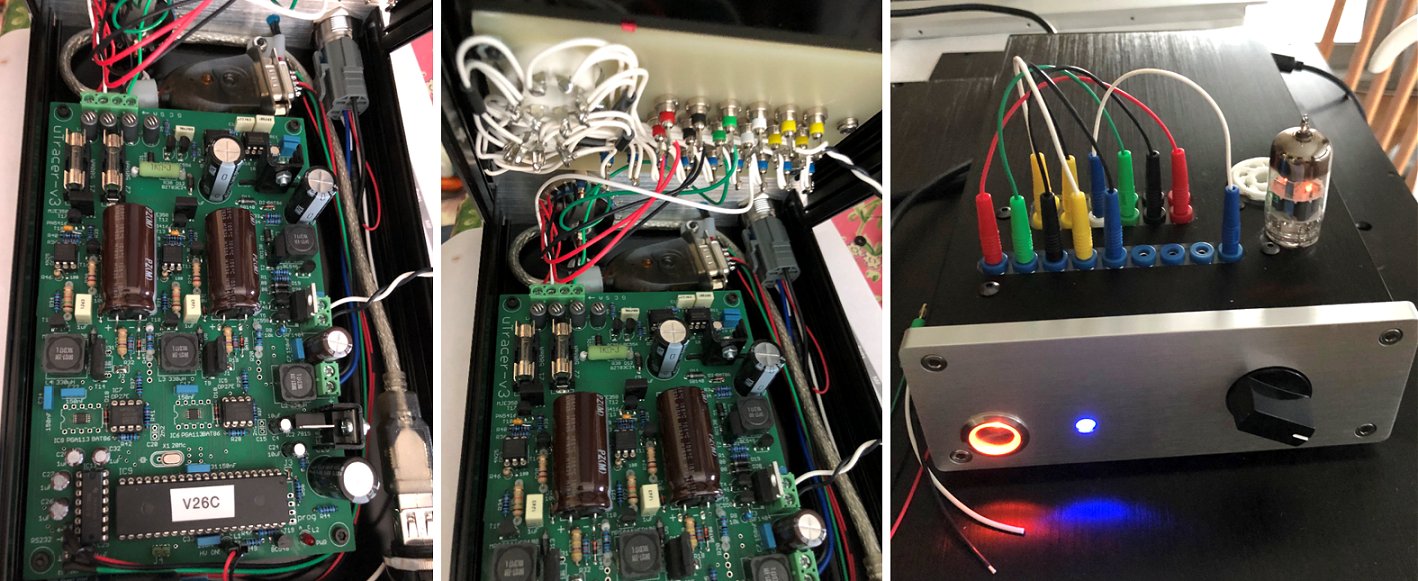

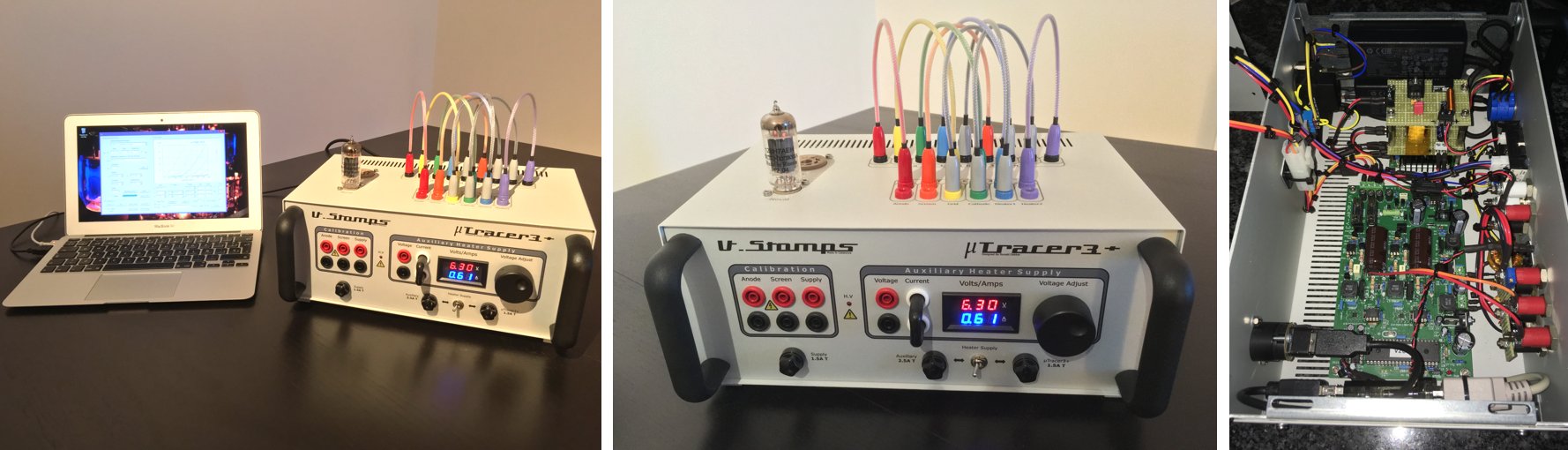

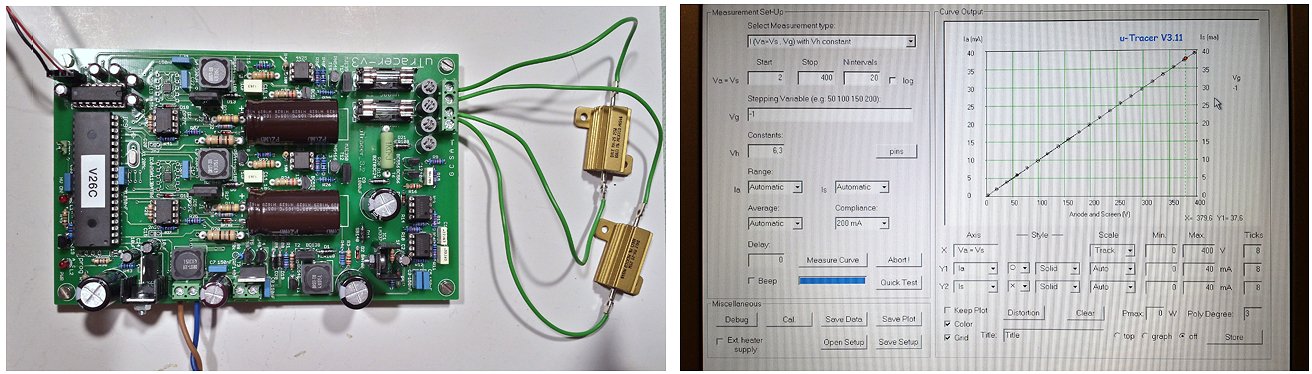

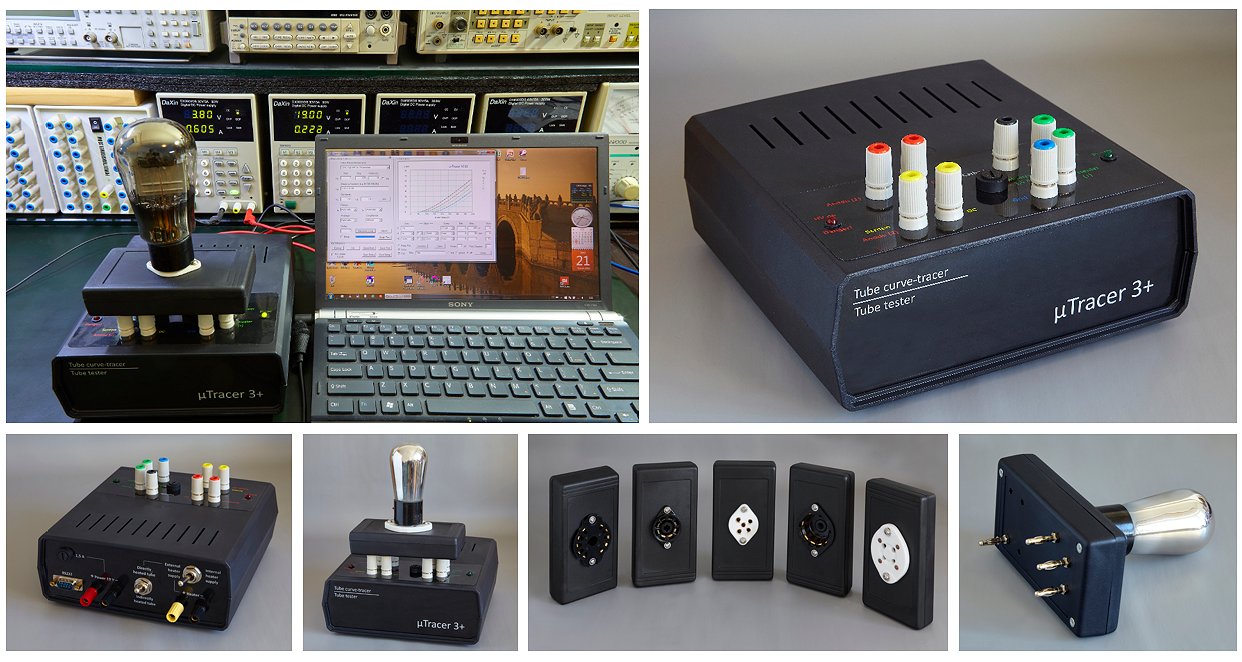

uTracer3 in service:

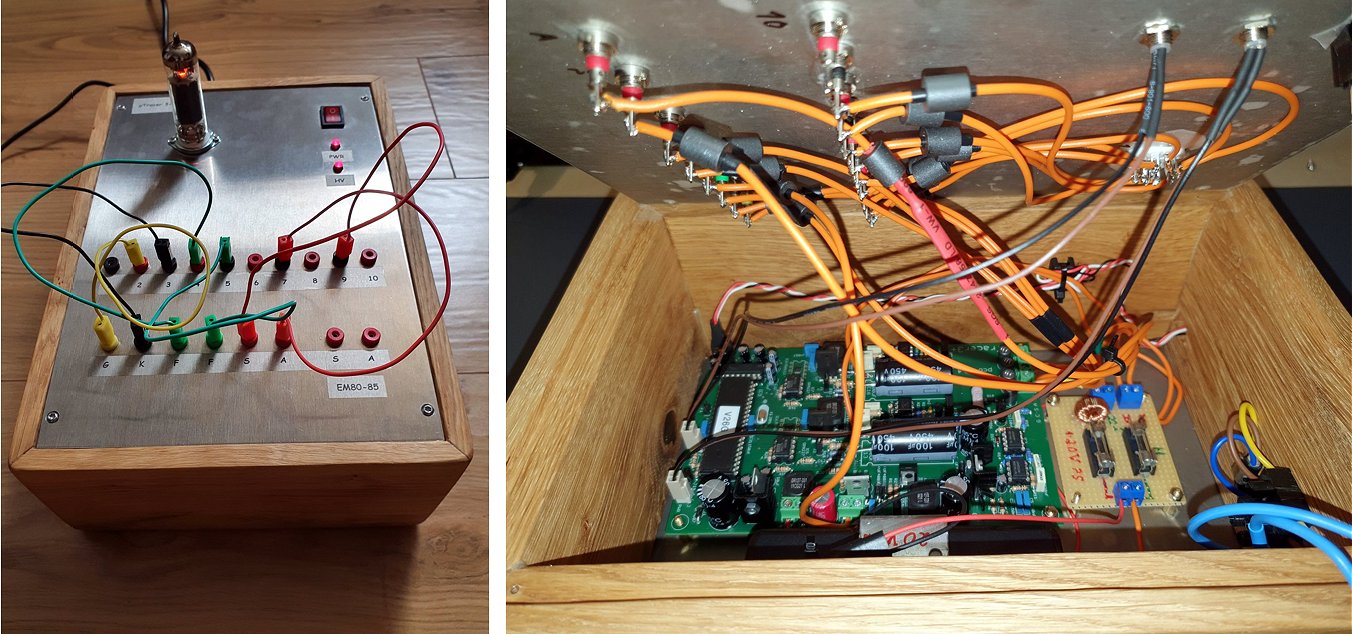

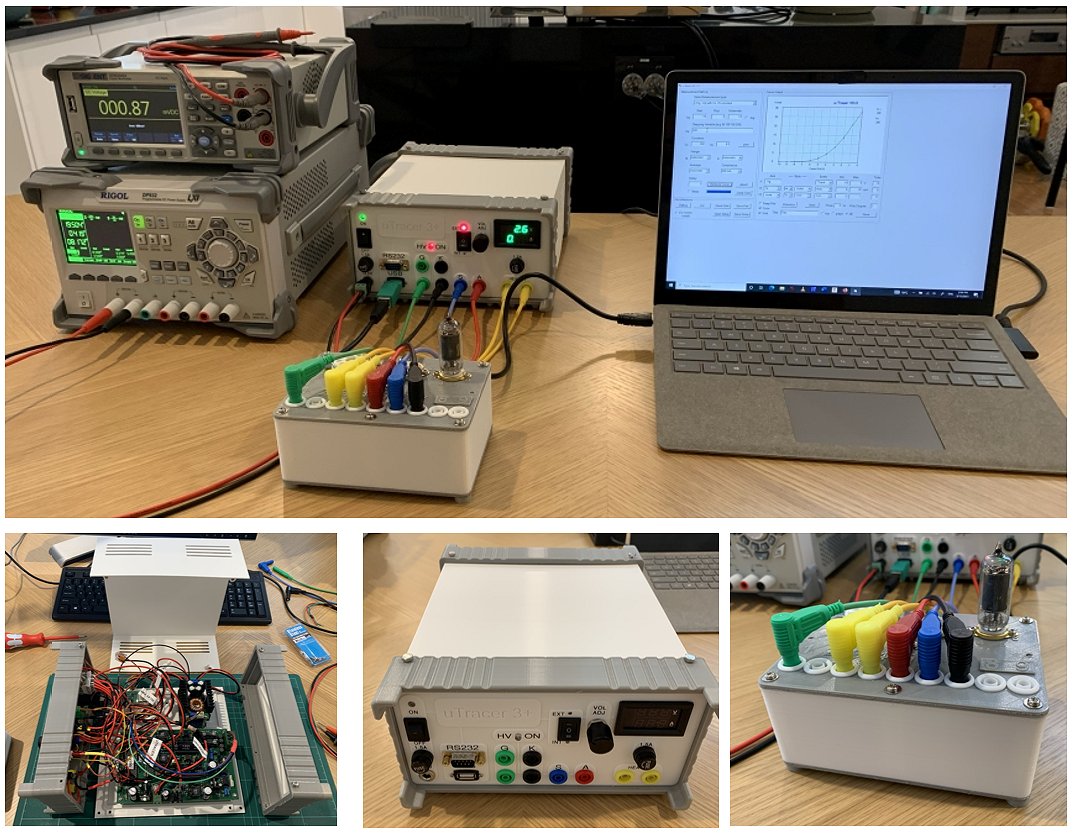

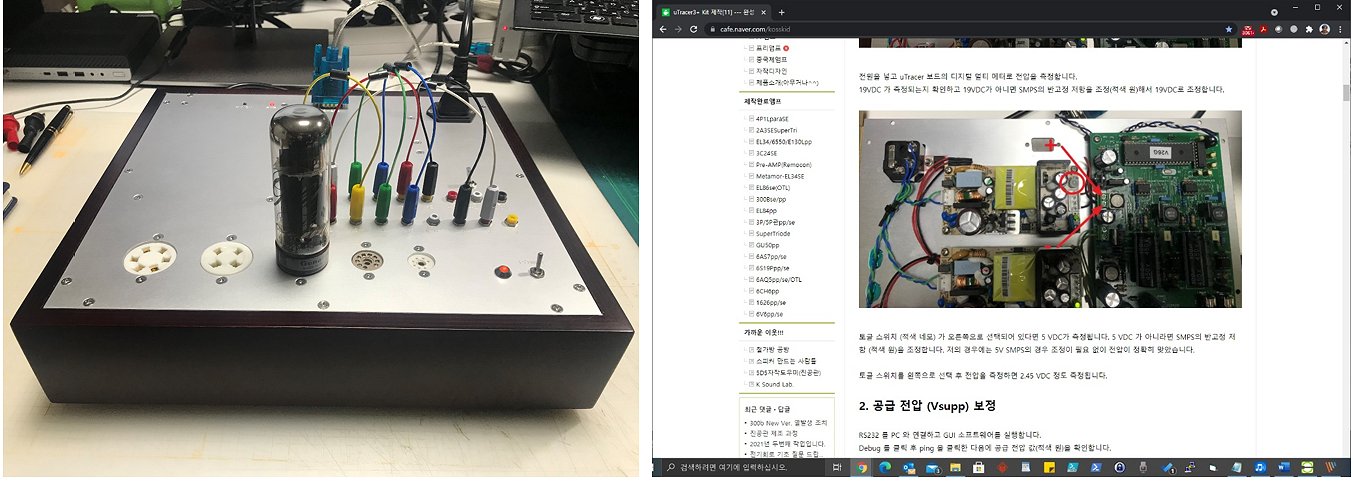

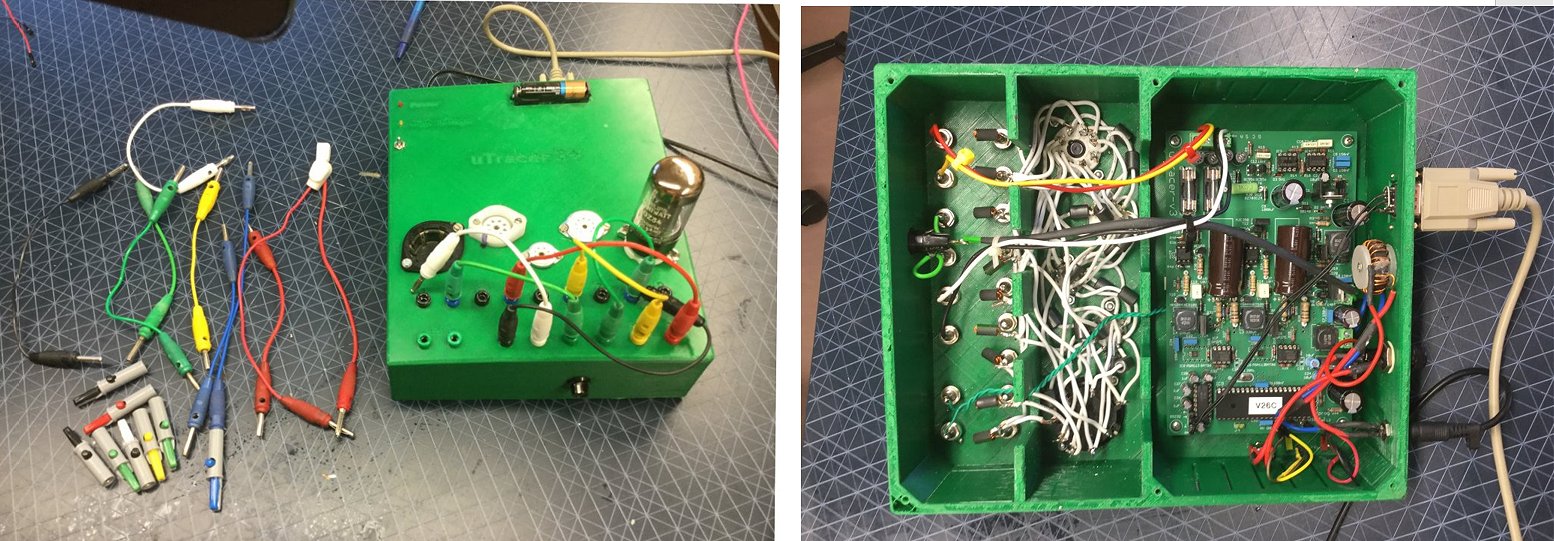

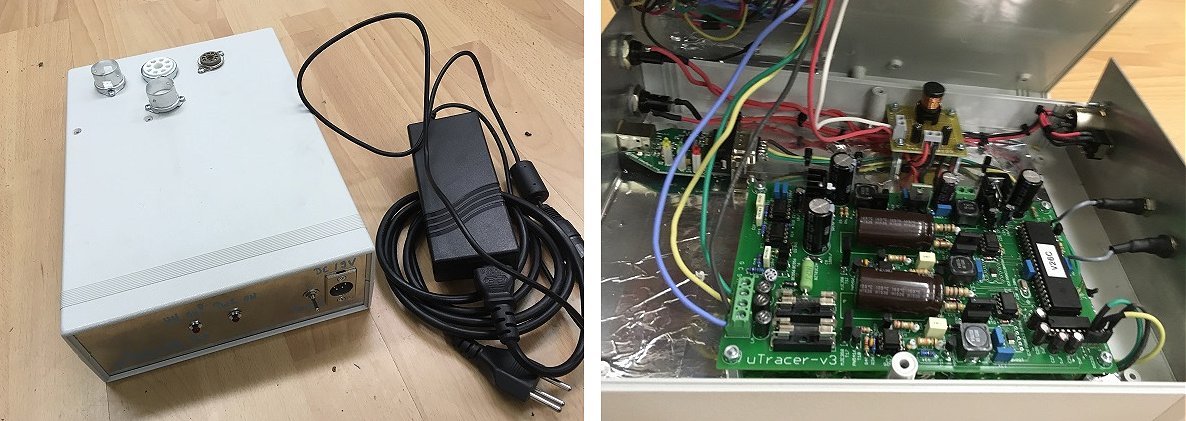

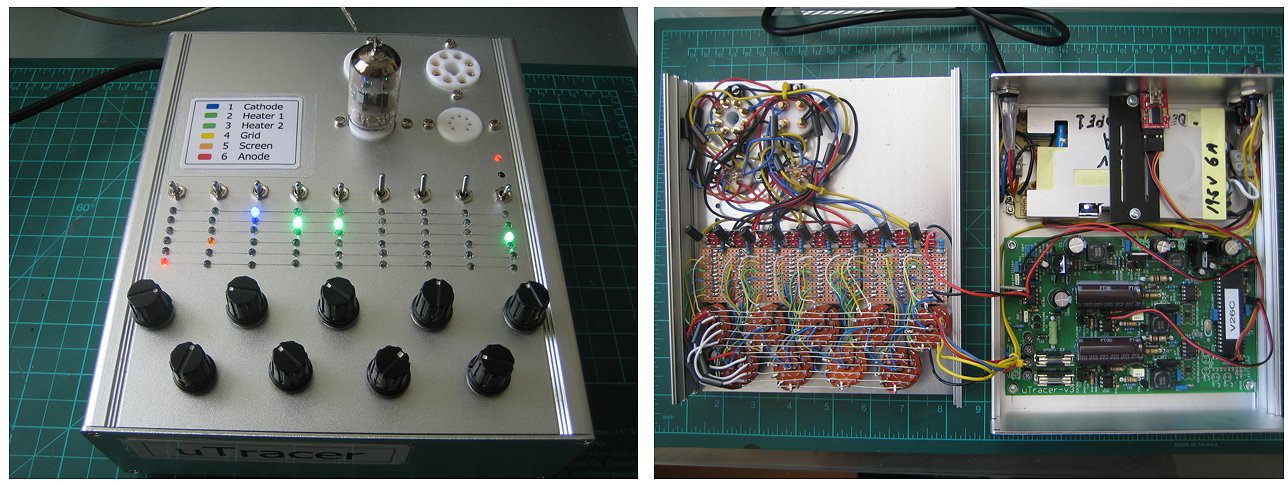

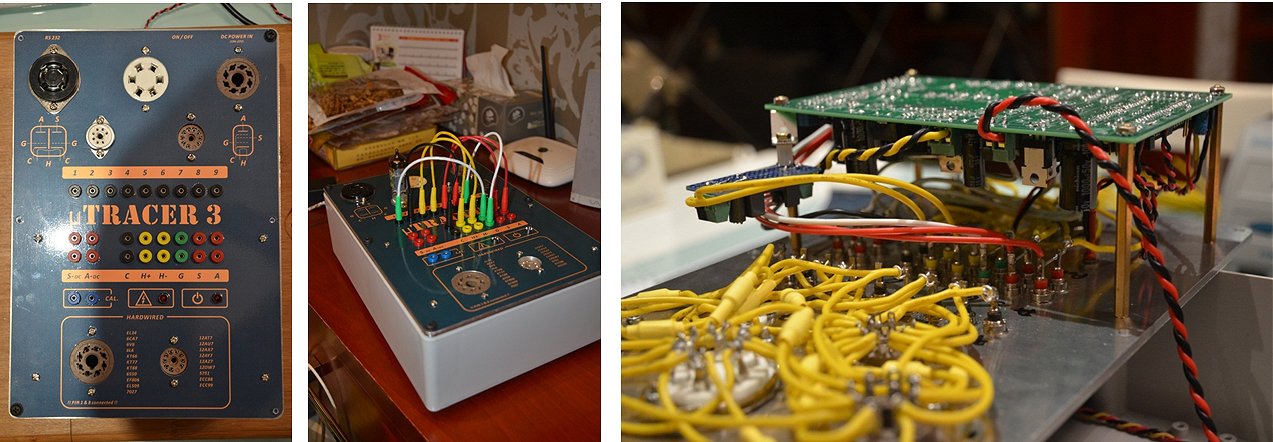

25th of December 2025, On Christmas Day 2025 Gerhard sent me a few pictures of his awesome uTracer3 and he is already looking forward to the uTracerNXT!

