If this is the first time you read about the uTracer, perhaps a little explanation is in order. About two years ago I had an idea to construct a tube tester / curve tracer. By using a pulsed measurement principle, the whole circuit could be kept very small. After several iterations, this led to the uTracer3. Many people liked the concept, and after many requests I decided to make a kit so that everybody could build their own DIY tube tester.

In the mean time some 60 uTracers are up and running in more than 20 countries and 4 continents! Although, without exception, people are very enthusiastic about their uTracer, there is always room for improvement. Both from people who have actually built the uTracer3 as well as from the thousands of people who have read the weblog, I received many emails with requests for improved / extended performance and added functionality.

Figure 1.1 A set of vintage beauties waiting for restoration left to right: Pilot T501 (done), NSF h207u, Philips LX452AB (battery tube radio), Philips BX200U (set for tropics).

On this page I want to make an inventory of these requests, and I want to test and compare circuit ideas to realize them. I have to emphasize here again that the goal is not to design the best all round, most complete tube tester that money can buy, but to find the balance between performance and complexity / costs! Having said that, I do not want to raise false expectations: I really have no idea if this will eventually result in a complete working system, let alone a commercial product! I write these pages primarily for my own documentation, and for communication with other enthusiasts. Making the uTracer3 kit has cost me a lot more time than I could have ever imagined, and besides making tube testers, there are many other projects waiting, such as the restoration of four beautiful vintage radios.

| to top of page | back to homepage |

Higher Anode and Screen voltages

This point is undoubtedly on top of the list of most people who have given me feedback. The maximum anode / screen voltage of 300 V is by many people regarded as the most severe limitation of the uTracer3.

So, why are the anode and screen voltages limited to 300V? At the beginning of this project I did some initial experiments, and I found that with standard available components the maximum output voltage of a straightforward boost converter is limited to approximately 450V. Since 100uF/ 400V electrolytic capacitors are commonly available and relatively cheap, I decided to limit the output voltage to 400V. And then again, during the experiments with the high voltage switches I decided to limit the output voltage to 300V because, given the simple circuit concept of the uTracer3, is was difficult to guarantee fully short-circuit proof outputs.

Personally I am not into Power Audio Amplifiers. For me the main motivation to build the uTracer was to have a means to visualize and study the phenomena which occur in more standard “small signal” tubes, so for me 300V was already more than enough. In the mean time I have learned that especially people developing and building power amplifiers are interested in triode characteristics up to much higher voltages. So the question is: how high? Values mentioned in emails I received vary from 400V, via 700V, all the way up to 1500V! I really could use some more input here: what tubes are commonly used in the somewhat bigger PA’s, and to what voltages and currents need they be characterized keeping in mind that there is always a trade-off between price and performance? Is there only a need for higher voltages for triodes, or are there also people who want to test pentodes to much higher voltages? Would a curve-tracer just for triodes be OK for most people? What type of tubes are you using? Any additional wishes ….

Extended grid bias range

More or less the same questions apply to the grid bias circuit. The grid bias voltage range of the uTracer3 is 0 to -50V. The choice for this range was on one hand given by practical reasons, such as supply voltage ranges of OpAmps and the maximum input voltage of the LM339 voltage regulator, and on the other hand by the fact that this range covers some popular tubes including the very popular EL34.

Figure 2.1 A PL509 tested at grid biases of -60 to -80 V with the aid of an external 50V voltage source.

Some creative solutions can be used to increase the grid bias range of the uTracer3. To be able to characterize a PL509 in the relevant bias range, Derk Reefman for example inserted an external 50V voltage source in series with the grid connection (Figure 2.1). I understand however that a somewhat higher (more negative) grid bias would be welcome.

Figure 2.2 The 801A is designed to be used for grid biases between -160 V up to 160 V.

I received one or two questions from people who would like to test tubes at positive grid biases. I have to admit that I had no idea that tubes were also sometimes used in this regime. As it turns out some tubes like the 801A, are even designed to be used at positive grid biases so that a higher output power can be achieved (More1,More2). The 801A is even specified for grid biases ranging from -160 V up to 160 V (Fig. 2.2)! A positive grid bias automatically results in a grid current which also needs to be measured.

Again, I am highly interested in the specifications that people “in the field” would like to see for the grid bias!

Larger heater bias range

To keep the uTracer cheap and simple an old laptop power cord is used as power supply. The idea is that most people have an old power cord lying around anyway, and if not they can by bought practically for free at flea markets, surplus shops etc. These power cords can easily deliver tens of Watts of power at an output voltage of approximately 19 V. With so much power available, it was natural to use some of it for the heater. By simply pulse-width-modulating the output of the power cord, heater voltages between 0 and 19V can be obtained with only a few transistors and an inductor. As it happens this covers quite a large range of tubes commonly used, but of course not all.

In the meantime it has become clear that the internal heater supply has difficulties with low voltages (< 4V) in combination with high currents (>1 A). It has become clear that this is a result of the PWM principle in combination with inductances in the heater circuit (More). This is certainly one of the things on my list to look into.

A number of people have asked me if it is possible to include a converter so that the uTracer can be extended to higher heater voltages. Personally I do not think it is worth the effort. Such a circuit will greatly increase the complexity, while it offers little additional functionality. Fortunately, the design of the uTracer3 is such that both for directly, as well as for indirectly heated tubes an external heater supply can be used. What I recommend as the most practical and economical solution is to use a simple external lab power supply for tubes with a heater voltage higher than 19V. For indirectly heated tubes, even a simple transformer can be used.

For low voltage / low current heaters, such as for delicate 1,5 V battery tubes (DL96, DK96, etc.), as well as for valuable vintage tubes, I personally always use a battery as heater supply. With a PWM regulator it is not so easy to accurately control the equivalent DC output voltage down to a tenth of a volt, especially not for low voltages. Additionally, in this way, under no circumstances, the heater can be damaged due to a hardware or software error. Next to these more rational arguments, I have to admit that emotionally I do not feel too comfortable to subjecting fragile heaters to a PWM signal with an amplitude of 19V! A few dry “A” cells can easily be included in the case and made accessible on the front panel.

USB Communications

A recurring “complaint,” especially on forums, is the lack of an USB interface. The good-old serial RS232 interface is considered to be outdated and obsolete. Well, what can I say? It certainly is a bit outdated, but by far not obsolete! There are still zillions of devices with a serial interface around interfaced to USB ports through cheap USB-to-serial converters. Even recent projects in leading magazines like Elektor are often RS232 based but use on board USB to serial converter. Basically there are a number of options:

Next to these “hot topics” there are some more minor issues which are on my personal wish list:

This list is by no means complete and will probably be expanded as this project develops. If you have suggestions, ideas, please mail them to me!

| to top of page | back to homepage |

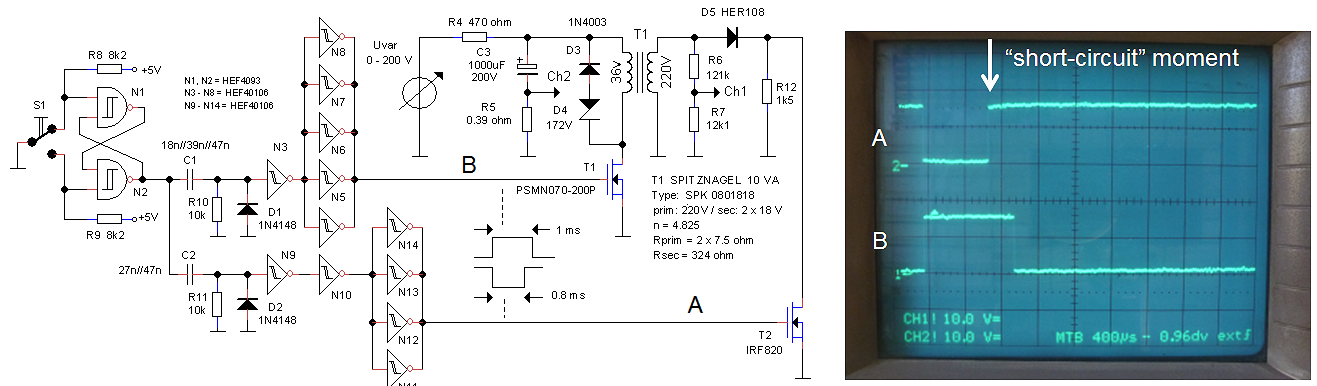

Georg Beckman is one of the people who bought a uTracer3 from the first series. He actually wrote a very nice review about it on the RadioMuseum forum. He also wrote me a few emails with some very interesting circuit ideas. One of these ideas was to get rid of the “high-side” high-voltage switch altogether by using a transformer. He reasoned: “transformers can transform a low voltage pulse to a high voltage pulse. If we generate a low voltage pulse on the primary side of a transformer which is used backwards and transform it up to a high voltage, we can get rid of the high-voltage switch.” The principle of the idea is shown in Fig. 3.1. We have some “low-voltage” adjustable voltage source and a MOSFET switch which generates a pulse on the primary side of the transformer. On the secondary side of the transformer we then find a pulse with, depending on the turns ratio, a higher voltage which drives the anode or the screen. Since the secondary winding is floating with respect to the primary winding, current measurement can be simple done by adding a current sense resistor to the “cold side” of the secondary winding.

Figure 3.1 Principle of the transformer based high voltage bias circuit.

I have to admit that my first reaction was not very enthousiastic; one of the very nice features of the uTracer3 is that it doesn’t contain any heavy and difficult transformers, keeping the circuit small, cheap and light. Introducing a transformer seemed to me a step back in time. When we talk about low-loss switched-mode power supplies we always use low-loss ferrite based inductors and transformers. So (obviously) my first assumption was that Georg wanted to use some fancy, specially made, ferrite transformer. A quick “back-on-the-envelope” calculation showed that, given a measurement pulse length of about 1 ms, that would be almost impossible because of magnetic saturation of the ferrite.

The idea continued to intrigue me however. If it would work, it has some very nice features. The fact that the whole rather complex and “sensitive” high-side (PMOS/PNP) switch can be replaced by a normal robust low-side NMOS is obviously very attractive. Also current sensing by means of a small series resistor at the cold-side of the secondary side of the transformer is straightforward. On top of that the galvanic isolation between the high-voltage side and the low-voltage driving electronics seems attractive, although this argument might be more emotional rather than rational.

When I confronted Georg with my reservations he explained to me that it was not his intention to use a fancy ferrite transformer, but an ordinary, cheap, off-the-shelf mains transformer. I did some experiments on which I will report in subsequent sections, and became convinced that the idea might work. So assuming for the moment that the transformer idea works, how could a uTracer based on that look like?

Figure 3.2 Two power supplies are needed to test tetrodes and pentodes.

First of all we need two of those transformer stages to bias both the anode and the screen grid independently (Fig. 2.1). Here already we run into a difficulty. One of the implications of using a transformer to generate high voltage bias pulses is that due to resistive losses in both the primary, but especially also the secondary (high-voltage) windings, as well as losses in the core, the voltage on the anode cannot be predicted accurately because it will depend on the current drawn by the tube! This doesn’t need to be a problem: although it cannot be predicted with great accuracy, it can be accurately measured! For a triode that is fine. Suppose we want to make an anode sweep, we then just make a best guess for the needed Uvar values (Fig. 3.1), but use the actually measured anode voltages for the plot. For a pentode or tetrode this is more difficult because here the anode sweep is made under the assumption that the screen bias is constant! Keeping the output voltage of the transformer bias circuit constant under varying load conditions is much more complicated and probably will require some iterative procedure. But nevertheless, let’s assume for the moment that we can fix that.

Figure 3.3 When a triode is tested the high-voltage supplies can be stacked or connected in parallel.

One of the very, interesting features of the concept is that the high voltage side is isolated from the driver side. This makes it possible to play some interesting tricks, provided that a triode is tested so that a separate screen supply is not needed. Occasionally I get questions from people who ask me for an option to test triodes to anode voltages in excess of 1000 V! By stacking two supplies (Fig. 3.3A) that is possible. Assume that each supply is capable of generating a pulse of 600 V at 200mA, then testing triodes to an anode voltage of 1200 V (@ 200 mA) becomes feasible. Alternatively, the two supplies might be connected in parallel to increase the output current to 400 mA (@ 600 V). These are indeed very nice specifications.

Figure 3.4 Idea for practical circuit implementation

Georg’s idea was to go directly from a low voltage to the required high voltage. What does that imply? Suppose that we use a power supply of 20 V and set the maximum high voltage at 600 V. This means a transformation ratio of 600/20 = 30 at least. In reality we will need a higher transformation ratio to make up for the losses. This means that the current at the primary side is at least a factor 30 higher than the current at the secondary side. So if we set – just as for the uTracer3 - the maximum anode current to 200 mA, this results in a primary current of at least 6 A, but more likely in excess of 10 A. Although that is not impossible, I am not really over-enthusiastic about the idea. I think it a better idea to use an intermediate high voltage of say something like 150 V and from there to use a transformer to step-up the voltage to 600 V. In that way the currents remain “manageable,” and since it requires less volume to store the same amount of energy at a higher voltage in a smaller capacitance (E=0.5*CV^2 with C inversely proportional, and V proportional to the volume) it also results in a (physically) smaller reservoir capacitance.

