|

|

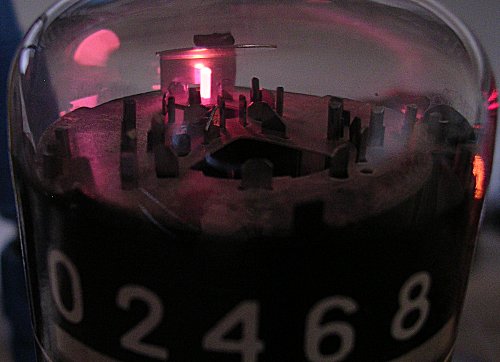

An E1T clock The making of the E1T |

|

The E1T tube you see on the left has been "in the family" for as long as

I can remember. Probably my father took it home from work (he worked at the

Shell laboratory in Rotterdam) or he bought it in one of the surplus shops

in Rotterdam my father and I used to visit every Saturday morning when

I was a child.

Because it was such a strange and funny looking

tube we always used to play with it. Being under the assumption

that the tube was broken, I was never particularly careful with it, nor did

I make any attempt to bring the tube to life.

Because it was such a strange and funny looking

tube we always used to play with it. Being under the assumption

that the tube was broken, I was never particularly careful with it, nor did

I make any attempt to bring the tube to life.

From the commonly available datasheet, I knew that this was not just a display device, but that the tube actually counts pulses and additionally displays the sum. This implies that the tube has a memory of the equivalent of 3.5 bits! On top of that, the tube even has a provision to generate a carry for the next digit. How did they do it? I work at the central Philips Research Laboratory in Eindhoven, Holland. Obviously, the Lab keeps a complete archive of all research reports and papers. Browsing through some old volumes of the Philips Technical Review in the library, I happened to stumble across a paper, which described the E1T tube in great detail [1]. It is one word beautiful! The whole paper reads like a poem, it is so elegant and ingenious; undoubtedly one of the masterpieces of vacuum tube engineering.

Unfortunately there does not appear to be a fancy and concise name for

the tube. Dieter categorizes the tube as a "beam Deflection Decade Counter Tube" [2].

I would have liked to believe Joris Roehrenbude who categorizes the E1T as a

Trochotron [3]. It sounds a hell of a lot more interesting than

a "Decade Counter Tube". Unfortunately on further investigation it appears

that a Trochotron is really something completely different [4].

Philips itself finally adopted the name "Decade Scaler Tube" [5]:

Unfortunately there does not appear to be a fancy and concise name for

the tube. Dieter categorizes the tube as a "beam Deflection Decade Counter Tube" [2].

I would have liked to believe Joris Roehrenbude who categorizes the E1T as a

Trochotron [3]. It sounds a hell of a lot more interesting than

a "Decade Counter Tube". Unfortunately on further investigation it appears

that a Trochotron is really something completely different [4].

Philips itself finally adopted the name "Decade Scaler Tube" [5]:

"The E1T, previously referred to as a "counter tube", is now termed a "Scaler

Tube" to preclude confusion with counter tubes such as Geiger-Muller tubes etc."

You will appreciate that I feel an emotional and moral obligation to follow

that convention.

Digging in the lab's archives I found two additional "Internal Research Reports" related to the E1T. The first report dates from February 1949 [6]. It is a short 3 page memo with some measurement results on 6 sample tubes, which had been prepared by the "proefafdeling" (sample department?). The tubes worked apparently as expected. It was emphasized that exchanging a tube for another tube did not require any adjustment of the biasing components. Apparently it was feared that the biasing of the tubes would be extremely critical. The second report is from September 1949 [7]. It was an interim report marking the transfer of the tube from research to the "radiobuizenlab" (radio tube laboratory). The nine page report shortly points out the critical construction aspects of the tube and how they relate to the performance. The efficiency of the report is striking. So already early in 1949 working research samples of the E1T were available! The first external publication probably marking the introduction of the E1T on the market I could find is from 1952 [8], it is the Dutch version of [1] published half a year earlier.