Hi Ronald,

Looking forward for the uTracerNXT in 2026.

I think you were planning keeping PCB size and mounting holes similar to the uTracer 3+ , which is awesome.

I recently 3D printed this great case and planning to put the uTracerNXT into it.

All the best,

Gerhard

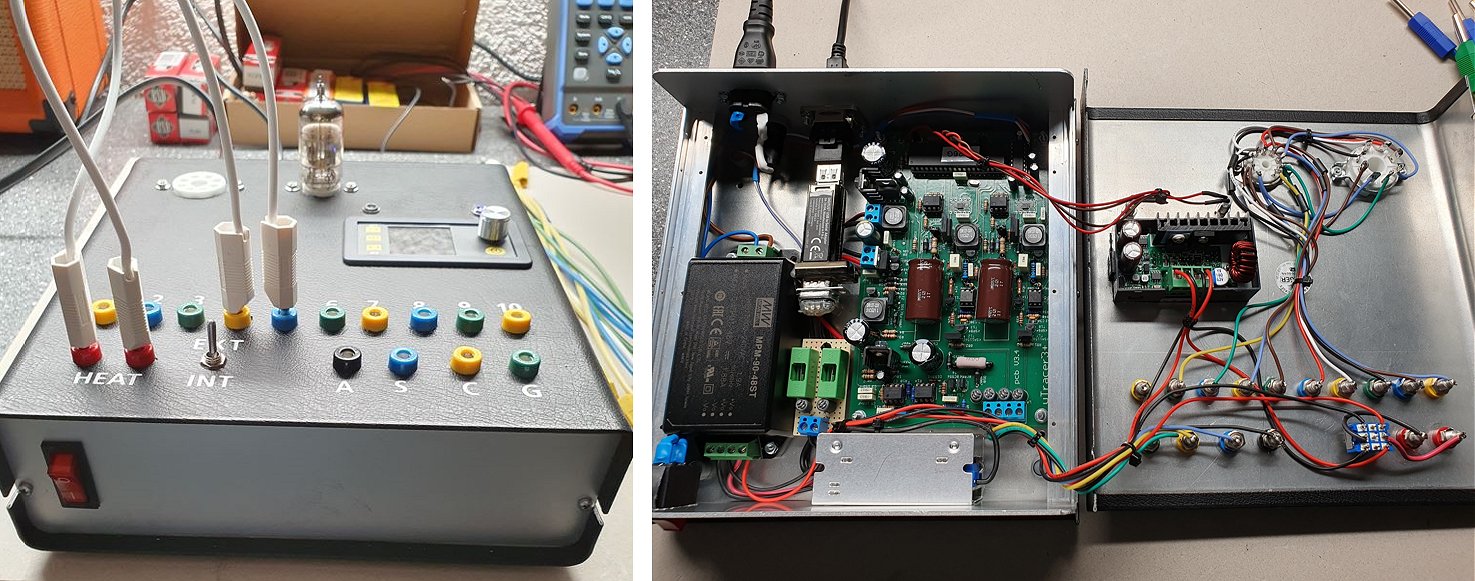

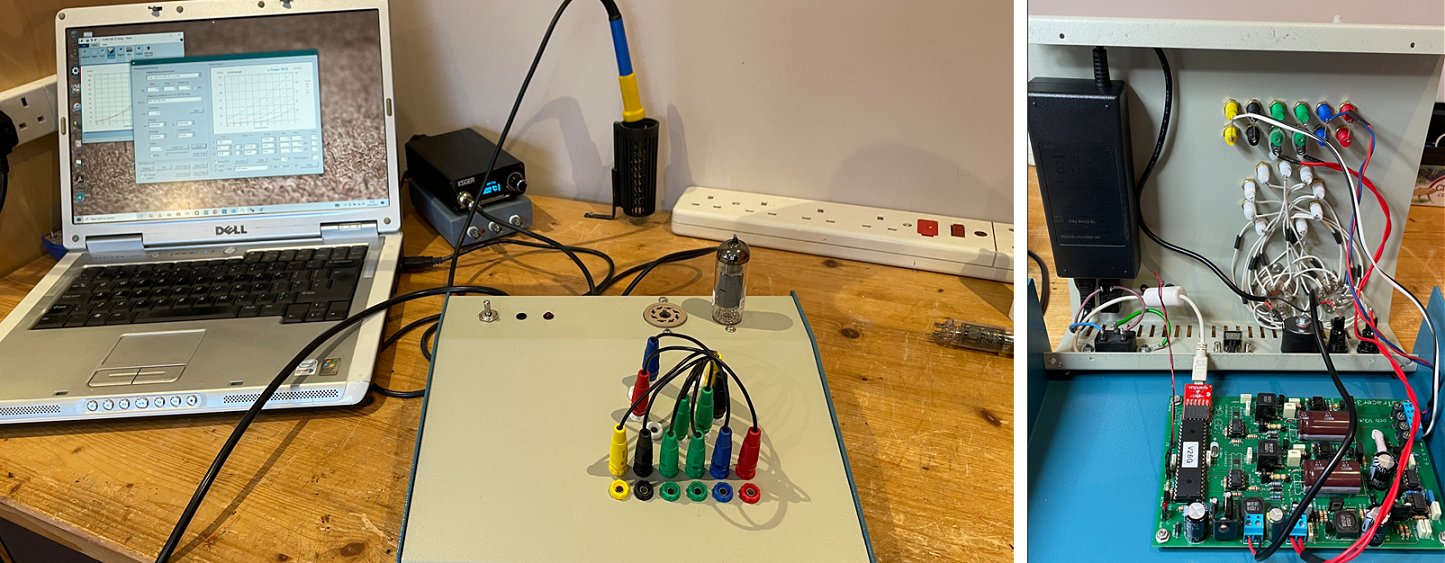

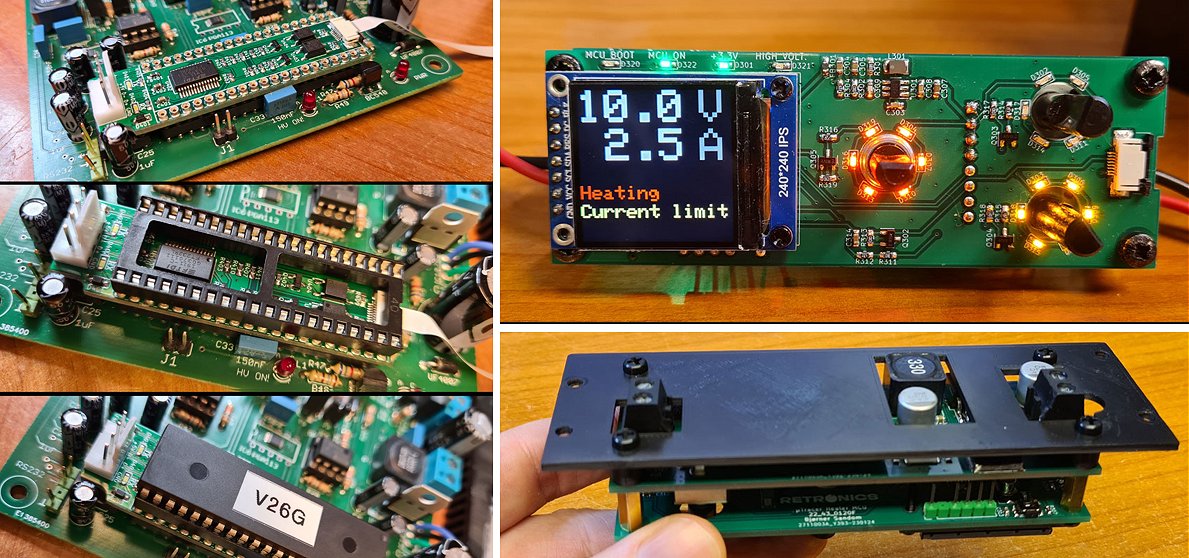

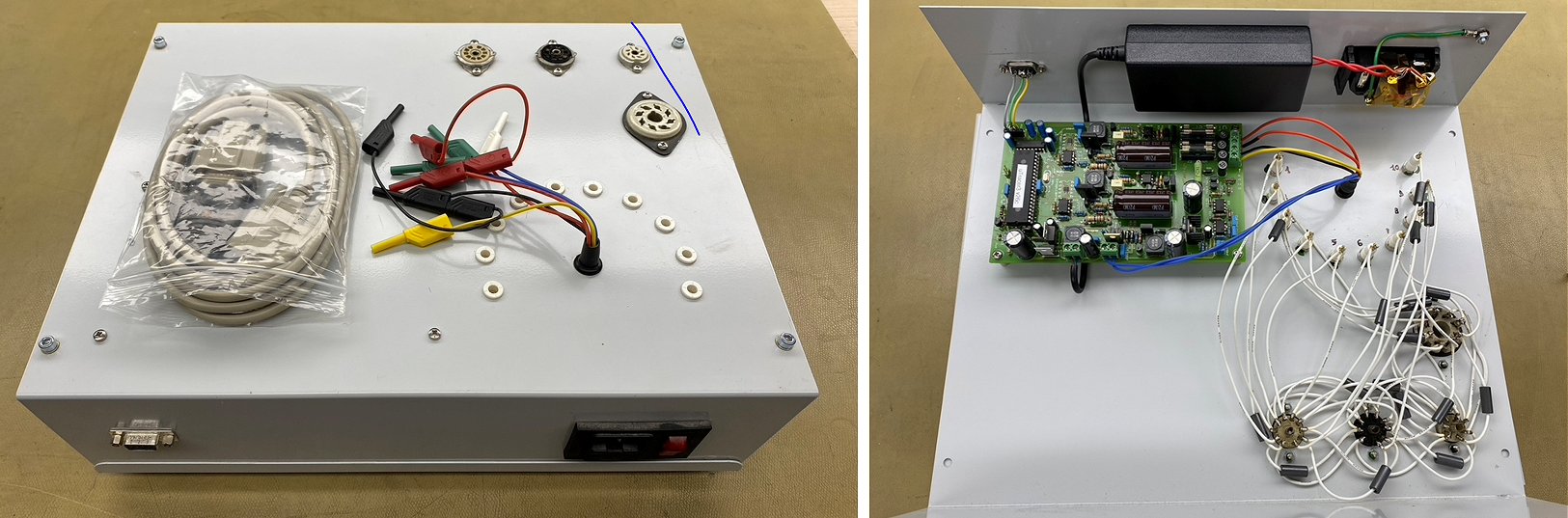

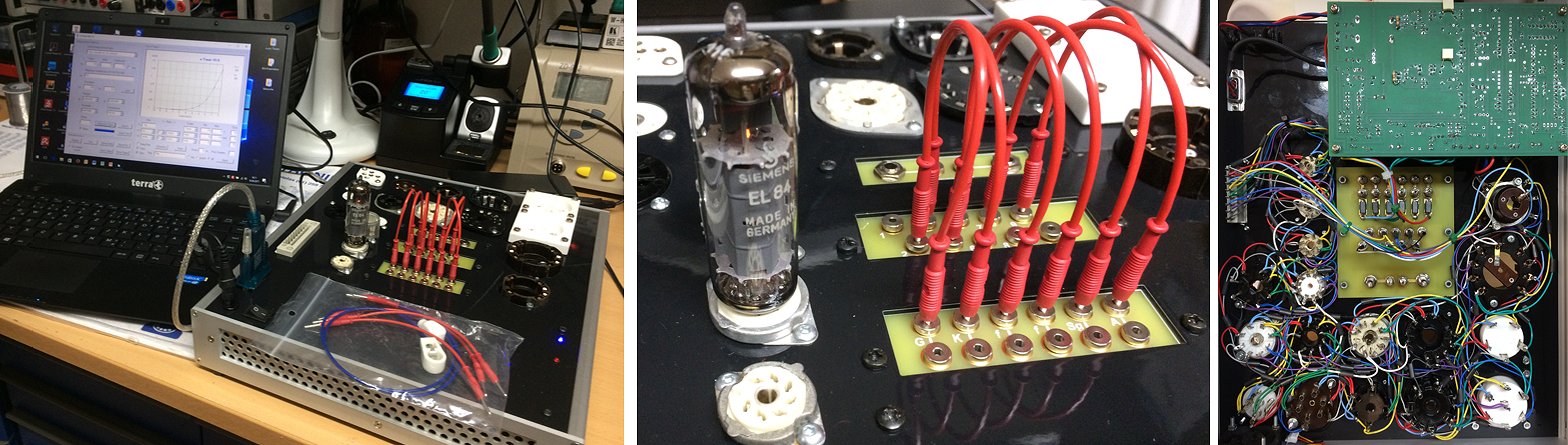

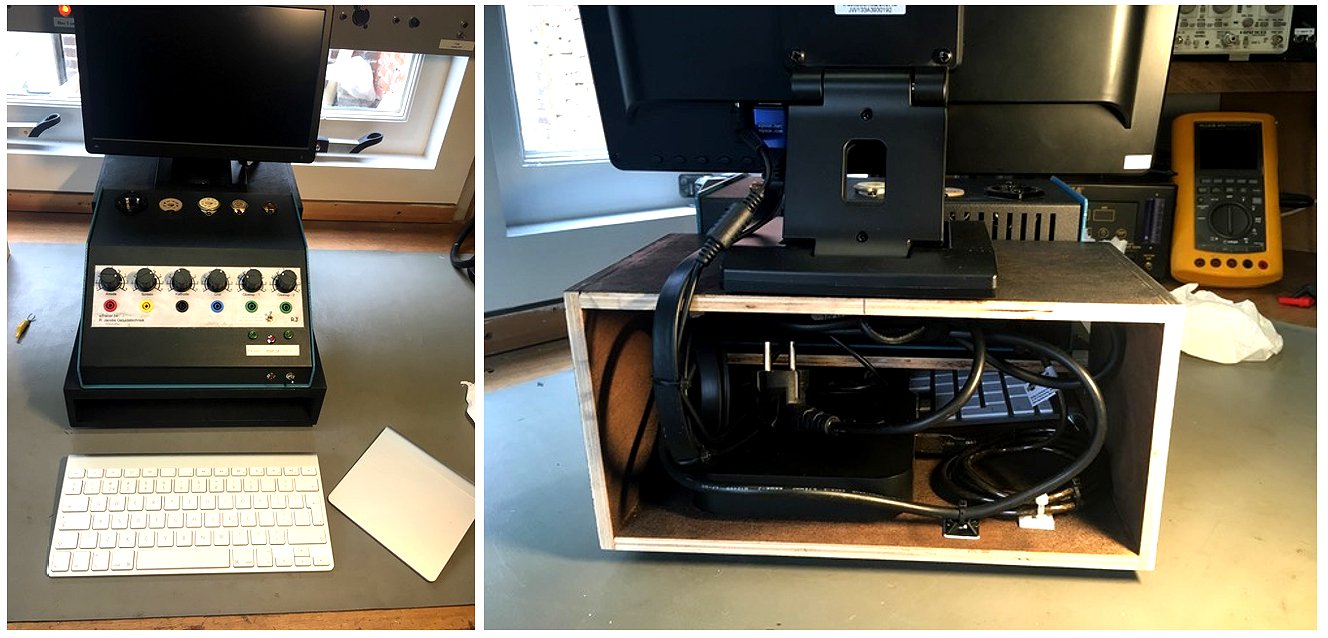

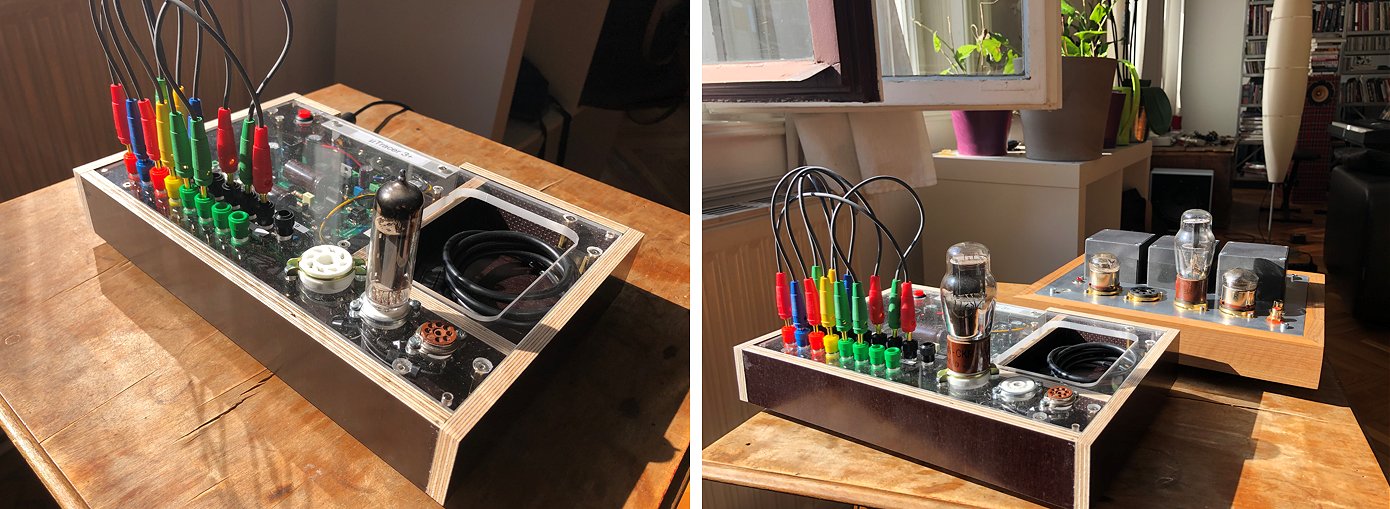

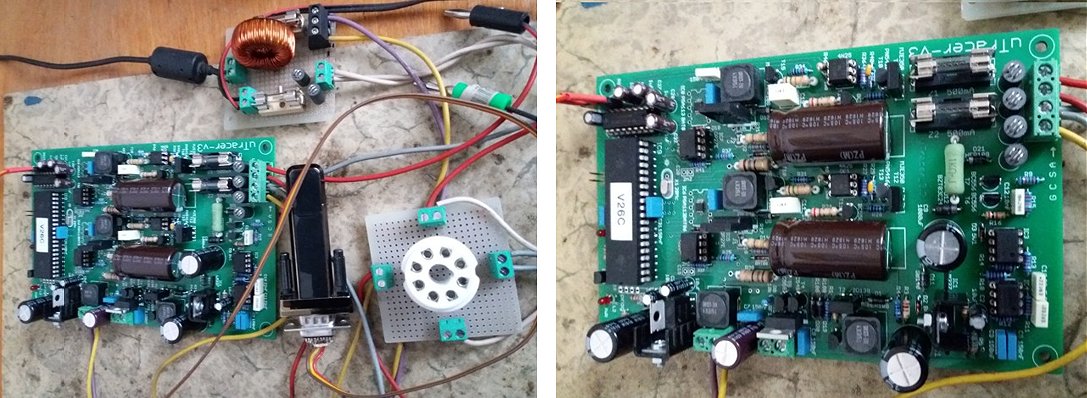