The actual circuit implementation I have in mind is something like the circuit shown Fig. 3.4. It consists of a small boost-converter identical to the one used in the uTracer3. The boost converter (L1,T1,D1) charges reservoir capacitor C2. If needed, C2 can be discharged through T2. Zener diode D3 removes the 19.5 V offset inherent to a boost converter. T3 pulses the transformer, while flyback diode D2 dissipates the energy that is released when T3 opens again.

Figure 3.5 Generating negative and positive grid bias pulses.

Continuing along the same line of thought it may even be attractive to use a transformer in the grid bias circuit. In the uTracer3 a constant grid bias was used, generated by an OpAmp with a special “high-voltage” discrete output stage. There is actually no reason why the grid bias voltage should be a constant voltage. Just as the anode and screen supplies, also the grid bias circuit can be pulsed provided that the grid bias pulse precedes the anode and screen pulses to prevent unwanted anode current transients. By using a transformer with a center tap and an additional NMOS switch, it becomes possible to generate in a very simple and elegant way both negative as well as positive grid bias pulses (Fig. 3.5).

All this sounds very nice and attractive, however, the biggest problem as I see it right now is – as already discussed – the difficulty to predict the correct driver settings for a certain bias condition. The losses in the transformer combined with the fact that currents drawn by the tube are inherently unknown will require some kind of clever iterative scheme or mathematical procedure. Having uttered these words of caution, I cannot conclude else than that the whole idea seems attractive. Time for some experiments!

| to top of page | back to homepage |

Transformers can be tricky components to understand. Most people are more or less familiar with the operation of a transformer for AC sinusoidal signals, but when it comes to (DC) pulses, most of us feel a bit uncomfortable. To explain how a transformer behaves for pulses, we first have to build an equivalent circuit model of the transformer. Central component in such a model is a device which only exists in theory: an ideal transformer. Figure 4.1A gives the circuit symbol of an ideal transformer. The current voltage relations of this imaginary device are identical to the equations we know for the real transformers we are all familiar with, with this exception that these relations are valid for any waveform be it AC or DC.

Figure 4.1 Left - ideal transformer, Right – the simplest model of a real transformer includes the magnetization inductance.

A real transformer (unfortunately) doesn’t behave like this. The reason is that we have used magnetic principles and effects to implement a practical version of this ideal device. Our everyday transformer is basically nothing more than two inductors which are magnetically coupled.

Figure 4.2 sketches what happens when a constant voltage is applied to the primary winding of a transformer with a turns ratio of n1:n2 = prim:sec = 1:2. The secondary winding of the transformer is left open in this example. The three rows of graphs in the figure show respectively the applied primary voltage, and the primary current and secondary voltage. The four columns show different moments in time. When the input voltage is first applied (Fig. 4.2A), the current through the primary winding increases linearly with time according I = V*t/L, with L the inductance of the primary winding. Since the magnetic flux (B) increases proportionally with the current (Ampere’s law), the voltage induced in the secondary winding (proportional to dB/dt, Lenz’s law) is constant. Since the ratio of the windings is two, the induced voltage at the secondary side will be twice the input voltage.

Figure 4.2 A constant voltage applied to a transformer with open secondary windings.

As long as the magnetic core of the transformer is not in saturation, the current will continue to increase linearly, and consequently the output voltage will remain constant (Fig. 4.2B). At a certain moment however, the core saturates. All the magnetic dipoles of the iron have now aligned with the magnetic field, and cannot help anymore to sustain a further increase in the magnetic field strength. In other words for a further increase in current, the transformer behaves as if the core was not there, resulting a sharp decrease in inductance and coupling between the windings. Due to the decreased inductance, the current through the primary winding will now show a sharp increase (Fig. 4.2C.) The output voltage of the secondary winding will collapse as a result of the vanishing coupling between the windings. Finally, the primary current is limited by the series resistance in the primary branch (Fig. 4.2D). When the current has become constant, the voltage at the secondary winding has become zero.

The simplest model of a real transformer is shown in Fig. 4.1B. In this model Lm represents the inductance of the primary winding with open secondary terminals. Lm is called the magnetizing inductance referred to the primary winding. The magnetization inductance models the magnetization of the core material. It is a real inductor showing saturation and hysteresis.

If we want to use a simple mains transformer as pulse transformer, what are then the boundary conditions for the input pulse (amplitude, duration) so that saturation is avoided? Iron cores saturate at a magnetic field strength B of around 2T (Bsat = 2T), but for off the shelf components the construction details needed to calculate the magnetic field are usually not available. Fortunately there is another method! We use the knowledge that mains transformers are designed to operate close to saturation under normal operating conditions. Knowing this, it can be shown (Appendix A) that the product of the pulse amplitude (V) and duration (t) should be V*t < 4.5 ms⋅Vrms (for 60 Hz transformers V*t < 3.8 ms⋅Vrms). For example, if we have a transformer with a primary winding of 36 V, then the V*t product of the input pulse should be less than 162 msV to avoid saturation. To take some extremes: a voltage pulse of 1 V during 162 ms, or a pulse of 162 V for only 1 ms.

Back to the idea of using a transformer to “boost” the high voltage pulses for anode and screen. The first choice is the transformation ratio. A high ratio results in high primary currents, while for a low ratio we could have saved ourselves the trouble of using a transformer. For the first experiments I picked a 10 VA transformer with two primary windings of 18 V (at nominal currents), which in series give 36 V, and a secondary winding of 220 V. Using a 6 V AC voltage I measured the transformation ratio of the secondary to primary windings which turned out to be 4.8. We have seen that for a 1 ms measurement pulse, the maximum amplitude of the input pulse for this transformer theoretically is 162 V, resulting in an unloaded output pulse of 4.8*162V = 780 V!

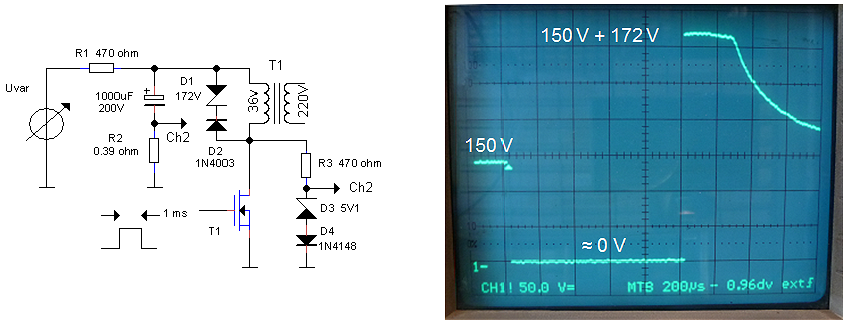

Figure 4.3 First test circuit used to test the pulse transformer principle

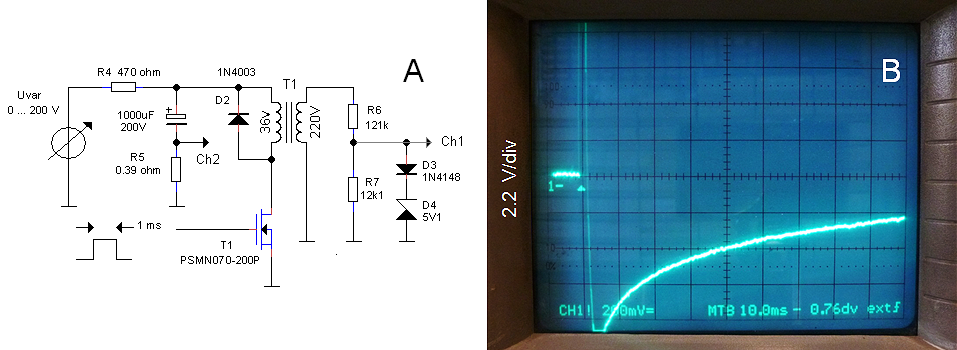

The circuit shown in Fig. 4.3 was used to test the new principle. Readers of my other tubes-tester weblogs will undoubtedly recognize my “standard” pulse generator circuit in the left part of the circuit diagram. The components have been chosen such that when S1 is pressed, the circuit produces a positive pulse of 1 ms. The energy for the primary high-voltage pulse is stored in a 1000 uF / 200 V electrolytic capacitor which is connected via a 0.39 ohm current sense resistor to ground. The capacitor is charged via R4 by a variable high-voltage power supply. R4 is selected such that during the pulse almost all the current through the transformer is supplied by the buffer capacitor. In that case the (negative) voltage drop over R5 is directly proportional to the current through the primary winding of the transformer. Flyback diode D2 absorbs the energy stored in the transformer when T1 switches off again. At the output I added a resistive voltage divider to reduce the output voltage to safe limits for my scope. The resistor values are a bit odd, but I happen to have these 1% resistors lying around. The division relation is

Vout = 11*Vscope.

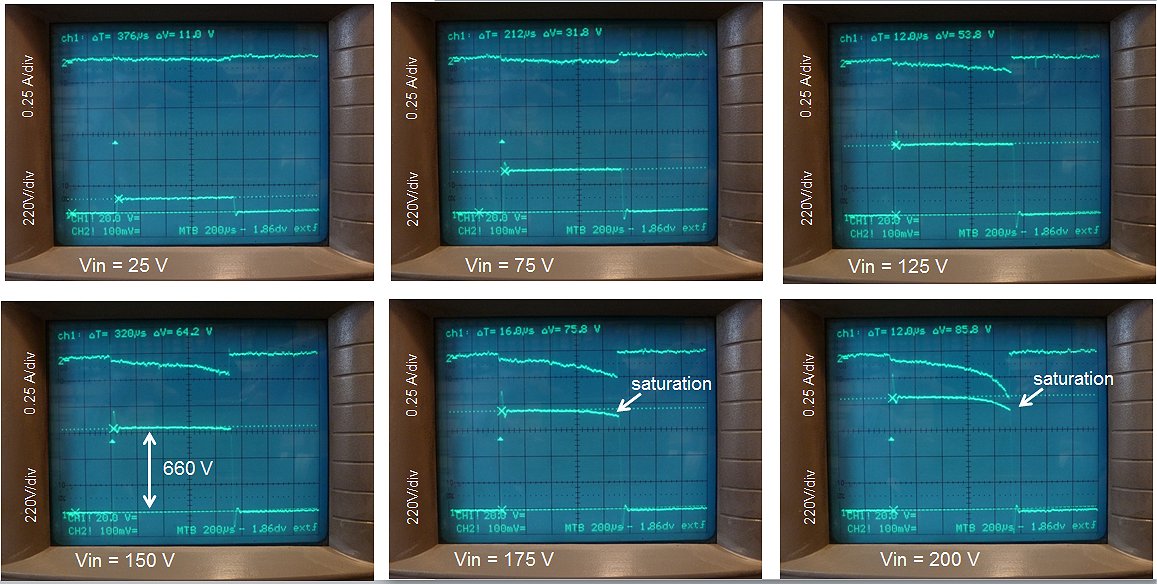

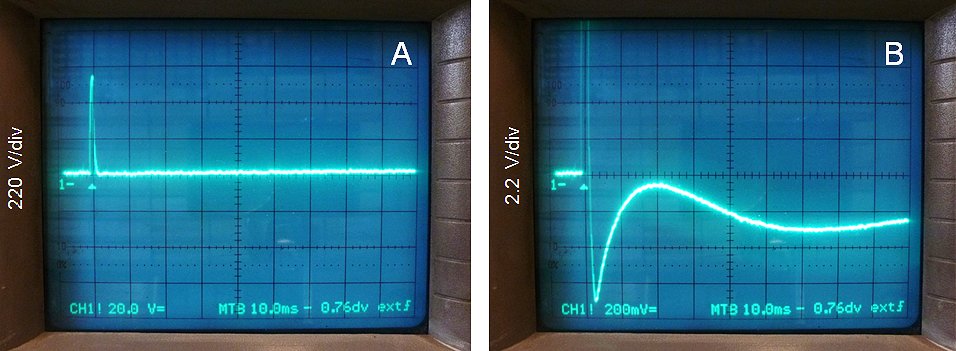

Figure 4.4 Primary current and output pulse for different input pulse amplitudes, and unloaded output.

Figure 4.4 shows in each photo both the current through the primary winding (top trace) as well as the output pulse (bottom trace). By the way, the current is measured over the sense resistor against ground, it appears as a negative signal. The output pulse amplitude increases linearly with the input pulse voltage (Fig. 4.6). For input voltages up to 150 V there are no signs of saturation. At that point the output pulse amplitude is 660 V! Note how the current almost linearly increases with time. At 175 V we observe, as expected, the onset of saturation near the end of the pulse. For 200 V the saturation becomes really pronounced, and we observe a sharp almost exponential increase in current.