Surfing the web I bought a second E1T from Mattijs de Vries [9]. Mattijs really offers excellent and prompt service and I can not recommend him too highly. When it appeared that there was a defect in a socket I bought from him, my money was refunded the same day without questions asked. Having a second tube, I set about trying to bring the tube back to life. It appeared that even the first tube that I had all along was fully functional, and it was very rewarding to see the filament glow-up for the first time in perhaps forty years.

At this point I would like to make an appeal: If you have one or more

E1T tubes lying around, and if you do not have any use for them, you can

make a clock addict very happy, send me an e-mail. You will find my

e-mail address at the bottom of my homepage.

Figure 1. The waking of the sleeping beauty. The filament glowing after forty years of sleep as if nothing happened.

| to top of page | an E1T clock | The making of the E1T | back to homepage |

In this section you find an edited version of the original description of the

E1T counter tube from the "Philips Technical Review" [1].

The full pdf version of the document is unfortunately too heavy for my web-page

(3M). On request (see e-mail address homepage), I will be happy to mail it to you.

The figure numbers in this section refer to the picture numbers of the scanned

images.

At given values of deflection, the beam passes through one of the ten

vertical slots in the slotted electrode (g4), which is at a positive

voltage. It will be shown later how a special circuit ensures that the

beam can occupy only one of these ten positions. Some of the electrons

passing through a slot impinge on the anode (a2) placed behind the slotted

electrode; the remainder pass through an aperture in this anode and

impinge on the envelope. The part of the envelope situated behind the

anode is lined with fluorescent material, so that a fluorescing mark is

produced behind the opening in the anode through which the electrons pass.

The number opposite this mark thus indicates the position of the beam.

When the beam passes through slot 9, it has not reached its extreme

position, but can be deflected slightly further under the influence of a

following pulse. When this occurs, it impinges on the so called reset

anode (a1). Before discussing this, it will be shown how the beam is

fixed at well defined positions.

Fig. 4a gives a schematic representation of an imaginary cathode-ray tube,

containing an electron gun, a set of deflection electrodes and an anode.

When the potential vD of one of the one deflection electrode is kept

constant and the potential vD' of the other is varied, the electron beam

will move along the anode, but the anode current ia remains constant (line

I in fig. 4b). When the deflection electrode D' is connected to the anode

and these two electrodes are fed via a common resistor Ra from a battery

with voltage Vb (fig. 4c), the following equation, however, applies:

va2 = vD' = Vb - ia*Ra. This relation is represented by the line II in

Fig. 4b. The point of intersection P of the lines I and II gives the state

of equilibrium; the electrode D' then assumes a potential which

corresponds to the abscissa of P, and according to this given potential

the beam occupies a well-defined position.

How the characteristic ia2=f(vD',a2) is obtained

When the beam is now made to move from slot 0 to slot 9 by (continuously)

lowering the voltage vD',a2 it might be expected at first sight that a

characteristic ia=f(vD',a2) as shown by curve I of fig. 7b is obtained:

each time the beam is redirected on a slot, ia2 reaches a maximum (which

is the value for all slots), and each time the beam points to the centre

between the slots, ia2 drops back to zero.

Assuming for the time being

that the characteristic had this form, it would be possible to proceed

according to fig. 5, and to give VB and Ra2 such values that the line II,

which represents eq.(1) graphically, intersects all waves of I (fig. 7b).

In practice, however, with a slotted electrode according to fig. 7a, the

characteristic ia=f(vD',a2) will not assume the form I of fig.7b, but that

of 7c. This is caused by a defocusing of the beam as it is displaced

further to the left due to the asymmetry in deflection (vD constant and

vD' variable). The disadvantages of the latter form are that the magnitude

of Ra2 (slope of line II) must remain within very narrow limits.

In order to obtain the much more favorable characteristic I of fig. 6,

the slotted electrode has been provided with additional apertures, which are

also scanned by the beam, so that an additional current is passed which

increases as the beam proceeds further to the left. The most obvious solution

is to make a triangular aperture in the slotted electrode (O in fig. 8). It

would nevertheless be very difficult to obtain the desired improvement in

this way. This is mainly due to the presence of the suppressor grid (g3)

in front of the slotted electrode. For this reason the idea of a narrow

triangular aperture was abandoned in favor of rectangular apertures whose

positions with respect to the grid wires are less critical.

