Readers of my pages will not be surprised to learn that, like so many other people, I am fascinated by vacuum tubes. In contrast to most of these tube-lovers I have, at least up to now, little interest in tube amplifiers. I simply do not have the ears for it! I am however fascinated by the technology of these fragile and romantic devices and I love to read and write about their history. I do however have quite an extensive tube collection, and from time to time I am playing with the idea of making a tube tester, or even better a tester which can measure a set of Ia-Va of Ia-Vg characteristics, in other words a tube curve-tracer.

My whole professional life has been devoted to the research, development and fabrication of semiconductor devices. The best term I can find to describe my profession is that of “Semiconductor Technologist.” My interest and fascination for semiconductor technology explain my interest in tube fabrication technology. Radio tube technology has these days almost become an extinct language like classical Latin or Greek, and I

sometimes wonder if also my “craftsmanship” will suffer the same fate? Anyhow, a curve-tracer is about the single most important measurement tool I use in my work both in- and outside the cleanroom. It allows one

to measure and evaluate very quickly not only transistor and diode characteristics, but also contacts of metals to semiconductors, stability of junctions etc. In short, in my view a curve traces is one of the most useful pieces of equipment around.

to measure and evaluate very quickly not only transistor and diode characteristics, but also contacts of metals to semiconductors, stability of junctions etc. In short, in my view a curve traces is one of the most useful pieces of equipment around.

The reason why I never actually undertook building a tube curve-tracer is the same reason why I dislike most tube circuits: they are always bulky, heavy, and tend to dissipate a lot of energy! Sometimes the most beautiful ideas come at the strangest moments. In this case it was actually when my mind wondered away during the sermon of the Christmas service in our church on Christmas morning 2010. The idea was very simple: instead of measuring the tube characteristics in a continuous mode, why not measure them in pulse mode?” Pulse mode measurements are frequently done for power transistors in order to be able to characterize the device under biasing conditions which would cause excessive dissipation in continuous mode. The beautiful thing is that when the tubes are measured in pulse mode all of the bulky high voltage power supplies can be eliminated. Instead a low power boost converter can be used to charge up a reservoir capacitor which can easily deliver several hundreds of milliamps during the few milliseconds necessary for the measurements.

The rest of the Christmas holidays were spend on performing the experiments necessary to establish the feasibility of the project. They were encouraging and at the moment I am quite exited about the whole concept. It is a beautiful combination of vintage and state-of-the-art electronics and potentially may even result in something useful. On this page you will find an account of the project as it evolves.

| to top of page | back to homepage |

I believe it was Philips Research Fellow Karel Kuijk who said ‘with a good idea, everything quickly falls into place’ (bij een goed idee zit alles mee). It also applies to this project. Once the idea of a pulsed tube curve tracer was conceived, all the parts of the system seemed to fall into place as if they had been waiting to be put together.

Figure 2.1 Symbolic circuit diagram of the µTracer.

Figure 2.1 shows the initial simplified circuit diagram for the uTracer. For clarity the processor and other digital parts have been omitted. Heart of the uTracer are the pulsed anode and screen-grid power supplies. In a normal curve tracer these would be by far the most difficult and by far the heaviest parts of the tester. They would have to be able to supply a programmable high voltage adjustable between 0 and say 350V at currents up to ca. 200mA. The output power of the anode supply e.g. should be in the order of 50 to 100 Watt requiring a bulky transformer, rectifier and an undoubtedly heavily cooled regulator. By pulsing the anode voltage the whole anode supply collapses into a tiny circuit consisting of only a dozen or so of small components.

The blocks designated “0–350 V boost converter” consists of little more than a 100uH inductor, a diode and a power MOSFET. The gate of the MOSFET is controlled by the microcontroller. The boost converters pumps charge into large reservoir capacitors. The voltage of the capacitors is monitored and adjusted by the microcontroller. Voltages up to 400V can be quite easily achieved this way. At the same time when the high voltage capacitors are being charged, a second – inverting – boost converter generates a negative supply voltage of -35V. This negative voltage is used for the negative control grid bias. Also the generation of the negative bias voltage is completely monitored and controlled by the microcontroller. An analog output of the microcontroller is used to set the grid bias. A single Op-Amp translates the 0-5 V DAC output to a 0 to -35 V grid to cathode bias voltage.

After the microcontroller has charged the high voltage buffer capacitors to the desired values, and has set the control grid bias, it stops pumping the boost converters to eliminate any switching noise and then opens the high voltage anode and screen-grid switches for about 3 ms. After a settling time of 1-2 ms both the cathode current and the screen-grid current are measured. The cathode current minus the grid current yields the anode current. Assuming a maximum anode current of 200 mA, the high voltage capacitor voltage drop during the 2 ms settling time will only drop V = Q/C = (I*t)/C = (0.2*0.002)/(0.0001) = 4 V. This is really a worst case scenario. For most measurements the voltage drop will be much less. Nevertheless, the controller additionally measures the actual anode voltage at the same moment the anode- and screen currents are measured. The cathode current is determined by measuring the voltage drop over a small cathode resistor. A programmable amplifier which amplifies the voltage drop over the cathode resistor enables the characterization of both low- and high power tubes.

| to top of page | back to homepage |

While doing the innitial experiments to study the feasibility of the uTracer project, quite by chance I happened to stumble on a series of articles in some early issues of the Philips Technical Review Magazine describing what are perhaps the first Curve Tracers ever conceived!

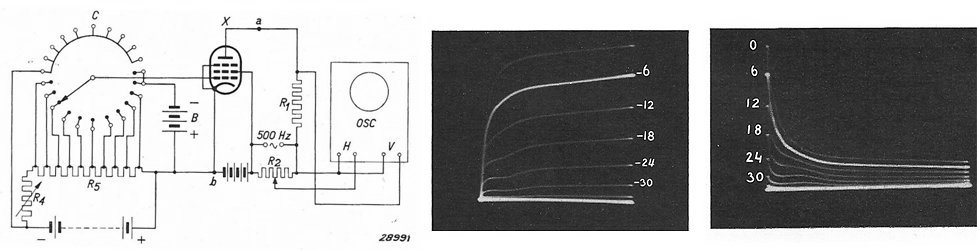

Figure 3.1 A few snapshots from a very early publication describing a curve-tracer mechano-electrical curve tracer [1]. The center picture shows an example a set of Ia-Va curves. The x-axis ranges from 0 – 500V, while the y-axis ranges from 0 – 200mA. The right picture depicts the screen-grid current of the same tube under the identical measurement conditions.

Figure 3.1 shows a few pictures from the first article taken from an article titled ”Applications of Cathode Ray Tubes IV,” from the Philips Technical Review of 1938 [1]. The left figure depicts the circuit diagram of the curve tracer. The anode voltage is derived from a 500 Hz high voltage generator, most likely a mechanical alternator. The stepping voltage for the control grid was generated by a rotating commutator. Ten of the commutator contacts are connected to a resistive divider ladder which provides negative grid biases at equidistant steps which can be adjusted by means of a variable resistor. Note that two of commutator contacts are connected to a fixed negative grid bias of -6 V. So the curve for -6 V is written twice and as a result it will appear lighter on the screen of the cathode ray tube. This fixed curve serves as a reference for the adjustment of the grid bias steps. When the first line coincides with the reference curve, the step is -6 V. When the second line coincides with the reference curve the step size is -3 V, etc. The other contacts on the commutator are connected to the highest negative voltage so that at these positions the tube will be cut-off. The purpose of this is to give the tube time to cool down. Especially during the moments when the anode voltage is low and the screen-grid potential is high, the resulting high screen grid current could otherwise easily overheat the screen grid (Fig. 3.1 right).

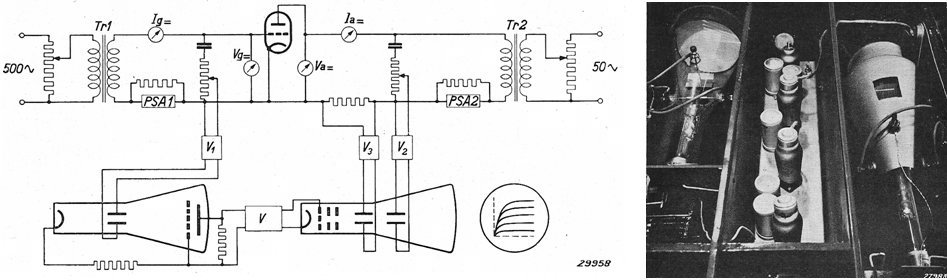

Figure 3.2 A description of this apparatus designed to measure transmitting triodes appeared in the Philips Technical Review of 1939 [2]. The right pictures shows both the normal cathode ray tube (left) as well as the “impulse tube” (right).

A year later in the same periodical an article is published describing a curve-tracer especially designed to characterize transmitter triodes [2]. During normal operation of transmitter triodes, it is quite common that the control grid becomes positive resulting in a significant grid current. It is therefore important that these tubes can also be characterized in that biasing regime. With the previous circuit this was difficult, the grid current would cause spark erosion of the commutator contacts while it would also disturb the proper operation of the resistive ladder divider. For this application the researchers therefore pursued a completely different approach. This time both the grid, as well as the anode are driven by alternating current sources (Fig. 3.2). For the anode a 50Hz source is used, while the grid was driven from a 500Hz power source. Without any further circuitry this arrangement would produce a rather complicated kind of lissajou figure on the screen of the cathode ray tube. The trick was the use of a specially designed “impulse tube.” This was a specially made cathode ray tube (Philips Research had all the fascilities needed to make these kind of special devices) in which the phosphorous screen was replaced by a plate with a second plate with narrow vertical slots punched into it placed in front of it. The x-plates of the impulse tube were connected to the grid voltage, so that only at certain grid voltages the electron beam could hit the plate behind it. This generated a pulse which would turn on the electron current in the normal cathode ray tube which would be otherwise suppressed. So the final set of characteristics was built up from dots corresponding to well defined grid biases. Pretty clever!

Figure 3.3 Click Here to view some more pictures of this amazing beast!

After the war Philips emerged as the dominant tube manufacturer in Europe. The pentode patent in combination with its enormous production capacity all over Europe made its position as the foremost player in this field unchallenged. The center of tube development is the tube-lab in the building in Eindhoven known as the “white-Lady” at the Emmasingel.

Already in a number of other pages I have discussed the organization and structure of this legendary tube-lab, which is otherwise poorly documented. One of the most well-remembered people of the tube-lab is the

almost legendary Bert Dammers. Dammers headed the group in charge of the development and application of consumer tubes. He wrote several books on radio and television tubes and tube circuits, and was renowned for his ability to think up new and innovative circuits for radio and television in which several functions were combined in as little as possible tubes.

almost legendary Bert Dammers. Dammers headed the group in charge of the development and application of consumer tubes. He wrote several books on radio and television tubes and tube circuits, and was renowned for his ability to think up new and innovative circuits for radio and television in which several functions were combined in as little as possible tubes.