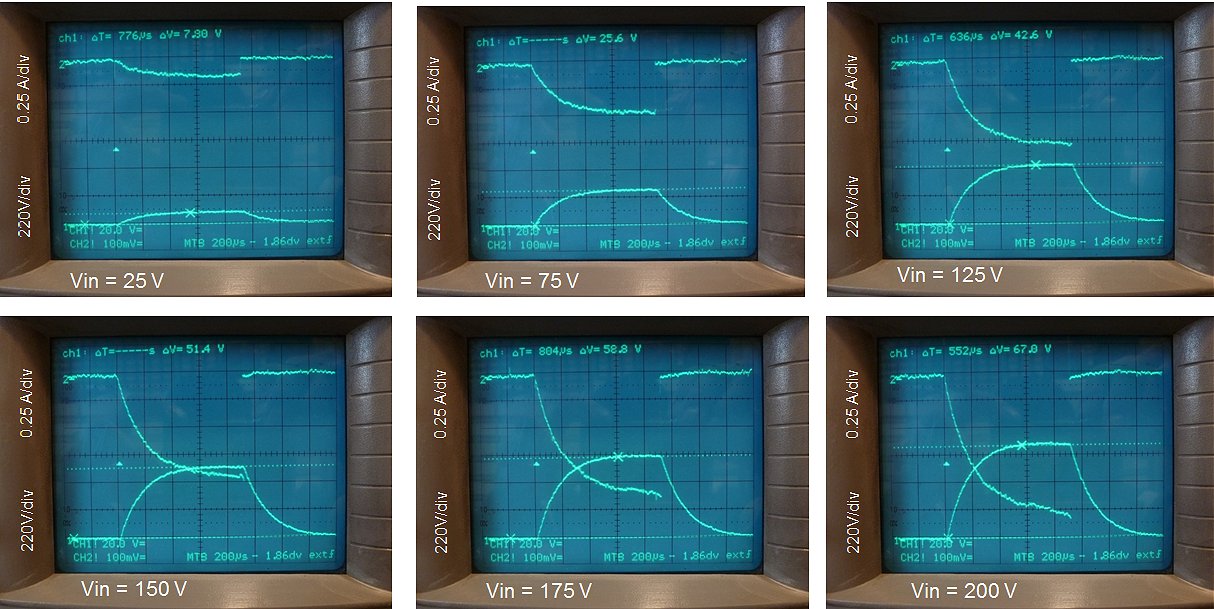

Figure 4.5 Primary current and output pulse for different input pulse amplitudes with a 3k3 resistor connected to the output of the transformer.

The next step is to test the circuit under load conditions. The simplest test was to redo the measurement above, but now with a 3k3 (10W) resistor connected to the output of the transformer. The output current will now be proportional to the output voltage. Just for reference, for an output voltage of 660 V the output current will be 200 mA, more or less my target output current value. We observe a number of striking differences.

First of all observe that the primary current is now much larger than in the unloaded case. A quick calculation: For an input pulse amplitude of 150 V, we find an output voltage of ca. 550 V. This results in a secondary current of 550V/3300Ω = 166 mA. This again results in a primary current of 4.82*166 mA = 800 mA, exacty the value we read from the photo.

We will consider the change in the slopes of the pulse and the absence of saturation in a next section, but first concentrate on the amplitude of the final pulse.

Figure 4.6 Output pulse amplitude versus input pulse amplitude taking losses into account.

In the graph in Fig. 4.6 the output voltage amplitude of the transformer has been plotted as a function of the input pulse amplitude for the case that the output of the transformer is left open and for the case that a 3k3 resistor is connected to the output (solid lines). For the loaded transformer the output voltages are obviously lower due to losses in the transformer. The circuit diagram in Fig. 4.6 shows the equivalent circuit of the transformer as far as DC resistive losses are concerned. The relation gives the output voltage of the transformer as a function of input voltage taking resistive losses into account. The dashed line in the graph gives the predicted input-output relation based in this relation and the measured DC resistances of the primary and secondary windings. We observe that most, but not all of the losses can be explained from the DC resistances of the transformer windings. Other losses can be caused by: discharging of the reservoir capacitor, series resistance of the capacitor, the current sense resistor and other losses in the transformer core and windings.

| to top of page | back to homepage |

When a load is applied to the output of the transformer, the shape of the pulse changes from a nice rectangular shape to a pulse with pronounced leading- and trailing edges (Fig. 4.5). This effect is caused by the leakage inductances of the transformer. These leakage inductances are associated with magnetic field lines originating from the primary winding which are not coupled into the secondary winding and vice versa. In the transformer model they are represented by two separate inductances in series with the terminal leads (Fig. 5.1A). In Fig. 5.1A also the series resistances of both windings have been included. For our purpose we will rewrite the transformer model of Fig. 5.1A into a slightly different model where the secondary leakage inductance and resistance have been referred back to, and included into, the primary leakage inductance and resistance (Fig. 5.1B). As long as Ls is much smaller than Lm, the transformer ratio of the ideal transformer hardly changes so it can still be approximated by n. By the way, a very simple method to measure Ls, is to short circuit the secondary winding and then measure the inductance at the primary winding. Short circuiting the secondary winding will short circuit Lm, leaving only Ls (Appendix C).

Figure 5.1 Complete model of a transformer including series resistances and leakage inductances.

If we neglect the magnetization current for a moment (which is a valid assumption under significant loads, compare Fig. 4.4 and 4.5), then all the output current has to pass Ls. The leakage inductance in combination with the output resistance forms an L-R combination with time constant τ = L/R. If we estimate from one of the graphs in Fig. 4.5 the time it takes for the current to increase to 63% (1/e) of its final value, we find ca. 200 us, this in combination with the output resistance of 3k3 gives a leakage inductance of L = τ*R = 200us*170Ω = 34 mH, which is for such a simple estimation close enough to the measured value of 22 mH (Fig. 5.2).

Figure 5.2 Estimation of the leakage inductance from the leading slope of the output pulse.

Note, that although in the measurements of Fig. 4.5 input voltages of up to 200 V were used, so well in excess of the “theoretical” saturation value of 162 V (for a 1 ms pulse), no saturation is observed! The reason is that it is the integral of the voltage over time (the area of the pulse) which counts, and which has to be less than the aforementioned 162 msV. So although it takes more time for the pulse to reach its plateau value, we can compensate for that by increasing the pulse length. The output pulse can be described by a simple first-order system resulting in an exponential behavior (Fig. 5.3). The time constant of this system is determined by the leakage inductance and the total series resistance referred to the primary winding. As long as the integral of the pulse over time is less or equal than the saturation criterion, no saturation will occur.

The leakage inductance results in a significant complication of the whole transformer pulse idea! With increasing load, the slope of the trailing edge of the output pulse decreases. As a consequence the length of the measurement pulse will have to depend on the load. On the one hand the pulse length has to be chosen such that the final plateau value (say to a value of 4τ, corresponding to 98% of the final value) is reached, while on the other hand it should not be chosen too long because otherwise the criterion for non-saturation is violated.

Figure 5.3 The output pulse shows a first-order exponential behavior.

When the MOSFET switch opens again, the current through the leakage inductance wants to remain constant. To achieve this, a voltage across Ls will develop so that the primary current continues to flow through the snubber diode. Gradually, the energy stored in the inductor will be dissipated in the load resistor, and the current will drop, resulting in a trailing edge of the pulse with the same time constant as the leading edge. Note, that when the diode is extended with a zener diode, Ls will have to develop a higher voltage to maintain the same current. The higher voltage will result in a faster “discharging” of Ls (t=V*t/L) and hence a reduced fall time. This at the expense of a significant dissipation in the zener diode and a higher breakdown voltage of the MOSFET.

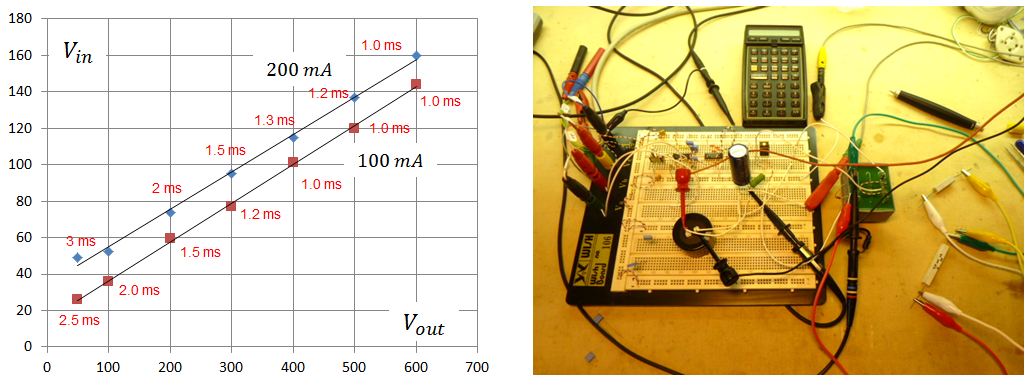

The measurement of Fig. 4.5 with a constant load resistor connected to the output of the transformer obviously results in an output current which is proportional to the output voltage. A pentode and tetrode however have output characteristics which much more resemble a constant current sink. In this case the pulse circuit has to be able to deliver high currents at low voltages. To investigate how the pulse circuit behaves under true constant output current conditions, a slightly different measurement was performed whereby the circuit was evaluated for a number of different output voltages rather than input voltages. So for each output voltage set point, a load resistor was connected which resulted in a current of either 100 mA or 200 mA, after which the input voltage was adjusted so that the desired output voltage was obtained.

Figure 5.4 Input voltage required to reach a certain output voltage for a current of 100 mA or 200 mA.

Figure 5.4 shows the result of this measurement. Next to each measurement point the pulse length required to reach the plateau value is noted. The good news is that with a simple 10 VA transformer pulses up to 600 V at currents of 200 mA can easily be obtained. The bad news is that both the input pulse amplitude, as well as the optimal pulse length are a function of the load (current) which is not known beforehand. A measurement even will therefore inevitably involve some kind of iterative procedure to obtain the optimal settings.

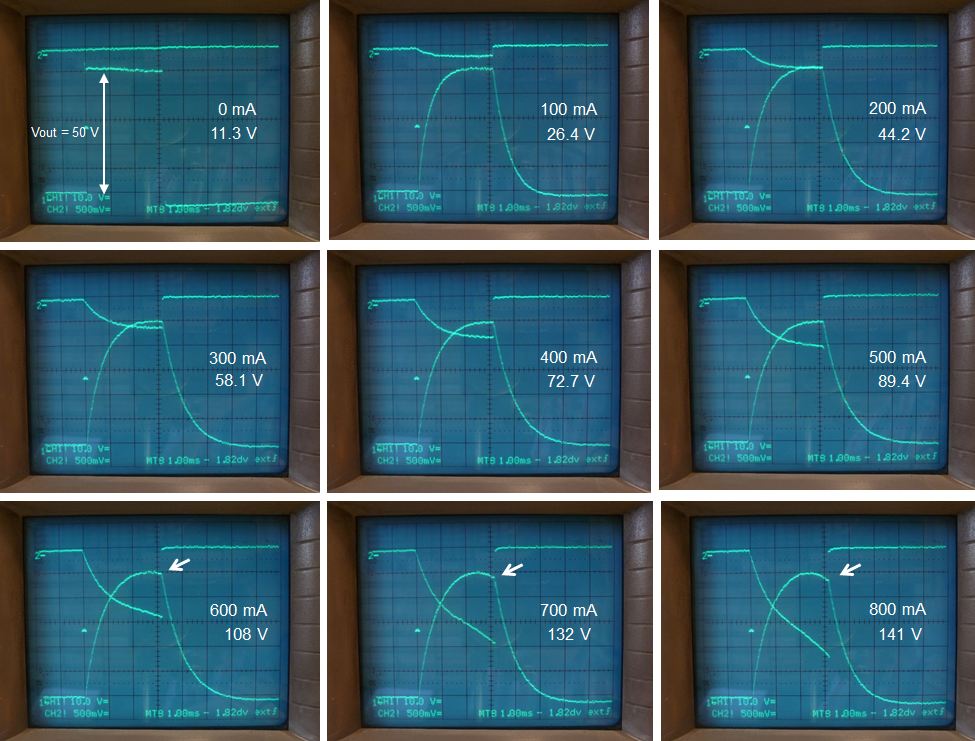

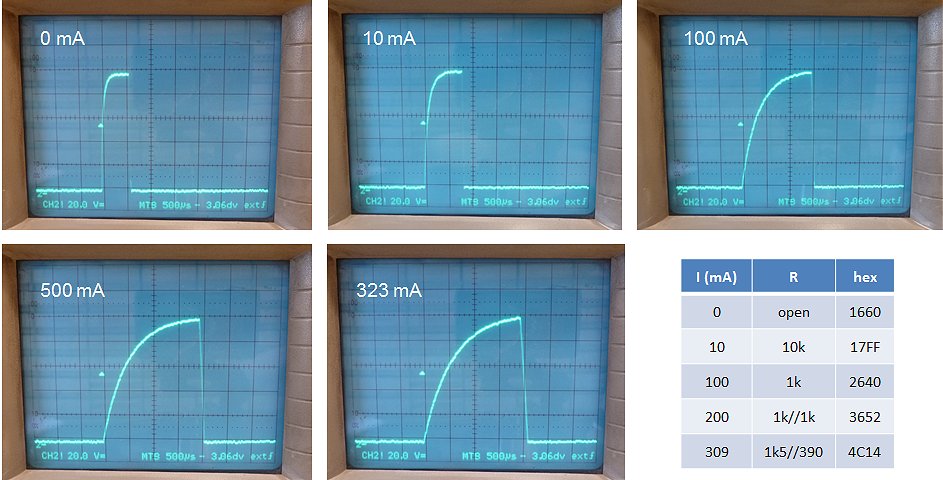

What seem most challenging are high current pulses at low output voltages. In this case the load impedance is lowest, resulting in a large LR-time constant. The question is whether a plateau value can be reached, while still avoiding saturation. Figure 5.5 shows a measurement where the output voltage was set to 50 volts while the load resistance was decreased resulting in an increase of load current. So for every new measurement with a lower load resistance, the amplitude of the input pulse (noted in Fig. 5.5) was adjusted so that a 50 V output pulse was obtained. Remarkably, the output current could be increased to 500 mA without any sign of saturation. At an output current of 600 mA the onset of saturation can be observed. At that point the input pulse amplitude is 108 V!

