 105 V is enough for a 100 V grid bias supply range with 5 V headroom left. The output of the LTC6090 can swing to about 100 mV from the positive power supply line (@ 1mA). Therefor the LTC6090 is connected to the anode side of D40. The 600 mV introduced by this diode guarantees that the grid voltage can really go up to 0 V.

A few more components in the grid circuit need explaining. The offset compensation circuit around P40 has already been discussed in section 5. The LTC6090 has an output disable input pin. When this input, which has an internal pull up, is pulled to ground, the output of the LTC6090 is disabled. This greatly reduces the dissipation. Normally this pin is connected to the open drain temperature flag output. When the internal temperature of the LTC6090 becomes too high, this pin pulls the disable pin to ground to protect the OpAmp for overheating. In the uTracer6 this pin is additionally connected to the collector of T40. In standy T40 conducts, thereby disabling the output. Only during the actually measurement pulse itself the output of the LTC6090 is enabled. With this precaution it is not necessary to use the nasty thermal pad underneath the LTC6090. When jumper J2 is removed, the output of the LTC6090 is enabled continuously. This is needed when the calibration phase the offset is adjusted with P40.

The remaining components in the grid section R46, C44, D41, D42 protect the circuit during a flash over from anode (or screen) to cathode or grid. During a flash over, the excess charge is dumped in C44. When the voltage of C44 becomes too high, D42 starts to conduct dissipating the excess energy. R46 discharges C44 when needed, and provides a continuous current through D40. Diode 41 diverts a flash over from the grid to the cathode to protect the LTC6090. Although these safety measures have proven to be quite effective in the uTracer3, it is never possible to protect the circuit for all possible calamities. It is therefore recommended to be cautious with “unknown” tubes, and preferable always perform a gas and short test on a regular robust tube tester. Please keep in mind that the uTracer foremost is a curve tracer, not a go / no-go tester!

Moving up we find the screen and anode supplies. These have already been extensively discussed in sections 2, 3, and 4. The only modification here is that the current sense OpAmp is now configured as a subtraction circuit instead of just an inverting amplifier. The addition of two 10k resistors greatly reduced the influence of spurious common mode signals. The default current sense resistor is 4.7 ohm. This will allow for currents of up to 1A to be measured over the 0 to 5 V input range of the PGA. It is not difficult to see that the high voltage divider circuits (R63/R64 & R83/R84) have been dimensioned in such a way that it can handle voltages up to 1000V. For R63 and R83 special high voltage SMD chip resistors were used. Just as in the uTracer3, the output of the high voltage divider is directly connected to one of the ADC inputs of the PIC, However, it is also connected to the second so far unused input of the PGAs. If needed, this will make it possible to increase the resolution at lower anode/screen voltages. However, this will require some fast switching between the two inputs of the PGAs and I am not sure if I will use this option.

Figure 7.3 Digital section of the uTracer6.

Compared to the analog part of the circuit, the digital part is pretty straightforward (Fig. 7.3). At the centre of the circuit is the 16F844 microcontroller. This is the recommended replacement for the 16F874A that was used in the uTracer3. The 16F874A is slowly being taken out of production and “not recommended for new designs” anymore. I get a continuous stream of emails regarding the choice of processor. I know there are more “modern” solutions that offer a wealth of additional features. The reason for me to stick with this processor is that the firmware, which is written in assembler, and which is very much intertwined with the hardware, has proven to work very well and reliable. My mistake with the uTracers4 and 5, which never made it into a working prototypes, is that I wanted to change too many things at the same time and for a one-man job, which basically has to be done in the evening hours, this is not a good idea. So I stick to the 16F844 running with practically the same firmware as was used in the uTracer3 (see next section).

To the left of the processor we find the standard RS232 interface. Owners of a uTracer3 can directly plug the RS232 connector of their uTracer3 into pin header A. People who want to use the popular TTL-232R-5V USB cable from FDTI can plug it directly into connector C (read more here). Finally, those of you who want to experiment with alternative interfaces, such as Bluetooth modules, can use connector C, which offers the serial interfac at TTL levels and a +5 V power supply connection. When either connector B or C is used, the MAX232 needs to be removed from its socket!