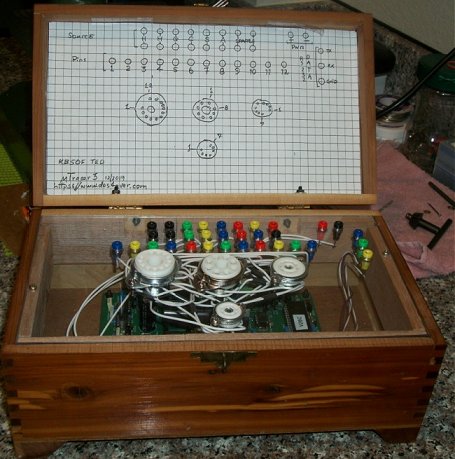

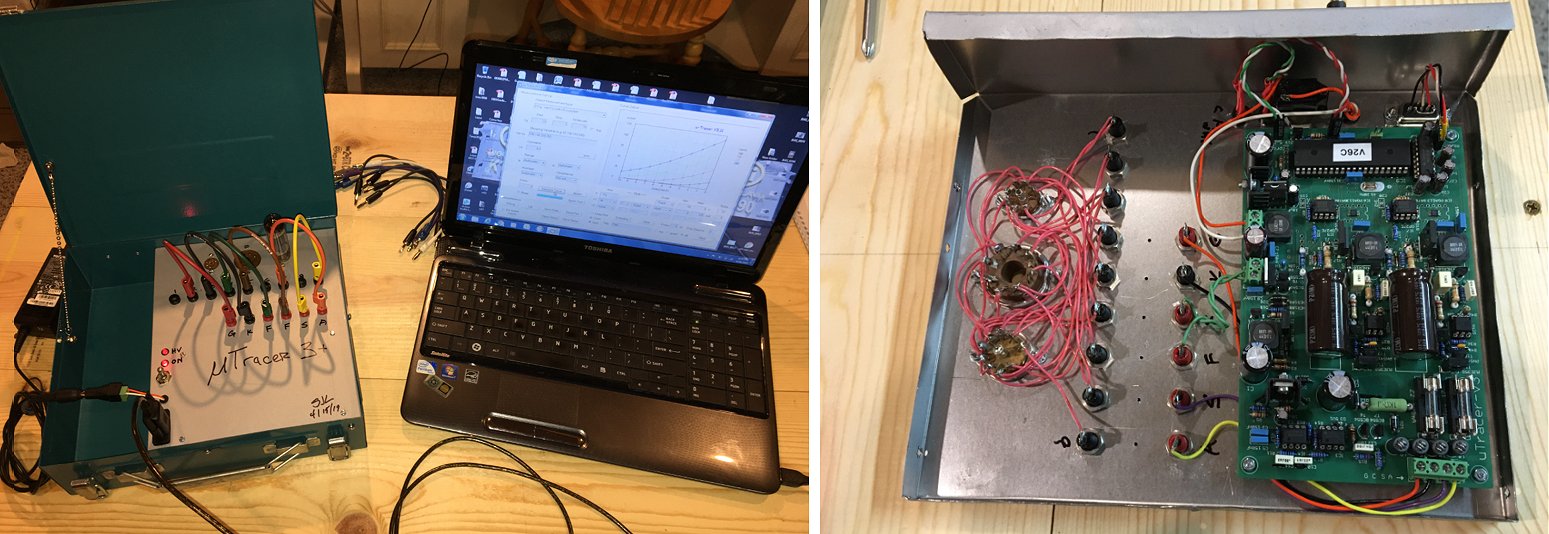

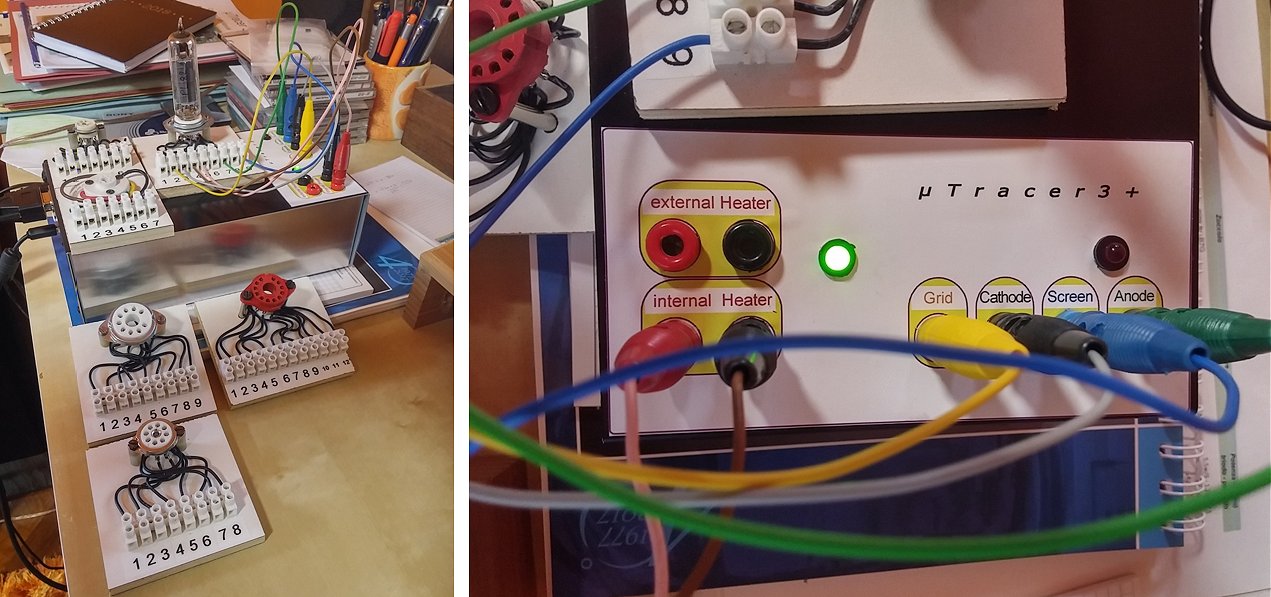

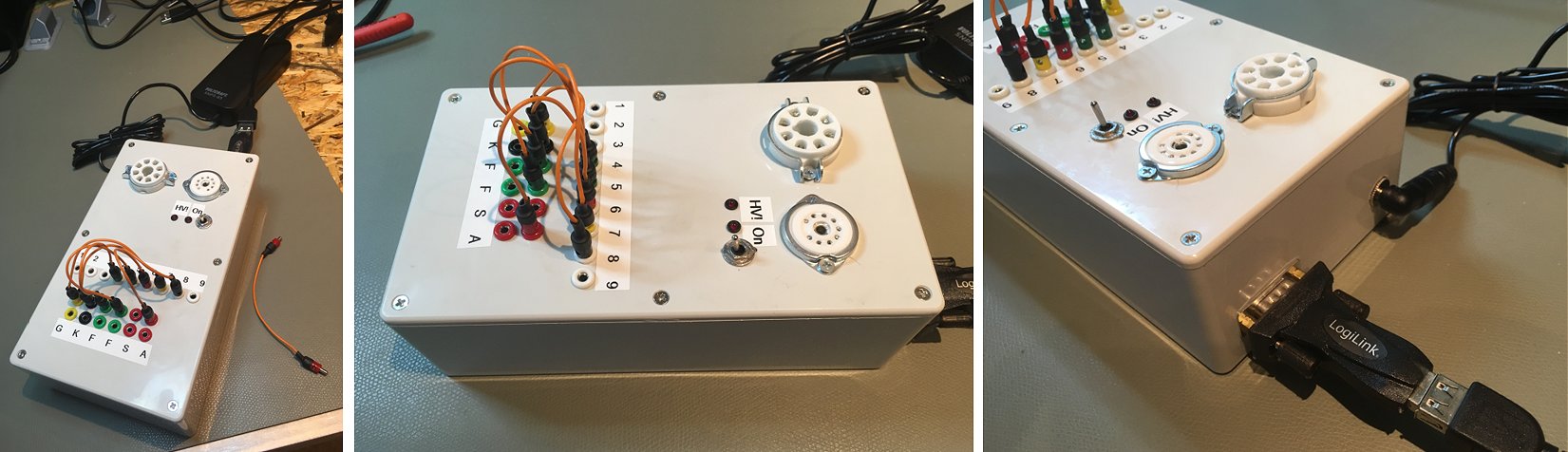

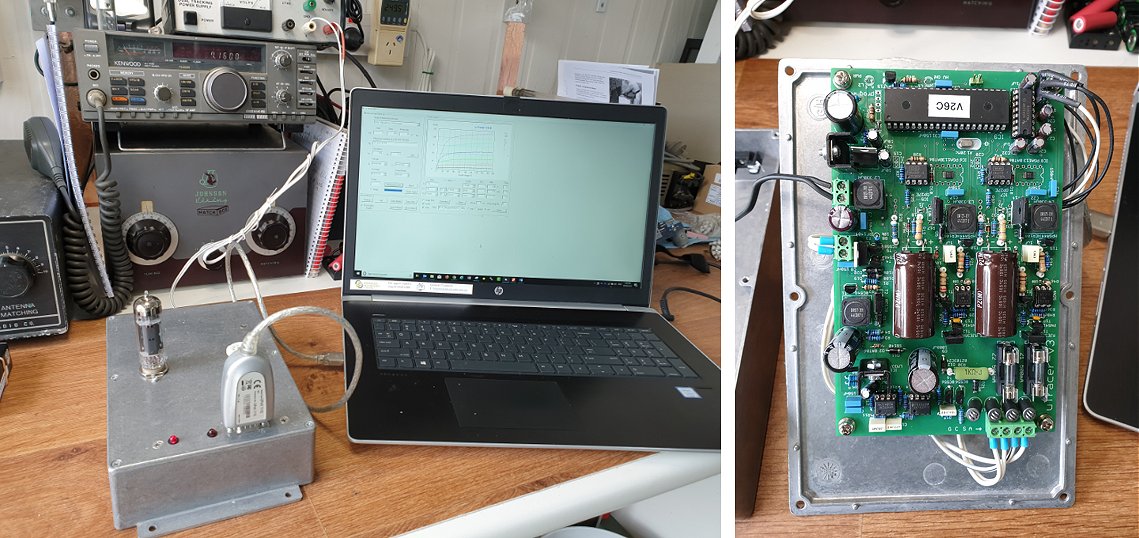

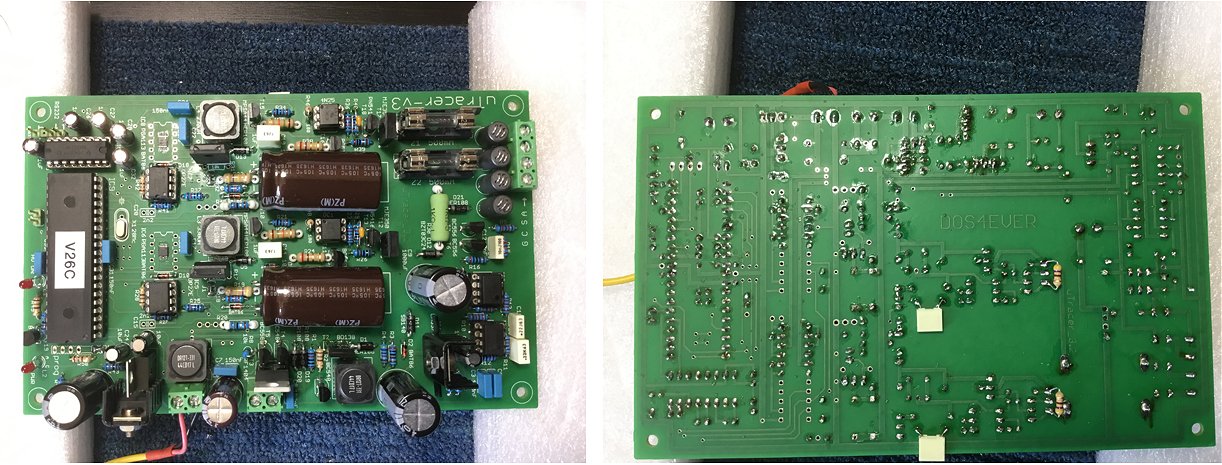

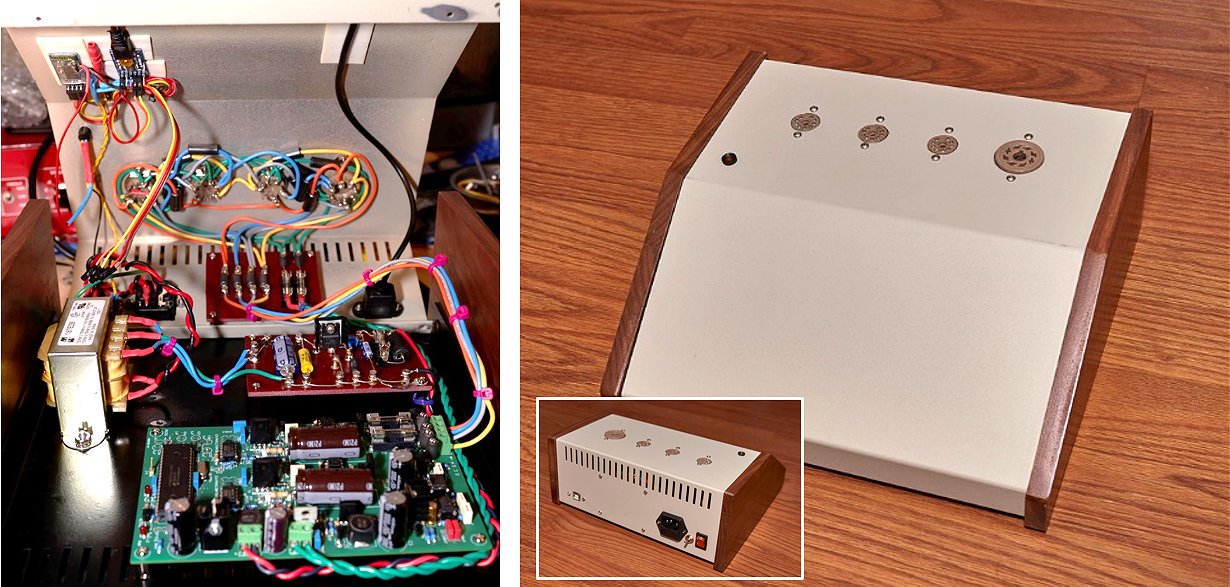

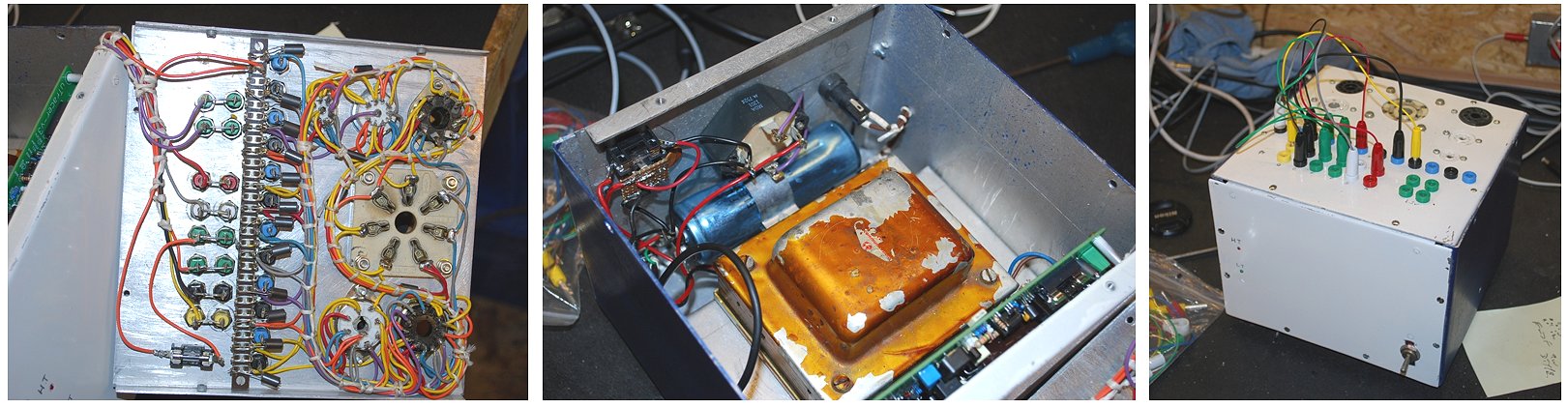

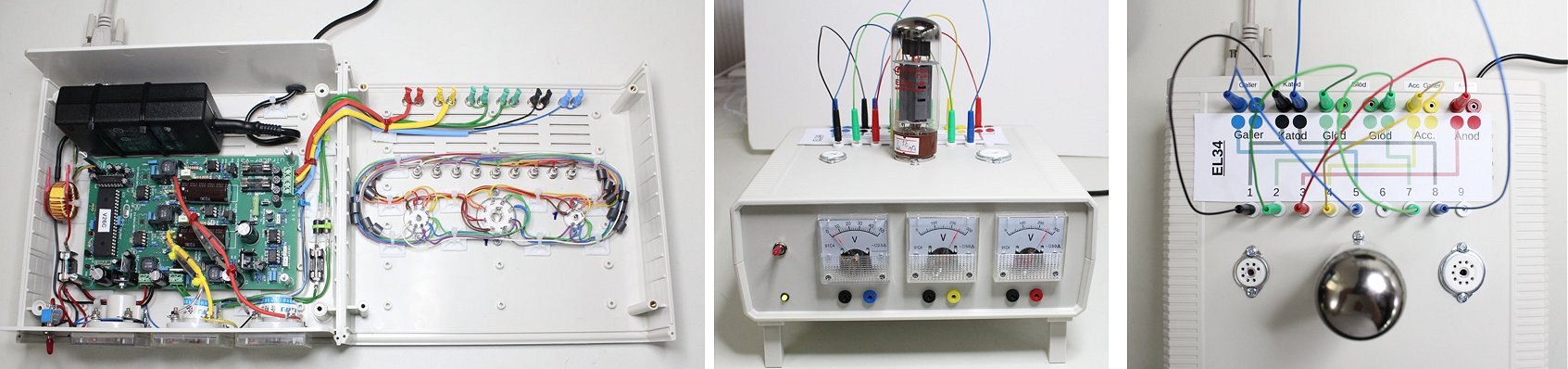

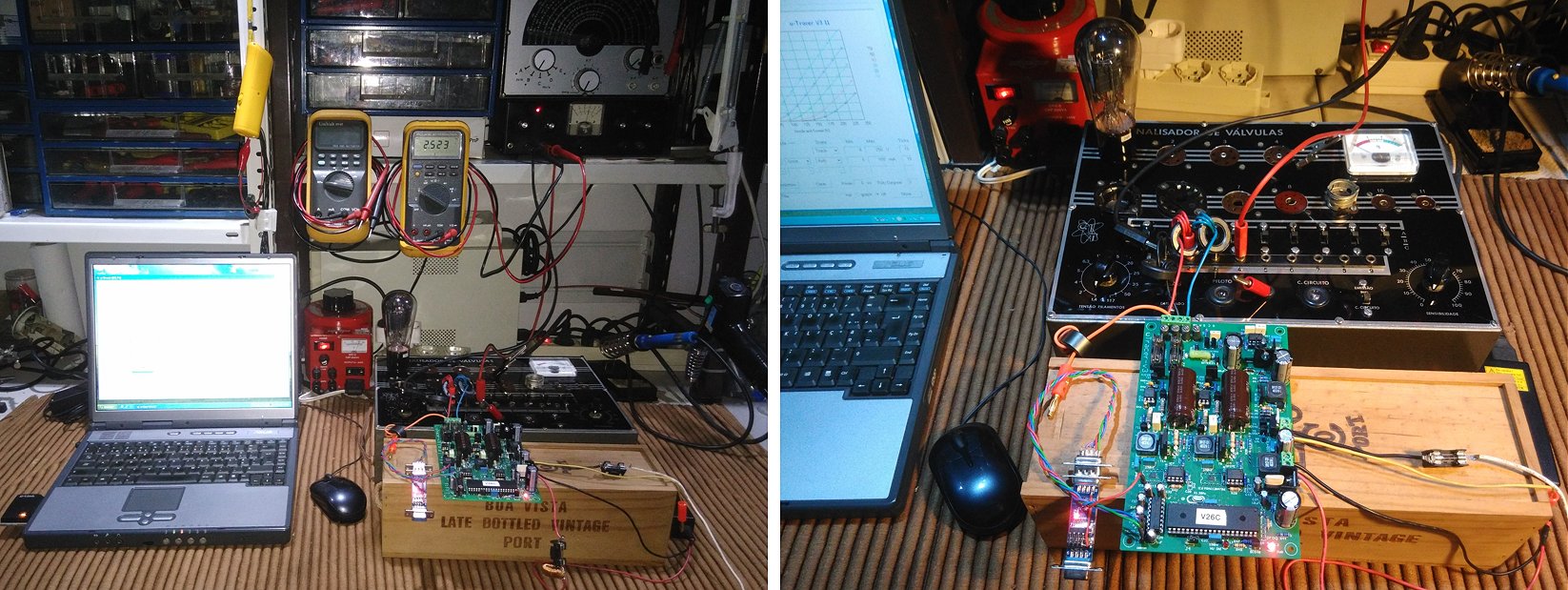

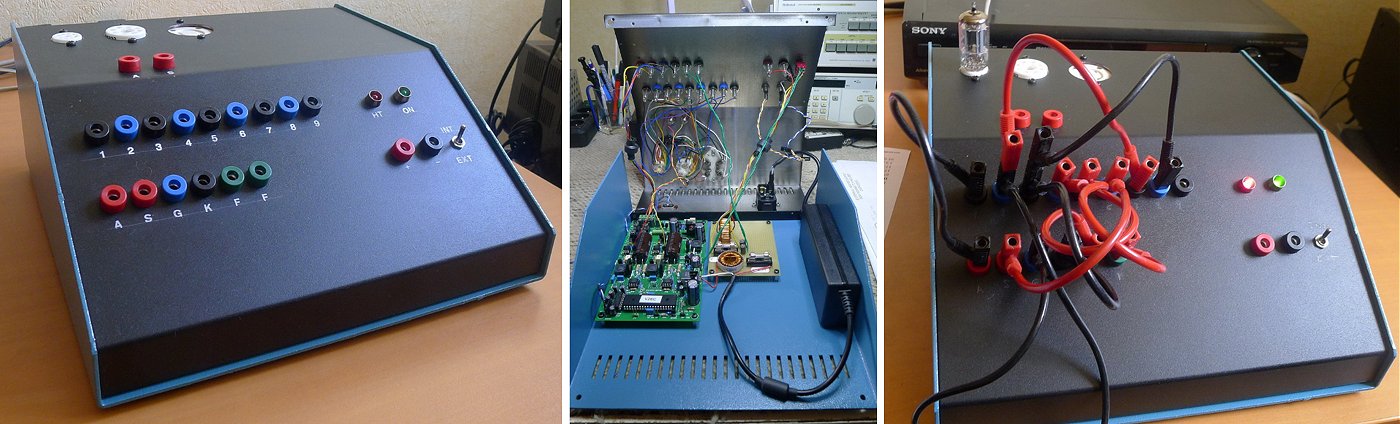

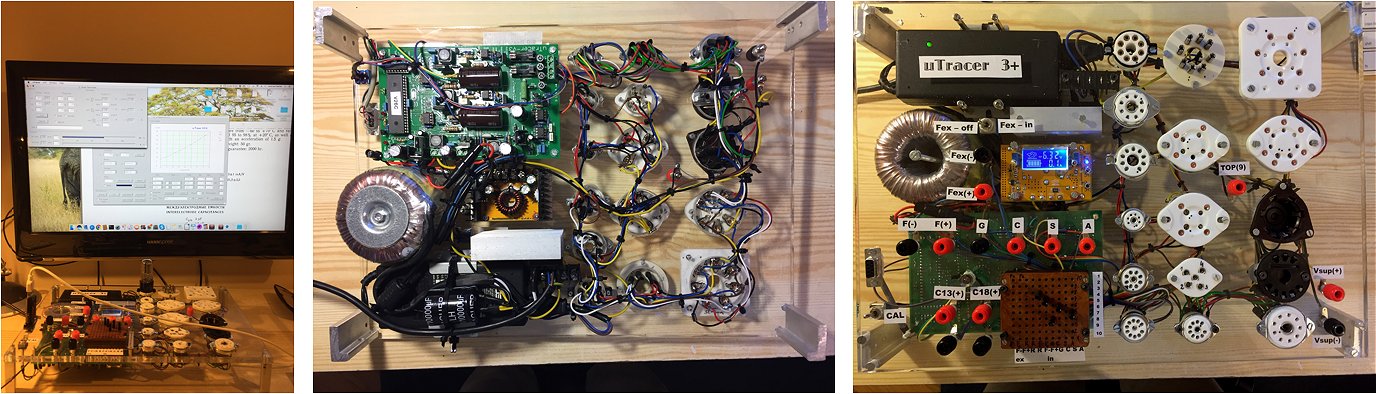

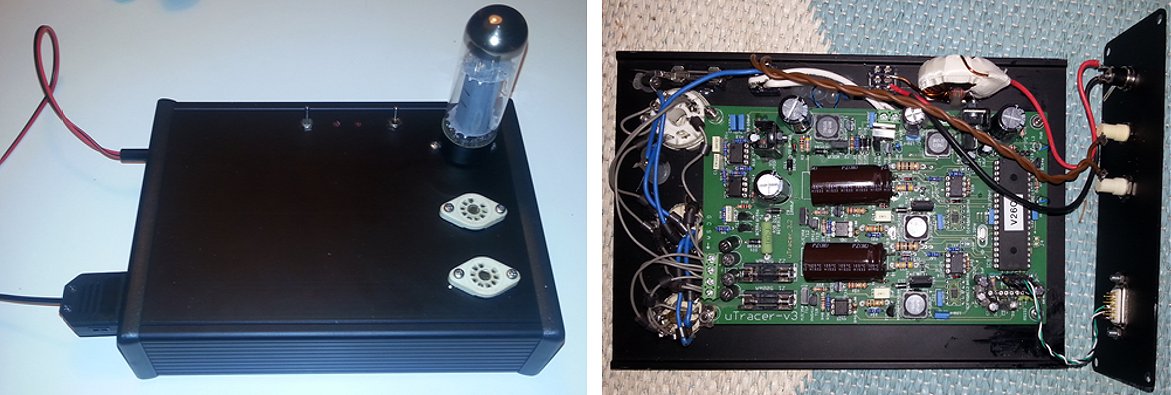

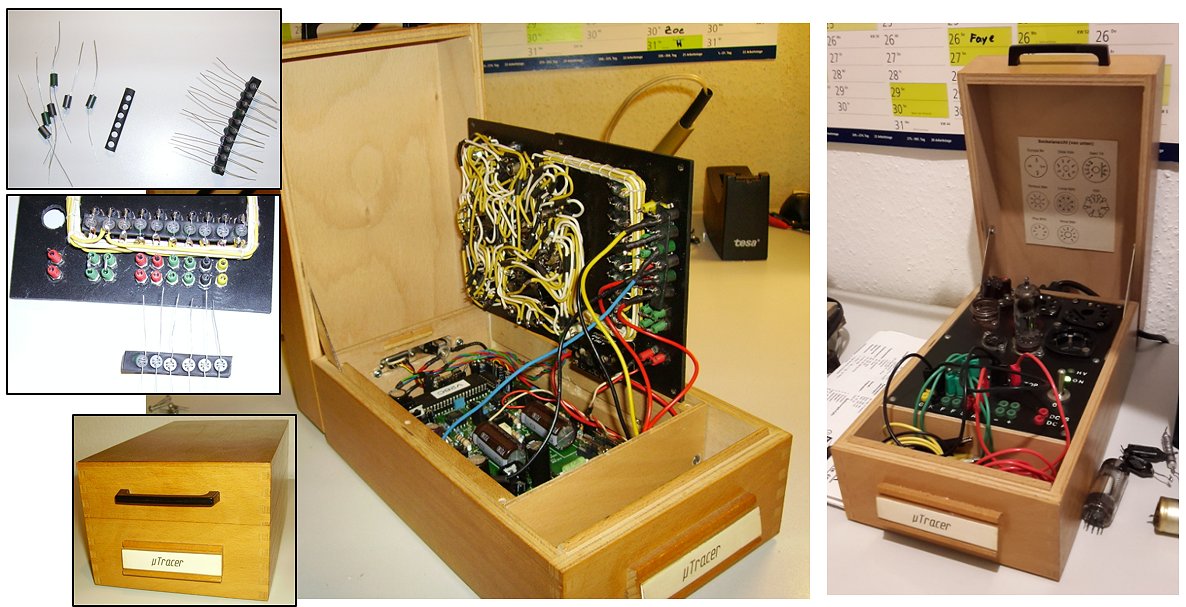