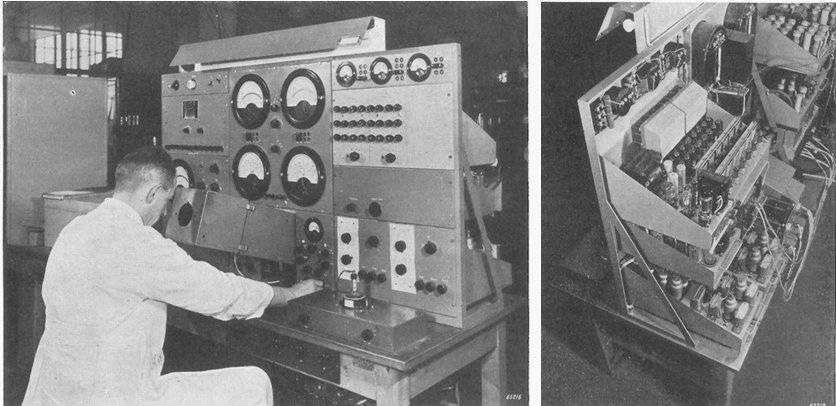

In the Philips Technical Review of 1950 Dammers published an article entitled: ”The Electrical Recording of Diagrams with a Calibrated System of Coordinates” [3]. It should be understood that the Philips Technical Review magazine in the first place was a publication of Philips Research. Nevertheless, from time to time also new developments from the development and application groups appeared in the magazine. The fact that Dammers article was also published meant that it was regarded as an important innovation. The article describes a fully electronic curve-tracer which basically comprises all the ingredients of the modern curve-tracer. The apparatus facilitated in quick and accurate characterization of the many test versions which were fabricated of new tube types. It also allowed characterization of tubes under bias conditions which would under static bias conditions cause excessive heating.

From the description of the system it becomes clear what a tremendous progress electronics had made in the decade 1940-1950. The mechanical commutator which in the earlier designs stepped through the grid biases is now replaced by a fully electronic “stair-case” voltage generator. Such a device was in the tube area already quite an undertaking! The “stair-case voltage” was synthesized by adding a number of square-wave signals which were phase-shifted with respect to each other. A special feature of the curve-tracer was that it also generated a reference grid which would allow for accurate measurements. To even further increase the measurement accuracy two cross-wires could be moved over the screen while the value of the corresponding anode voltage and current could be read from two meters situated directly abode the cathode ray tube. The sine-wave shaped anode voltage was generated by a power amplifier consisting of a balanced amplifier with 2x2 EL34 tubes in parallel. The amplifier could generate 200 W at a maximum output voltage of 620 V!

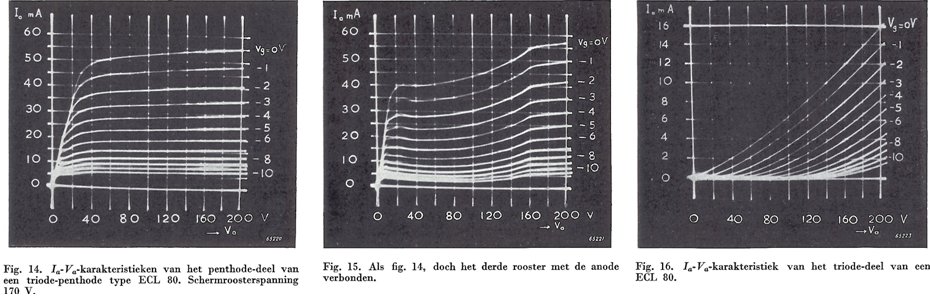

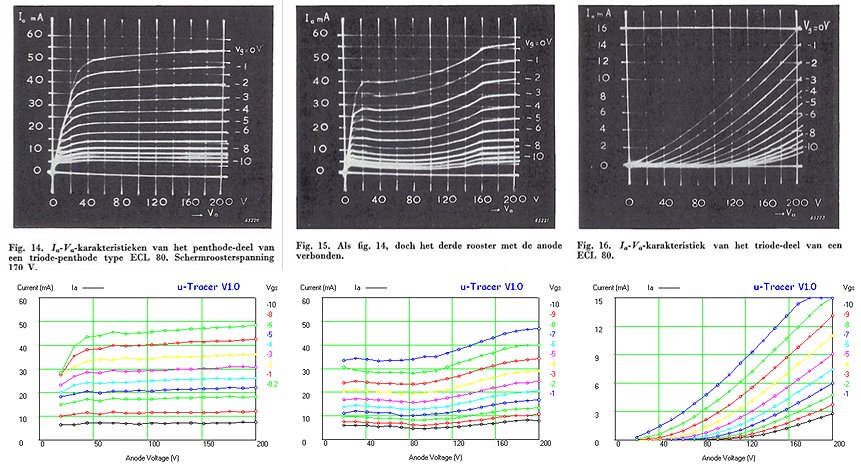

Figure 3.4 As an example of what the curve-tracer of Fig. 3.3 was capable of these measurements on an ECL80 are shown. Left, the pentode section, middle, the pentode switched as tetrode and right, the triode section.

The whole monster comprised some 200 tubes. Assuming an average life-time expectancy of 10.000 hrs for each individual tube, this meant that on average this would result in a system malfunction due to a tube failure every 50 hrs of operation. Therefore the whole system was designed in a modular form so that when a failure occurred the curve tracer could be quickly repaired by just replacing the failing module. At the end of the paper some measurement examples on two state of the art tubes where shown the PL81 (a line output pentode for television) and the general purpose pentode/triode combination tube ECL80 (Fig. 3.4). A nice feature of the pentode section of the ECL80 is that it can be switched at tetrode by connecting the third grid to the anode. I still have some ECL80 tubes lying around, and I have made it my goal to reproduce these curves on the uTracer.

| to top of page | back to homepage |

After that blissful moment of conception that Christmas morning, the remainder of the Christmas days was spent on breadboard experiments to get an idea about the feasibility of the whole concept. Fortunately we didn’t have that many family obligations so there was plenty of time for experimenting. The questions that needed answering were:

The boost converter

Figure 4.1 depicts the test circuit that was used in the first experiments to ascertain whether a voltage in the range of 300-400 V can be achieved with a simple boost converter. The heart of the boost converter is formed by inductor L1, MOSFET T3, and diode D2. For a more complete explanation of the working of boost converters, interested readers are referred to my ”Flyback Converters for Dummies” page. When T3 closes, a constant voltage of 12 V is applied over L1. This causes a linear increase of current through the inductor. Assuming that an inductor of 100 uH is used which saturates at a current of about 2 A, the maximum on-time for T3 follows from:

Figure 4.1 Test circuit for the boost converter

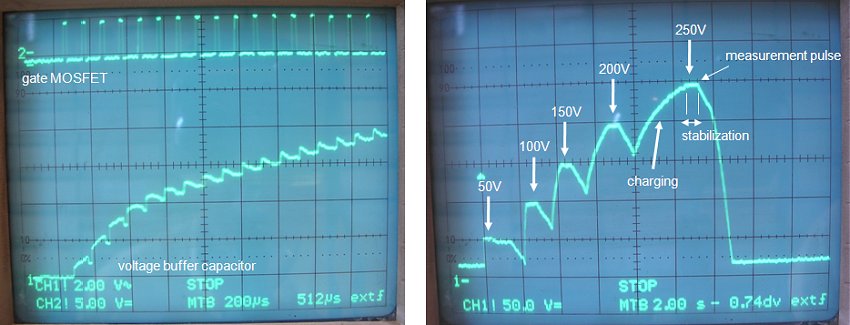

With a supply voltage of 12V the final un-loaded output voltage was about 450V. The charging time of the output capacitor strongly depended on the input frequency. For an input frequency of 2 kHz it took for 200V 10” / 300V 40” / 400V 2’. For an input frequency of 20 kHz the charging times drastically reduced to 200V 1” / 300 V 3” / 400 V 10”. So obviously if we want to avoid excessive large charging times, the processor will need to be able to generate such a clock frequency, while at the same time monitoring the capacitor voltage(s). Not impossible, but it need to be taken into consideration in designing the software.

Remaining Issues:

- how to organize the software?

- can the MOSFET be driven directly from the processor?

- how large are the voltage increments per cycle.

Measuring the Screen Current

In the original plan I had, the anode current was measured my measuring the cathode current via the voltage drop over a cathode resistance. This in reality measures the sum of the anode current and the screen current. For normal output pentodes the screen current is usually relatively low compared to the anode current, so the error wouldn’t have been too large. However, for RF pentodes the screen current can be up to 50% of the anode current (e.g. EF94). Moreover, if we measure the full device characteristics to tube becomes biased in regions were the anode voltage is low while the screen voltage is high, under these biasing conditions the screen current can be very high (see e.g. Fig. 3.1). So it is important not only the independently set the screen voltage, which implies a second high voltage boost converter, but also to measure the screen current.

At first this seemed rather to spoil the whole simplicity of the concept. All kind of complex circuits sensing the high-side screen current, translating it to a low side voltage which could be measured by the processor where dreamt up, but none of them very simple. Then I realized that under most biasing the absolute screen current will be still quite small in absolute value. This makes it possible to use a very simple circuit: a good old-fashioned pnp current mirror!

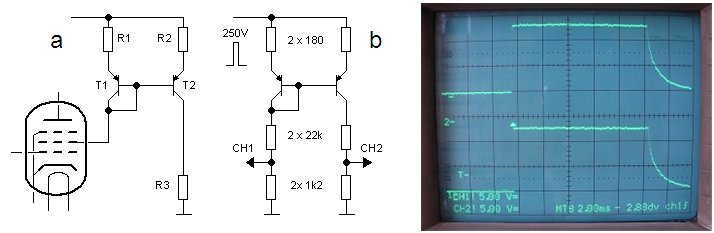

Figure 4.2 The current mirror for measuring the screen-current

Current mirrors are widely used in ICs, but you don’t see them that often in normal circuits. The most left diagram in Fig. 4.2 depicts the pnp current mirror as I have intended it for this application. Note that T1 is switched as a diode, more precisely as the diode in the emitter-base junction. If we neglect for a moment the current flowing to the base of T2, then all of the screen current will pass through the emitter-base diode of T1 and R1, causing a voltage drop. Now first the voltage drop

over the emitter-base junction. As for any diode there is an exact exponential relationship between the current though this diode and the voltage drop over it. This fact is used in current mirrors in ICs. Here the resistors R1 and R2 are usually omitted and since the transistors are made in the same process on the same wafer and very close to each other, the current voltage relations may be assumed to be identical. Si the voltage drop over the emitter-base junction of T1 will be applied also over the emitter-base junction of T2, causing an identical current to flow through T2! However, if we built up a current mirror with discrete

components, T1 and T2 will be usually not exactly identical. This is the reason why R1 and R2 have been added. These resistors linearize the current-voltage relation of the transistors, making the matching of the currents less dependent on the exact matching of the transistors. But this comes at a penalty. In especially low voltage circuits the additional voltage drop over the resistors is simply not possible, here this fortunately is not such an issue, although it does introduce a small error in the sense that the actual screen grid voltage is a bit less than the set screen grid voltage.

over the emitter-base junction. As for any diode there is an exact exponential relationship between the current though this diode and the voltage drop over it. This fact is used in current mirrors in ICs. Here the resistors R1 and R2 are usually omitted and since the transistors are made in the same process on the same wafer and very close to each other, the current voltage relations may be assumed to be identical. Si the voltage drop over the emitter-base junction of T1 will be applied also over the emitter-base junction of T2, causing an identical current to flow through T2! However, if we built up a current mirror with discrete

components, T1 and T2 will be usually not exactly identical. This is the reason why R1 and R2 have been added. These resistors linearize the current-voltage relation of the transistors, making the matching of the currents less dependent on the exact matching of the transistors. But this comes at a penalty. In especially low voltage circuits the additional voltage drop over the resistors is simply not possible, here this fortunately is not such an issue, although it does introduce a small error in the sense that the actual screen grid voltage is a bit less than the set screen grid voltage.