Mechanism of the displacement of the beam from 0 to 9

The positive-going pulses to be counted are applied to the left deflection

electrode D via a blocking capacitor. In order to understand how the beam is

shifted to a following position at each pulse, it should be recognized that

the characteristic I shown in fig. 6 is applicable to a constant voltage vD at

the left deflection electrode, and that the angle of deflection is a

function of vD'-vD. An increase of vD by an amount Vi therefore corresponds

to the line I being shifted to the right over a distance corresponding

to Vi (fig. 13).

In practice, however, the stray capacitance to earth of the electrodes a2

and D' and their wiring, represented by Ca2 in fig. 5, is shunted across

Ra2 and impedes sudden changes of the potential of a2 and D'. Provided the

condition is satisfied that the leading edge of the pulse is sufficiently

steep, the potential vD',a2 may be considered constant during the rise time

of the pulse. This amounts to the line I of fig. 13 being shifted to the

right (I') over a distance equal to the amplitude Vi of the pulse, the anode

current thus assumes the value A1A. This differs from the original value;

the difference is supplied by the capacitance Ca2.

Provided that the second condition is also satisfied, namely that the decay

time during which the input pulse decays from Vi to zero, is sufficiently

long, the characteristic I' will gradually return to I, and A will be shifted

to the adjacent stable point of intersection between I and II, i.e. point 1.

In order to ensure that the beam is shifted just one step to the left,

a third condition must be imposed to the beam, namely that the amplitude

Vi should be roughly equal to the voltage difference Ve which corresponds

to the horizontal difference between two adjacent stable points of

intersection and amounts to approximately 14 V; it will be clear that at too

small an amplitude the beam will return to its original position, whereas

at too large an amplitude it will advance two or more positions.

Fig. 3a shows a cross-section of the decade counter tube, whilst fig. 3b

shows the diagramic representation which will be used in circuit

diagrams. The cathode is of the conventional type as used in receiving

valves, apart from the fact that it emits electrons from on side only of

its rectangular cross-section. A control grid (g1), four rod-shaped

focussing electrodes (p1, p2) and an accelerating electrode (g2), together

with the cathode, form the electron gun. This has been so designed that

the cross-section of the electron bean thus obtained is not circular but

ribbon-shaped. A ribbon-shaped electron beam has the following advantages:

Fig. 3a shows a cross-section of the decade counter tube, whilst fig. 3b

shows the diagramic representation which will be used in circuit

diagrams. The cathode is of the conventional type as used in receiving

valves, apart from the fact that it emits electrons from on side only of

its rectangular cross-section. A control grid (g1), four rod-shaped

focussing electrodes (p1, p2) and an accelerating electrode (g2), together

with the cathode, form the electron gun. This has been so designed that

the cross-section of the electron bean thus obtained is not circular but

ribbon-shaped. A ribbon-shaped electron beam has the following advantages:

The ribbon-shaped beam thus obtained proceeds between two deflection

electrodes (D, D', fig. 3). These have been so positioned that the beam

almost touches one of these electrodes in each of it's extreme positions,

deflection sensitivity thus being at a maximum.

Step-wise deflection of the beam

Advantage is taken of this principle for fixing the position of the beam

in the counter tube. In this case too, the anode a2 and the deflection

electrode D' (i.e. the one nearest to the figure 0) are connected to

direct voltage source Vb via a common resistor Ra2 (fig. 5); the potential

of D and a2 is denoted by vDa2. The straight line I of fig. 4b is now,

however, replaced by the undulated curve I of fig. 6; the way this curve

is obtained will be shown presently. This curve is intersected 19 times by

the resistance line II. Each of these points of intersection corresponds

to a condition of equilibrium - although only ten points of intersection

numbered from 0 to 9 represent stable positions. From this it may be seen

that the position of the beam indicated diagrammatically in fig. 3a is one

of its stable positions, i.e., passing partly through a slot and impinging

partly on the metal on the left of this slot: in fact, when the beam is

deflected further to the left the current initially increases, in

accordance with characteristic I near the points of intersection 0...9

(fig. 6).