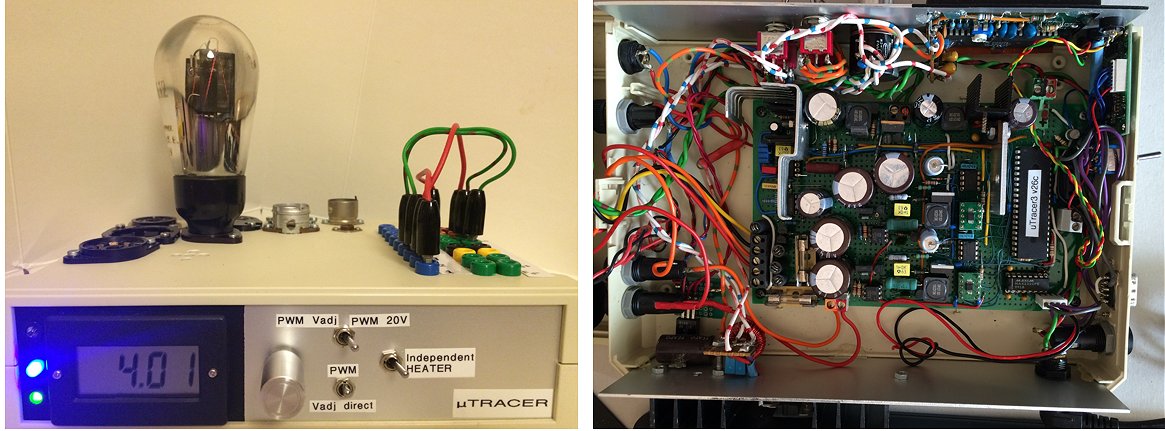

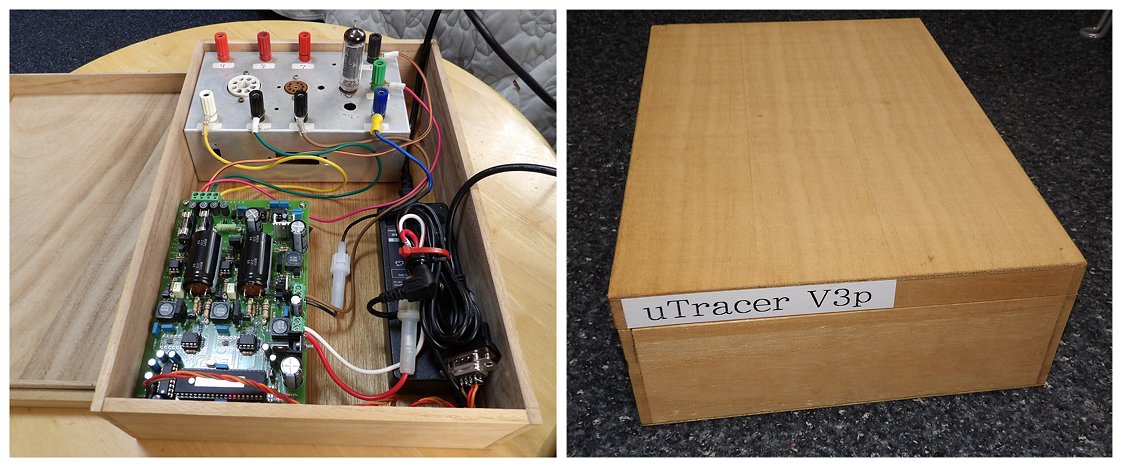

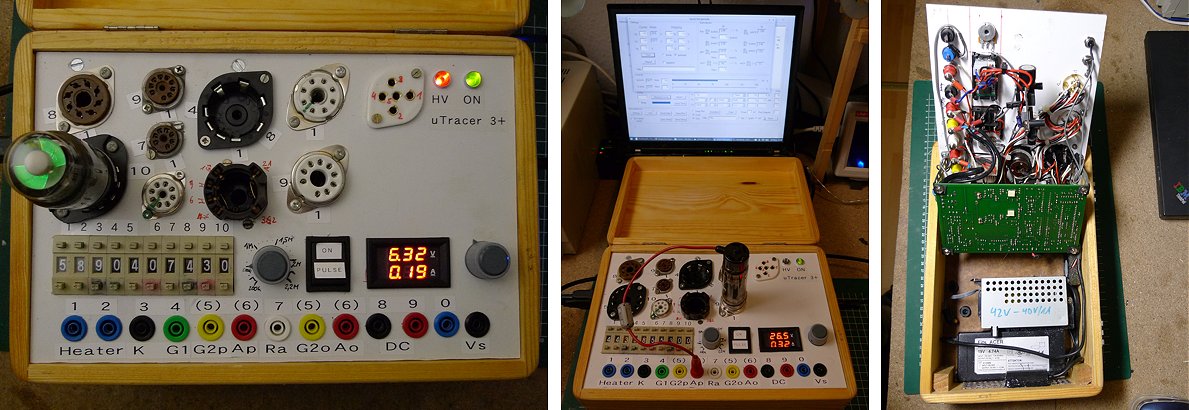

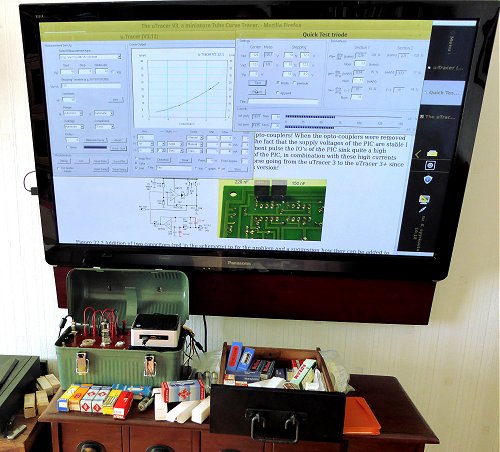

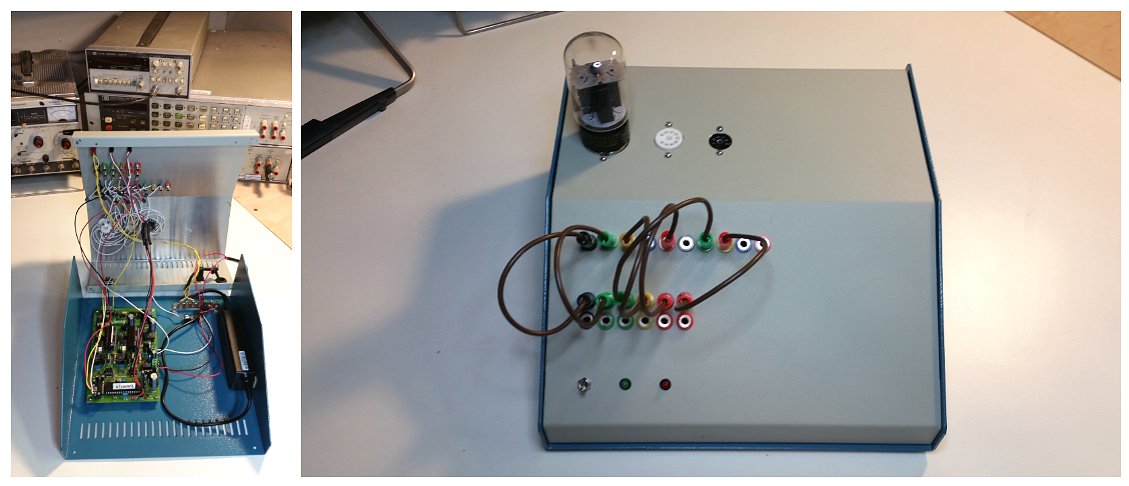

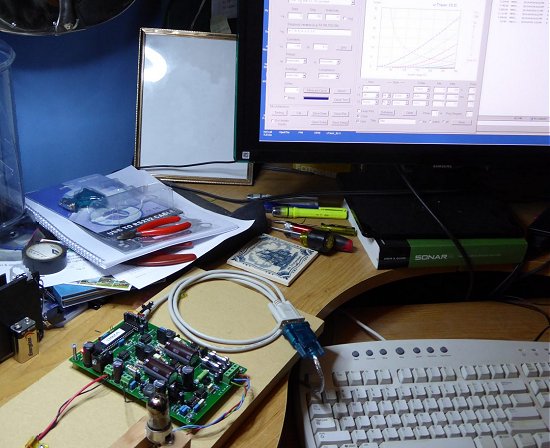

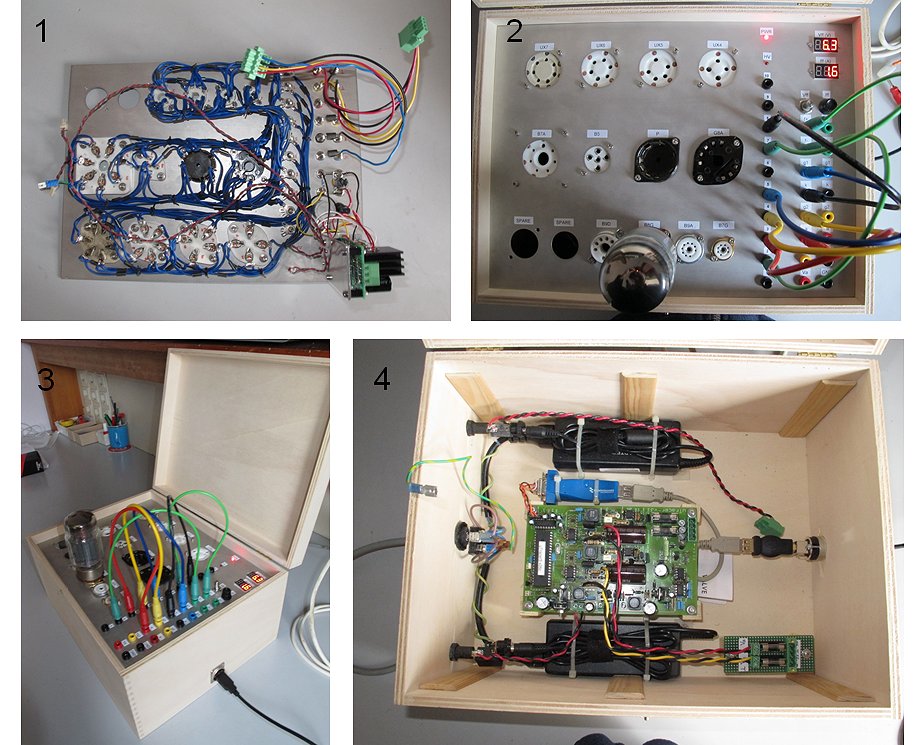

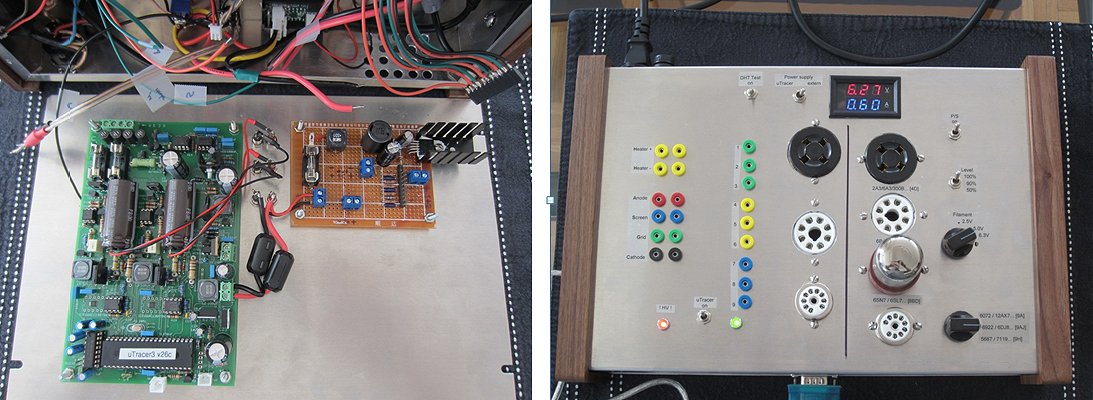

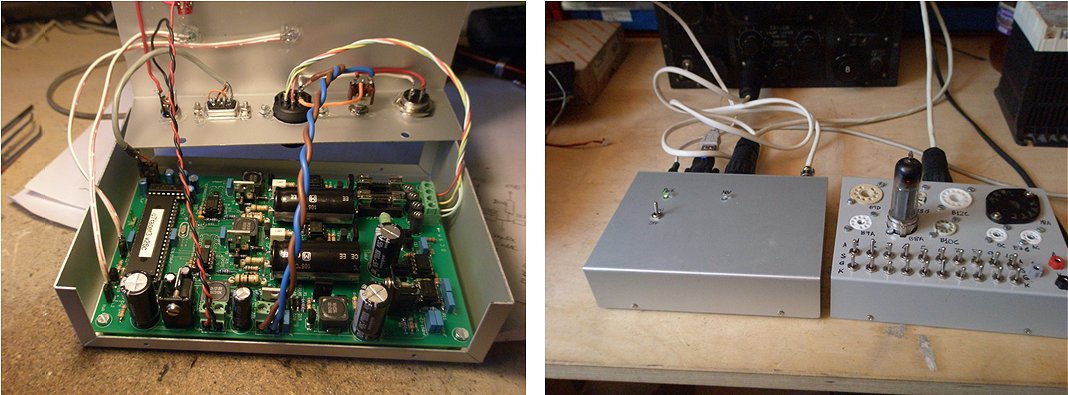

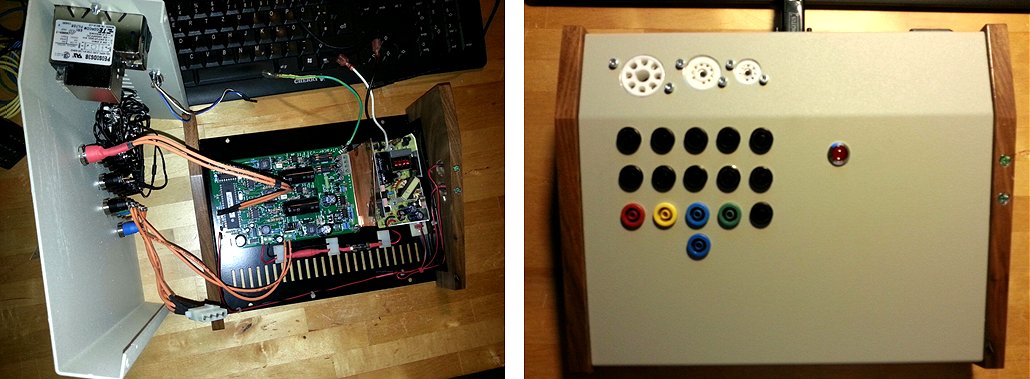

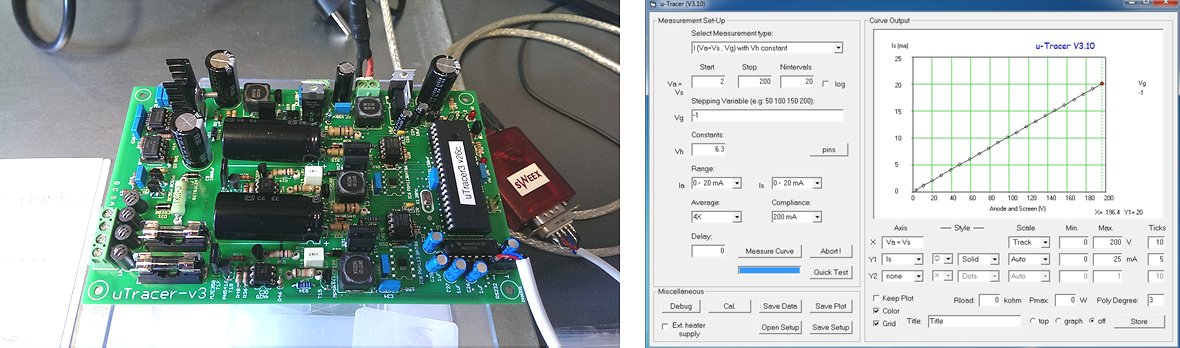

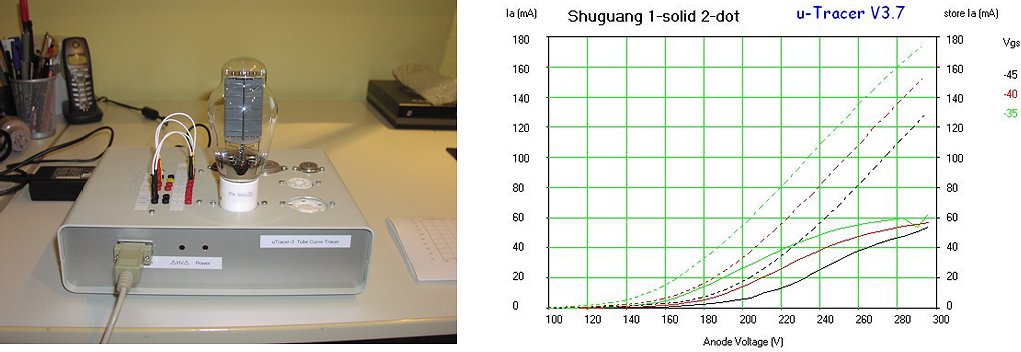

14th of November 2025, Heikki from Finland sent me a few nice pictures of his practical uTracer!