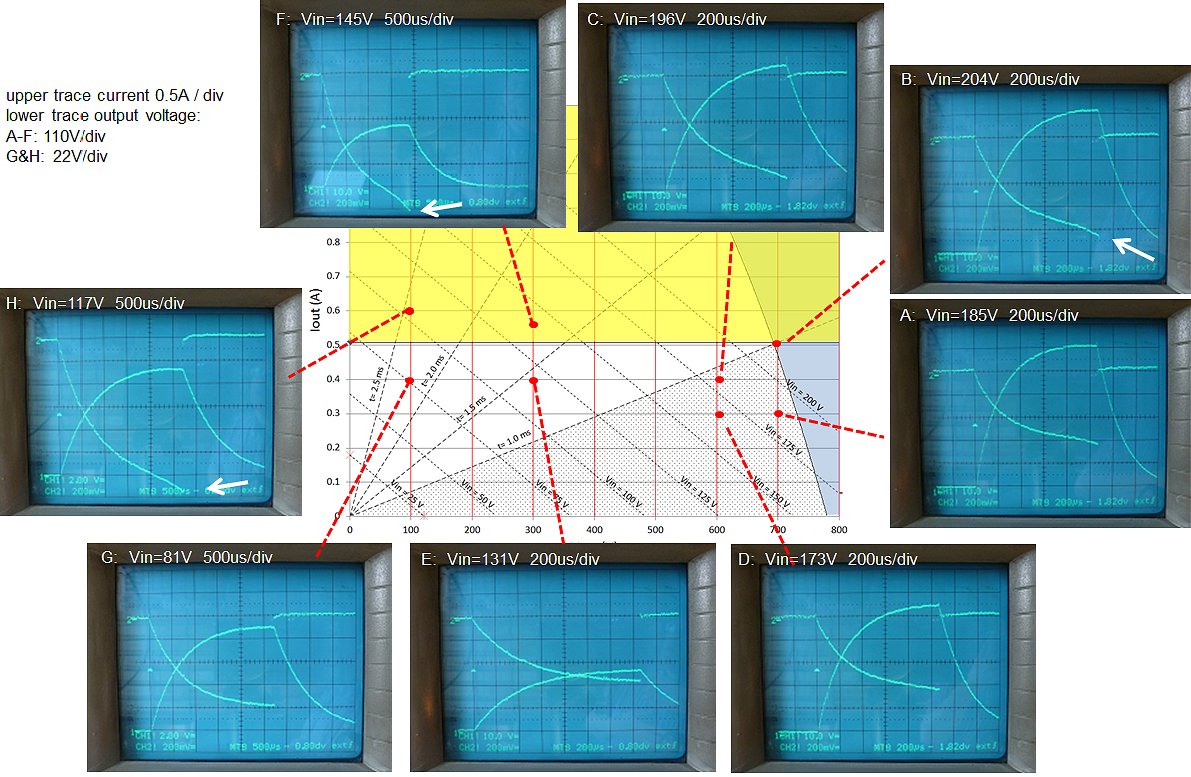

Figure 5.5 “worse case” test with a low output voltage and high output current (low output impedance situation). The output voltage was kept constant at 50 V while the load resistance was decreased.

| to top of page | back to homepage |

Lets try to summarize what we learned so far. A simple mains transformer can be used to “boost” a voltage pulse. When the transformer is unloaded, the output pulse will be rectangular, and the “boost factor” will be almost equal to the ratio of number of turns secondary/primary. To avoid saturation, the area of the input pulse (amplitude times duration) should be smaller than a certain non-saturation criterion which depends on the design of the transformer. When the output of the transformer is loaded, two effects complicate the situation. In the first place the amplitude of the output pulse will drop due to resistive losses in both the primary, as well as the secondary windings. In principle this is not so bad because we can compensate for that by just increasing the amplitude of the input pulse. The other effect is that the leading edge of the output pulse changes from a rectangular shape into more gradual “first order” increase characterized by a time constant τ. This time constant is proportional to the leakage inductance of the transformer, and inversely proportional to the load resistance. As a result higher load currents require a longer measurement pulse duration than smaller load currents. At the same time care has to be taken not to violate the non-saturation criterion. Fortunately nature helps a bit here: the higher the load current, the longer the pulse, but also the more gradual the increase in voltage, and since it is the integral of voltage versus time that counts, the integral also increases at a slower pace. For high load resistances on the other hand the measurement pulse cannot be too short, because we need some time for the electronics to stabilize and for the AD conversions themselves. In short, both the amplitude as well as the duration of the measurement pulse are variables which depend on the actual load being measured, which is in principle unknown!

Figure 6.1 Saturation criterion calculation for a pulse length of 4*τ.

In this section I want to have a look at how the optimum duration of the measurement pulse has to be chosen in relation to the output current and voltage. As mentioned, the output pulse behaves like a first order system characterized by a time constant τ (Fig. 5.3). In order for the pulse to stabilize to a certain constant plateau value, I decided that the pulse length should be at least 4 times τ. In that case the voltage has stabilized to within 2% of its final value. In order to avoid saturation, the integral of the voltage over time from 0 to 4*τ has to be less than the saturation criterion (162 msV for our test transformer). Figure 6.1 shows the calculation of this integral, and quite remarkably we find that this integral only depends on the output current, and not on the output voltage. As long as the 3*n*Ls*Iout is less than 162 msV, saturation is avoided.

Figure 6.2 Vout / Iout selection plane and boundaries.

Figure 6.2 shows in a (rather complicated) graph the complete output voltage (x-axis) and output current (y-axis) space. In the area below line A, the integral of the voltage over time from 0 to 4*τ is less than the saturation criterion of 162 msV. So the conclusion is that as long as we can scale the duration of the measurement pulse with the time constant τ inversely proportional to Req (see Fig. 6.1), saturation will only occur above a certain current level, regardless of the output voltage. However, the higher the output voltage, the shorter the measurement pulse. Unfortunately, the measurement pulse cannot be made too short. Some time is needed for the electronics to stabilize and also the AD conversions take some time. So let’s say the minimum measurement pulse length is, just as in the uTracer3, 1 ms. How does that then limit the possible output voltage/current values?

Figure 6.3 Saturation criterion calculation for a fixed pulse length of 1 ms.

To find that limit we have to calculate for which Vout/Iout pairs the area of the input pulse for a fixed length of 1 ms equals the saturation criterion (Fig. 6.3). Unfortunately the resulting equation cannot be solved analytically (at least I couln’t), but the numerical solution is shown in Fig. 6.3 by line B. So for a constant pulse length the area right to line B is forbidden. The total operation range is now reduced to the uncolored area below line A but left to line B. The highest output voltage that can be obtained is with an unloaded output, indicated by point C.

Figure 6.4 Calculation of lines with constant pulse length.

The dashed lines in Fig. 6.2 indicate the measurement pulse length corresponding to 4*τ. The calculation of these lines is straightforward and given in Fig.6.4. In the shaded area below the line for 1 ms the pulse length corresponding to 4*τ is less than 1 ms. So in this area a constant pulse length of 1 ms is used as explained above. As a result this area is on the right side limited by line B. Above the 1 ms line the optimal pulse length has to be increased as indicated. Finally, the dotted lines in Fig. 6.2 give the required amplitude of the input pulse for a certain Vout / Iout combination, based on a simple model only including resistive losses.

Figure 6.5 Checking the validity of the model.

In Fig. 6.5 the validity of the theory is explored along the boundary of the valid measurement region. For each measurement first a target output voltage was selected and a load resistor was connected which would result in the desired output current. Next the amplitude of the input pulse was increased so that the target output voltage was obtained. The standard time base was 200 us/div, for some measurements the time base had to be increased. In general I would say that there is a very reasonable agreement between the experiments and the simplified model. For all the points in the “forbidden” area, saturation is observed (white arrows), while the points within the white area are saturation free. Also the predicted input amplitude and measurement pulse length are in fairly good agreement.

| to top of page | back to homepage |

The experiments and calculations in the previous sections tend to convince me that the whole “transformer idea” actually might work! But so far we only considered the generation of the pulse itself. However, during the pulse a considerable amount of magnetic energy is built up in both the core of the transformer as well as in the leakage inductances, and as soon as the pulse is over, that energy has to go somewhere! The question more precise is: how can we de-magnetize the transformer in an efficient way, and quickly enough so that it is completely de-magnetized before the next measurement pulse. Because if the core is not completely de-magnetized before the next pulse, the field of the new pulse will add-up to the field already in the core, eventually resulting in magnetic saturation.

What happens after the MOSFET switch opens again at the end of the pulse is far from straightforward, and in a subtle way depends on the measurement conditions, especially the load. In this section we will first look at the situation when there is no load, or when the load is very small (low current). We will then consider the case when a substantial load is connected to the transformer.

Figure 7.1 Current distribution during and after the measurement pulse in case the transformer is not loaded.

Figure 7.1 shows the current distribution in the transformer during and after the measurement pulse in case the transformer is unloaded. Figure 7.1A depicts the current distribution near the end of the measurement pulse. The MOSFET switch is still closed, and since there is no current through the secondary winding, the only current through the primary winding is the magnetization current through Lm. Since Lm is large, this current is relatively small, in our case something like 100 mA. When the MOSFET switch is opened, the currents through Ls and Lm initially remain constant. To achieve this, the voltage across Lm has to change polarity so that the snubber diode starts to conduct. The voltage drop across the diode is very small, in the order of 1 V. This voltage appears transformed at the secondary side of the transformer, resulting in a voltage of approximately -5 V for this particular transformer. The low voltage drop over the diode also has a disadvantage: remember that the current through an inductor as a result of a constant applied voltage is I = (V*t)/L. In other words the time it takes to (de-)magnetize an inductor to a certain current is: t = (I*L)/V. So when V is small, e.g. 1 V in the case of a simple diode, it takes approximately (0.1*2.3)/1 = 230 ms before the current through Lm has dropped from 100 mA to zero. This is way too long if a number of measurement pulses needs to be fired in quick succession. To reduce de-magnetization time, a zener diode is connected in series with the diode. To maintain a constant current the moment the switch is opened, Lm now has to develop at least the zener breakdown voltage across the transformer terminals. When a sufficiently high zener voltage is chosen, it is possible to de-magnetize the transformer in a few milliseconds.