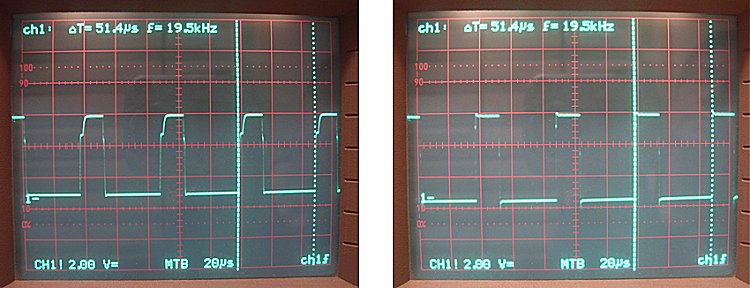

Using the high side voltage switch (from one of the next sections) the current mirror was tested under pulsed conditions. In this experiment a resistor was used to set the current in the diode branch of the mirror (Fig. 4.2 left b). The current in both branches was monitored by measuring the voltage drop over a 1k21 resistor. With in total 22k + 1k21 = 23.21k in the diode branch, this would set the current to 250/23.21k = 10.8 mA. The voltage drop over the resistors in the left and right branches of the mirror are displayed in the right picture of Fig. 3.2. As can be seen, they are, as far as can be judged from the oscilloscope picture identical. The pulse height is approximal 12.5V corresponding to a current pulse of 12.5 / 1k21 = 10.33 mA. Well within measurement tolerances. So all in all the current mirror idea seems to work quite well for this application.

Note that this circuit can only be used because it is operated in pulsed mode. Suppose e.g. that the screen current is 10 mA and the screen voltage 400 V. This is equivalent to a dissipation of 400*0.01 = 4 W! In pulsed mode the average dissipation is of course reduced proportionally to the pulse / pause ratio. Another point of concern is the maximum value of the screen current. In biasing conditions where the anode voltage is low and the screen voltage is high the screen current can be quite high. The circuit should be able the measure this.

Remaining Issues:

- how small can the linearization resistor be made (to reduce the voltage drop)?

- What is the maximum screen current that can be handled.

The high-side voltage switch

The high-side voltage switch which pulses the high voltage to the anode and screen-grid of the tube is one of the key components of the circuit. It should be able the switch on the voltage quickly enough, and should have a low voltage drop. Basically there are two options for this switch: a high voltage p-type MOSFET or a high voltage pnp transistor. I know that most people would choose for a MOSFET. They can easily handle the currents involved and can have a very low on-resistance. The fact that MOSFETs are relatively easy to understand makes that a lot of people prefer MOSFETs over bipolar. However, the choice for high voltage p-type MOSFETs is not so large and driving a high-side gate is also not that straightforward. I personally prefer bipolars, not in the last place because I have a box with 2000 PN5416 high voltage transistors waiting to be used in a nice circuit!!

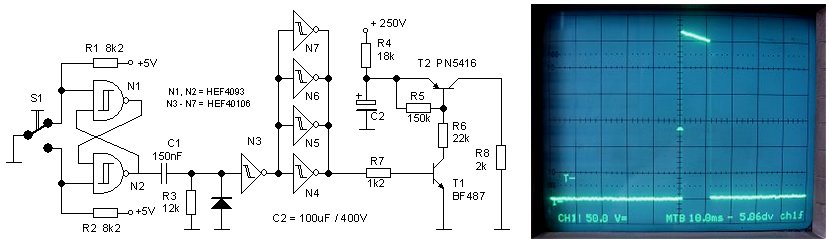

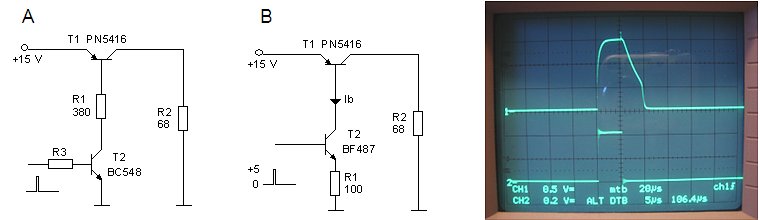

Figure 4.3 Test circuit for the high voltage switch

The first test circuit is displayed in Fig. 4.1. The flip-flop around N1/N2 debounces switche S1. When the switch is pressed, they output of of N2 becomes high. The differentiating network C1, R3 in combination with N3 reduces the pulse length to ca. 10 ms (negative going). Inverters N4 – N7 buffer and invert this pulse. The high-side switch itself is formed around T1 and T2. Just like in the real tube tester the high voltage is supplied by a charged capacitor. The way the switch has been set up is straightforward, in fact too straight forward. R5 keeps T2 off when T1 is not conducting. When high voltage T1 is on, it provides the base current for T2. A dummy load resistor of 2k (R8) is used to simulate a load that would pull about 300 / 2000 = 150 mA at an voltage of 150 mA. At such a high collector current the hFE of T2 will be biased in the high current regime and the hFE will be significantly reduced. Here it was assumed that the hFE was reduced to something like 10 so that T2 needs a base current of about 15 mA to keep it into saturation. Resistor R6 sets a base current of 300 / 22k = 13 mA. The left picture in Fig. 4.3 shows an output pulse of the test circuit for a voltage of 250 V. Quite to my surprise the rise time of the pulse is very sharp, well within 1 ms, which is great because it means that the measurement time can be kept very short. Also observe the discharging of C2 during the pulse.

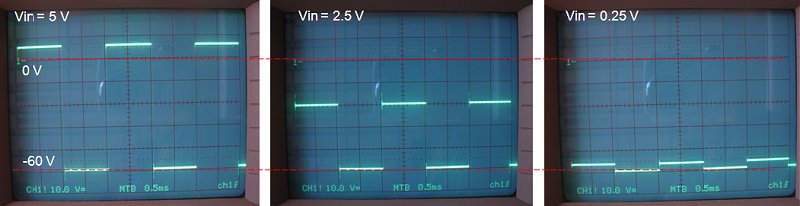

Figure 4.4 First pulsed measurements on an EL84.

Figure 4.5 First pulsed measurements on an EL84. A. shows the oscillations in anode voltage (bot) and voltage drop over the cathode resistor (top). B. shows Ia (bot) and Ib (top) of the EL84 under typical biasing conditions.

I was so satisfied with this result that I had forgotten to actually check the saturation voltage (or in other words the emitter-collector voltage drop) of T2. Having realized this, the left circuit of Fig. 4.5 was quickly put together to measure it. Since I didn’t want to fool around with potentially lethal voltages unnecessarily, the circuit was operated from 15V. At this point I realized a serious flaw in this circuit: for a given base current (and hence anode current) the value of R1 depends on the voltage of the circuit! So far I had assumed that the circuit would always operate at a voltage of say 200 – 350V. But of course in a curve tracer the voltage may vary between 0 and 350 V! Since the base current is set by (V – 0.9)/R1 with 0.9 the emitter-base voltage drop of T2, the base current would decrease proportionally to the supply voltage, which would make it impossible to measure high currents at low voltages. Anyhow the circuit was used to determine the saturation voltage and the base current needed to reduce it to the minimum. The load resistor of 68 ohm sets a collector current of 16 / 68 = 220 mA. Experimentally it was found that a value of something like 380 ohm for R1 reduced the saturation voltage to a value less than 1V. This corresponds to a base current of (15 – 0.9)/380 = 37 mA.

Figure 4.6 Improved driver circuit for the high voltage switch (center) and the voltage pulse over the load resistor (top 5 V/div), and the voltage drop over R1 (bottom 2 V/div).

A much better solution is circuit B in Fig. 4.6. Here T2 is used as a current source whose current is determined by the amplitude of the input pulse and the value of R1. Under the (valid) assumption that the forward emitter-base voltage of T2 is more or less constant (0.9V), the current through R1, and hence the current though T2, is determined by (Vpulse – 0.9)/R1. Since the microcontroller will generate a pulse with an amplitude of 5 V, a resistor of 100 ohm results in a collector current for T2 (which is the base current of T1) of (5-1)/100 = 40 mA. Note that whereas in the first circuit all energy is dissipated in resistor R1, it is now dissipated in T2. Let’s make a worst case calculation. Assume V = 400 V and Ib = 40 mA, in that case the dissipation in T2 equals 16 W. Let’s furthermore assume a measurement pulse of only 3 ms, one per second. This would result in an average dissipation of 48 mW. According to the datasheet of the BF487, it can dissipate continuously 800 mW, corresponding to 800 / 48 = 16 measurements per second under worse case conditions. Figure 4.6 right shows the voltage pulse over the load resistor (top 5 V/div) as well as the voltage drop over R1 (bottom 2 V/div). Note that the saturation voltage is much less than 1V.

Generation of the control-grid bias

For the control-grid bias it was assumed that a range of 0 to -20 V would be sufficient to cover most tubes. This bias needs to be applied with respect to the cathode. Since the cathode current is measured by the voltage drop over a series resistance, some kind of circuitry was needed to correct for this voltage drop. Furthermore the on-chip PWM generator with an output voltage of 0 to 5 V (after filtering) was to be used for setting the negative grid bias.

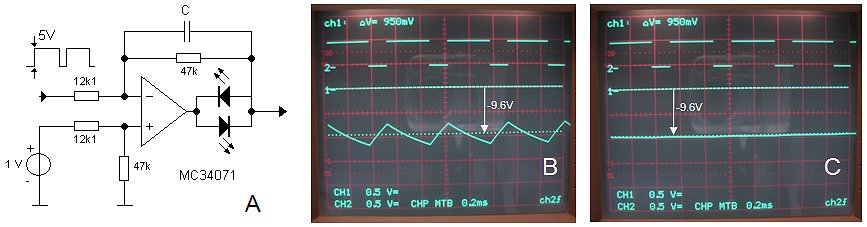

Figure 4.7

It turned out that both requirement could easily be met with a single OpAmp. Figure 4.7A shows the standard OpAmp subtraction circuit. In Fig. 4.7B this circuit is used to bias the control-grid. The resistors in the circuit have been chosen such that the amplification of the circuit is four. The negative input of the circuit is connected to the PWM output (after filtering), while the positive input is taken from a tap on the cathode resistance. The tap is such that it is at exactly 0.25 of the total voltage drop over this resistor.

Figure 4.8

A square wave signal with a frequency of 2 kHz, variable duty-cycle and 5 V amplitude was used as input signal. A voltage drop over the cathode resistance was simulated with voltage source. An arbitrary voltage of 1 V was chosen. Resistors of 12k1 and 47k were used because there were readily available. This sets the amplification factor at 47/12.1 = 3.88. As an example a duty-cycle of 70% was used. This effectively means an input voltage of 0.7*5 = 3.5 V. Theoretically the output voltage then follows from 3.88(1-3.5) = -9.7V. The measured output voltage was 9.6, very nicely within all the measurement tolerances.

The negative power supply

With already two boost converters for the anode and screen voltages, it seemed only logical to use a third (inverting) boost converter for the generation of the negative supply voltage for the OpAmps. Figure 4.9 shows the circuit that was used to test the circuit. The working of the circuit is simple. The BC548 npn is driven with the same 15-20 us pulse that is used for the high-voltage converters. This transistor will pull the pnp transistor into saturation causing a linear increase of the current through the inductor. When the BD138 shuts off, the inductor wants to keep the current flowing and the only way it can do this is to reverse the polarity over its terminals so that the diode starts to conduct, thereby negatively charging the electrolytic capacitor.

Figure 4.9

Rather unconventionally an pnp power transistor was used instead of a PMOS transistor. The reason is that I didn’t have one “in stock” but that I did have a whole bunch of BD138 transistors. Agreed,a power PMOS transistor would perform better in this circuit, but the performance is not that critical so that a simple BD138 performs good enough. That is the same reason why a simple BAV10 (1N4148) diode was used instead of a fast switching rectifier diode. The circuit was tested using a 2 kohm resistor as load and a pulse width of 15 us. Figure 4.9 right shows the output voltage and the output power as a function of puls repetition frequency. For a repetition frequency of 7 kHz the circuit generates an output voltage of 47 V in 2 kohm at a current of 24 mA (ca. 1 Watt).