Advantage is taken of this principle for fixing the position of the beam

in the counter tube. In this case too, the anode a2 and the deflection

electrode D' (i.e. the one nearest to the figure 0) are connected to

direct voltage source Vb via a common resistor Ra2 (fig. 5); the potential

of D and a2 is denoted by vDa2. The straight line I of fig. 4b is now,

however, replaced by the undulated curve I of fig. 6; the way this curve

is obtained will be shown presently. This curve is intersected 19 times by

the resistance line II. Each of these points of intersection corresponds

to a condition of equilibrium - although only ten points of intersection

numbered from 0 to 9 represent stable positions. From this it may be seen

that the position of the beam indicated diagrammatically in fig. 3a is one

of its stable positions, i.e., passing partly through a slot and impinging

partly on the metal on the left of this slot: in fact, when the beam is

deflected further to the left the current initially increases, in

accordance with characteristic I near the points of intersection 0...9

(fig. 6).

In fig. 7a a slotted electrode and an anode have been drawn as flat

planes. It is assumed that the ten slots have the same dimensions and are

equidistant and that the thickness of the ribbon-shaped beam exceeds the

width of the slots and is less than the width of the spaces between the slots.

In fig. 7a a slotted electrode and an anode have been drawn as flat

planes. It is assumed that the ten slots have the same dimensions and are

equidistant and that the thickness of the ribbon-shaped beam exceeds the

width of the slots and is less than the width of the spaces between the slots.

As a starting point it is assumed that the beam occupies one of its stable

positions, for example position 0. If a positive pulse is now applied to

the left deflection electrode, so that vD is temporarily increased, the

beam will tend to move to the left (fig. 3a); the number of electrons

passing through slot 0 decreases, i.e. the anode current ia2 is reduced. If

no stray capacitances were present, the decrease of ia2 would result

in a rise of the potential of the anode and of the right deflection electrode

connected to it, and this increase of vD',a2 would counteract the deflection

to the left, so that the beam would be retained at position 0.

As a starting point it is assumed that the beam occupies one of its stable

positions, for example position 0. If a positive pulse is now applied to

the left deflection electrode, so that vD is temporarily increased, the

beam will tend to move to the left (fig. 3a); the number of electrons

passing through slot 0 decreases, i.e. the anode current ia2 is reduced. If

no stray capacitances were present, the decrease of ia2 would result

in a rise of the potential of the anode and of the right deflection electrode

connected to it, and this increase of vD',a2 would counteract the deflection

to the left, so that the beam would be retained at position 0.

| to top of page | an E1T clock | The making of the E1T | back to homepage |

Before starting the description of the tester, it should be stressed that the

voltages used in this circuit are lethal! Never touch any part of the circuit

while the high tension supply is on.

Figure xx depicts the circuit diagram of the tester.

The circuit consists of three different parts:

1. The E1T valve with biasing circuit, 2. a pulse generator and pulse shaping

circuit, 3. the reset circuit.

Figure 2. Circuit diagram of the E1T tester.

The upper part of Fig. 2 forms biasing

circuit. It is directly copied from the E1T datasheet. The voltage

devider around R14, R15 and R16 provides the biasing voltages for the "input"

deflection plate D (156 V) and the control grid g1 (12 V). Any transients

on these voltages are removed by decoupling capacitors C9 and C8.

The current

through the voltage divider is ca. 2 mA. This is enough for the low-current LED

D1 to indicate that the high voltage supply is on. The total energy dissipated

in the divider is ca. 0.6 W, a bit too high for standard 1/4 resistors. One watt

resistors would do, but I only had two watt resistors. Although the tube is designed

for a 6.3 V filament voltage, I use 4 V just not stress these old beauties too much.

The most crucial resistor

in this part of the circuit is R21. This 1M resistor links the anode current

and the deflection plate voltage. The datasheet is very fussy about the tolerances

of the resistors, especially of the 1M anode resistor which is specified at 1%.

If you are not interested in pushing the tube to it's counting speed limits

5% resistors will also work well. In my circuit the maximum counting speed was about

1 kHz.