Hello Ronald & Marie-José,

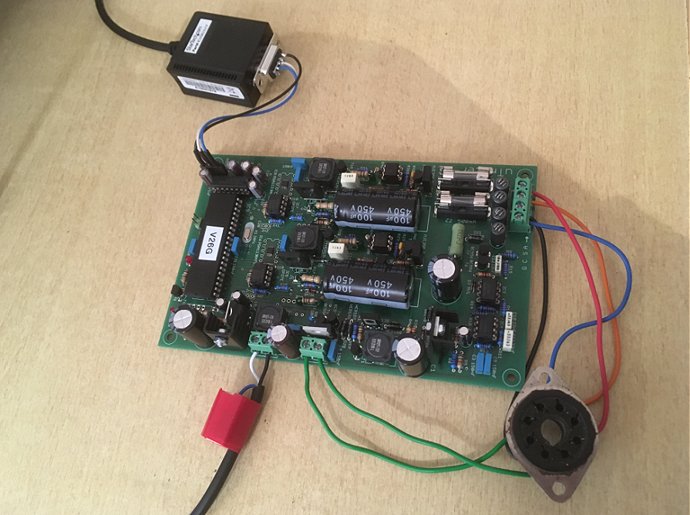

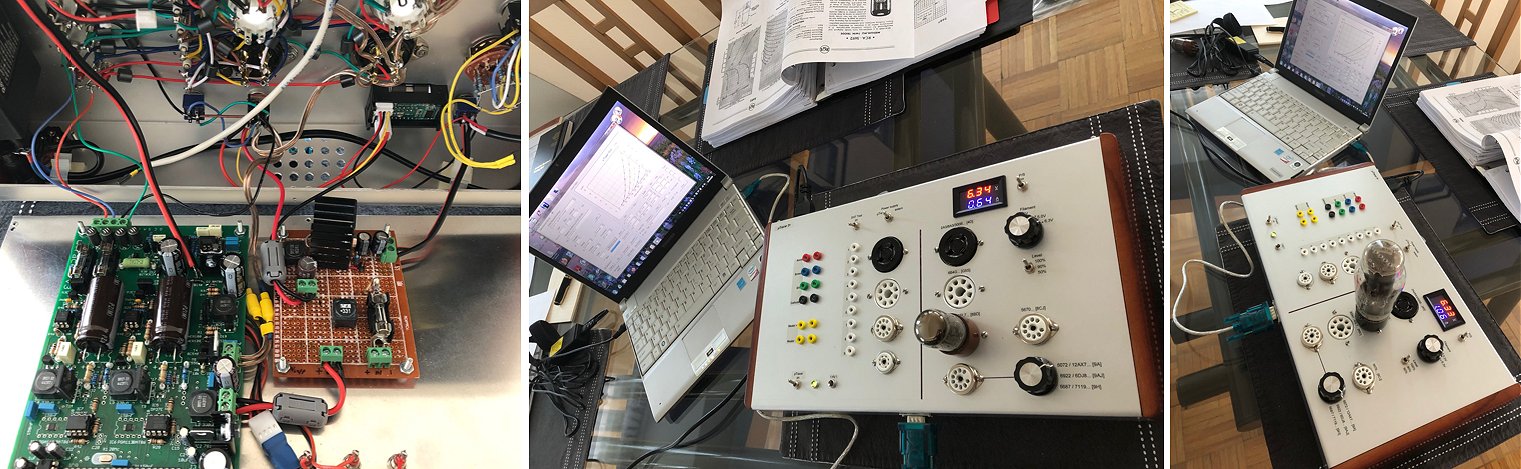

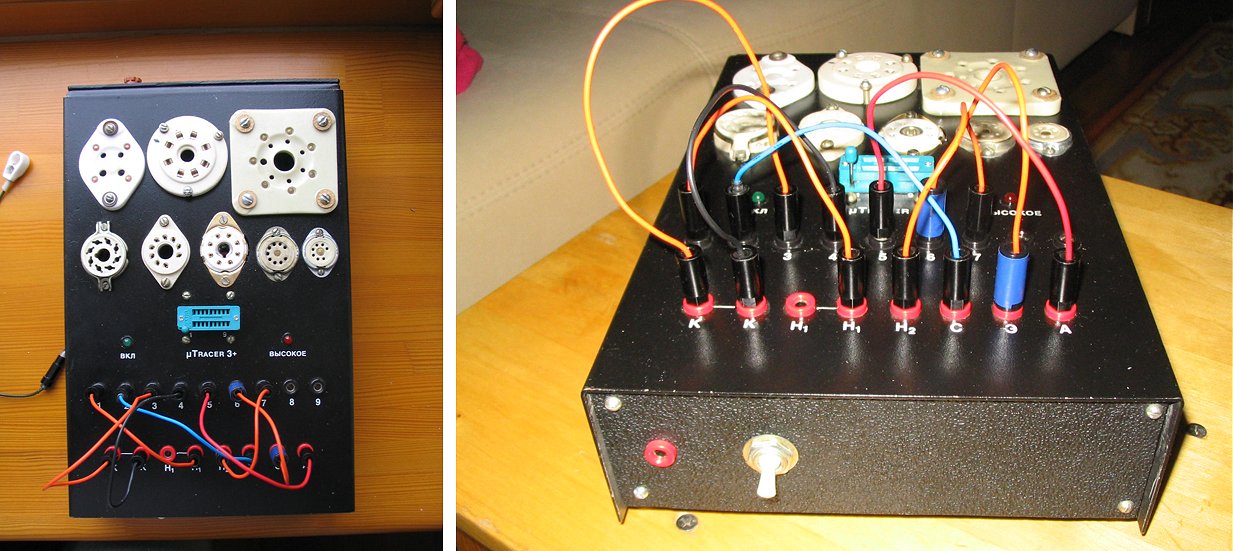

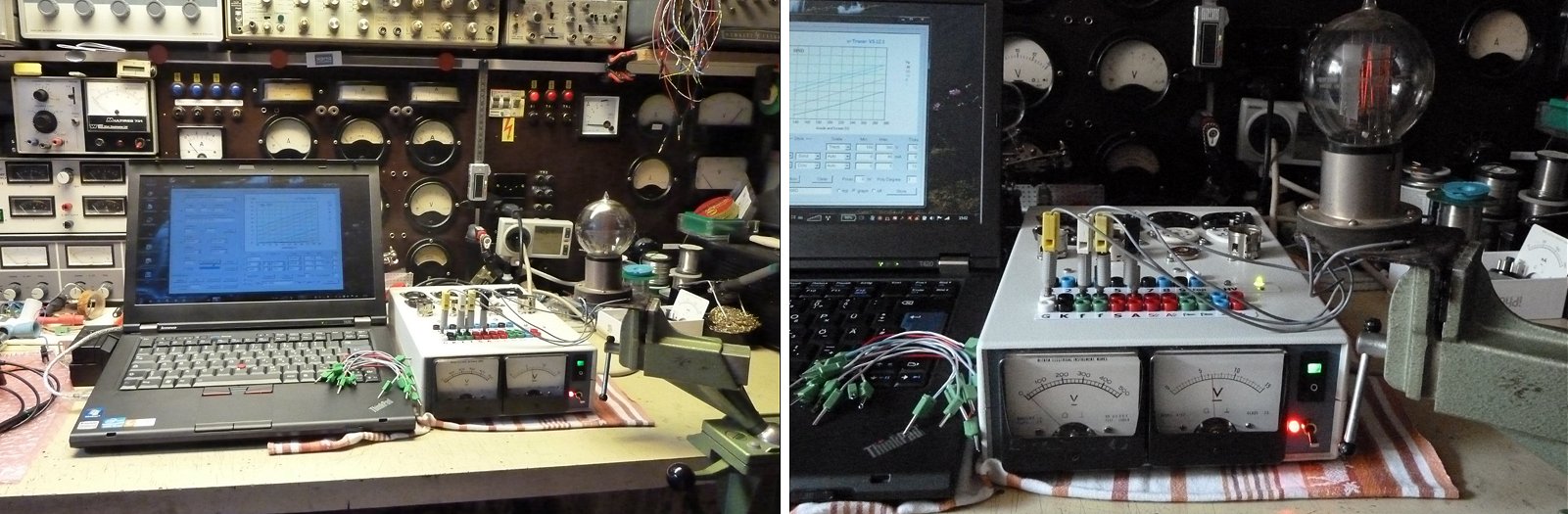

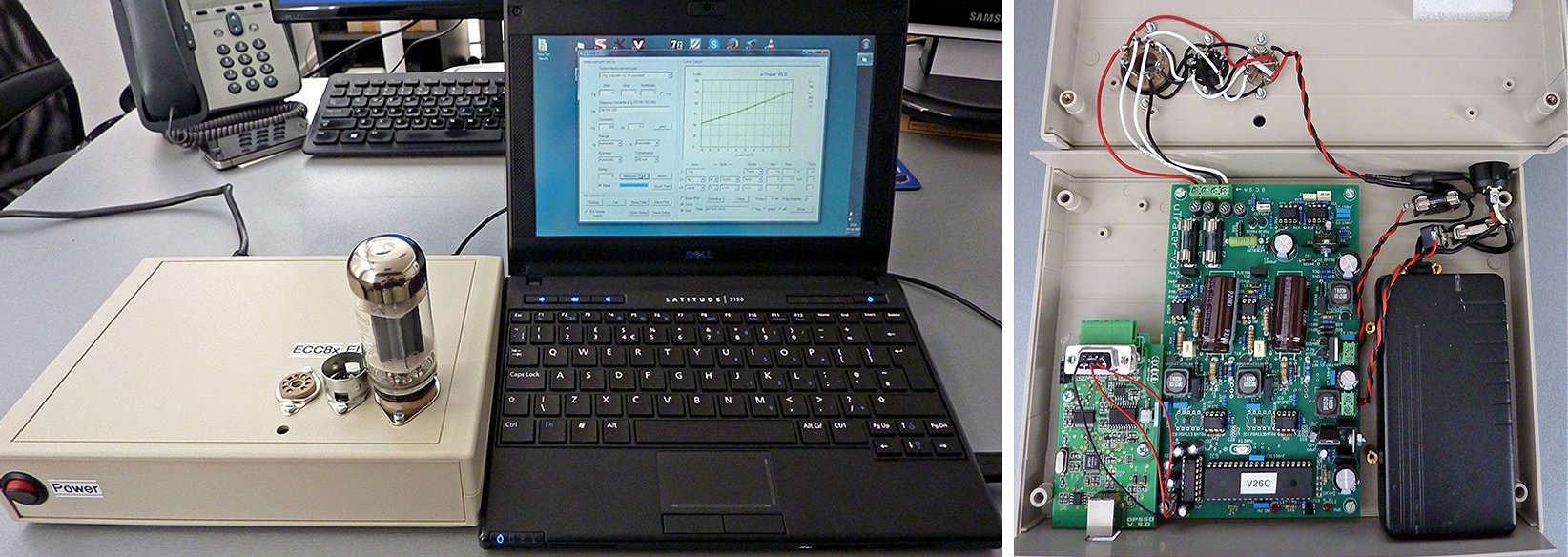

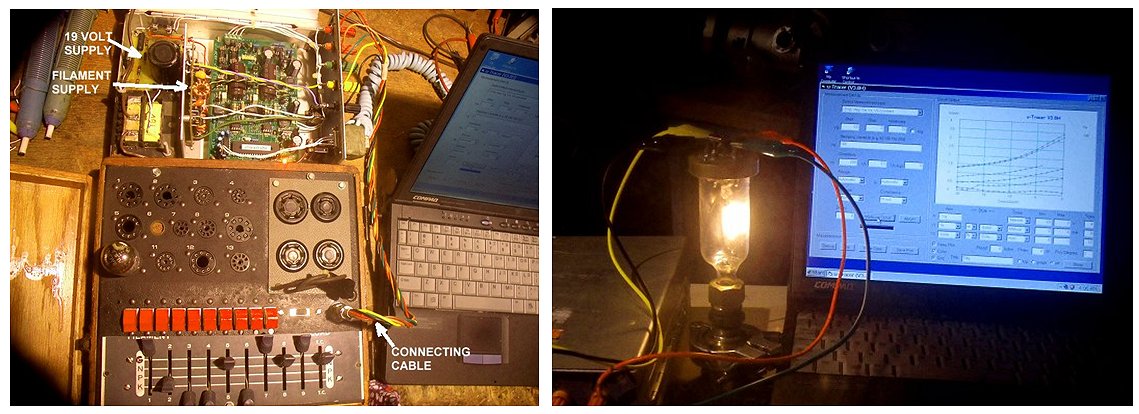

Here are a couple of figs. from my vacuum tube work station based on dos4ever PC board.

The wooden box has two advantages: easy to work with and two cooling openings :). The top plate is reinforced with an aluminum profile. It is also hoped, that easy wood work leaves some energy to the proper tube work itself. An external filament transformer is located inside the box and the filament voltage lowering resistor is attached to the binding posts at the top plate.

Thanks a lot for the marvellous design of uTracer!