The SCT2750NY SIC transistors and the high voltage 2NK100Z MosFets have a relatively high Vt so they cannot be driven directly from the PIC processor. Instead the very common gate driver IR25600 is used to bring the gate signals to power supply voltage levels. Attentive readers may have wondered why the LEDs in the two opto couplers are driven by two separate transistors (T1 and T2). The very simple reason is that in this way it was easier to retain the symmetry in the layout of the PCB.

On the right side of the PIC we find the connector for the extension board, which in first place is intended for the positive grid supply, but that also can be used for other extension options. The table below lists the meaning of the pins on the extension connector.

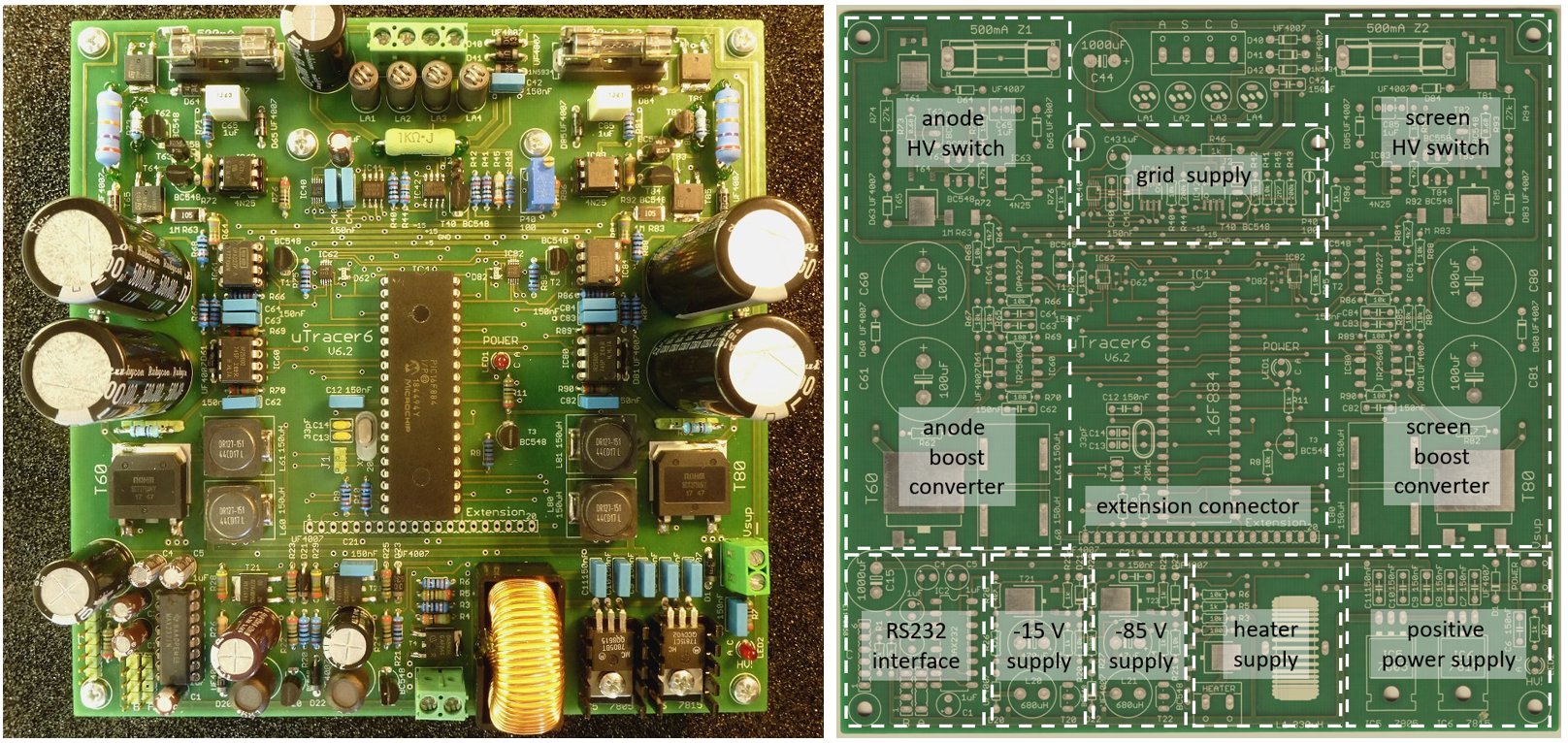

Figure 7.4 The PCB of the uTracer6 after three iterations

I very rarely design PCBs, so again also this time it was again quite an adventure to dive into an old version of Eagle I bought years ago and get going. For myself it is very important that a PCB is aesthetically pleasing. For me symmetry is very important! So I spend quite a bit of time shifting components over the board until I came to a design that I liked. Figure 7.4 shows the almost final version of the PCB for the uTracer6. A special design constraint was that at in some parts of the circuit we have to deal with high voltages (up to 1000 V), which requires a somewhat spacious design. In the centre of the board, space is reserved for the extension board “shield.” Both the anode and the screen high voltage sections can be found on the left and right side of the PCB. The circuits appear to be completely mirrored, but to make this possible, many of the active components had to be rotated by 180 degrees! The dimensions of the board are exactly 6x6 inch, or 152.4x152.4 mm.