The current

through the voltage divider is ca. 2 mA. This is enough for the low-current LED

D1 to indicate that the high voltage supply is on. The total energy dissipated

in the divider is ca. 0.6 W, a bit too high for standard 1/4 resistors. One watt

resistors would do, but I only had two watt resistors. Although the tube is designed

for a 6.3 V filament voltage, I use 4 V just not stress these old beauties too much.

The most crucial resistor

in this part of the circuit is R21. This 1M resistor links the anode current

and the deflection plate voltage. The datasheet is very fussy about the tolerances

of the resistors, especially of the 1M anode resistor which is specified at 1%.

If you are not interested in pushing the tube to it's counting speed limits

5% resistors will also work well. In my circuit the maximum counting speed was about

1 kHz.

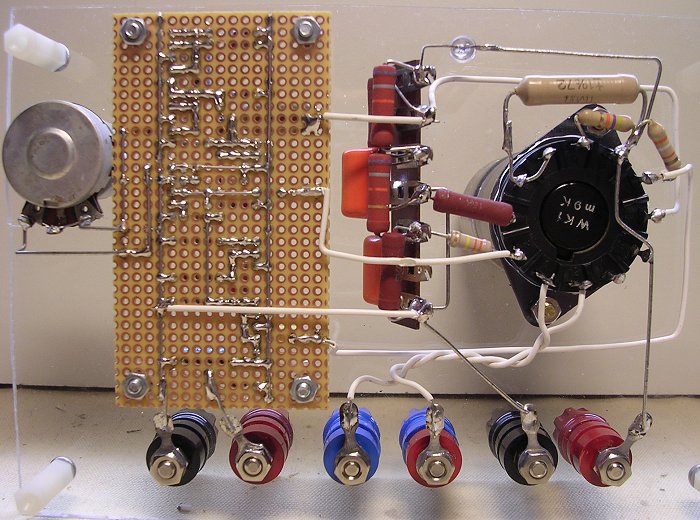

Figure 3. Front side view of the E1T tester.

The pulse generator and reset circuit were designed only using npn and pnp transistors. The primary reason was that I thought these would be more "rugged" than ICs in such an high voltage environment. Additionally I wanted to show that for these simple functions there are still simple alternatives for the relatively complex (and boring) integrated standard solutions. The additional advantage is that the circuit works over a wide supply voltage range. The heart of the oscillator is the multivibrator around T2 and T3. At "non-inverting" output, the collector of T3, we find 330 µs pulses (determined by C2 and R6) separated by a much longer variable length pause (determined by C1, R4 and R5). By adjusting R5 the repetition frequency is adjusted between 0.5 and 200 Hz.

As explained in the previous section,

the rising edge of the input pulse to the E1T should be steep enough so that

the voltage at the node of anode a2 and deflection plate D' can be considered

constant. The datasheet specifies a leading edge of at least 20 V/µs.

On the other hand the slope of the trailing edge should not exceed

1.2 V/µ second so that the potential vD', a2 can follow the trailing

edge. Both conditions are met by using an active pull up by means of

transistor T1 and resistor R1 for a passive pull down. The base of T1 is

connected to the "inverting" output of the multivibrator. This output is

normally high, and is low during the 330 µs pulses. During the low time

T1 is switched on and driven hard into saturation. The trailing edge of the

pulse is determined by C5 and R1.

Figure 4, a rear view of the tester.

When a new input pulse is given when the tube is already in the ninth

position, the electron beam advances to the left again an now impinges

on anode a1. This anode is connected to the 300 V supply via resistor R18.

The anode current now flowing through R18 will cause a negative trailing

edge at a1. After removal of the DC component by blocking capacitor C6, this

pulse is used to trigger the one-shot pulse generator formed by T4 and T5.

It appeared that also during normal counting from 0 to 9 small pulses where

induced at the anode a1. Capacitor C3 is used to filter these pulses so that

they do not cause unwanted resets. The one-shot produces on the collector

of T5 a positive going pulse of 2.2 ms. This pulse will switch on T6 which

in turn will cause a negative pulse of -15 V on the control grid g1. This

negative pulse will cut-off the electron current in the E1T. As a result

the potential on anode a2 and deflection plate D' will return to 300 V

again. When the valve is turned on the beam is in the right position again,

in other words being reset to zero. Isn't it beautiful !?