The voltage divider(s)

The voltage dividers reduce the high voltages so that they can be measured with the on-chip AD converter which has an input voltage range of 0-5V. They consist of a simple resistive voltage divider and a protection diode. The protection diode ensures that when, for any reason, the input voltage is too high, the voltage on the input of the AD converter is clamped to Vdd.

Figure 4.10

The conversion formulas for the circuit including conversion by the 10 bit (0 – 1023) AD converter. Here Vin is the high voltage input, Vout the input voltage of the AD converter, and n the output value of the converter. To ensure the in the datasheet of the AD converter specified acquisition time, the impedance of the circuit connected to the AD converter should not be much higher than 2k. Figure 4.10C is dimensioned for this impedance using 1% resistors. In total the resistance of the divider circuit is in this case 184k. This value is fine for sensing the high voltages after high voltage switches, but the value would be a rather high load for the boost converters if it was used before the high voltage switches. Therefore at that position higher resistance values are used (Fig. 4.10B). This will result in a somewhat higher acquisition time, but when it is a problem the impedance can be decreased by placing a small buffer capacitor over R1.

Figure 4.11

| to top of page | back to homepage |

I regularly get emails from people who experience difficulty in starting and completing (!) a project like this. In my opinion (but who am I) the most common mistake leading to disappointment is that most people are inclined to go directly from idea or a paper circuit diagram to an etched PCB. Very often too little time is spend on actually testing (parts of) the circuit. The result is that the circuit does not work properly. Since a circuit on a PCB is difficult to modify it is difficult to debug the project resulting in frustration, and not seldom these people end up finding another hobby.

For all those people some tips that I find useful:

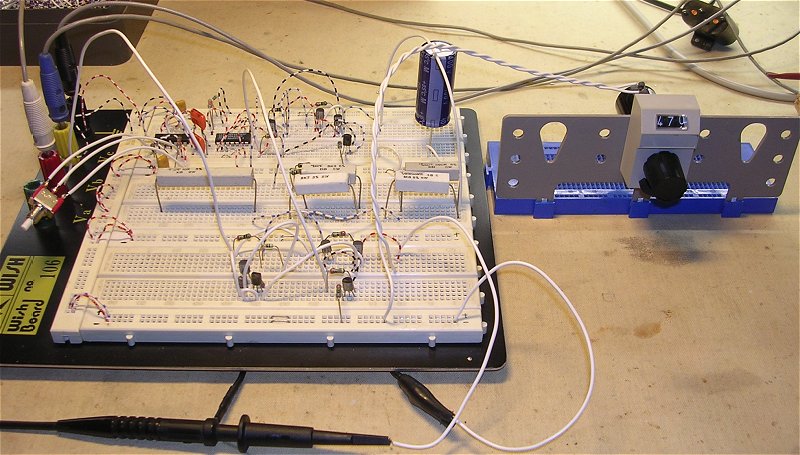

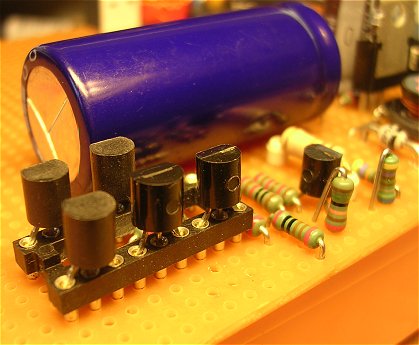

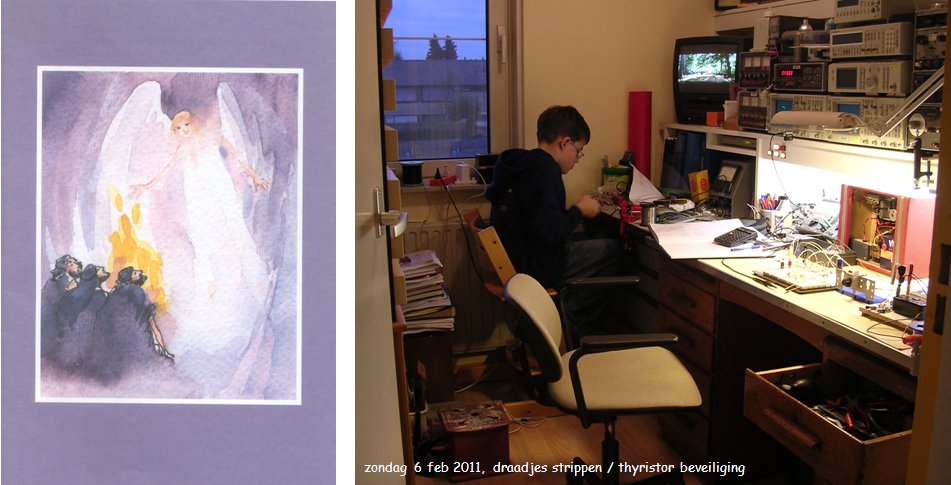

Figure 5.1 One of the best parts of any project: bread board testing! In this case the thyristor protection circuit is being tested.

Figure 5.2 When all the difficult circuit parts have been tested on breadboard, everything comes together on perfboard.

After writing all this I can summarize my advice just by saying: “keep things simple, and take small steps at a time.”

Back to the uTracer!

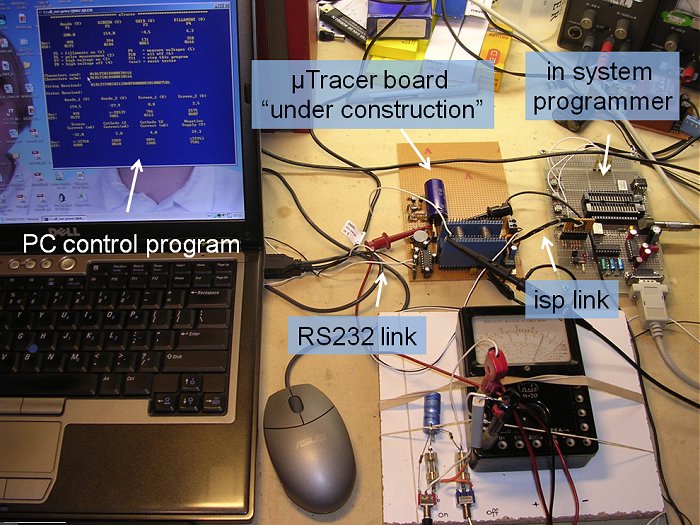

The total uTracer system consists of 4 components:

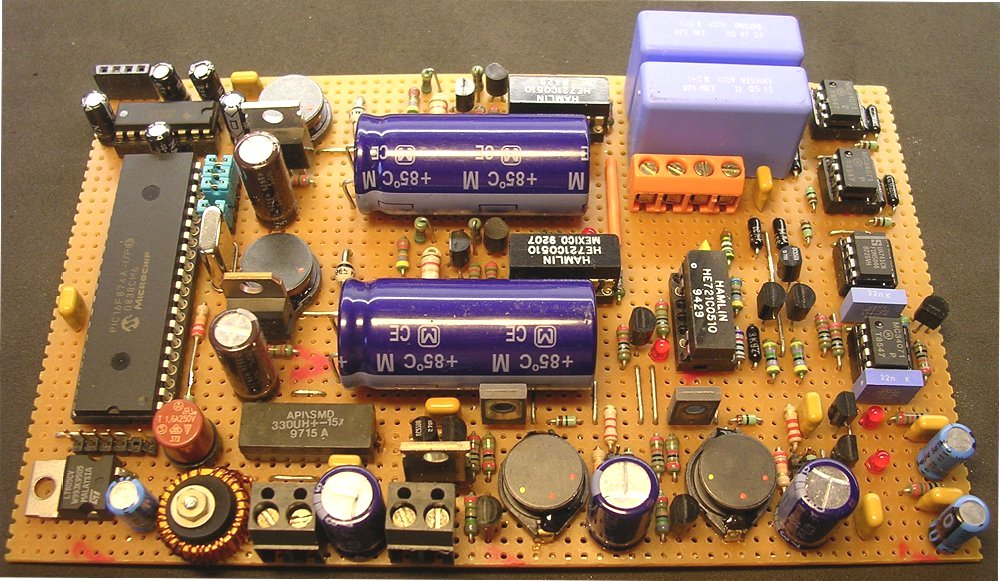

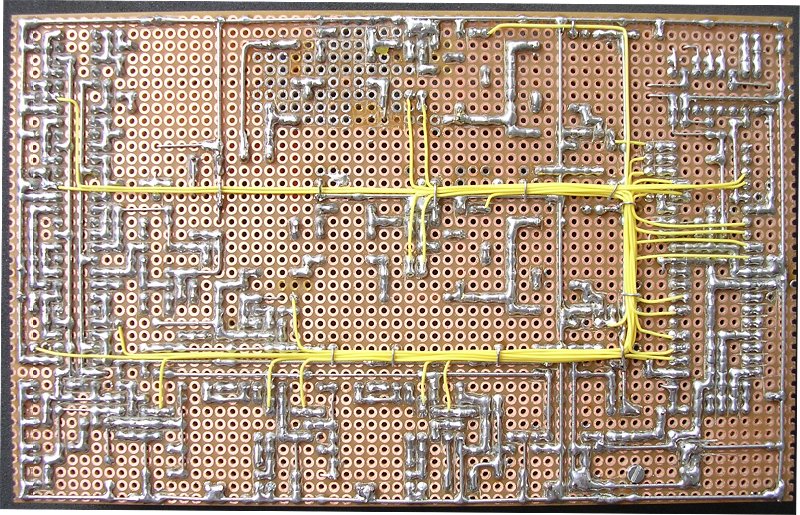

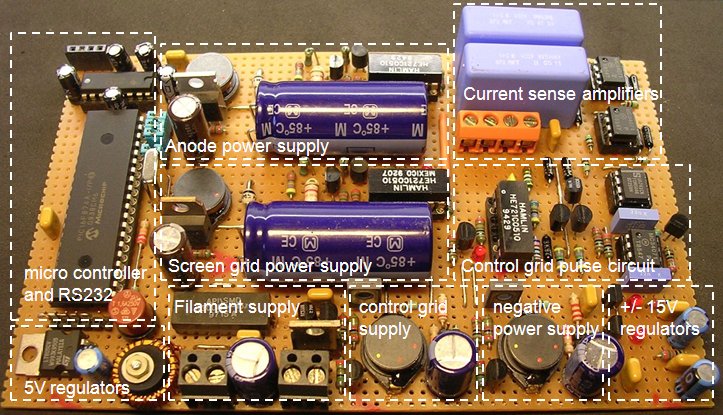

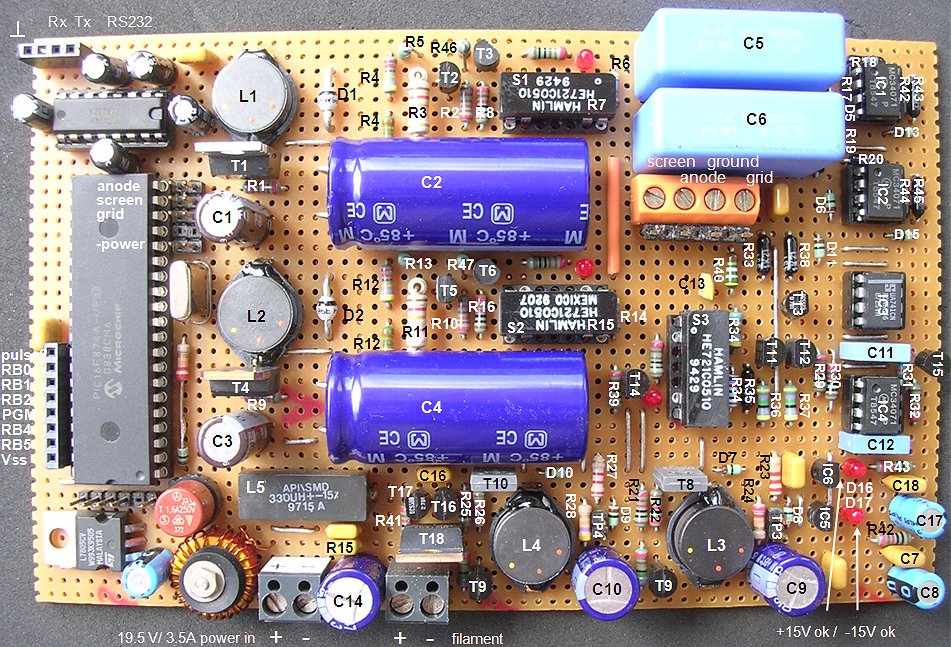

The Analog Electronics

Many of the sub-blocks of the analog part of the uTracer have already been discussed in the previous section. At the moment “I have pretty strong indications” that some parts will certainly need to be discussed again! However, at this moment the analog part of the circuit as I have it in mind is shown in Fig. 5.3. I you have read the previous section, the circuit will look pretty familiar and straightforward.