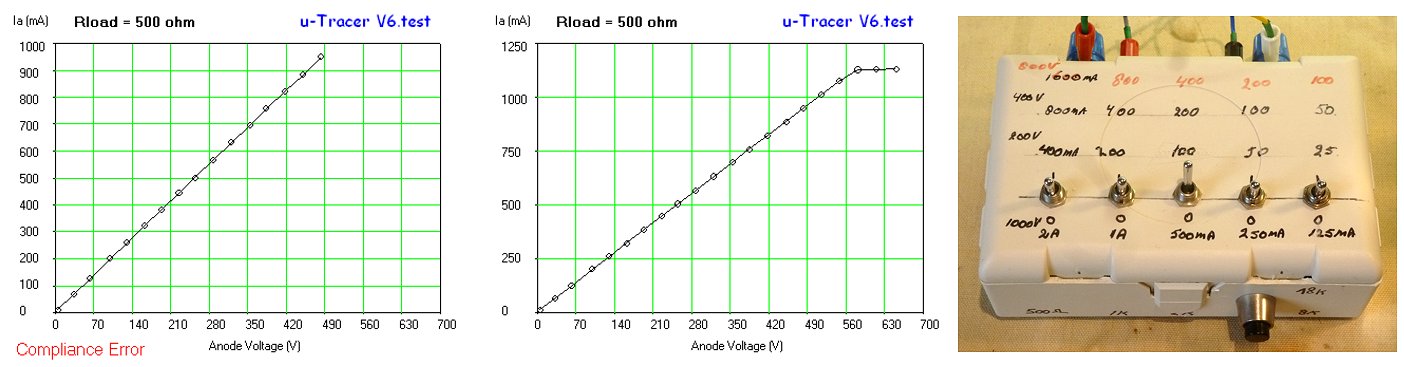

Figure 7.5 First measurements with the uTracer6.

Nr

Connection

Description

1

-15 V

-15 V power supply for analog electronics

2

Vcat

Cathode potential reference

3

+19.5 V

+19.5 raw power supply

4

+19.5 V

idem

5

RC0

Universal digital I/O, normally pulled up by a 10k resistor

6

RC1

idem

7

RD1

Measurement pulse strobe, active high

8

Analog B

Buffered second output of the grid DAC

9

RA4

Universal digital I/O

10

+5 V

+5 V power supply

Nr

Connection

Description

11

0 V

ground

12

RC3

grid enable, becomes low before the measurement pulse, active low

13

-85 V

-85 power supply

14

RD2

Serial peripheral interface, clock

15

RD3

Serial peripheral interface, data

16

RB6

Digital output for positive grid power supply boost pulse

17

RB3/AN9

Analog input to measure voltage of the positive grid supply

18

RB0/AN12

Analog input reserved for measuring the grid current

19

RD7

Universal digital I/O

20

+15 V

+15 V power supply for analog electronics

The command and result strings.

The communication with the uTracer is via a serial RS232 link at a speed of 9600 baud, 8 bits, no parity, and one stop bit. The commands to the uTracer are given in the form of a string of 28 (Uppercase) ASCII characters. Each character sent to the uTracer is immediately echoed. Failure to echo a character represents a malfunction of the uTracer.