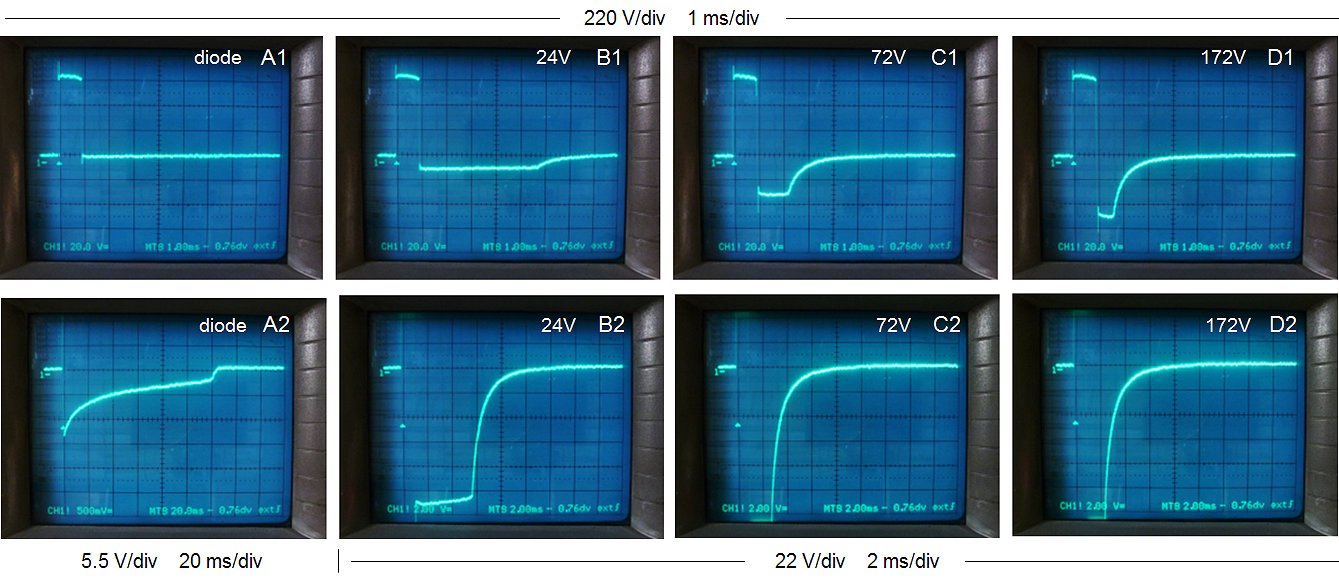

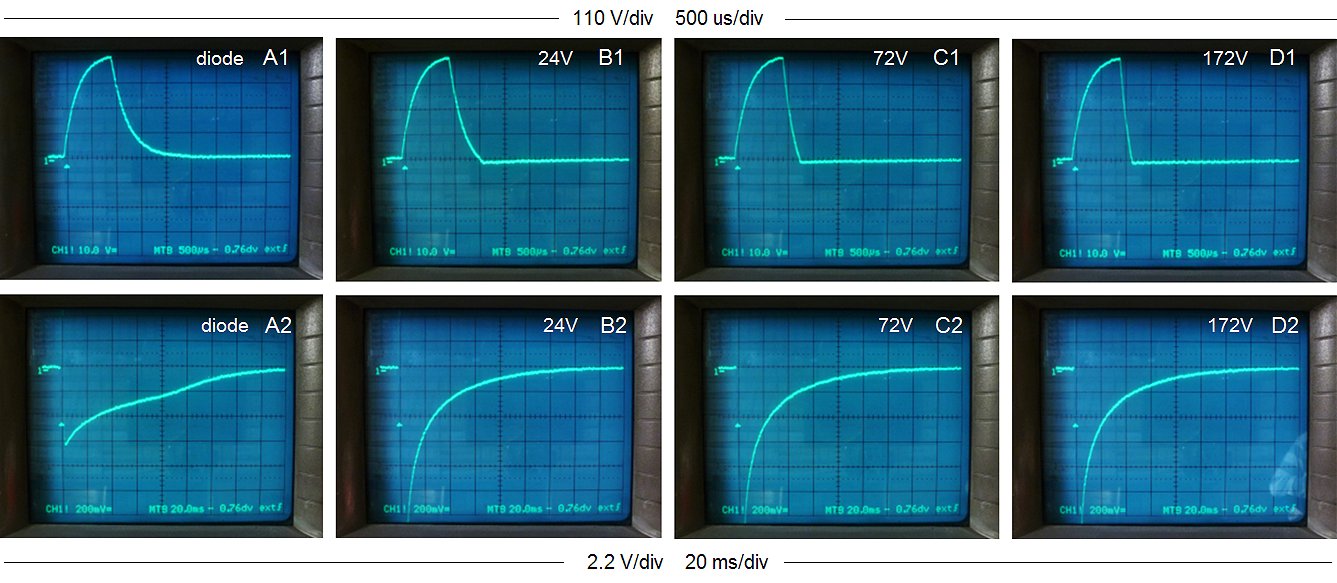

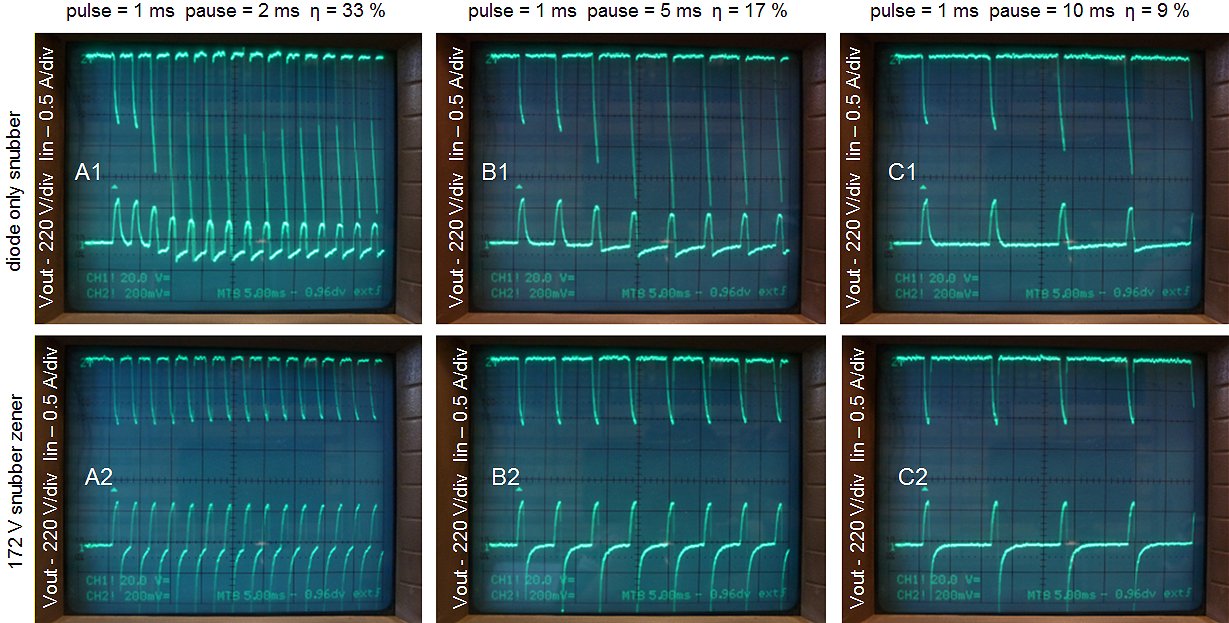

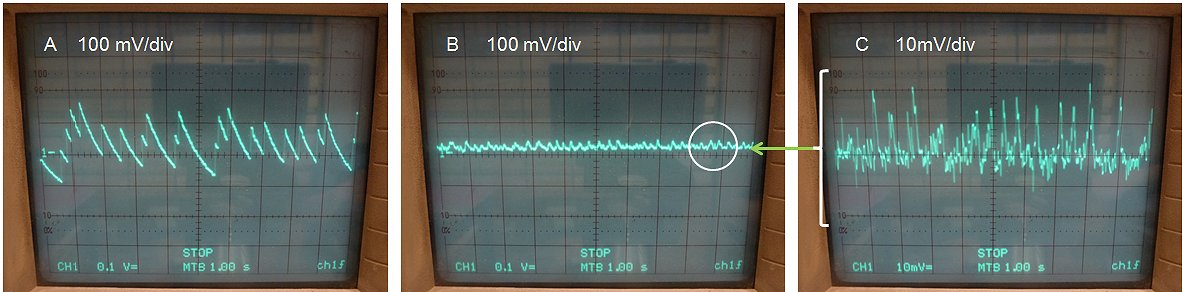

Figure 7.2 Output voltage at the secondary side of the transformer for the unloaded transformer. The amplitude of the input pulse was 150 V. Column A represents the case only a diode snubber was used. For columns B-C a zener/diode snubber was used with a zener breakdown voltage as indicated.

The pulsing of an unloaded transformer is illustrated by the measurements in Fig. 7.2 which, by the way, were not without difficulties. In all measurements the output voltage of the transformer was recorded with a memory scope. In column A only a single snubber diode was used. In columns B,C and D, a diode/zener combination was used with zener breakdown voltages of 24 V (B), 72 V (C), and 172 V (D). The upper row of photos shows a global picture of the output pulse shape. In the lower row of photographs, both the vertical, as well as the horizontal axis have been magnified to highlight especially the negative voltages occurring after the measurement pulse. For the lower row of pictures, the measurement pulse itself is not clearly visible, but the beginning of the pulse (the trigger moment) is indicated by the small white triangle, while the 0 V line is indicated by the ”1-“ marker.

At first sight, a single snubber diode (Fig. 7.2 A1) results in the cleanest pulse. However, on magnification (Fig. 7.2 B1) we observe a long negative de-magnetization tail with a duration of at least 120 ms. If new measurement pulses were to be issued during this tail, the currents would accumulate, eventually resulting in saturation. The addition of a zener diode clearly results in a negative output pulse (Fig. 7.2 A1,A2,A3). With increasing zener voltage, the amplitude of this negative pulse increases, but the length of the pulse decreases proportionally! For a zener voltage of 172 V, the de-magnetization time has reduced to less than 10 ms (Fig. 7.2 B4).

Figure 7.3 Current distribution during and after the measurement pulse in case the transformer is loaded.

The situation changes significantly when the transformer is loaded. Figure 7.3 shows the current distribution in the transformer circuit near the end of the measurement pulse in case a load is connected to the transformer. Next to the current through the magnetization inductance Lm, there is now an additional current caused by the load. Under significant load conditions, this current will be much larger than the magnetization current. If we assume e.g. a transformation ratio of 1:5, and a load of 300 mA, then the current caused by the load will amount to 1.5 A. So, despite the fact that Ls is usually much smaller than Lm, also a significant amount of energy is now stored in the leakage inductance. In fact, under realistic load conditions the amount of energy stored in the core is about equal in magnitude to the amount of energy stored in the leakage inductance. When the MOSFET switch is opened (Fig. 7.3B), the large current through Ls will continue to flow. To achieve this, Ls will develop such a high voltage that the zener/diode combination will open. Since the current through Lm initially also cannot change, the current through Ls remains flowing through the load. A lot of energy is now dissipated in the zener diode, resulting in a linear decrease in current. At a certain point, the current through Ls has become zero. However, since the inductance of Lm is much larger than the inductance of Ls, it will take a much longer time for the magnetization current to drop to zero. After the load current through Ls has become zero, the current still running through Lm can follow two paths: through the zener/diode combination or through the load. The current through Ls had no choice, it had to go through the zener snubber. The magnetization current however, will follow “the easiest” path and rather than developing a high voltage to open the zener, it will (slowly) discharge through the load. Note that to do that the current through the load will change sign!

Figure 7.4 Output voltage at the secondary side of the transformer when the output is loaded with a 1.5 kΩ resistor. The amplitude of the input pulse was 150 V. Column A represents the case only a diode snubber was used. For columns B-C a zener/diode snubber was used with a zener breakdown voltage as indicated.

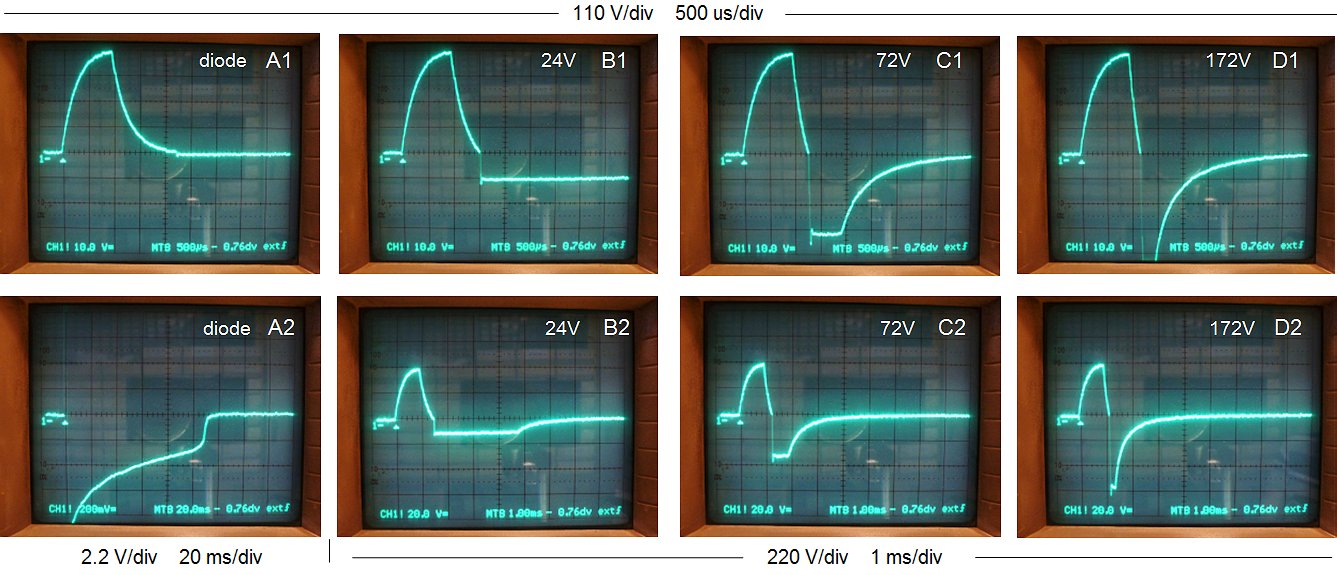

The whole process is illustrated by a series of measurements shown in Fig. 7.4. Again the output voltage of the transformer is recorder with the memory scope, but this time a load resistor of 1.5 kΩ was connected to the output. Just as for the previous measurement in column A only a single snubber diode was used. In columns B,C and D a diode/zener combination was used with zener voltages of 24 V (B), 72 V (C), and 172 V (D). The upper row of photos shows a global picture of what is happening. In the lower row of photographs both the vertical as well as the horizontal axis have been magnified to highlight especially the negative voltages occurring after the measurement pulse. For the lower row of pictures, the measurement pulse itself is not visible, but the beginning of the pulse (the trigger moment) is indicated by the small white triangle, while the 0 V line is indicated by the ”1-“ marker.