Figure 5. The working of the transistor one-shot multivibrator: A. rest

position, B. potentials in rest position,

C. situation during pulse.

Although most people are fairly familiar with the transistor multivibrator

circuit, the one-shot circuit is less know. Its working is easy to

understand. In Fig. 5A the npn version of the one-shot circuit is depicted.

Lets for the moment assume that the one-shot is in its stable rest

position. The capacitor will be charged then, so that we may think it

removed from the circuit (Fig. 5B). In this situation the base of T2

is pulled high by R2 so T2 is conducting. As a result the collector of

T2 will be low so that T1 is not conducting so that it's collector

will be high. When in this situation

a positive pulse is applied to the base T1, T1 will start to conduct,

pulling it's collector low. Since the capacitor was charged to 15V as indicated

in fig. 5A, the base of T2 will initially be pulled down to -15V,

assuming that the emitter-base junction of T2 does not break down (Fig. 5C).

This situation continues until the capacitor is charged so far that T2 starts

to conduct again. The one-shot is now back in its rest position.

| to top of page | an E1T clock | The making of the E1T | back to homepage |

The tube worked directly without any adjustments. At a filament voltage of 4 V

it takes about 30 seconds for the filament to warm up. I did not make any

special attempts to push the tube to its speed limits. The rather lengthy

reset pulse limits the counting speed to ca. 1 kHz. Although designed for

a HT supply of +300V, the circuit of Fig. 2 works fine for voltages

as low as 200V.

Figure 6. Anode a2 = deflection plate D', voltage while stepping from 0 to 9.

The scale is 50 V per division, 1- indicates 0 V.

Figure 7. Defocussing of the beam when it is deflected further to the left.

All in all the tube was quite easy to handle. I would love to make a clock

out of them, but unfortunately I have "only" two tubes. For a clock I would

not make use of the carry anode a1. I think it would be simpler to drive

the pulse and reset inputs of every individual tube directly by a

micro-controller. This would only require an additional +15V supply and a few

simple driver circuits. For the input pulse driver the simple circuit

consisting of T1,T2,R1,R2,R3 and C5 would do. For the reset pulse driver

T6,R12,R13 and C7 would do. Driving each tube individually would enable some

nice visual effects, e.g. a "slot machine" kind of spinning of every digit

for every new minute. I personally would not leave a clock with such rare

tubes on all the time. I would use one of these simple and low-cost motion

detectors that you may also find in garden lights etc.. to switch the clock

on only when somebody is in the room for a longer period of time.

After reading this page, Vincent Crabtree remarked that the most stressful time

for the heater is the moment when the coil is cold and power is applied. He suggested

to implement a soft start heater PSU or a constant current source to gently

heat the fillament. Thank you Vincent !

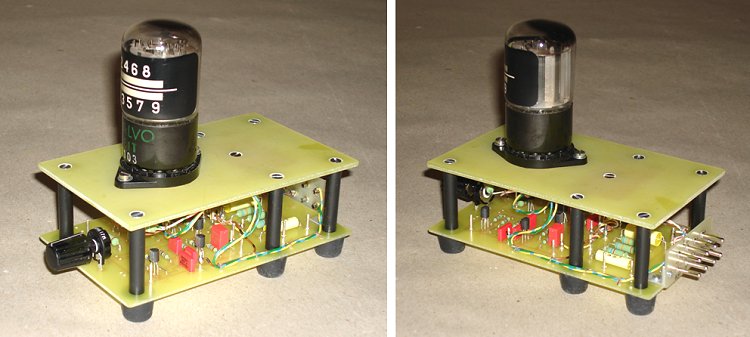

Figure 8. The E1T Tester as built by Dusan from Germany.

Figure 9. The E1T Tester built by Roger Leifert from Germany.

| to top of page | an E1T clock | The making of the E1T | back to homepage |

| to top of page | an E1T clock | The making of the E1T | back to homepage |

"Oh, Sorry", Radio Bulletin, no. 7, 1955