Best regards,

Heikki

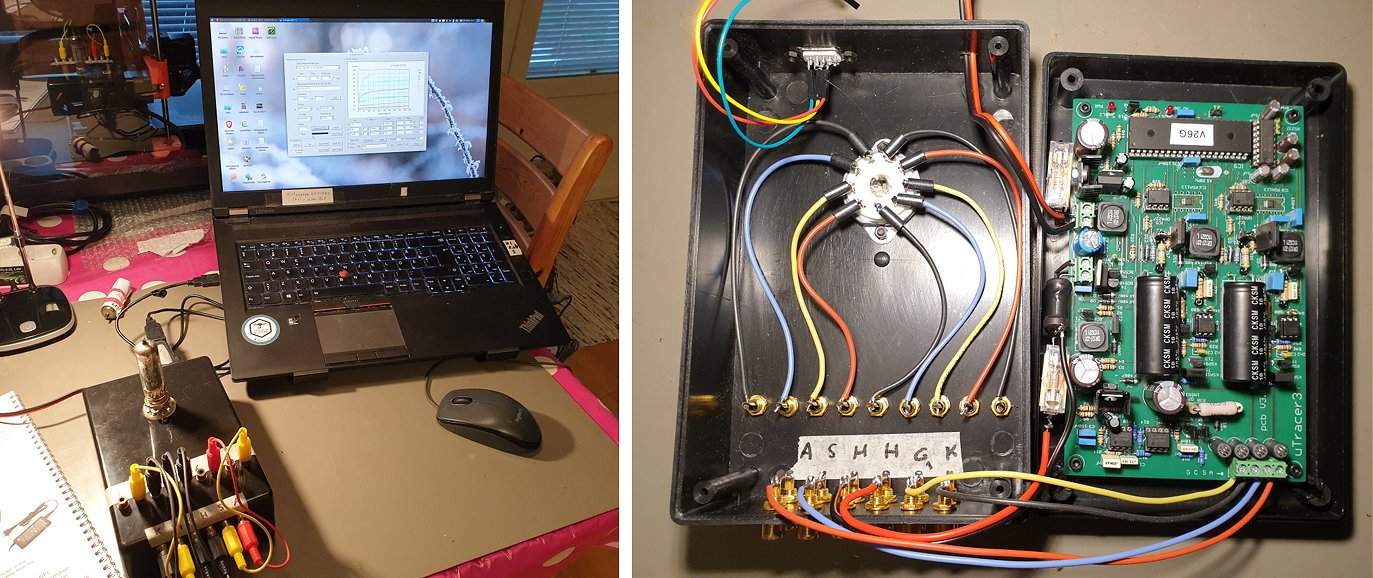

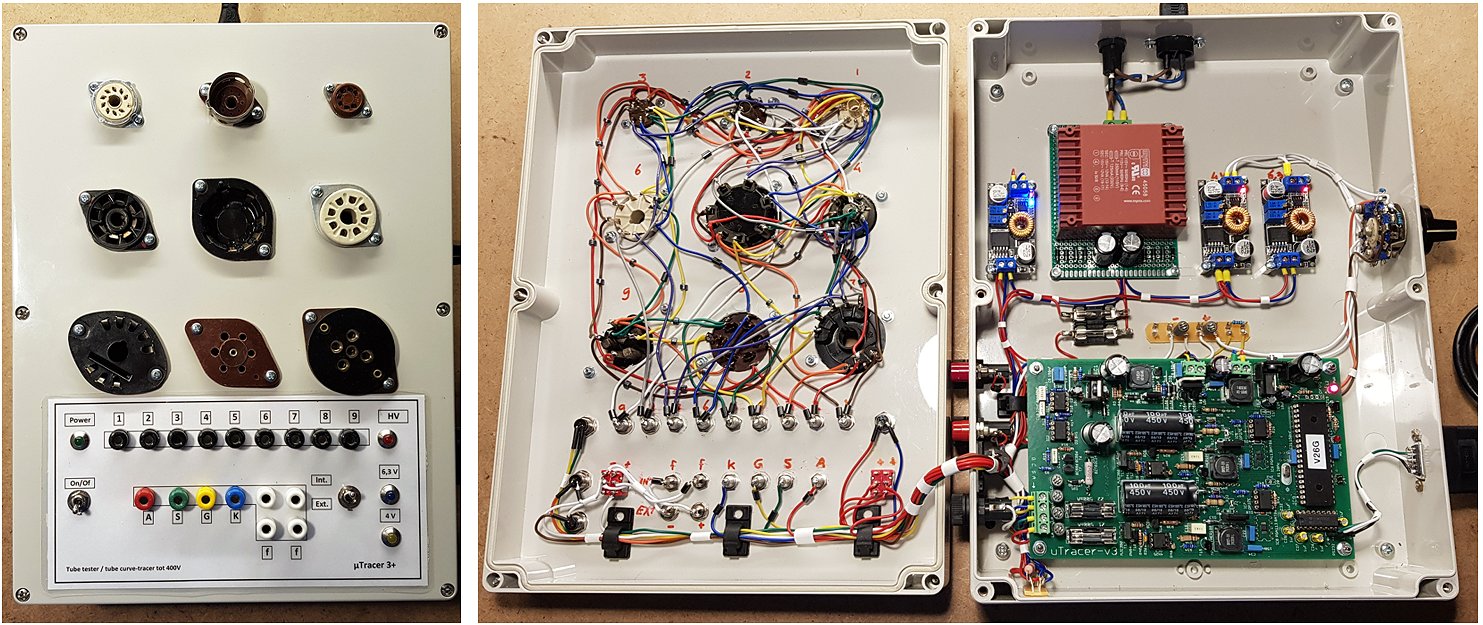

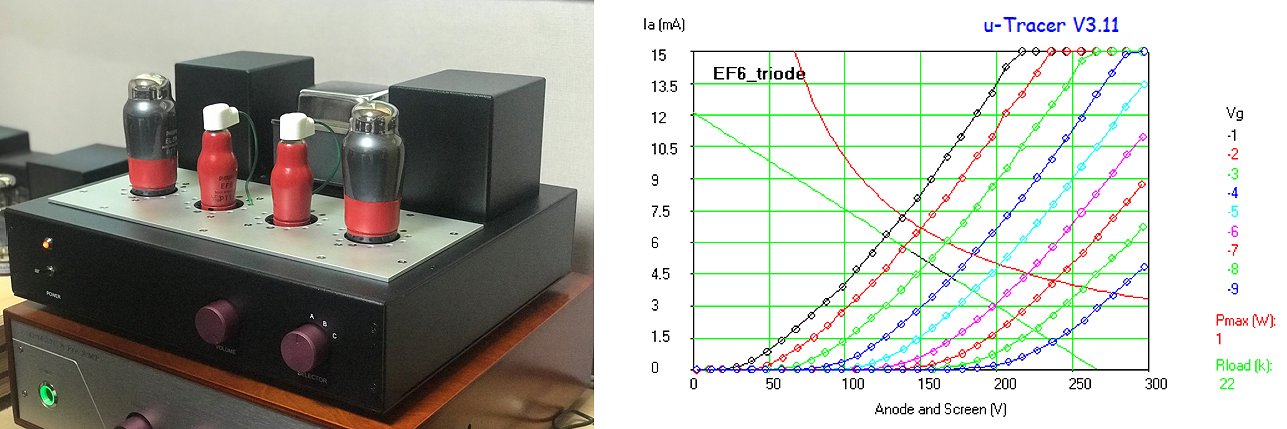

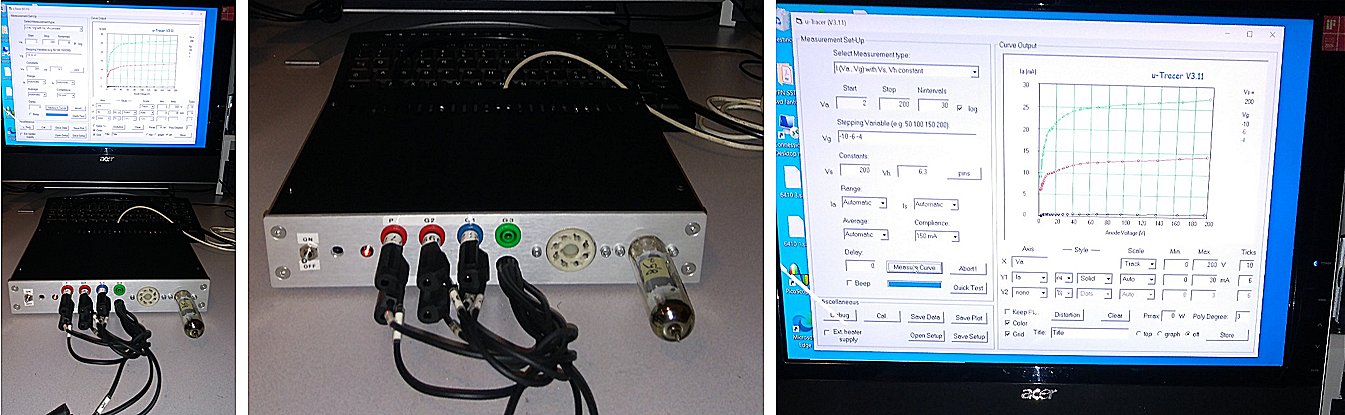

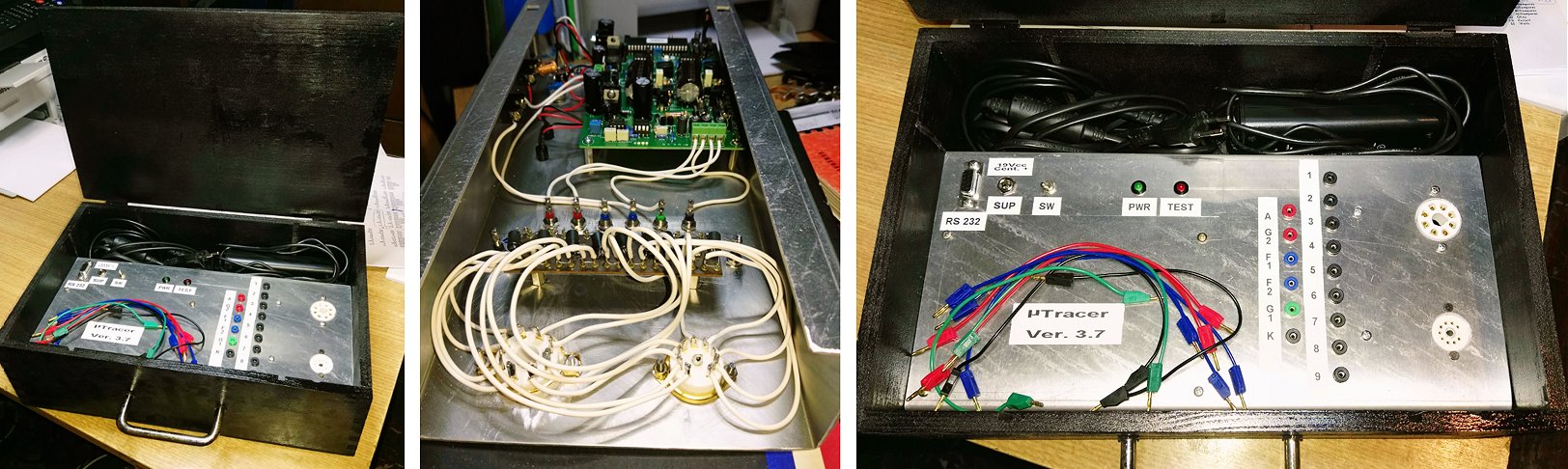

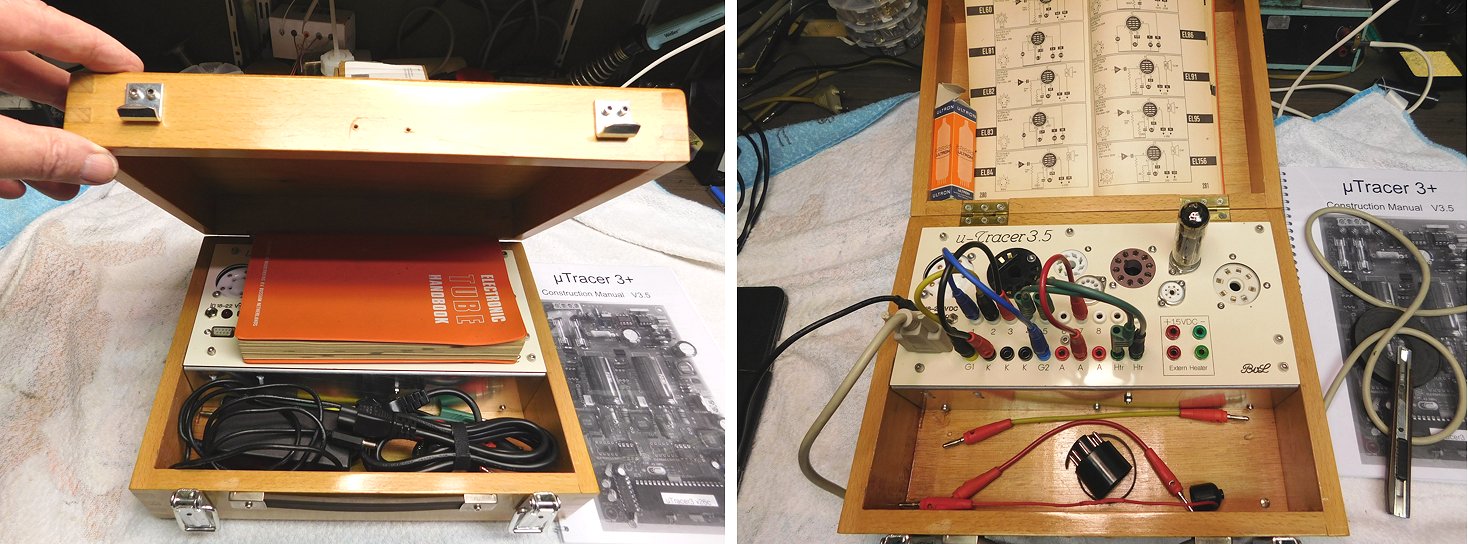

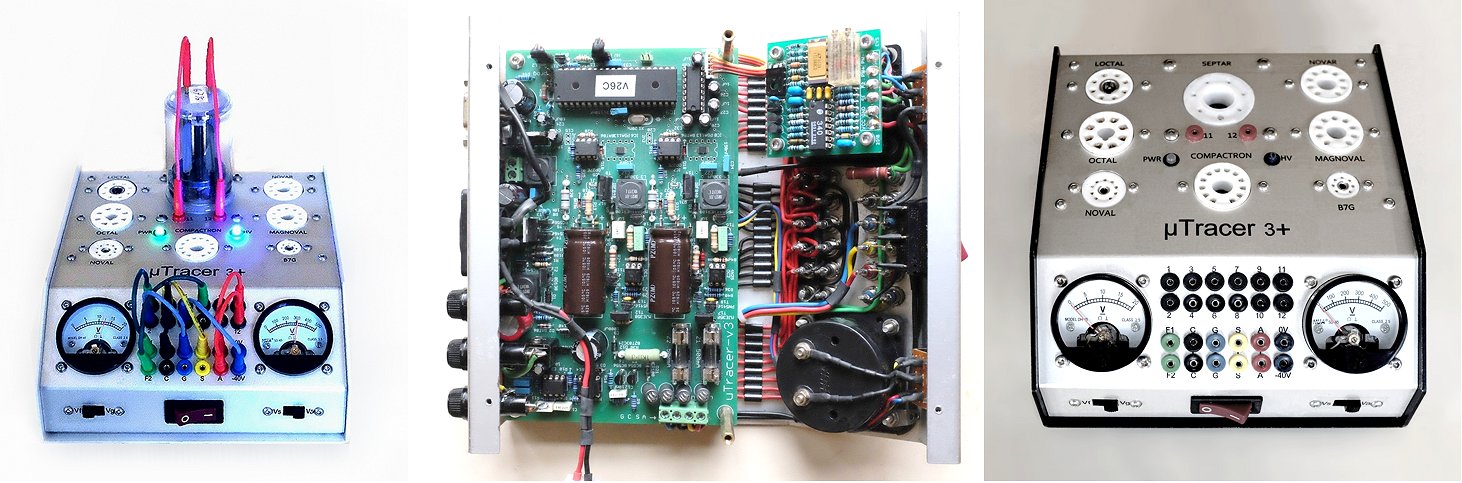

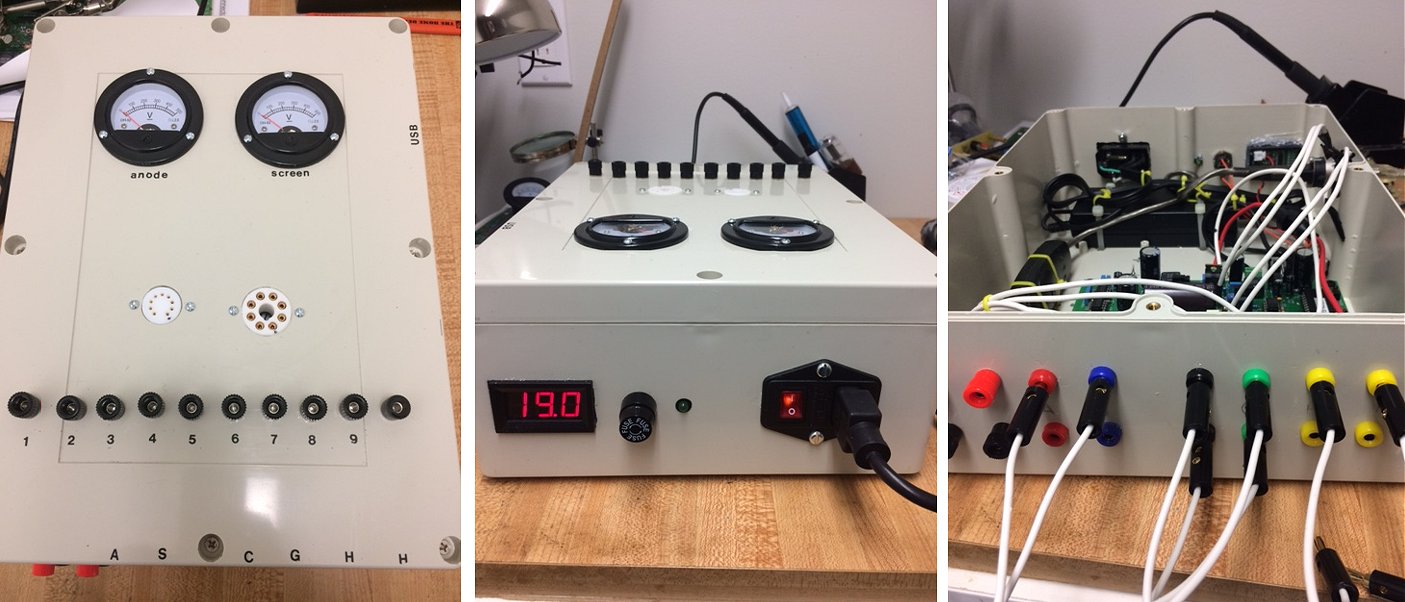

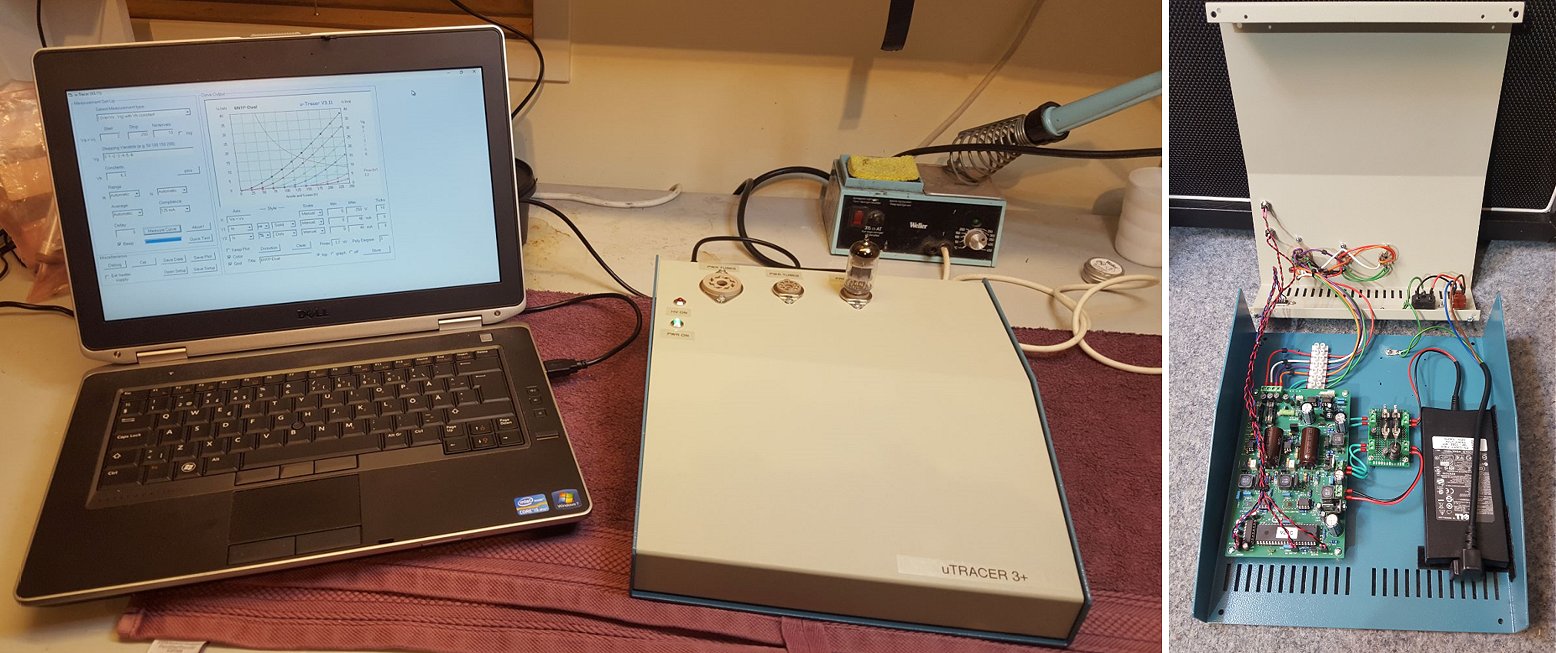

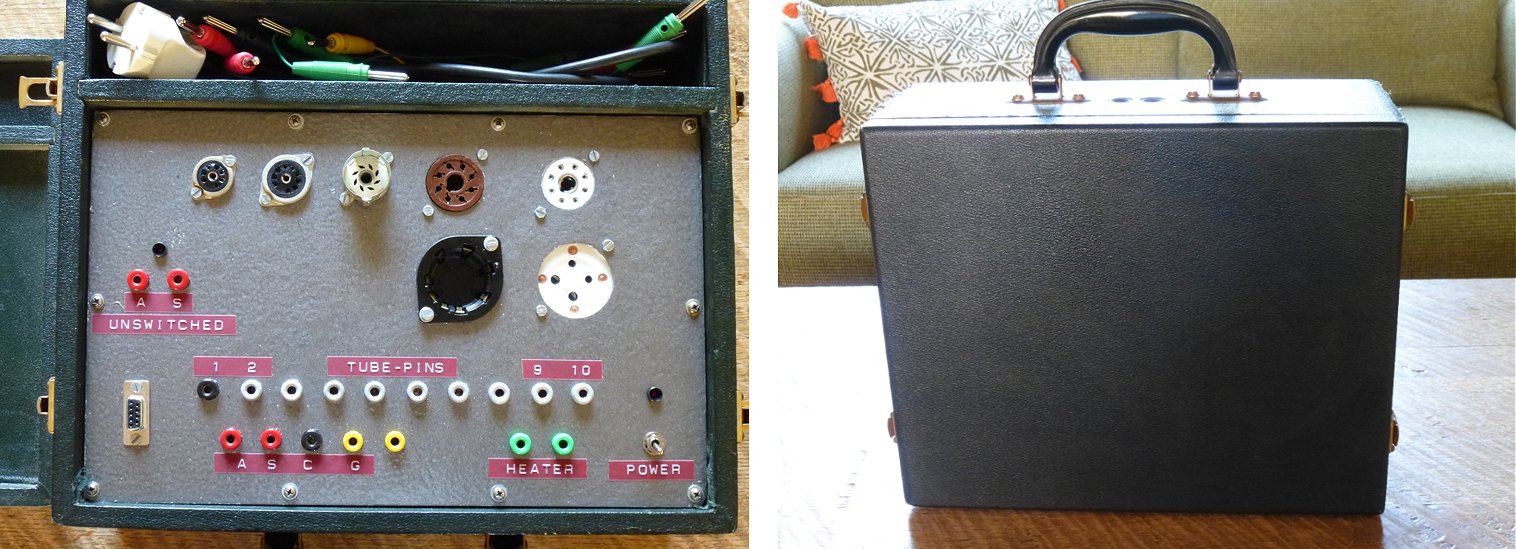

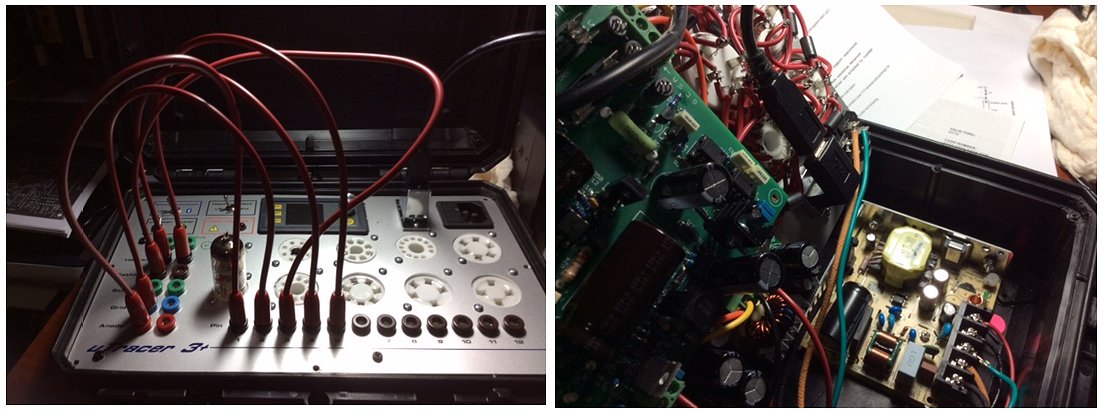

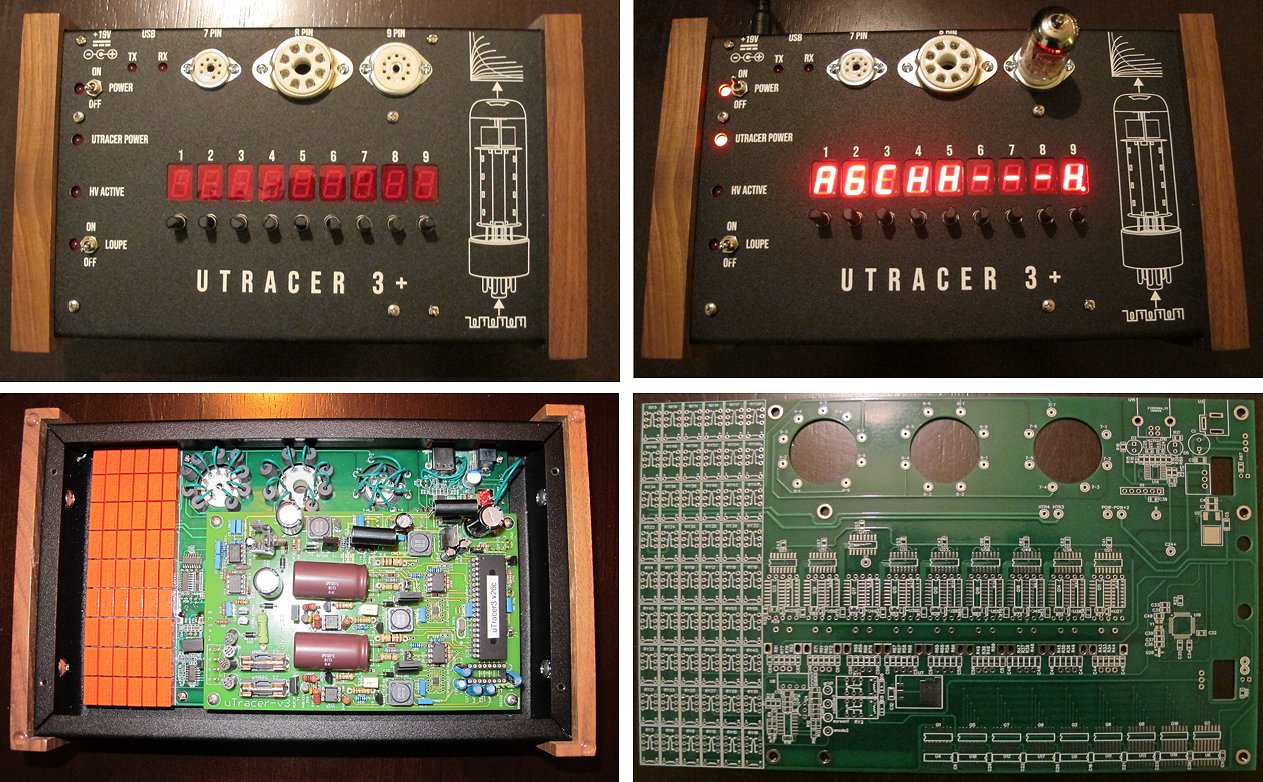

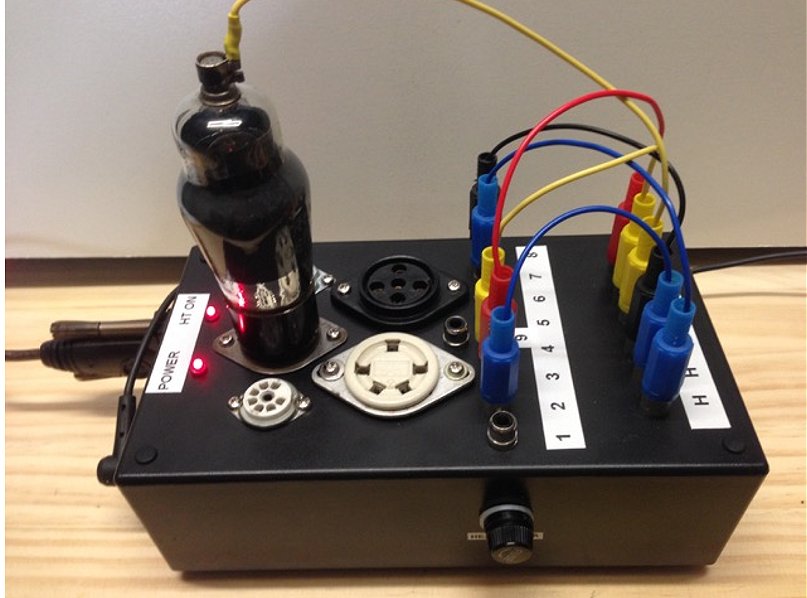

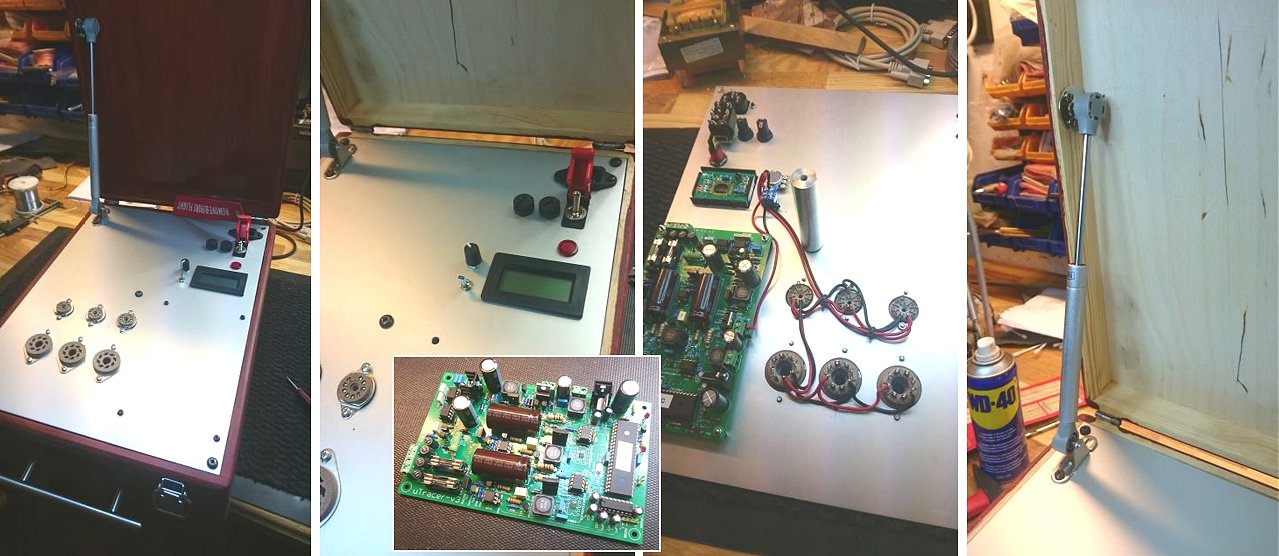

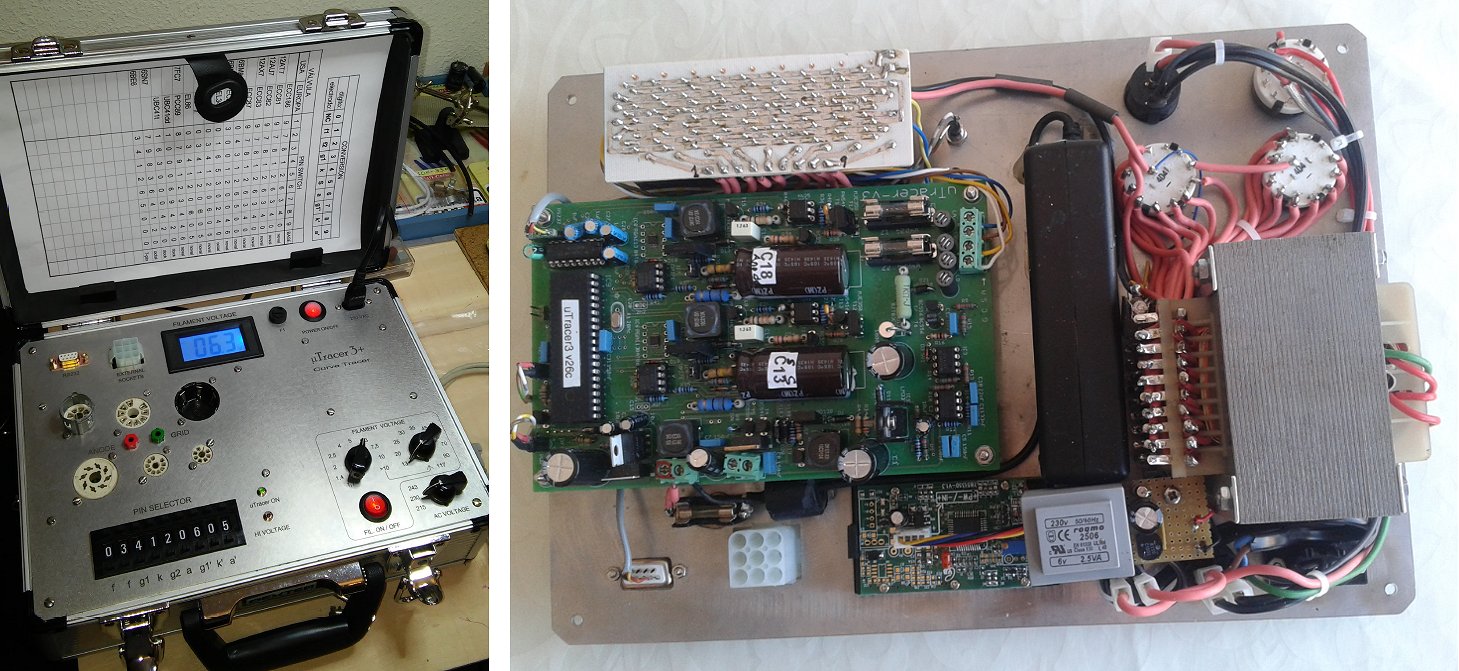