When only a single snubber diode is used, Ls can basically only discharge through the load resistance. This will result in a logarithmic decay of the current with exactly the same time constant as the rising edge of the current (see also section 5). When a zener/diode combination is used as a snubber, the voltage across the zener diode will quickly de-magnetize Ls at a rate t = (I*L)/V. The higher the zener diode breakdown voltage, the faster Ls is de-magnetized. As soon as Ls has been de-magnetized, the current flowing through Lm remains. The decay of this current is shown in the lower row of photos in Fig. 7.4. Note the enormous difference in both voltage as well as time scale between the series of measurements. Since Lm only has to develop a tiny voltage to maintain the current, the de-magnetization progresses logarithmically at a very slow pace, of course independent of the zener breakdown voltage. The complete de-magnetization of the core takes at least 160 ms! Fortunately, there is a beautiful trick to speed things up a bit.

Figure 7.5 Current distribution during and after the measurement pulse in case the transformer is loaded and a blocking diode in the circuit at the secondary side of the transformer is used.

Figure 7.6 Output voltage at the secondary side of the transformer when the output is loaded with a 1.5 kΩ resistor and a blocking diode in circuit at the secondary side of the transformer is used. The amplitude of the input pulse was 150 V. Column A represents the case only a diode snubber was used. For columns B-C a zener/diode snubber was used with a zener breakdown voltage as indicated.

The process is again illustrated by four measurements Fig.7.6 A1-D1. In all four measurements the diode in the secondary circuit was used. The difference between the A,B,C,D measurements was, as in the previous examples, the breakdown voltage of the snubber zener diode. When only a simple diode snubber is used, the de-magnetization of the core proceeds almost the same as in the case when no diode is used in the secondary circuit. However, when a zener/diode combination is used as snubber, the de-magnetization of the core proceeds very quickly. The higher the zener breakdown voltage, the faster the de-magnetization occurs. Note that the area of the negative part of the output voltage pulse is always the same, regardless of the zener breakdown voltage. For a zener diode breakdown voltage of 172 V the core de-magnetizes in only 5 ms.

Figure 7.7 The transformers response to a quick succession of measurement pulses. In the upper row a single snubber diode was used across the primary winding while in the lower rom a zener/diode (172V) combination was used. The transformer was loaded with a 1k5 resistor. The input pulse amplitude was 100 V.

Whereas this all may sound very nice, “the proof of the pudding” as the English say, is a test whereby the transformer is subjected to a quick succession of measurement pulses with a minimum delay in between. For this experiment the test circuit of Fig. 4.3 was modified so that the push-button was replaced by a pulse generator. The resulting output pulses and input current was recorded with the memory scope. The circuit was connected to a load of 1k5 and the amplitude of the input pulse was 100 V. The pulse width was fixed at 1 ms, while the pause between two pulses was 2, 5 or 10 ms.

The upper row of three photos shows the input current and the output voltage of the test circuit with only a snubber diode across the primary winding. Observe that for every pulse the amplitude of the current increases. Apparently even a pause of 10 ms is not enough to demagnetize the transformer. At a certain point the amplitude of the current pulses seams to decrease. This is due to the fact that the high-voltage reservoir capacitor (1000 uF, 200V in this case) slowly discharges. Also note that the base line of the voltage at the secondary side drops below zero. With the zener/diode snubber (lower row of photos) the current pulses and output voltage pulses are constant indicating that the transformer is completely de-magnetized, even for a pause of 2 ms!

“That infernal zero!” was what Peter Blanken - a colleague of mine and a transformer expert with whom I’ve had many discussions during the writing of these pages - remarked when he saw the measurements. In the upper row of measurements the base-line of the output voltage drops below zero so that the average output voltage remains zero. In the lower row the negative pulses compensate for the positive pulses. Alas, I again failed to invent the DC transformer!

| to top of page | back to homepage |

The first time I heard of the term “ruggedness” in the context of electronic circuits was in the mid nighties. At that time I was working at Philips Research on a project aimed at the development of a new generation of RF-power transistors for mobile phones (GSM). Just for the insiders, these were: double-poly silicon transistors, with an implanted base and poly-emitter, a selective collector implant and an Ft of 30 GHz. The most important design parameters for these transistors were the gain and the output power. Another, vaguer design constraint was the “ruggedness.” The transistors had to survive a total miss-match at the output (broken off, or shorted antenna) at the maximum supply voltage (phone connected to charger). This requirement really was a pain in the neck because, as so often in nature, there was a trade of between the gain and the requirements for ruggedness. Now, almost 20 years later, I am confronted with the same problem for the uTracer.

One of the design constraints of the uTracers is that they have to be short circuit proof at maximum output voltage to protect the circuit against operator faults and flash-overs. It was this design constraint which actually made me limit the output voltage of the uTracer3 to 300 V.

In this section the “ruggedness” of the transformer pulse generator concept will be investigated.

Figure 8.1 Pulsing the circuit with output short circuited @ Vin = 200V.

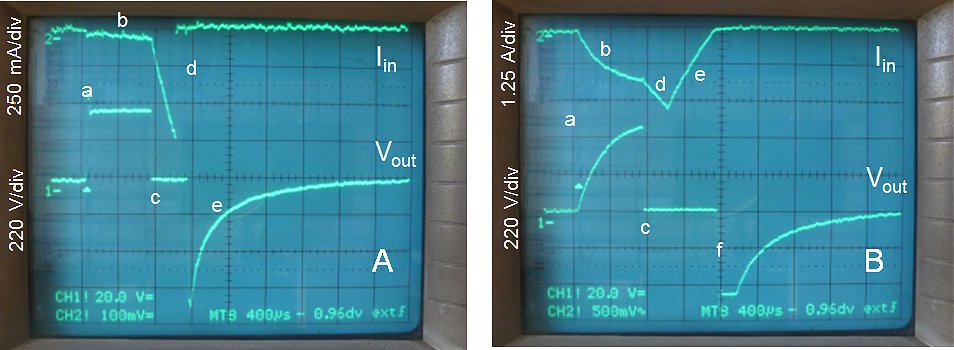

The first measurement that was performed was to pulse the transformer with shorted output at the maximum input pulse amplitude of 200 V, and a pulse duration of 1 ms. No protection circuit whatsoever was used. The left photo of Fig. 8.1 shows the current in the primary winding (upper trace), and the output voltage (lower trace). The right photo in Fig. 8.1 again shows the current in the primary winding on the upper trace, together with the current through the secondary winding on the lower trace. The peak input current is almost 4 A. The output voltage remains zero until the leakage inductance is de-magnetized, and then becomes negative during the de-magnetization of the core since the de-magnetization diode was used in the series with the load in the secondary circuit. The output current reaches a maximum peak value of 750 mA. This doesn’t seem much, but it represents a peak dissipation in the secondary winding of P = I^2*R = 324*(0.75)^2 = 182 W! The circuit servived the repeated short circuit test easily without the slightest problem.

Figure 8.2 Test circuit used to simulate flash-overs.

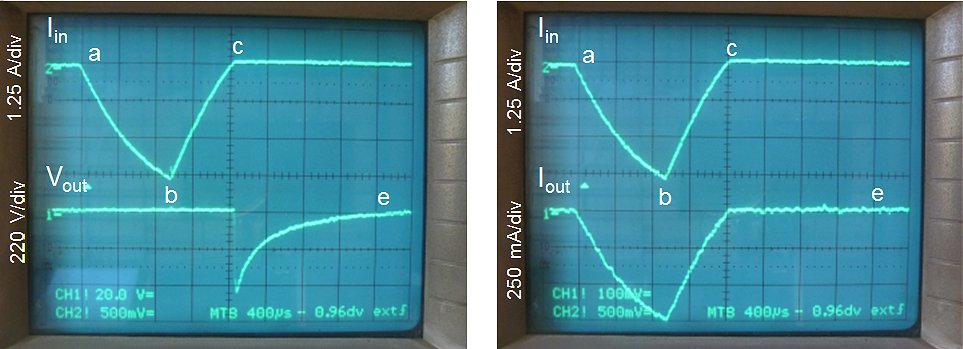

In reality a short circuit can also occur as a flash-over in the tube during operation. To test the ruggedness of the circuit against flash-overs the test circuit of Fig. 8.2 was used. The circuit contains an additional high voltage transistor T2 which short circuits the output of the transformer at approximately 800 us after the start of the high voltage pulse. The simulated flash-overs are shown in Fig. 8.3. In both cases the input pulse amplitude was adjusted so that T2 just would not go into avalanche. Figure 8.3A shows the flash-over simulation with unloaded output. The input pulse amplitude in this case was 100 V. The upper trace shows the current through the primary winding, while the lower trace shows the output voltage. Point “a” marks the beginning of the high voltage pulse. Since there is no load connected to the output, there is only a small current flowing as a result of the magnetization current through Lm which increases linearly with time (“b”). At point “c” the simulated flash-over occurs, and T2 closes forcing the output voltage to zero. This causes a sharp increase in current as the current starts to built-up in the leakage inductance Ls. At point “d” the high voltage pulse is over, and the core and leakage inductances de-magnetize quickly as a result of the zener/diode snubber.

Figure 8.3 Simulated flash-overs. A) under no-load condition @ Vin = 100V , B) under nominal load condition Rload = 1k5 @ 180 V.

Figure 8.3B shows the flash-over simulation in case the output is loaded with a 1k5 resistor, corresponding to a maximum output current of approximately 330 mA. Point “a” again marks the beginning of the high voltage pulse. With the load connected, there is a large current flowing which increases logarithmically due to the leakage inductance Ls (“b”). The output voltage also increases logarithmically until at point “c” T2 closes, resulting in a sharp increase in input current (“d”). At the end of the measurement pulse Ls demagnetizes through the zener/diode combination resulting in a linear decrease of the input current (“e”). After Ls has been fully de-magnetized, the core also demagnetizes through the zener/diode snubber resulting in a negative output pulse (“f”).

In reality the effect of a short circuit is even less serious since the output current is continuously monitored, similar to the over-current protection in the uTracer3. As soon as the output current exceeds a certain maximum value, an interrupt is generated which terminates the measurement pulse within micro-seconds. The fact that a transformer represents a huge inductance thus appears to be extremely beneficial to make the circuit short-circuit proof. Due to these inductances the currents in the transformer change at such a slow pace that, on the time scale of the measurement pulse, they cannot reach dangerous values, let alone when the active over-current protection circuit is used. This intrinsic robustness of the transformer pulse generator circuit is really a huge advantage!

In Summary

At this point it seems a good moment to make up the balance and come to a first tentative circuit for the anode/screen pulsed power supply. First a list of pro’s and con’s:

The pulsed high voltage supply circuit as I have it in mind at this moment is the simplicity itself. On the left we find the software controlled boost converter which is nearly identical to the boost converter for the uTracer3 with the exception of D2 which has been added to allow output voltages down to 0 V. The projected maximum output voltage is 200 V. D3-D5 take care for a quick de-magnetization of the transformer. The output current is measured as a voltage drop over current sense resistor R7. Since this voltage drop is negative it is inverted by OpAmp IC1. The actual output voltage is measured

Nice! An advertisement found on “marktplaats” (the Dutch version of eBay) offering 2 EL34 tubes with test report, taken with the uTracer!

| to top of page | back to homepage |

Sometimes one takes things too easily for granted. It has always been such a given factor to me that the output voltage of a boost converter can never be lower than the input voltage that I never questioned it. It was one of the reasons why in the version 3 uTracer the cathode of the tube is references to the positive supply voltage rather than to ground. For the transformer based circuit I was planning to solve it by inserting a zener diode with a voltage larger than the supply voltage in series with the output of the boost converter (see section 2). This solution has the obvious disadvantage that there is a kind of “dead region” in the output voltage range of the boost converter which has to be compensated for my means of some kind of calibration. Furthermore the voltage drop over the zener diode will not be constant, and vary a bit, especially for voltages just above the zener voltage.

Figure 9.1 Breadboard circuit used to test the “rail-to-rail” boost converter concept.

It occurred to me that a much better solution is to shift the zener diode one position to the left so that it makes part of the boost converter (Fig. 9.1). The breakdown voltage of the zener diode is chosen such that it is higher than the supply voltage. What happens is the following: when the boost converter is off, the zener diode is not conducting and the output voltage is zero. When the boost converter starts working the flyback pulses of the inductor will increase to such a voltage that the zener diode starts conducting, and a current will flow into the reservoir capacitor. Obviously the zener diode takes away some of the reserve of the boost converter since it dissipates some energy. Figure 9.1 shows the test circuit used to test the idea. In this example a very large reservoir capacitor of 1000uF / 200V was used. The input circuit produces pulses of 30 us. Without the zener diode it takes the boost converter seconds to charge the 1000 uF capacitor to 200 V. With the zener diode included this increases to 7 seconds. Both a BZT03C24 as well as the better available 1N5934BG work equally well. The 1000 uF is perhaps a bit of an overkill. In the final circuit perhaps a 470 uF capacitor will suffice. In that case the charging time will be halved.