Figure 5.3 Preliminary circuit diagram of the analog part of the uTracer.

The Digital Part

The digital part of the circuit could hardly by more straightforward. The main reasons to use a Microchip 16F874 PIC processor were that I was familiar with it and that it had enough digital and analog I/Os for this applications. For maximum speed and accurate serial communication timing an external 20 MHz Xtal was used. Communication with the PC is via an RS232 link with the “evergreen” MAX232 taking care of the necessary level translations. There really is not anything more to tell about it.

Figure 5.4 The digital part of the uTracer.

The firmware in the microcontroller

I decided to let the PC do the entire user interface so that the tasks for the microcontroller are rather limited. The microcontroller in the first place has to receive the settings from the PC. When the settings are received, it will charge the buffer capacitors in the boost converters and set the grid bias. When the anode, screen and grid voltages have reached their set-point, all boost converters are switched off to reduce noise, and the electronic switches are closed. After a short stabilization time of about 1 ms, all analog voltages and currents are measured as fast as possible after which the switches are closed again. The measured values are then reported back to the PC.

Figure 5.5 Example of the command and reply strings.

The communication protocol between PC and microcontroller is very simple. The PC always sends a command string with fixed length of 18 ASCII characters to the microcontroller, and the controller in return always returns with a reply string of 34 ASCII characters. Figure 5.5 gives an example of the syntax of both strings. Each two consecutive characters in either string represent a byte. The command string first starts with a byte which represents the command. The next two bytes (so four characters) are the set point for the anode voltage in 16-bit binary format. Since the AD and PWM converters of the microcontroller are only 10 bits, only the lowest 10 bits in these 16 bit words are used. The next word (so two bytes = 4 characters) set the screen voltage. The command string is terminated with the grid and filament voltages. The reply string has a similar definition. It starts with a byte which is a status byte. It is followed by 8 words which represent:

The user interface software on the PC

For me, the user interface software is one of the more challenging parts of this project. In the end I want to have a nice windows interface a nice Ia-Vgk graph and all the other features one would expect from a windows interface. From the fact that I have named my website “dos4ever,” it is not difficult to deduce that I have very little affinity (and experience) with windows oriented programming languages. However, for the past year my son Daan (11 years) has been playing with Visual Basic so it cannot be that difficult! In the mean time I have written a simple interface program in good old QBASIC 4.5 (the compiler version). For the past 15 years QBASIC has served me very well in many projects. It is simple, fast and the build-in compiler generates a nice and compact code!

Figure 5.6 A screen dump of the “debug” user interface program written in QBASIC and running from a dos command window.

A Screen dump of the user interface of the program is shown in Fig. 5.6. On the top of the screen the adjustable voltages can be found. By pressing F1, F2, F3 or F4, the setting for the anode voltage, the screen voltage, the grid voltage and the filament voltage can be changed. The program converts the voltage setting to the corresponding AD converter values. In order to calculate this, the AD converter range (0-5V), number of bits (10) and the divider ratio of the resistive voltage dividers are used. Underneath the voltage settings, the corresponding decimal value of the AD converter is given (200V in this case corresponds to 512 decimal) and underneath the decimal value the corresponding hex word is displayed (which is 200H just by chance). Underneath this the commands are displayed which can be issued by pressing one of the other function keys. When a command key is pressed a command string is send to the microcontroller which is displayed in the center of the screen. To check if the controller is functioning properly the echoed character string is also displayed. On the next part of the screen the reply string coming from the controller is shown. This string is taken apart into a status byte and eight measured values, which are again converted to understandable values. The whole program consists of a single loop and was written in a day. It has proven to be a very useful debug tool!

Mainly for my own documentation I have included here a zip file which comprises both the microcontroller firmware as well as the QBASIC (debug) user interface in the state it is at this moment. Which means that only the anode boost converter and switch are implemented. When a command is issued, the buffer capacitor is charged to the voltage which has been set. Then a the switch is closed and after 1 ms the anode voltage is measured and reported back.

Figure 5.7 This picture has absolutely nothing to do with this page, it is just here for my pleasure. A souvenir of a visit to what is claimed to be the largest radio-tube collection in the world in the “studieverzameling” (faculty collection) of the faculty of electrical engineering of the Technical University of Delft. The collection amongst others holds the “Jonker Collection.” Hans Jonker was in charge of the radio tube research at Philips in the fifties, and was also a part-time professor at the Delft University. He brought together a large tube-collection containing many research and development samples. This photograph made Mart Graef (in the center of both pictures) remark: “geluk zit in een doosje” (happiness comes in a box).

| to top of page | back to homepage |

It had to happen sooner of later. I knew from the beginning of this project that the high-voltage switch would be the most difficult part of the circuit. It has to switch voltages up to 400 V with currents up to 200 mA. Moreover, I had set it in my mind that I only wanted to use “small signal” TO92 envelop transistors. The reasoning behind it was that since the pulse width is so very short, excessive dissipation is avoided. Well, I overlooked two things: in the first place devices, especially transistors, heat up much faster than I realized. Secondly, – and this was a much more fundamental thing I overlooked – the switch should be protected against the excessive currents which flow if the output is short-circuited e.g. as a result of a defect tube, unrealistic tube bias conditions, or an operator error. Overlooking both issues, I confidently tested the switch circuit depicted in Fig. 4.4 at maximum voltage and maximum current. It resulted in a nice crisp “pets,” and a flash from somewhere in the switch circuit region after which the complete circuit was dead! On inspection it appeared that not only the transistor in the high-voltage switch had died, but also the power MOSFET, the processor as well as the MAX232! I was very fortunate indeed that both the Laptop as well as the in-circuit PIC programmer where still alive! In short, as our Anglo speaking friends say, ‘back to the drawing board!’ Time for some very serious circuit reflections ......

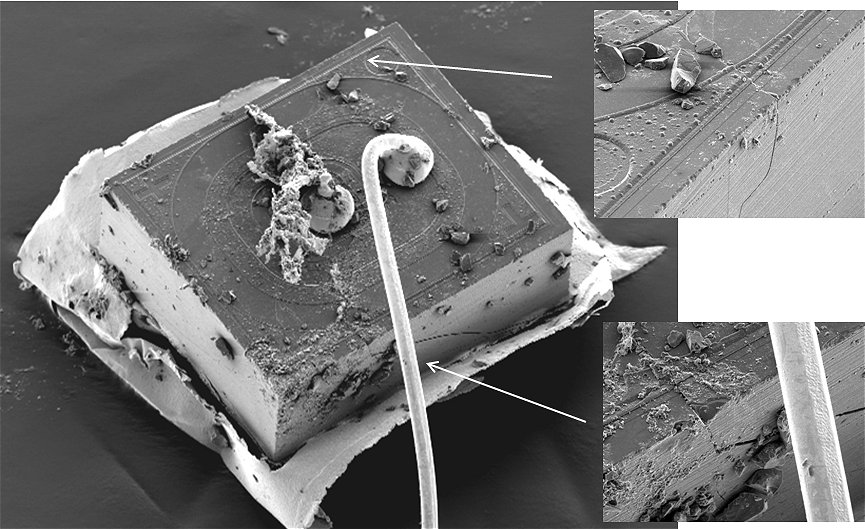

Figure 6.1 A SEM micro-photograph of the BF487 transistor die that failed during testing of the high-voltage switch.

Before diving into the circuit, I was very curious to see what actually happened to the BF487 high voltage transistor when the full power of a 100 uF capacitor charged to 400 V was dumped into the rest of the circuit through this tiny device. To have a look at the actual silicon transistor

crystal, the plastic package was first dissolved in hot fuming nitric

acid. Now this may sound a bit superfluous, but don’t try to do this at home! Fuming Nitric Acid is a very dangerous highly oxidizing acid, whith very toxic fumes, and you do not want to mess around with it! Although I

have spend my whole working life in semiconductor technology, and have

designed and made quite a number of discrete transistors myself, I am still amazed to see how small the actual transistor die itself is. After dilution of the Nitric Acid and filtration it is sometimes very difficult to even find the remains of the transistor die which measures something in the order of 500 x 500 um. After drying the remains of the

transistor were analyzed with a Scanning Electron Microscope (Fig. 6.1). First of all, this is typically a high voltage transistor. The round shapes and the large overlays of the base metallization over the collector area (field-plates) all help to reduce the electric field and thus to increase the breakdown voltage. It can be clearly seen that the extreme dissipation in crystal caused it to crack and split into at least two parts straight through the middle of the active area. Ok, enough played with the SEM, back to work.

crystal, the plastic package was first dissolved in hot fuming nitric

acid. Now this may sound a bit superfluous, but don’t try to do this at home! Fuming Nitric Acid is a very dangerous highly oxidizing acid, whith very toxic fumes, and you do not want to mess around with it! Although I

have spend my whole working life in semiconductor technology, and have

designed and made quite a number of discrete transistors myself, I am still amazed to see how small the actual transistor die itself is. After dilution of the Nitric Acid and filtration it is sometimes very difficult to even find the remains of the transistor die which measures something in the order of 500 x 500 um. After drying the remains of the

transistor were analyzed with a Scanning Electron Microscope (Fig. 6.1). First of all, this is typically a high voltage transistor. The round shapes and the large overlays of the base metallization over the collector area (field-plates) all help to reduce the electric field and thus to increase the breakdown voltage. It can be clearly seen that the extreme dissipation in crystal caused it to crack and split into at least two parts straight through the middle of the active area. Ok, enough played with the SEM, back to work.

Let’s briefly recall how I arrived at the circuit that just propelled most of my tube-tester circuit into eternity. In section 4 I reported on the first experiments done with the HV-switch. The first experiments involved a simple high-voltage pnp that was pulled into saturation by an high-voltage npn (Fig. 6.2A). Since the transistors in that circuit are either fully conducting with negligible voltage drop or they are completely shut off, the dissipation in the transistors themselves is very low. The circuit was tested at 400 V and currents up to 200 mA. The problem was that the circuit also has to work at low voltages. It is difficult to dimension R1 in such a way that it will safely pull T1 into saturation over the entire voltage range of 20-400V. The solution I choose was to replace T2 with a current source that would supply the required base current, regardless of the supply voltage. The simple circuit of Fig. 6.2B does the trick. The collector current of T2 is now determined only by R1 and the amplitude of the input pulse. The problem now is that the dissipation is in this case shifted from R1 in Fig. 6.2A to T2 in Fig. 6.2B.

Figure 6.2 High-voltage switch configurations.