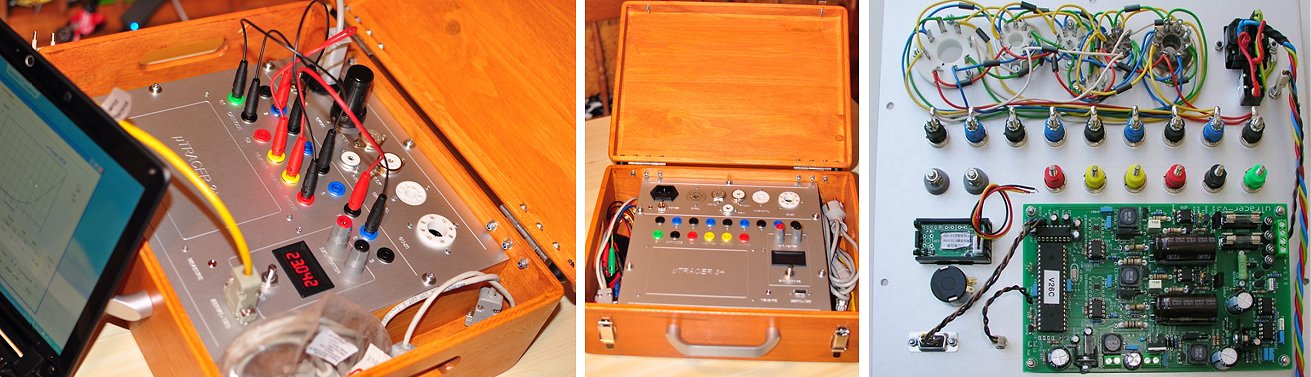

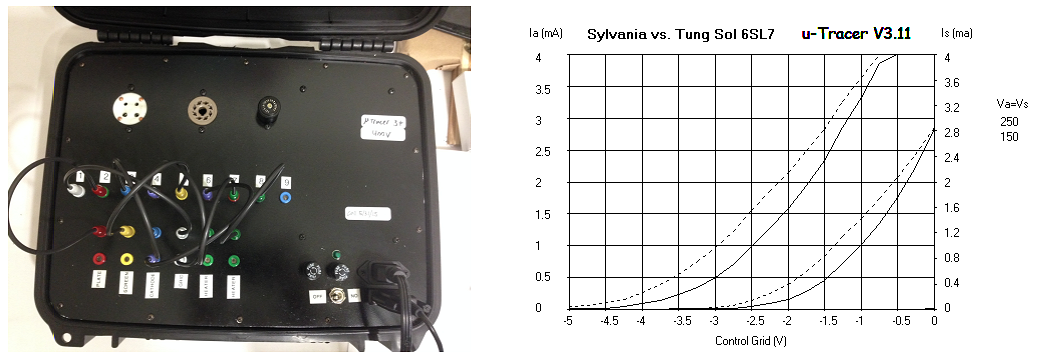

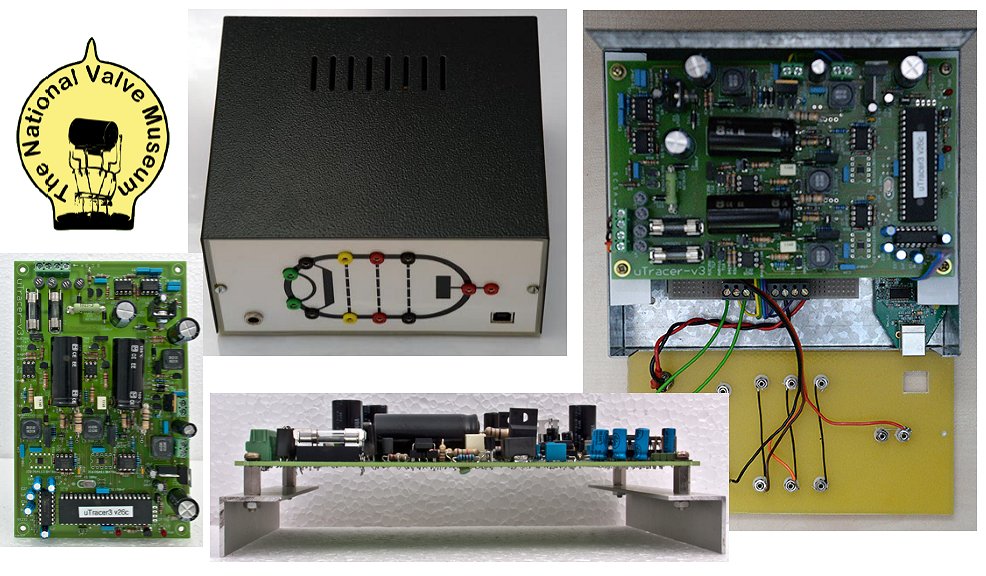

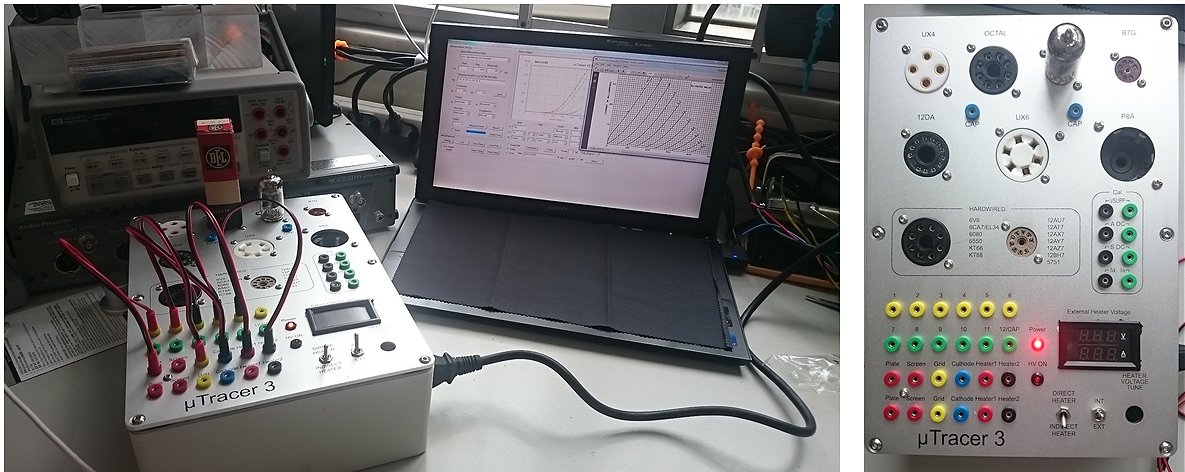

3rd of November 2025, Preben from the Sønderjyllands Radiomuseum sent me a nice picture of their beautiful uTracer!

Hi Ronald and Marie-Jose,

Thank you for your efforts in developing and distributing uTracer kits.

And we look forward to following the development of the new NXTracer.

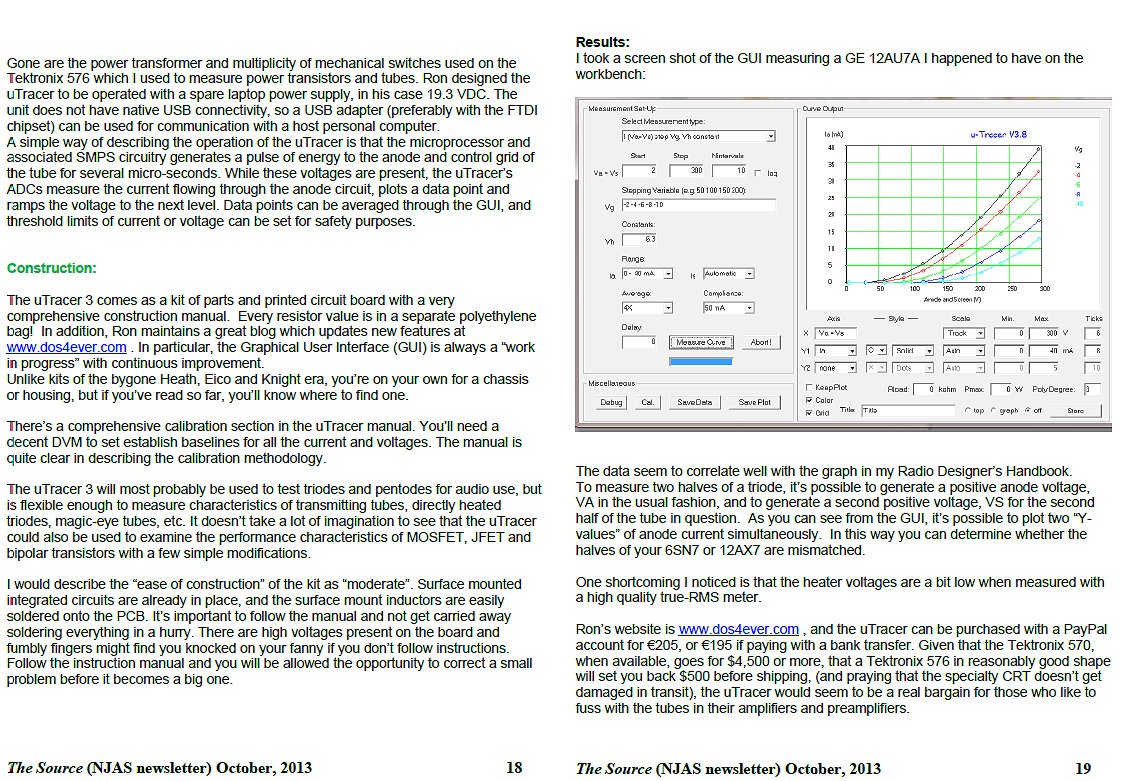

We are very happy with our uTracer 3+ here at the Radio Museum.

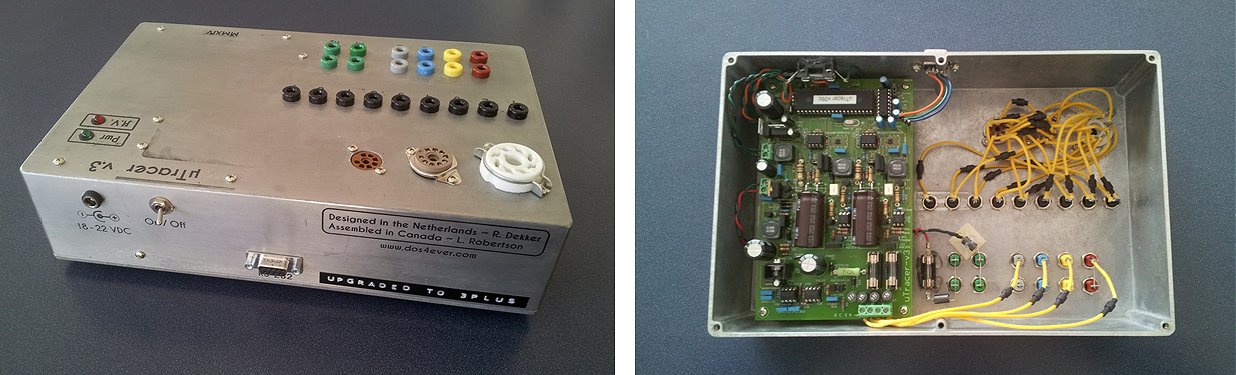

Attached picture of our version of uTracer 3+.