”Rail-to-Rail” OpAmp?

One of the improvements that I have in mind with respect to the uTracer3 is to get rid of the negative power supply. In the uTracer3 the negative power supply is used for three things: the negative grid-bias circuit, the low-pass filter OpAmp which makes a DC signal out of the PWM generator for the grid bias, and the inverting OpAmps in the current sense circuits. I will deal with the first two later and concentrate now on the inverting OpAmps.

Figure 9.2 Breadboard circuit used to test the “rail-to-rail” OpAmp.

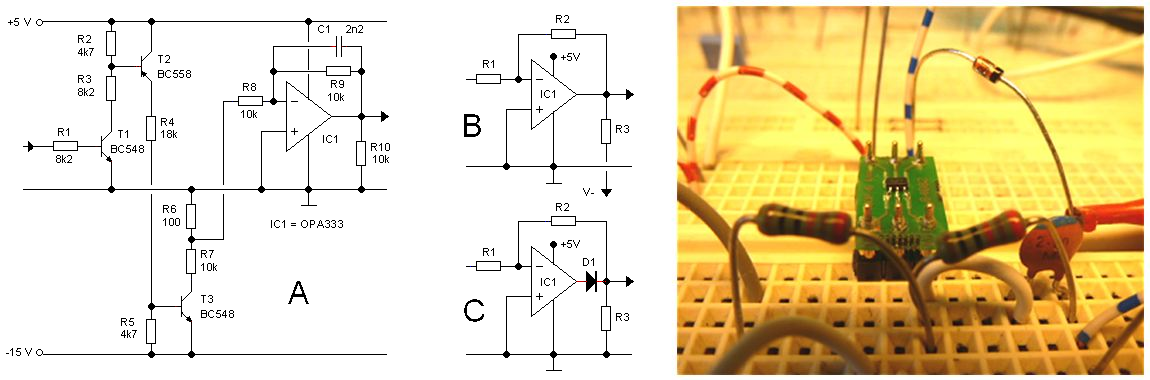

One of the drawbacks of having an enormous stock of components is that these components always tend to be “a bit out of date.” Obviously when a circuit is finally working, there is not a real motivation to go searching for modern alternatives. For the uTracer3 this happily coincided with my plan to use as little SMD components as possible, because most modern components are no longer available in “through hole” packages. The OPA333 is such a component. It is really a beautiful OpAmp with specification which a few years ago would have been unheard of. It is designed for rail-to-rail operation at a maximum power supply voltage of 5 V and an offset voltage of only 10 uV! The latter specification is only possible by using a special auto-calibration technique which zero’s the offset of the OpAmp every 8 us. The only drawback of the raltive small bandwidth (350 kHz) and slewrate (0.16 V/us) which is “on the edge” for this application.

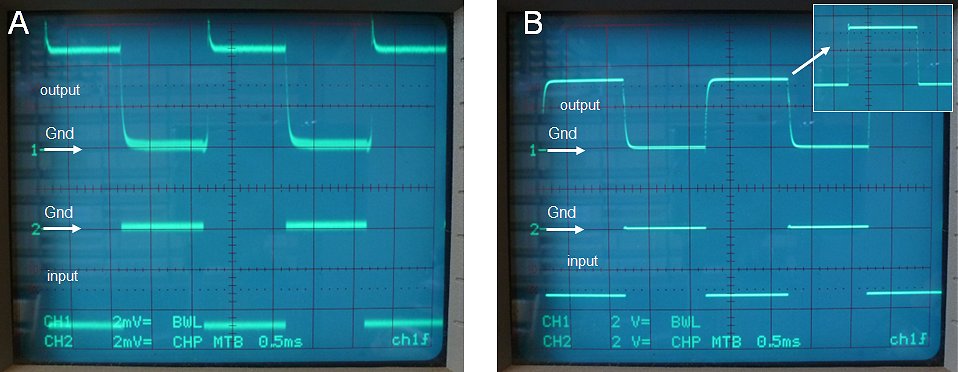

Figure 9.3 Behavior of the inverter circuit for small and large amplitude pulses.

“Rail-to-rail” however appears to be a relative notion. From the datasheet we learn that the specification for the minimum output voltage is approximately 15-30 mV above the lower supply voltage, ground (for a load resistor of 10k). Unfortunately 15 mV is quite a lot. If e.g. like in the uTracer3 we use a sense resistor of 18 ohm, then 15 mV corresponds to 0.0015/18 = 83 uA. The datasheet of the OPA333 explains that by connecting the output of the OPA333 to a negative voltage via a 40k resistor, also ground, and even slightly negative voltages can be obtained (Fig. 9.2B). A negative voltage was however something I was trying to avoid! A solution I had in mind myself was to include a (Schottky) diode in series with the output. The voltage drop over the diode would make it possible to include ground (Fig. 9.2C). A disadvantage is however that the output of the circuit would need a resistive pull-down. As it turned out, the diode circuit didn’t work out at all. I still do not exactly understand why, but with zero input voltage, the output voltage got stuck at about 270 uV?

It turned out that a simple pull down resistor of 10k to ground resulted in an output voltage of only several uV (Fig. 9.2A). To test the OpAmp in a circuit which approaches the real circuit as much as possible, the test circuit of Fig. 9.2A was built. The input of the circuit is connected to a 5V square wave signal source set to 500Hz. The pulse is transferred to T3 which pulses voltage R6/R7 down to -15V. By selecting the proper ratio for R6/R7 negative voltage pulse of any desired amplitude can be obtained. Fig. 9.3A shows both the input of the inverting OpAmp (taken at node R6/R7) and the output for an input pulse of only a few millivolts. The output tracks the input very well. Also for large signal with an amplitude of several volts, the circuit behaves very well. The slow rise and fall times at the output are for the largest part caused by the integrating capacitor C1. When C1 is removed the slopes become much steeper (inset), but the limited slew-rate of the OpAmp can be clearly observed.

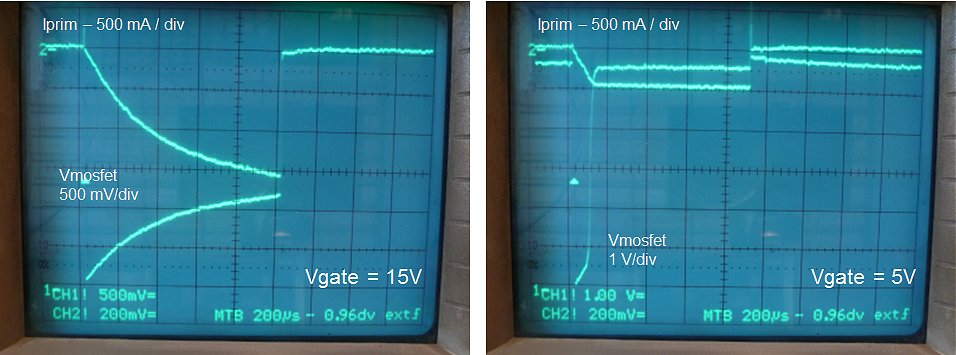

”Dynamic on-resistance of the MOSFET switch” OpAmp?

With the transformer test circuit of Fig. 4.3 in place, I took the opportunity to check the on-resistance of the MOSFET switch at the primary side of the transformer. The on-resistance is not particular critical, but obviously it should not be too high, and after my experience with the dodgy IRF840 transistors in the uTracer3 I just wanted make sure I wasn’t overlooking something here. In the transformer experiments so far I used a PSMN070-200P. This transistor has a breakdown voltage of 200 V, which is a bit too low if we want to use the diode/zener snubber. In that case a higher breakdown voltage of at least 400 V is required.

Figure 9.4 Determination of the dynamic on-resistance of the MOSFET switch.

Figure 9.4 shows a detail of the pulse test circuit. It allows for the simultaneous measurement of the current through the MOSFET - which appears as a negative voltage pulse over sense resistor R2 - and the voltage drop over the MOSFET. The ratio of the two gives the dynamic on-resistance during switching. To avoid overload artifacts of the scope, a simple clamp circuit consisting of R3, D3, and D4 was used.

The scope trace in Fig. 9.4 shows the voltage at the drain of the MOSFET with respect to ground. Before the pulse, the drain voltage is approximately 150 V, the supply voltage in this case. During the pulse the voltage drops to (nearly) zero. After the pulse the transformer de-magnetizes by developing a reverse polarity over its primary turn which opens the 172 V snubber zener diode, resulting in a drain voltage in excess of 300 V.

Figure 9.5 Voltage drop over a “doggy” IRF840 at a gate pulse amplitude of 15 V (left) and 5 V (right).

Figure 9.5 shows the same measurement, but in this case the vertical scale has been magnified to 0.5 V/div (lower trace) while the voltage drop over the current sense resistor has been added (upper trace). In the example of Fig. 9.5 one of the “doggy” IRF840 transistors was used. In the left photo a gate voltage amplitude of 15 V was used, while in the right photo a gate voltage pulse amplitude of 5 V was used. Proper operation at 5 V is important because I want to use a single power supply for the next generation tube testers. At a gate pulse of 15 V the transistor works fine with an on-resistance of approximately 1 Ω, which is comparable to the on-resistance of “good” IRF840 or a 07N60C3. However, at a gate voltage of 5 V we see that the current through the transistors saturates at 0.5 A, and that the voltage over the switch explodes, whereas for a 07N60C3 the on-resistance at 5 V is only marginally higher than at 15 V (not shown).

To wrap up, a simple and cheap 07N60C3 has an on-resistance of slightly less than 1 Ω at a gate pulse amplitude of 5 V under a maximum load condition of 1.5 A. The high breakdown voltage of 650 V allows for fast de-magnetization of the core.