Unfortunately I was so stupid only to test this circuit only at 40 V because I was too lazy to build-up the high voltage circuit! The point I totally overlooked was that a resistor, because of its larger mass compared to a transistor, is much easier capable of dissipating high power pulses. The test at 400V and 0.2A caused an instantaneous dissipation of 16 W in T2, and although the pulse lasted only 2 ms, it was enough to destroy it. When T2 short-circuited, the full charge of the fully charged 100 uF / 400 V capacitor, was released in the processor with devastating consequences! The simplest solution to limit the dissipation in T2 is to increase the current gain of the pnp switch. The simplest way to do that is to replace it with a Darlington (Fig. 6.2C). This will approximately multiply the hFE of T1 with the hFE of T2 (at low bias values). Now a base current of only 2 mA is already more than enough to pull the pnp Darlington into saturation. The circuit of Fig. 6.2C was tested over the complete bias and current ranges, and worked very well. However, I realized a serious problem: the circuit of Fig. 6.2C has no protection whatsoever against excessive currents which could flow if the tube is biased in an unrealistic regime or in case of a short-circuit!

Figure 6.3 Implementation of an overcurrent protection circuit in the high-voltage switch (left), and characterization of the protection circuit at a voltage of 40 V.

The simplest way to implement an overcurrent protection is shown in Fig. 6.3. R6 is the current sense transistor which usually has a small value. When the voltage drop over R6 reaches 0.8-1.0 V, transistor T1 starts to conduct, pulling away base current from the output darlington T2/T3. The higher the output current, the more T1 will conduct, and the further the darlington will be cut-off from base current. When properly designed, this feedback mechanism will result in a constant maximum output current, the value of which is approximately determined by 1.0/R1. The circuit depicted in Fig.6.3 was used to test the concept on a 40 V DC power supply. The load of the test circuit was a 1k ten-turn potmeter. The output current was measured by measuring the amplitude of the voltage pulse over the load resistor with the memory scope. The current was calculated from pulse_amplitude/Rload. As long as the overcurrent protection is not activated the output current should be proportional to 1/Rload, which it is. As soon as the overcurrent circuit is activated, the output current remains nicely constant.

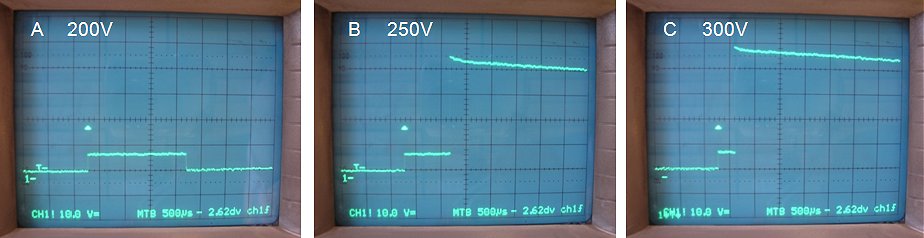

Figure 6.4 Dynamic behavior of the overcurrent protection circuit at high voltages. For voltages higher than 200 V, the dissipation in the pnp transistor apparently reduces the breakdown to such a value that after some time the transistor breaksdown.

The circuit proved to be rather a disappointment when it was tested with the high-voltages that the switch has to control in reality. In this test the circuit was loaded with a 10k resistor, and the current limit resistor was 10 ohm which would limit the current to approximately 70 mA (Fig. 6.2 right), and the current was measured over a 100 ohm resistor. Figure 6.4A shows that for 100 V the circuit worked perfectly. Note that 7 V over 100 ohm corresponds to 70 mA. For 200 V however, the output transistor went into avalanche after approximately 1 ms. Apparently, the dissipation in a pulse even as short as 2 ms causes so much self heating of the transistor that the point of avalanche breakdown is reduced to below 200 V! The situation is even worse for 300 V. A higher voltage results in more dissipation, more self heating and even faster breakdown. The breakdown by the way was non-destructive.

Figure 6.5 This thyristor overcurrent protection circuit abruptly opens the high voltage switch when an overcurrent condition is signaled. The circuit is automatically reset when the pulse is over.

What really was needed was a protection circuit that would turn the power completely off as soon as an overcurrent condition is signaled. To realize this I ended up with quite a simple circuit that I have not seen used before. The overcurrent transistor is simply replaced with a thyristor, build up from a discrete npn/pnp pair. On one of my other pages the two transistor thyristor is discussed in some depth. The principle of the circuit is explained in Fig. 6.5A. When an overcurrent

condition occurs, the voltage over R1 will increase to such a value that at a certain point T3 will be pulled into conduction through D1. The collector current of T3 is the base current of T4 so that when T3 starts conducting, T4 will also start conducting. However, the collector current of T4 will keep T3 in conduction etc. This condition will persist until the current is completely shut off, which of course occurs automatically at the end of the measurement pulse.

condition occurs, the voltage over R1 will increase to such a value that at a certain point T3 will be pulled into conduction through D1. The collector current of T3 is the base current of T4 so that when T3 starts conducting, T4 will also start conducting. However, the collector current of T4 will keep T3 in conduction etc. This condition will persist until the current is completely shut off, which of course occurs automatically at the end of the measurement pulse.

Figure 6.5B shows the practical implementation of the thyristor protection circuit. Resistors R8 and R12 were added to reduce the sensitivity of the thyristor. This sounds a bit strange, but it should be realized that modern discrete transistors are so good that they still have a high current amplification even at nA or pA level. This means that the smallest current spike on one of the bases of the thyristor will cause it to latch. R8 and R12 add a small “base current” resulting at an hFE < 1 for low current levels. As a result a “significant” current pulse of several uA is needed to trigger the circuit. It was found that a voltage drop of approximately 0.66 V over R10 is needed to activate the protection circuit. With R10 = 2.5 ohm the maximum current is 150 mA. Resistor R9 was added to at least have some impedance in the output loop in case of a hard short circuit. Assuming a maximum current of 200 mA, the voltage drop over R10 will be 10 V. especially since the micro controller measures the voltage directly on the anode of the tube, this is not too bad, and we can compensate for it by increasing the output voltage a bit. Finally R4, R6 and D2 were added as a final safety measure to protect the rest of the circuit should the high voltage switch fail. Assuming that for some reason T5 breaks down, the base of T5 becomes directly connected to the high-voltage capacitor which can be up to 300 V. In this case D2 will start to conduct, and R4 will limit the current to 30 mA. Since D2 has a non-zero series resistance this can still mean that the voltage of the anode of D2 is pulled significantly above Vdd. In that case R6 in combination with the input protection diodes on the PIC processor protect the input of the processor for further damage.

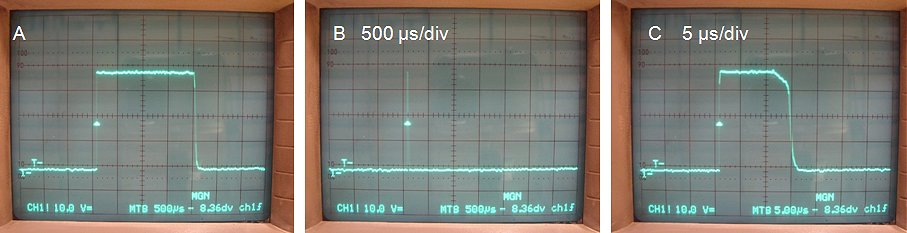

Figure 6.6 Dynamic behavior of the thyristor protection circuit.

Figure 6.6 shows the dynamic switching behavior of the thyristor protection circuit. In Fig. 6.6A the current is below the overcurrent condition value, resulting in a normal output pulse. Figure 6.6B is recorded on the same scale and shows what happens when an overcurrent condition triggers the thyristor. In Fig. 6.6C the short event of Fig. 6.6B is magnified revealing that already after a few micro-seconds the thyristor is activated, thereby shutting-off the output pnp Darlington.

To do some reliability testing the circuit depicted in Fig. 6.5B was modified so that it would “fire” a pulse every second. Then the circuit was tested for several hours on a row for the maximum voltage 350 V under a variety of load conditions, including short-circuited output.

|

Finally a few last words about the construction around R10, R12 and R13 in Fig. 6.5 which, I can imagine, will have raised some eyebrows. The observant reader will no doubt have spotted that resistor R12 has no function whatsoever, given the values of R10 and R13. This is totally true. In the first version of the circuit however, R13 was replaced with a diode (cathode connected to R10) which triggered the thyristor when the voltage across R10 reached the critical value. With the diode instead of R13, the circuit was extremely sensitive to transients and noise. By replacing the diode with a resistor it became much more robust. Despite this modification, the switch remained a rather “difficult” sub-circuit. Although it was tested for all possible load conditions, I noticed remarkable differences between different versions of the circuit (e.g. on breadboard or perfboard) which were apparently due to parasitic capacitances and inductances. A sign which always gives me the very uncomfortable feeling that the circuit is hard to tame, and that there can be problems directly behind every corner.

| to top of page | back to homepage |

After the adventures with the high-voltage switch is became clear that also the current mirror would need a thorough revision. The problem was again dissipation. The simple current mirror as used in Fig. 4.2 uses two transistors. In one of the transistors only the emitter-base diode is used. The voltage drop over this diode isapplied to a second identical transistor which then “mirrors” the current flowing through the first transistor. Since the voltage drop over the first transistor is always limited to a forward diode voltage drop (ca. 1.0 V), the dissipation in this transistor is not an issue. It is the second transistor, the current source, which worst case has to “digest” the maximum screen voltage (300 V) at maximum screen current (say 50 mA). Worst case this could result in peak dissipations in excess of 15 W. In the last section we have seen that this is too much for a small TO92 envelop transistor.

I have to admit that while I am writing these words, I have already abandoned the whole tube tester concept as presented in the previous sections. The problems with the high voltage switch and the current mirrors had given me the uneasy feeling that this was not the right way to go. After some thinking a new concept was developed that didn’t need any high-voltage switches or current mirrors and that was all in all much more elegant. This new concept is presented the next section. Nevertheless, just for documentation sake, a few words on possible solutions for the current mirror.

Figure 7.1 Three circuit ideas to reduce / limit the dissipation in the current mirror.

So, how to reduce the dissipation in the current mirror? One solution could be to reduce the voltage drop over the current regulating transistor, e.g. by adding a resistor in series with the collector. In principle this works fine, but it reduces the working range of the circuit. At high currents, the voltage drop over the resistor limits the usable screen-voltage range. The only other option then is to reduce, or at least limit, the current. Figure 7.1 illustrated three possible ways to achieve this. The first, and least elegant way, is to distribute the input current over more than one diode (Fig. 7.1 A). By placing e.g. ten diode-resistor sections in parallel, the input current will divide itself so that each individual diode only carries a tenth of the input current. It is this current which is mirrored by the output transistor. The output current, and thus the dissipation, is in this way a tenth of the original input current. Although the method is quite straightforward and often used in ICs, it is in its discrete form hardly elegant!

Figure 7.2 First order analysis of the current mirror depicted in Fig. 7.1 B.

A second method makes use of the fact that already some emitter resistors were used to average out any fabrication differences in the transistors. Since the current drop over the emitter resistors determines to a large extend the current, changing the ratio of the transistors can also be used to reduce the mirrored current. Figure 7.1 B illustrates this principle. The input current causes a voltage drop over the emitter-base diode as well as over the emitter resistor. In the mirror branch, this voltage is applied over a resistor with a ten times higher resistivity. As a result the current will be approximately ten times as small. The problem is that the voltage drop over the diodes does not linearly scale with the current. In Fig. 7.2 a first order analysis of the circuit is given. The derivation is quite straightforward and neglects the base resistance. What it boils down to is that there is a “small” error in the output current, which is more or less constant and which reduces for higher emitter resistances. This is logical since for higher emitter resistances the behavior of the mirror will be dominated by the resistors. All in all it does not seem unfeasible to compensate for the measurement error in the software, but again it is hardly elegant.