Every two consecutive characters in the ASCII string represent an eight bit byte. The first byte is the command code. The following 8 bytes represent data. Different formats for the data are used depending on the command code, however in most cases the eight bytes are grouped into four 16 bit words representing the anode voltage, the screen voltage, the grid voltage and the filament voltage.

Some strings do not result in a response from the uTracer. Other strings result in the uTracer sending a result string. The result string also has a fixed format, and consists of 38 ASCII characters. Again every two consecutive characters in the ASCII string represent an eight bit byte.

The first byte is the status byte which signals if the command to which the result string was a response was executed successfully. The remaining 18 bytes represent data grouped into 9 two byte words. The format of the result string is fixed (Fig. 8.2).

Figure 8.1 Definition of the Command Strings.

The data in both the command string as well as in the result string is always in 10 bits binary format. This means that the upper 6 bits of the data word are not used. These bits should be zero. In most cases the binary data directly represents a 10 bit result of the on-chip AD converter, or a setting of the 10 bit on-chip PWM modulator. All conversion of for the user meaningful numbers to and fro binary representations is done in the GUI. In this way a minimum amount of intelligence is needed in the micro-controller.

Figure 8.2 Structure of the Result String

Structure of a complete measurement sequence

The different commands should be send in a certain order, although sending the commands in a random will not result in an error. The preferred command sequence is shown in Fig. 8.3. When the “Heater On” command is pressed, the GUI send a “Set Settings” (<00>) command followed by a “Ping” (<50>) command to obtain the current supply voltage. It then sends “Switch On Heater” (<40>) command. The only thing this command does is to copy the last word of this command to the filament PWM generator. The other words should be “0000”. The filament

voltage can be directly set to the final value or the GUI can generate a “soft-startup” by issuing a sequence of <40> commands with increasing filament voltage values. The uTracer does not send a response after receiving a <40> command

Figure 8.3 Structure of a typical Measurement Session

While the filament is heating, the user has the time to select a measurement type on the GUI and to set the proper measurement conditions. When next the user presses the “Measure Curve” button, the sequence to measure a set of curves is started. The first command issued is the <00> “Send Settings” command. This command transfers the gain settings for the anode and screen amplifiers, the required number of average measurements and the current compliance value. There is no response of the uTracer to the <00> command. Next the GUI starts issuing <10> “Do Measurement” commands. The four words in the command exactly specify the anode, screen, grid and filament voltages. After reception of the command the uTracer sets all the specified bias conditions and performs the measurement. The result is communicated back to the utracer in a result string. The value of the status byte indicates if the measurement was successful. If the status byte = 10H everything is ok, a value of 11H indicates a compliance issue on one of the two channels. The GUI can issue any number of <10> commands. At the end of a measurement sequence the GUI issues the <30> “End Measurement” command. This command discharges the high voltage buffer capacitors and set the grid voltage to zero. In the same measurement session more curves or a different type of curve can be measured by repeating the <00>,<10><10><10>….,<30> sequence. At the end of the session the filament voltage is switched off by issuing a <40> command with a specified filament of zero volt.

The format of the variables

In this section the format of the variables that are used in the communication with the uTracer will be defined. Some of these variables are one byte, while other variables use two bytes (a word).

anode and screen gain

The anode and screen gain variable is only one byte long, and used both in the <00> command string, as well as in the result string. In the command string it is used to specify the gain of the anode or screen current amplifiers, or to specify that the “auto gain/range” option is selected. In the return string the variable returns the actual gain as it was determined by the “auto range” algorithm in the uTracer and used for the current measurement point. The lower nibble directly reflects the gain convention as it is used by the PGA113: 00H=1X, 01H=2X, 02H=5X, 03H=10X, 04H=20X, 05H=50X, 06H=100X, 07H=200X. In addition code 08H is used to indicate that the auto-gain algorithm has to be used.

cThe average variable is one byte long. The variable is only used in the <00> command string. In principle the variable can have any value in between 1 and 32 (001H and 20H). In practice only the values 1, 2, 4, 8, 16 and 32 are used. This is because the user can only choose from these values. When the variable has the value 40H it indicates that the auto-averaging algorithm has to be used

compliance