| to top of page | back to homepage |

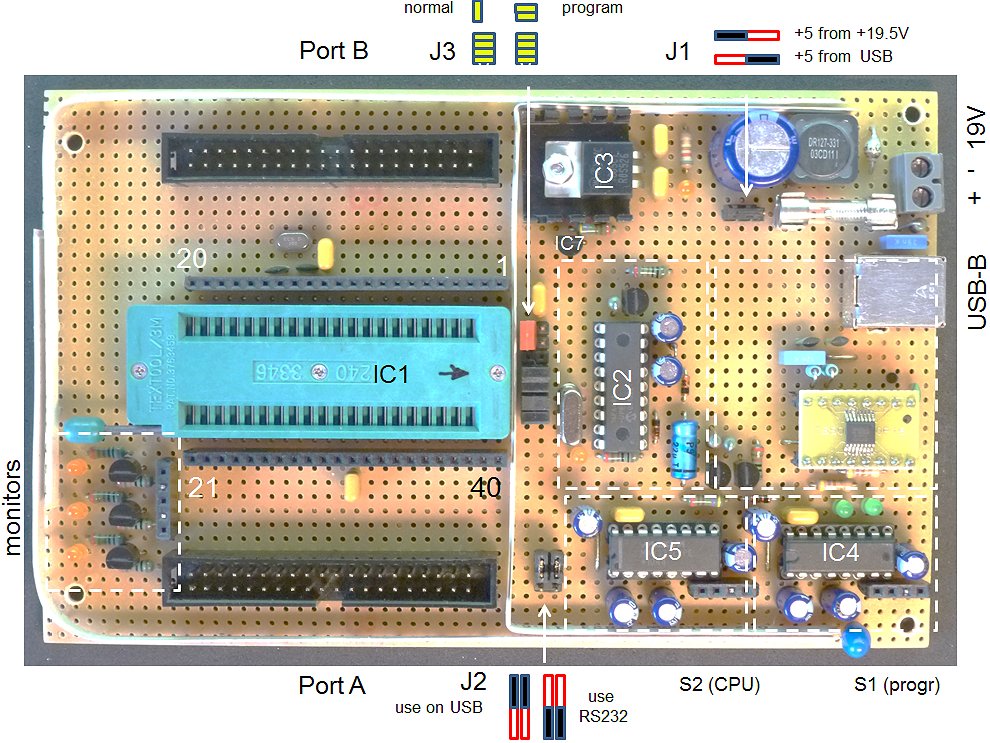

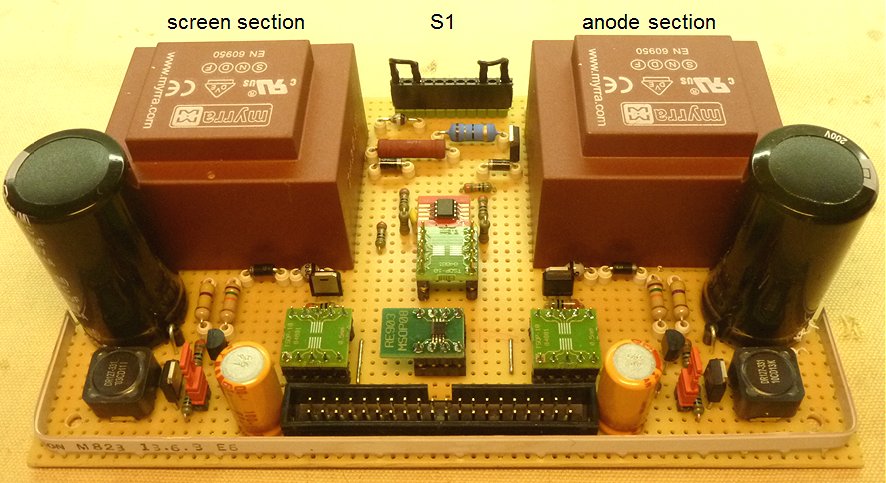

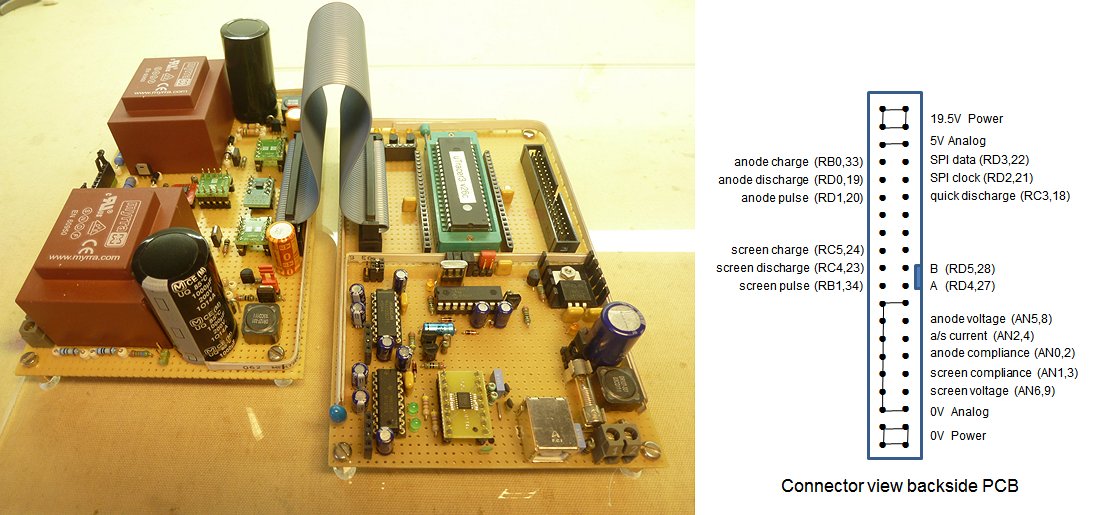

The first module that was built was the CPU module. I designed it into a stand-alone board so that it could be used in different configurations and experiments. The heart is again the 16F874 processor. All 40 pins of the processor can be probed via a female connector adjacent to the pins of the processor. There are three monitor LEDs La,Lb,Lc with amplifying transistors which can be used to monitor the level of any of the 40 pins of the processor.

Figure 10.1. Circuit diagram of the CPU board

For the serial interface a standard MAX232 is used. I had never used one of the USB-to-serial chips from FTDI myself, so this board was a good opportunity to experiment with it. I used an FT230XS-R (Mouser: 895-FT230XS-R) from FTD in a tiny SSOP package. The chip is made in 3V3 CMOS. It has however 5V tolerant IO’s for the USB port and can be powered directly from the 5V USB port. In this mode it generates its own 3V3, power supply. Unfortunately the IO’s towards the processor are also 3V3 so that level shifters are needed to interface it with the PIC processor. I used a simple diode clipper consisting of D4, R9 to clip the 5V Tx signal of the PIC to 3V3. Two discrete transistors T2, T3 are used to bring the output level of the FT230 to standard TTL levels. This arrangement appears to work perfectly for my purpose.

Figure 10.2. The CPU board

For the programing of the uTracer3 I used my trusted “Wisp648” PIC programmer designed by Wouter van Ooijen. I have used this programmer for years to my complete satisfaction. The programmer is so small and simple that I decided to include it onto the CPU board so that it doesn’t need to be connected to the separate programmer all the time. The programmer consists of a 16F648 (IC2) which uses a charge pump to generate the required 12 V programming voltage. The programmer has its own MAX232 (S1) for serial communication. Jumper J3 allows the 16F874 to be connected to the on-board programmer, the plug of my external programmer, or to run in normal mode.

In the uTracer3 a 7805 was used both for the 5V power supply, as well as for the reference voltage. This increased the number of calibrations necessary. For the new design I have included a real voltage reference in the form of an LM4040D50ILPRE50 (Mouser 595-LM4040D50ILPRE3). This is an integrated 5V precision reference in a TO92 envelope which simulates a zener diode. Resistor R13 biases the reference to a current of approximately (19.5-5)/4.7 kΩ ≈ 2.5 mA.

Port A and Port B will connect to two PCBs with the analog electronics, one board containing the anode and screen supply, while the other board will contain the grid and heater supply.

Parts of this page were written during our beautiful 2013 summer holiday to the Dutch coast in Cadzand in the extreme south west of Holland.

| to top of page | back to homepage |

Figure 11.1 Schematic diagram of the uTracer4.

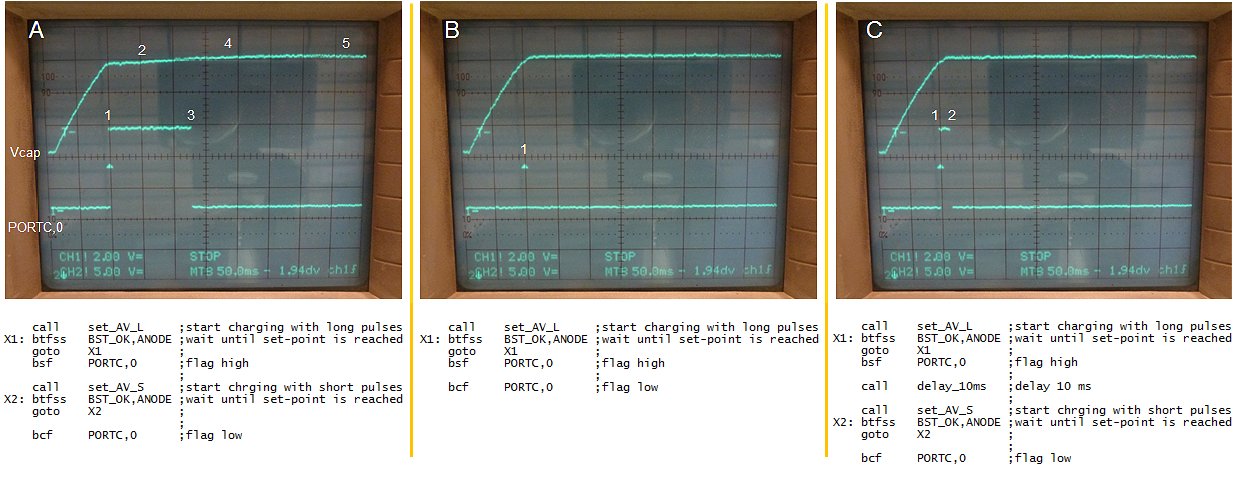

Figure 11.1 shows a schematic diagram of the uTracer4 limited to the essential blocks needed for this section. On the left hand side we start with three input voltages Ua, Us and Ug, with the subscripts obviously standing for anode, screen and grid. These three input voltages are subsequently “up converted” by transformers, resulting in the voltages Va, Vs and Vg which are applied to the tube, resulting in three currents Ia, Is, and Ig. The transformer unfortunately is a lossy component. This means that the ratio of the output voltage Vx/Ux is not constant and only depending on the transformation ratio, but it also depends on the current! The current(s) in turn are depending on the characteristics of the tube (which is unknown), and on the voltages applied to the tube: Va, Vs, Vg. In mathematical form we can write that each of the three voltages Va, Vs and Vg as a function of the voltages Ua, Us, and Ug (Figure 11.1 right). The question now is, which voltage triplet Ua, Us, and Ug needs to be applied in order to obtain the set-point values for Va, Vs, and Vg?

Since the characteristics of the tube are unknown, there is no way to analytically derive formulae for Ua, Us, and Ug. The best we can do is use an iterative scheme whereby the correct values are determined through a series of “educated guesses.” There are several way how this can be done. In this section I want to discuss what I think is the most plausible method at this moment. I am not sure how to continue from here. One possibility is to build the hardware and to test the algorithms, the other possibility is to simulate the hardware using models for the

hardware and the tube, and in this way to study and test the algorithms.

Linearization

To improve the readability of this section we will use a kind of shorthand writing whereby U represents the vector U = (Ua, Us, Ug, and V the vector V = (Va, Vs, Vg). In the simplest scheme, we just try different values for U until the resultant V is close enough to the desired set point value Vset. If we had only one knob to turn, that would not be so difficult, however, in this case we have three knobs to turn (Ua, US, Ug), and each of these knobs influence each other! So we need to have some kind of clever method to reduce the number of “guesses”. A possible suitable method is through linearization of the problem.

Figure 11.2 Finding your way on an unknown curve in one dimension by linearization.

Figure 11.2 recalls the idea behind linearization. Suppose that we have some kind of transfer curve, indicated by the lightly colored line. We do not know the shape of the curve, but by applying a voltage U to “the device” we can obtain the corresponding value of V. We furthermore know that the curve does not contain any strange features such as discontinuities or singularities. We start the iteration procedure by making two best (“educated”) guesses for U. These points are indicated in Fig. 11.2A as points 1 and 2. Through these two points we now construct a straight line (Fig. 11.2B). With this straight line known we can now derive a better guess for U, and testing this value of U will give a new point on the curve (point 3), which is hopefully a bit closer to the desired set-point value (Fig. 11.2C). The whole procedure is repeated again with the two points which are now closest to the set-point value (Fig. 11.2D). Note that this doesn’t automatically imply the last two points! In Fig 11.2E e.g. the line is constructed through points 2 and 4, resulting in point 5. The procedure is repeated until abs(V-Vset) < error.

This simple example illustrates the linearization method for only one dimension. In two dimensions, a three dimensional landscape of hills and values is approximated by a flat plane. In this case we need three best guesses. Also in three dimensions the same procedure can be used, be it that it is very difficult to imagine “a three dimensional flat space”! Nevertheless, the math works just fine. Note that in this case we need (in principle) four best guesses!

So in the vicinity of the point of interest, we can linearize the unknown equations of Fig. 11.1 as:

Using the “shorthand” matrix notation:

This can be simplified to:

We now use our knowledge of the system to simplify this a bit. We know that when U=0 (Ua=0, Us=0, Ug=0) the output voltages are zero, so V=0. This means that the constants Ka, Ks and Kg in the linearized equations are 0, so K=0. The equation now reduces to:

With the elimination of the constant term, we only need three points to fully determine C. The iteration process therefore starts with a “list of points” containing three “best guess” points = {(U1,V1) (U2,V2), (U3,V3)}. How these points can be obtained will be discussed later.

The iteration process is straightforward and closely follows the iteration process for one variable that was outlined above. We start with a list of points. At the start this list will only contain three points: “the best guesses”. During the course of the iteration process, the list of points will grow. From the list of points three points are selected which are “closest” to the set point voltage vector. These three points are used to linearize the transfer function resulting in matrix C. Using the inverted matrix C now a new vector Un+1 is obtained. Voltages Un+1 are set in the hardware and a new measurement is performed resulting in voltages Vn+1. At this point it can be that Vn+1 is already accurate enough. In that case the iteration process is stopped. If Vn+1 is still not accurate enough (Un+1,Vn+1) is added to the list of points, and a new iteration loop is started.

“Closest” is hardly a mathematical term, but the figure above shows how the distance between a certain voltage (vector) and the set-point voltage (vector) can be defined. We can calculate the distance in absolute value, but in that case higher voltages will be dominant over the lower voltages. It therefore is perhaps a good idea to weight the voltages differences by the average values, so that a relative distance is obtained. For the stop criterion we simple calculate the relative error of the three separate voltages. When the relative error of all three voltages is smaller than a certain value, the iteration process is stopped.

Calculating matrix C

Calculation of matrix C from three points is straightforward and really high-school stuff. Nevertheless, just for completeness and documentation here is how determination of C reduces to the solving of three sets of equations which can be solved by a simple Gaussian elimination procedure:

In order for the solver strategy described above to work fast, it is important that the starting points are close to the final solution. There are several ways to generate a suitable set of starting points. One strategy could be to start from the previous measurement point on the curve. We will talk about this possibility later. However, when it is the first point on to be measured, no data at all is available. In that case we can use our knowledge of the system. We know that the output voltage of the transformers with reasonable precision can be written as:

With n the transformation ratio, r the equivalent resistance of the transformer referred to the output, and i the output current flowing to the tube terminal. Unfortunately there is always a small error we make due to non-linearities in the circuit or losses which can not be accounted for by r. In the above equation these inaccuracies are accounted for by the error term δ(u,i), which – as indicated - in general is a function of the bias conditions.

My hesitation stems from the fact that in case the currents are very small, or negligible, especially the last two points will almost coincide because I=0 and Δ was determined during the first measurement, so that the three points are not very suitable as a base for a reliable linearization. On the other hand, it can very well be that in case the currents are very small, the set-point value for V is already reached during the first three guesses. After every guess it is therefore necessary to check if the “guessed point” satisfies the accuracy criterion.