Finally, in Fig. 7.1 C a brute force method is presented to protect the mirror against too high currents. Depending on the value of the emitter series resistors and the breakdown voltage of the zener diode, the output current of the mirror is clamped to a certain predetermined maximum value. But now, as they would say in Monthy Phyton: “for something completely different”

| to top of page | back to homepage |

Despite the fact that the issues with the high-voltage switches and the current mirror are solvable (and interesting!), they somewhat reduced the simplicity of the concept I had originally in mind. Pondering about this fact, it struck me that there was a very obvious thing I had overlooked. Rather than using quite difficult and critical high-voltage switches implemented in silicon, it is also possible to use the radio-tube itself as the switch! When the control grid is biased low enough so that the tube is completely cut-off, no anode or screen grid current flows and the boost converters can charge the buffer capacitors. By pulsing the grid-bias from the negative cut-off region to the desired (negative) grid bias the current through the anode and screen grid is switched on! This does not require a difficult and fragile high-side switch while the tubes are rugged enough to take pulsed overload conditions should they occur.

Figure 8.1 In the new concept the tube itself is used to switch the anode and screen. The currents are measured by the voltage drop over a simple series resistors which is AC coupled to the AD converter.

The only problem now left is to find an elegant way to measure the anode- and screen current. Measuring the anode current by measuring the voltage drop over a cathode resistors works but has the disadvantage that the voltage drop over the cathode resistors lowers the anode-cathode voltage. Using a current mirror for the anode current is simply not an option; the currents are just too high. Then a rather nice idea occurred to me which is based on the fact the voltage across a (charged) capacitor cannot change instantaneously. The idea is depicted in Fig. 8.1 and further explained in detail in Fig. 8.2.

Figure 8.2 AC coupling of the voltage drop over the current-sense resistors is only possible since the measurements are done in pulse-mode.

Basically both the anode and the screen currents are sensed with a simple series resistor (Ra and Rs). These resistors are chosen in such a way that for the maximum current the voltage drop is 5V. Assume for the moment that the uTracer is just switched on, and that the first anode voltage setting is 100 V. The control grid of the tube is held at a sufficiently low potential so that the tube is shut off, and there is no anode- or screen current flowing. The boost converter will now charge the buffer capacitor Cb to 100 V. At the same time Ca will be charged to 100 V with the charge current flowing through the diode (Fig. 8.2A). At a certain moment both Cb as well as Ca are charged to 100V and the charge current will reduce to zero (Fig. 8.2B). Now the grid voltage of the tube is set to the desired bias point. As a result a current will flow through both the anode as well as the screen grid (Fig. 8.2C). This current will cause a voltage drop over Ra which is proportional to the current, in this example 5 V. We assume now for the moment that the measurement interval is so small that the voltage over Ca will not change. In that case the input of the inverting amplifier consisting of A1, R1 and R2 will be pulled to -5 V. When R1 = R2 the amplification is set to -1, so that as a result an output pulse of 5 V will appear at the output of the amplifier. So in this circuit a charged capacitor is used to bridge the potential difference between the “high-side” of the circuit and the “low-side.”

Figure 8.3 Charging of a capacitor.

Since the inverting input of the OpAmp can be regarded as a virtual ground, the time constant which determines the rate at which Ca is charged and discharged is determined by (Ra+R1)Ca. Since Ra << R1 this reduces to R1Ca. One limitation of the “trick” described above is that the time constant R1Ca has to be so large in comparison to the measurement pulse length, that the voltage across Ca indeed not significantly changes during the measurement. On the other hand the time constant should be small compared to the time available for charging of Ca (and Cb). Figure 8.3 depicts how the voltage across a capacitor in a series RC combination evolves after a step wise change in the voltage source. From the equation in Fig. 8.3 we can easily estimate the error introduced as a result of the discharging of Ca during the measurement.

Table 8.1 Charging of a capacitor (equation Fig. 8.3) for some T/RC values.

From Table 8.1 we learn that when T/RC=0.005 the error in the measurement is less than 0.5%. Supposing that the measurement time is 1ms, this corresponds to an RC time of 0.2s. If we for this RC time allow for a realistic charging time of about 1s (T/RC=5), we find in table 8.1 that the charging error is also less than about 0.5%. The application window for which this circuit trick can be used appears to be rather small: a measurement pulse shorter than 1ms is not realistic because we need some time to stabilize the tube and to do the AD conversions, while a longer charging time would result in unacceptable long measurement times. Rather surprisingly the circuit perfectly matches the uTracer design constraints.

Figure 8.4 Expected voltage drop over the current sense resistors.

There is a second source of error, and that is the discharging of the buffer capacitor Cb during the measurement. Although the buffer capacitor is quite large (100 uF) the voltage drop at maximum anode current can be relatively large. If we assume an anode current of 200 mA, then the voltage drop in 1 ms can be as high as (0.2*0.001)/1E-4= 2V, which is in the same order of magnitude as the voltage drop over Ra. Fortunately there is a simple way to correct for this error. Figure 8.4 shows the voltage at the anode for the circuit diagram depicted in Fig. 8.2. In part ‘a’ of the curve the tube is cut-off and the anode voltage equals the voltage of the buffer capacitor Cb. At t=0 the tube is biased into conduction, and an anode current will start to flow. This current will cause a voltage drop over Ra indicated in Fig. 8.4 by jump ‘b’. During the measurement pulse the anode current discharges the buffer capacitor which is reflected by a linear drop of the anode potential (Fig. 8.4 ‘c’). At the end of the measurement pulse the tube is cut-off again, and the voltage drop over Ra as a result of the anode current disappears so that the anode potential jumps up again (Fig. 8.4 ‘d’). Since there is no current flowing anymore the anode voltage will now remain constant (Fig. 8.4 ‘e’).

Compensating for the discharging of the buffer capacitor is relatively simple. Referring back to Fig. 8.4 the voltage drop we are interested in is given by VRa. However, if the voltage is sampled at T=t1, then the voltage measured is VRa + VCdis. The discharging of Cb is approximately linear so that with and additional measurement directly after the pulse, when the tube is shut-off again, the rate of discharge can be determined from V(T)/T. VRa can now be calculated from the formula given in Fig. 8.4. The only thing to take care of is that the range of the measurement circuit is such that it can measure VRa + VCdis.

In summary, the new concept has the following advantages:

| to top of page | back to homepage |

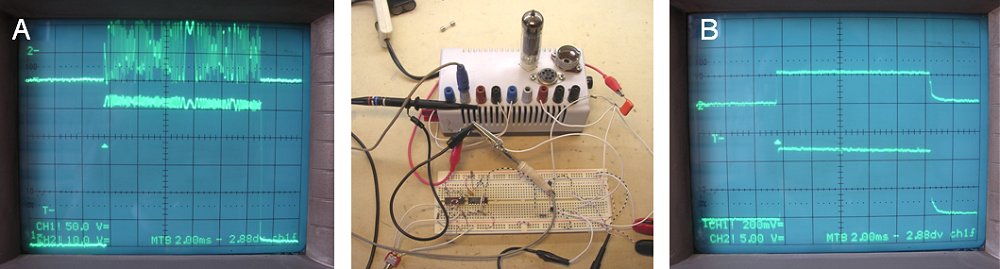

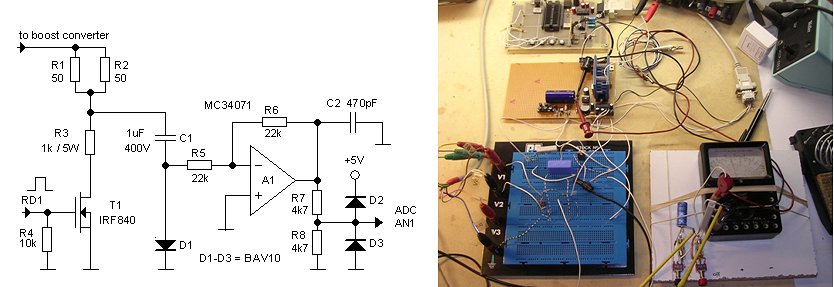

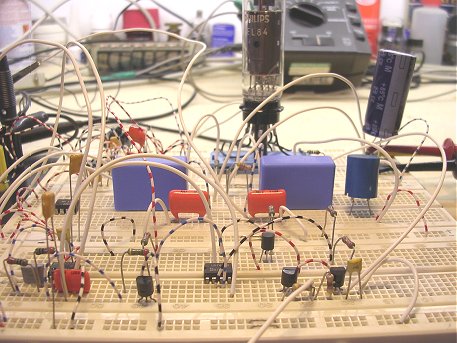

Although the new concept looked fine “on paper” and contained little uncertainties, it obviously had to be tested. For this the circuit depicted in Fig. 9.1 was used. In this test circuit the tube was replaced by a high voltage power MOSFET which could easily be driven from the micro-controller. In this application it can be considered as an ideal switch. A 1k/5W resistor was used to set the current to a known value. Resistor R4 keeps the MOSFET closed when the output of the microcontroller is in high-impedance state. Resistors R7 and R8 increase the input voltage range of the circuit to 10V.

Figure 9.1 Circuit used to test the new concept. The tube is replaced by a high voltage MOSFET and the current is determined by a resistor.

The software of both the controller as well as the program running on the PC were slightly modified to facilitate the experiment. After pressing function key F5, the program produces a pulse on the gate of the MOSFET for 1 ms. Exactly 500 us after the beginning of the pulse the analog input is sampled. Immediately after the pulse the analog input is sampled again. Both values are send to the PC which calculates the corresponding current values and also calculates the current compensated for the discharge of the reservoir capacitor (Fig. 9.3). The first finding was that C1 should be a good quality capacitor, certainly not an electrolytic type. The 10 uF electrolytic capacitor I first tried gave very irreproducible results. The low leakage current of the electrolytic capacitor constantly resulted in a non-zero starting voltage. A 1 uF MKT capacitor on the other hand gave very good results.

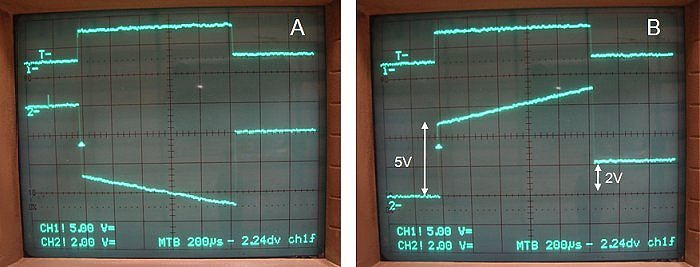

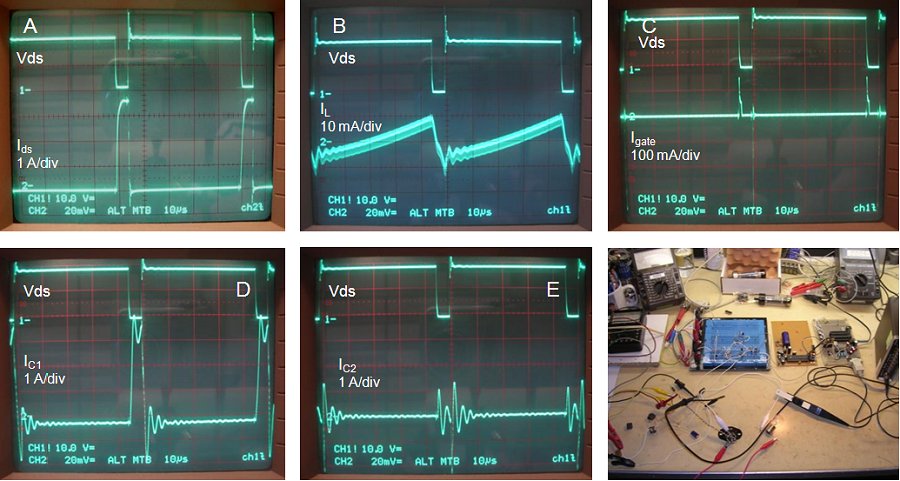

Figure 9.2 Measured voltage drop over the current-sense resistor at the input (left) and output (right) of the inverting OpAmp.

Figure 9.2 gives an impression of the waveforms in the circuit. In this case the reservoir capacitor was charged to 200 V. In the left picture the voltage at the input of the inverting amplifier (node between C1, D1 and R5) is displayed. The upper trace gives the pulse used to drive the MOSFET which signal is used as trigger for the oscilloscope. In the right picture the inverted signal at the output of the OpAmp is displayed. For a voltage of 200 V and a load resistor of 1 k we expect a current of 200 mA. The voltage drop over the 25 ohm sense resistor for 200 mA is 5 V, exactly the voltage drop we find on the scope. For an average current of 200 mA during 1 ms we expect the reservoir capacitor to be discharged by: (I*t)/C = (0.2*0.001)/(0.0001) = 2 V, exactly the value we find at the end of the pulse. Figure 9.3, by way of illustration, shows a screen dump of the output on the PC.

Figure 9.3 Screendump of the output window of the adapted uTracer PC program.

To get an idea of the accuracy of the current sense circuit a series of measurements was performed at different voltages and thus different currents. The buffer capacitor was charged to 50, 100, 150, 200, 250 and 300 V respectively, and at each voltage the MOSFET was pulsed ten times and the current was recorded from the value calculated by the PC control program. The exact current was calculated by first measuring the reservoir capacitor voltage with a multimeter and dividing this voltage by the total resistance (25 ohm sense resistor and 1030 ohm load). It appeared that there was a small offset between the voltage as set by the microcontroller, and the actual capacitor voltage, something I will have to look into later. For each measurement point the difference between the measured current and the “theoretical” current was calculated, and plotted (black dots in Fig. 9.4). Also for each voltage setting the average error was calculated and plotted (red squares and trend line in Fig. 9.4). All in all the error was rather small, most times less than 1 mA, and in all cases better than 1 percent! For the lower currents the resolution of the AD converter added to the inaccuracy. In any case for the uTracer I would say that the results were more than good enough.

Figure 9.4 In this rather complicated graph, I have tried to assess the accuracy of the current measurement method proposed in the previous section. Like in fig. 9.1 the current was set by the sum of the current sense resistor and the load resistor (= Rtot in this case 25+1030=1055 ohm) in combination with the applied voltage (= voltage of the buffer capacitor Vcbuf). Vcbuf was varied between 50 and 300 V in 50 V increments. For each voltage setting the current was measured 10 times. The difference between the measured current and the calculated current was plotted on the vertical axis. The standard deviation of the current difference is plotted in the top of the graph.

| to top of page | back to homepage |

The experiments in the previous section were a good indication that indeed the new concept might work. The next job was to design a circuit that could produce the necessary control grid pulse which switches the tube on and off. In the off state this circuit has to output a voltage which is low enough to switch the tube fully off (Voff). The first plan was to use a voltage like -25 V for Voff. This is enough to switch most tubes completely off. However, there are a number of tubes which require a significantly lower cut-off voltage. The popular EL34 for instance, requires not less than -55 V (at Va = 400V) to switch it completely off. Therefore I decided to design the circuit for a Voff of -60 V. During the “on-pulse” the output voltage should quickly rise from Voff to any desired control-grid bias voltage between Voff and 0 V (-60V to 0V). The value of Vbias is set by one of the two Pulse Width Modulator outputs of the micro-controller which generate a voltage between 0 and 5 V.

Figure 10.1 Control-grid pulse definition (left) and test version of the pulse generator circuit (right). Note that the component values in this circuit may differ from the final component values.

The most straightforward solution would be to use a high voltage (high power) OpAmp. These high power/voltage OpAmps are however very expensive, and on top of that I prefer to build my projects from “old stuff” I have lying around. So after some experiments with circuits which were oscillators rather than pulse generators, I arrived at the circuit depicted in Fig. 10.1. The circuit is basically a voltage controlled current mirror.

A few words about the selection of the component values: the current range for I was chosen to be 0 – 4.13 mA, for Vin 5 – 0 V. On one hand the current should not be too low because we need some current to switch the control grid, and on the other hand the current should not be too high because that would result in excessive dissipation in the transistors. Most dissipation occurs in T1 when it is biased at maximum current (4.13 mA). In this case T1 dissipates ca. 4.1*60 = 200 mW. It turned out that this was no problem at all for a common BC558 transistor. If desired a somewhat larger BD138 can be used. Resistors R3 and R4 linearize the current mirror so as to obscure small differences between T2 and T3. Note that at maximum current the voltage drop over R3 and R4 amounts to almost 2V. To this one Veb (1 V) a minimal Vcb of 1 V has to be added so that we should reserve at least 4 V for the current mirror. The circuit will perform best if for all resistors 1% resistors or better are used.

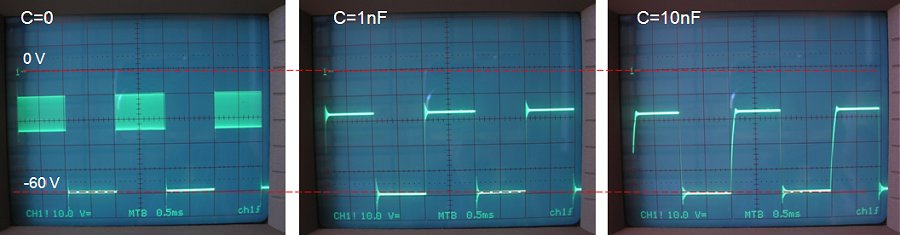

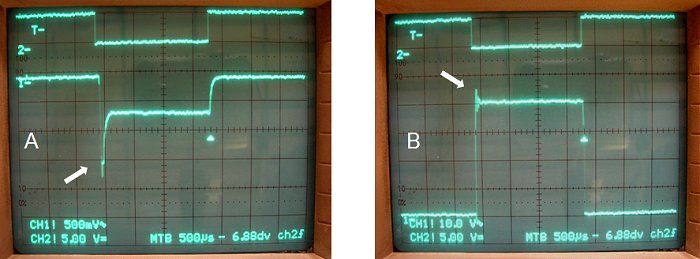

Figure 10.2 Using an MC34071 OpAmp, the circuit of Fig. 10.1 tended to oscillate for certain bias setting. By adding a small capacitor to the output it was possible to suppress the oscillations. If the capacitor is too small, the oscillation is suppressed but there is still and damped oscillation overshoot (middle). If the capacitor is too large the pulse rise time is significantly reduced (right).

The circuit was first tested using a MC34071 OpAmp. The reason I use this OpAmp quite often is that I have a whole box full of them. At certain values for Vbias however, the circuit showed a quite persistent tendency to oscillate (Fig. 10.2 left). By adding ca. 1 nF of capacitance to the output of the circuit the oscillation could be suppressed, leaving only a small (oscillating) overshoot (Fig. 10.2 center). By increasing the output capacitance this overshoot can also be suppressed at the expense of a less steep trailing edge of the pulse (Fig. 10.2 right).

Figure 10.2 Different OpAmp behave differently (obvious!). It appeared that somewhat “slower” OpAmps behaved better with respect to oscillation. A fortunate thing, because low-offset accurate OpAmps usually have a smaller bandwidth.

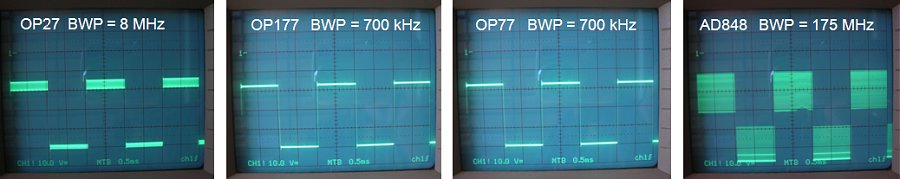

Experimenting with different OpAmps it was found that in general OpAmps with a smaller bandwidth gave better results with respect to stability. The best choices from the OpAmps which I tested were either an OP177 or OP77. These OpAmps are however rather expensive, but they do have a very small offset. Quite surprisingly the good old 741 proved to be a stable (and cheap) alternative, especially if an external pot-meter is used to compensate for the off-set. Figure 10.3 shows the 741 in action for different pulse heights.

Figure 10.3 A good old 741 OpAmp worked perfectly in this circuit. The Figure shows the output pulse for different input voltages.

At this point the moment had arrived to put several blocks together, to see how the different elements of the new concept would perform in combination with a real tube. The test circuit depicted in Fig. 10.4 brings together the basic building blocks in a way that allows easy testing without the need for a micro-controller. In this case the boost converter was simply replaced by a high voltage power supply connected via a high value resistor R12 to the 100 uF buffer capacitor C3. This construction has the advantage that in case of a short circuit or other accident, “only” the charge of the capacitor is dumped in the circuit.

The anode and the screen-grid are connected to the buffer capacitor via current resistors R13 and R14. The voltage drop over these resistors, which is as we know a measure for the currents, was measured with the memory-scope (input AC coupled). Capacitors C6 and C7 and resistors R15 and R16 simulate the current sense amplifiers discussed in the previous section.

Figure 10.4 Final test circuit to test the “New Concept” on a tube.

The measurement pulse is generated by a simple “one-shot” active low pulse generator circuit which is activated by a push-button. This signal is also used to trigger the memory scope. In the real circuit one of the two PWM generators on board of the micro-controller is used to generate the analog control grid input voltage. Using a 20 MHz X-tal, a frequency of 19.5 kHz is the highest frequency which still allows for 10 bits resolution (see datasheet). To convert the 0-100% duty-cycle PWM square-wave signal to a 0-5 V analogue voltage a low-pass filter is needed.

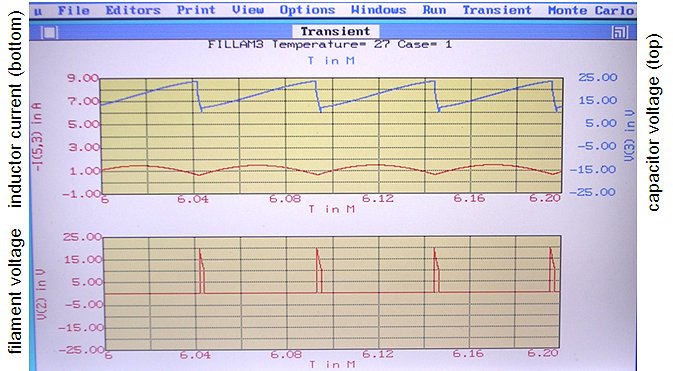

The design of this low-pass filter was a nice small project in itself. The most important design constraint for the filter is that the output ripple (peak-peak) for a 5 v peak-peak input voltage should be smaller than 1 LSB (5/1024 = 5 mV). Obviously, this can be realized with even a simple first order filter by choosing the corner frequency low enough. The penalty is that at the same time the time it takes for the output of the filter to settle to its final value increases. I personally had no feeling at all for the order of magnitude of these values, but this is typically one of these problems where a circuit simulation program can be of great help! For this kind of problems I always use the good old, almost antique, Micro-Cap program.

Figure 10.5 Peak-peak output ripple and approximate settling time for a first (left) and second order (right) low-pass filter as a function of corner frequency (freq = 19.5 kHz, Vin = 5 V pp, 50% duty-cycle square wave).