Best regards

Sønderjyllands Radiomuseum

Preben

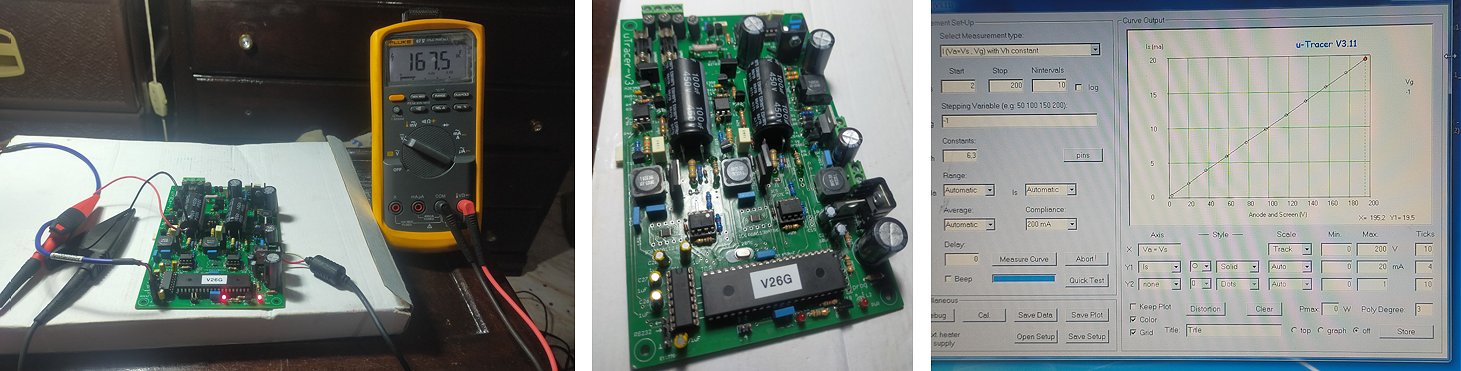

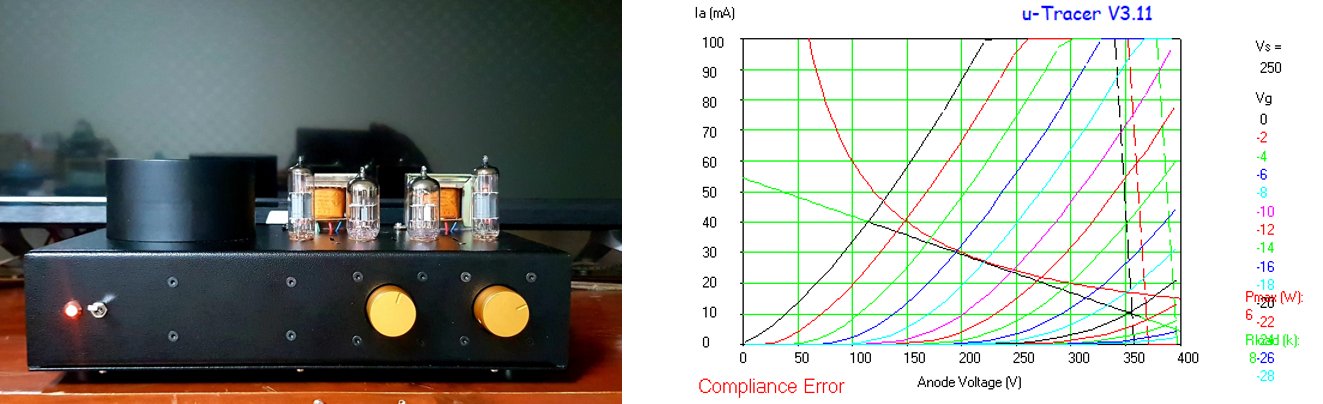

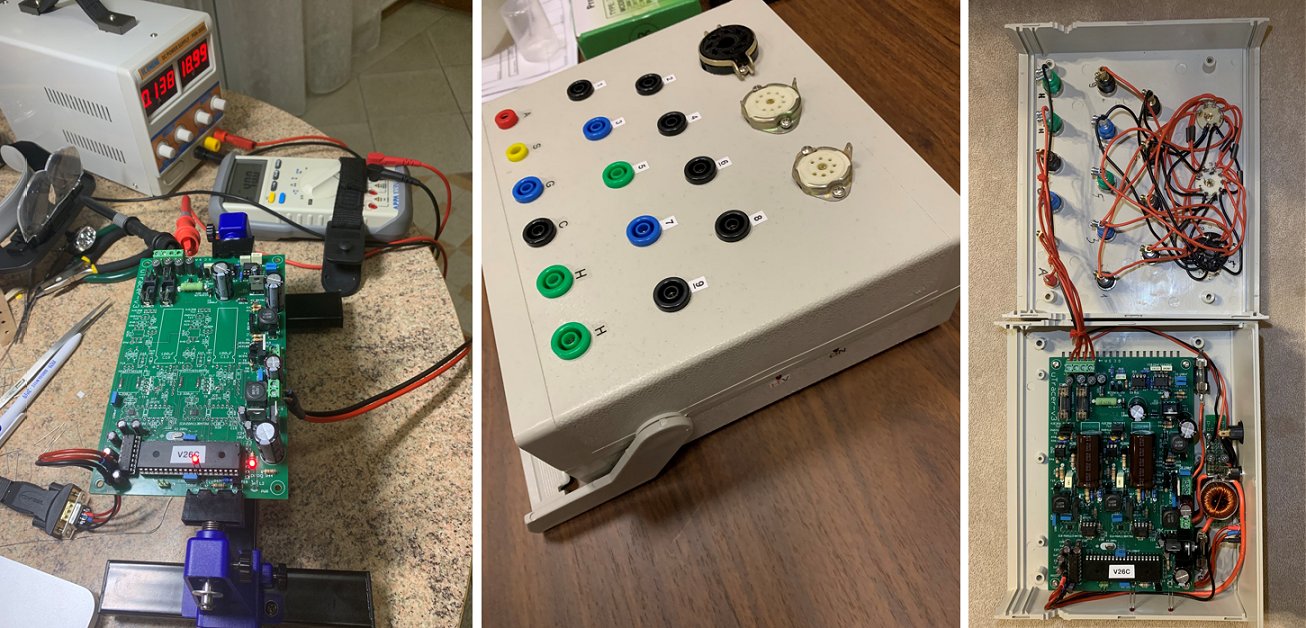

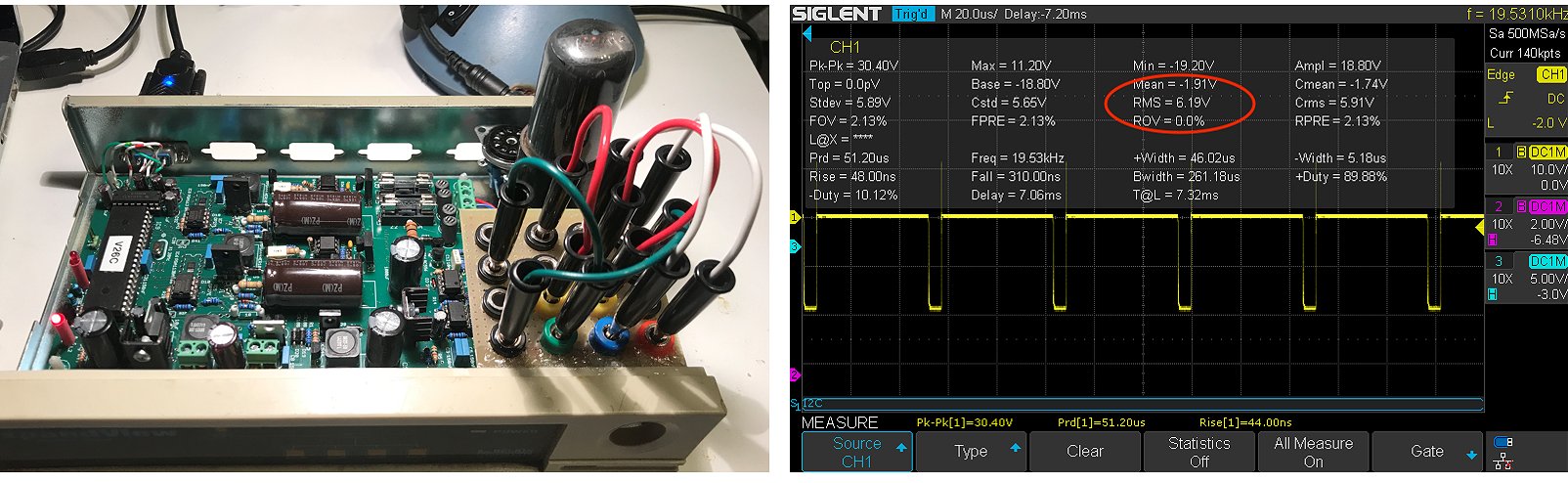

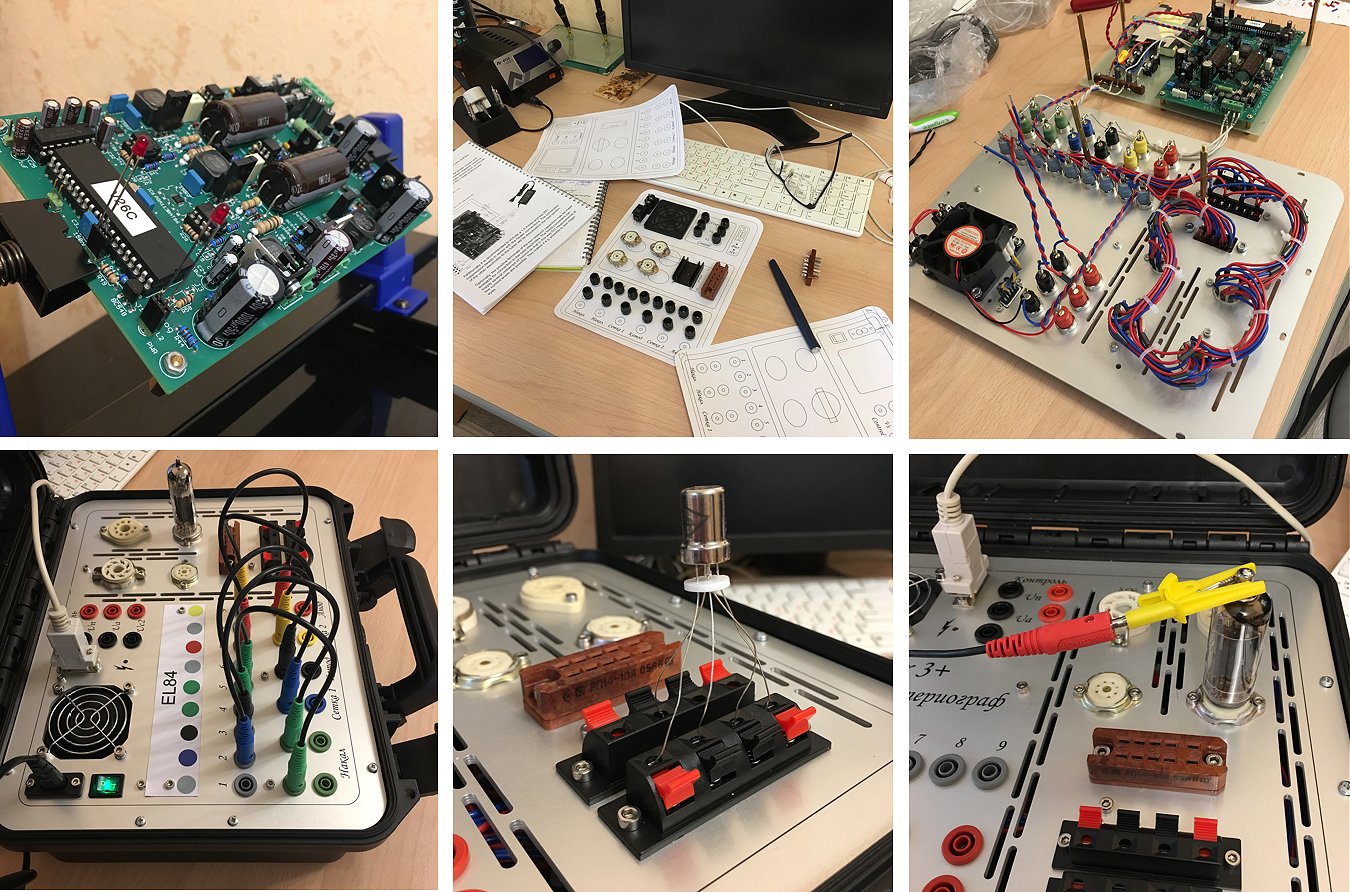

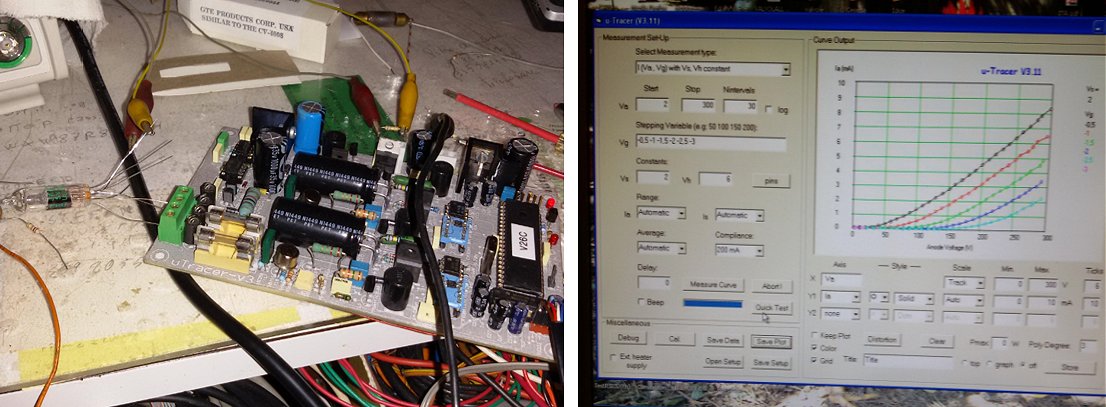

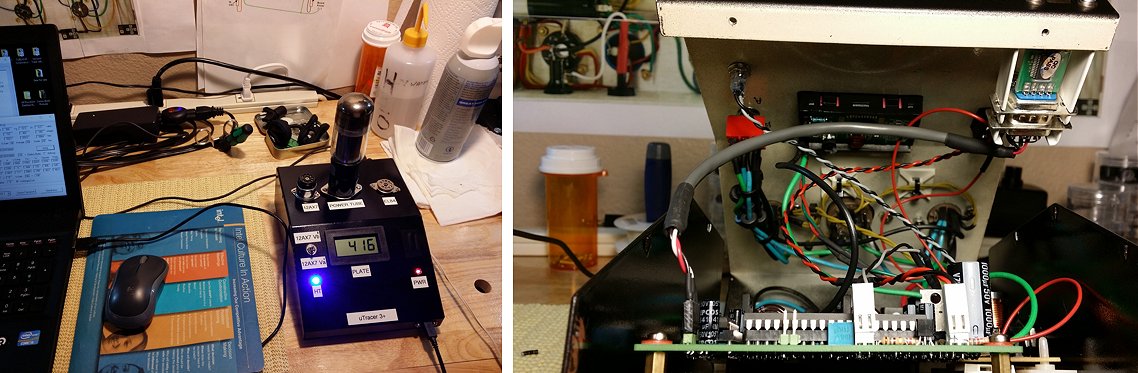

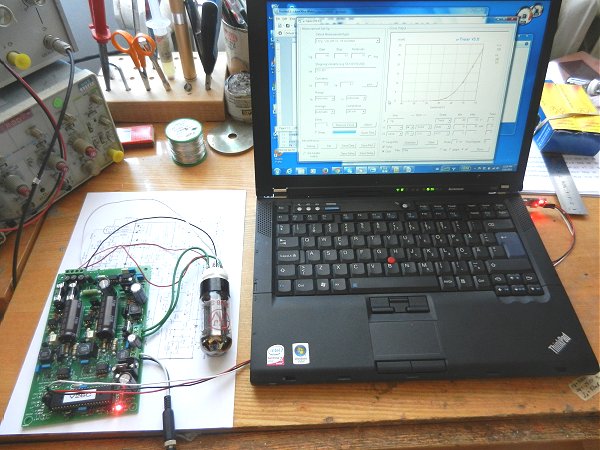

25th of Oktober 2025, After a small hiccup, Todor reports his uTracer fully functional!

Hello Ronald,

Thank you. You were right, the resistor was the problem.

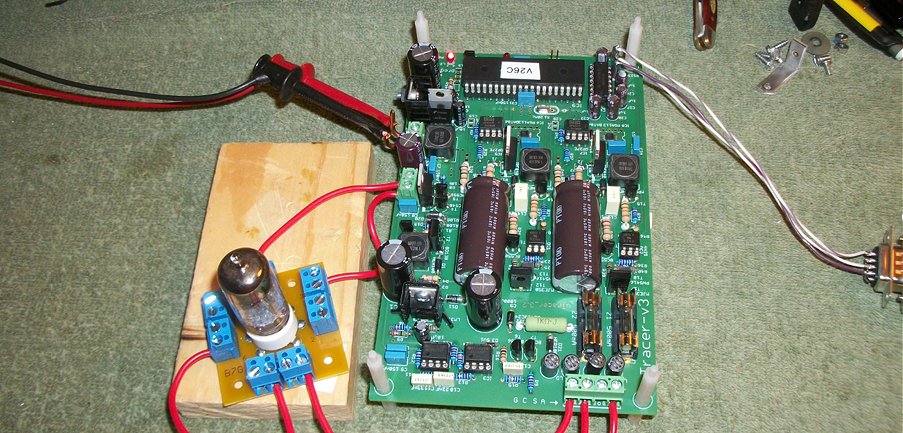

Everything is Ok. I'm sending you a photo of the final calibration. I just need to put it in a box. When I'm done, I'll send you a photo.

I wish you health and happiness in your family.

Todor

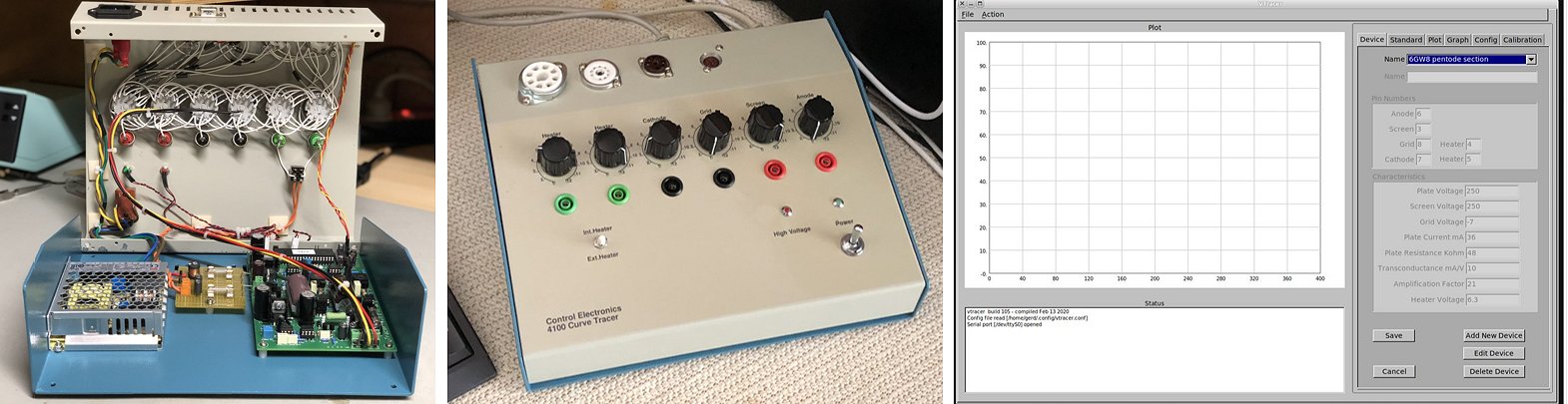

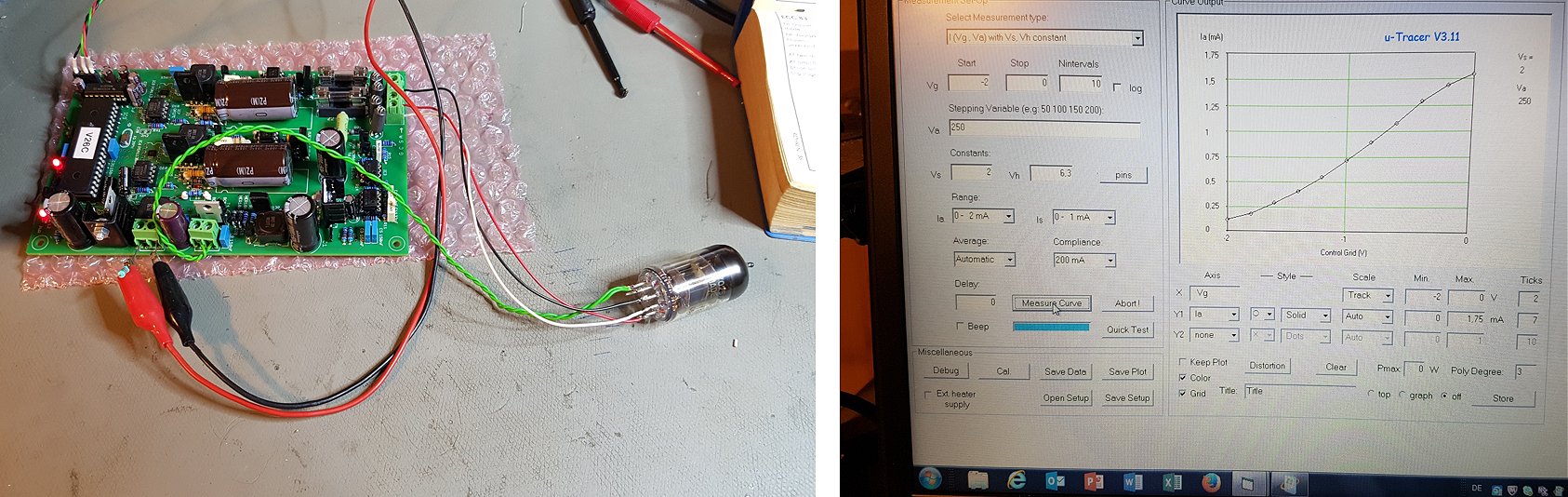

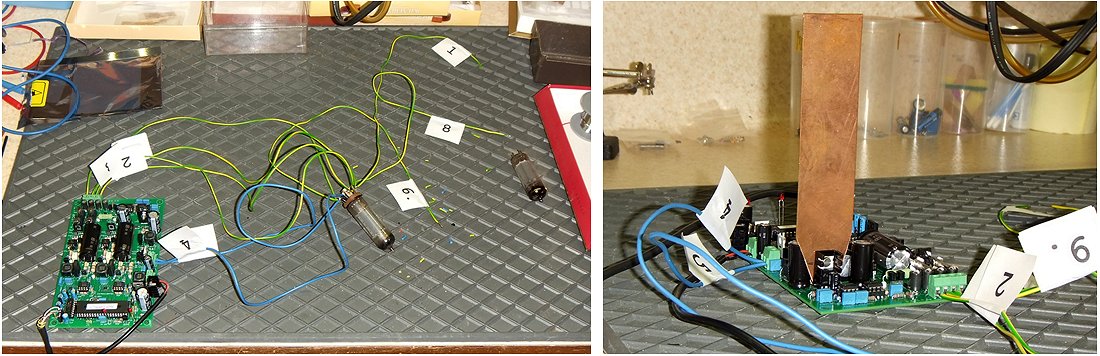

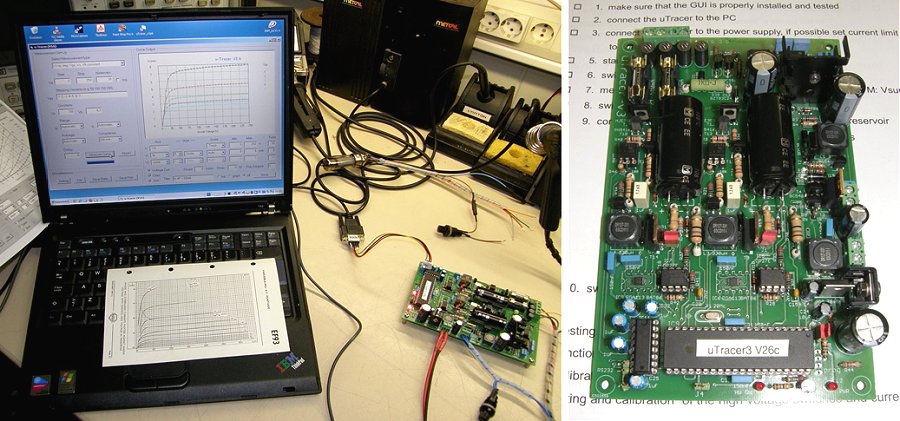

22nd of Oktober 2025, Frank reports his uTracer working!

Hello,

Everything is ready now.

First Tubetests works with no problems.

Only housing is missing and I have to build.

Thank you very much for this great tool.

Best regards

Frank

Mit freundlichen Grüßen

Frank

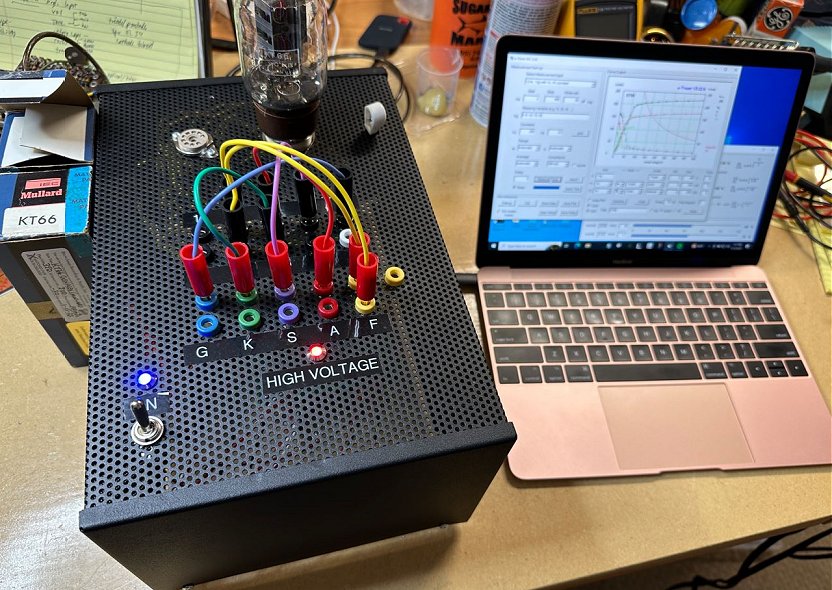

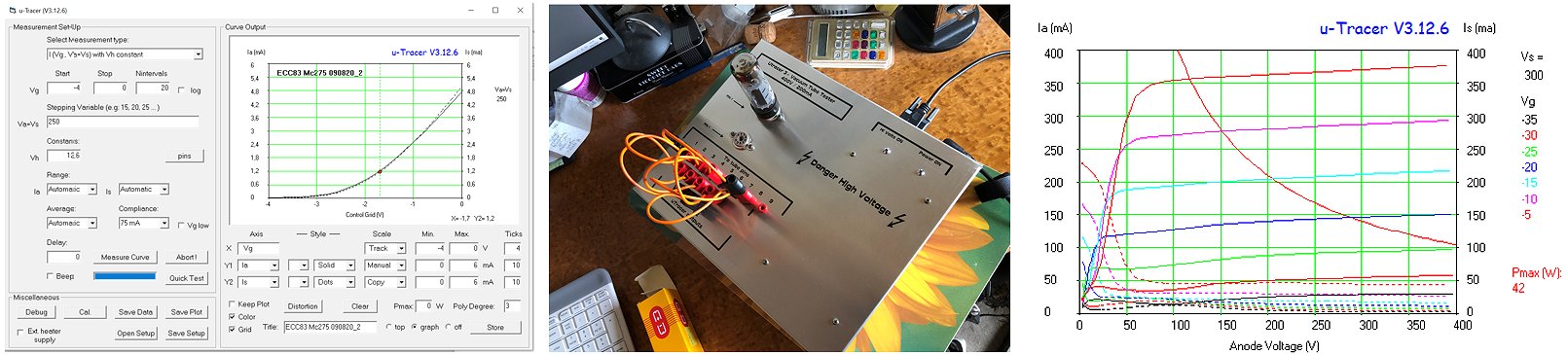

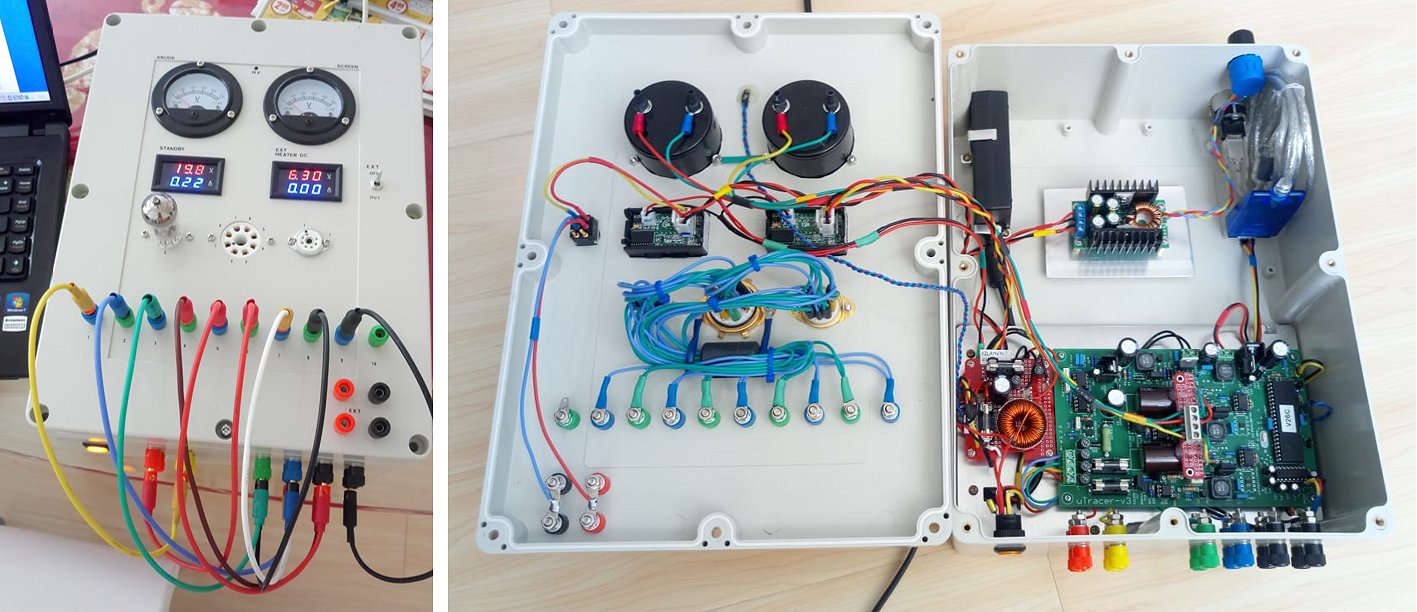

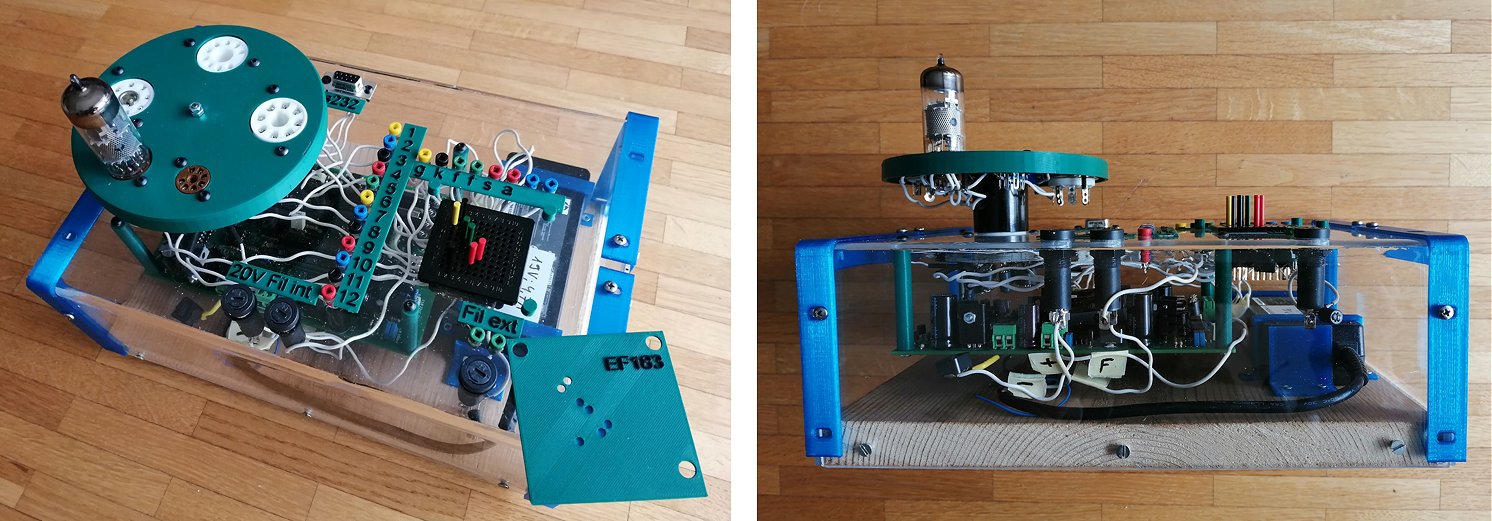

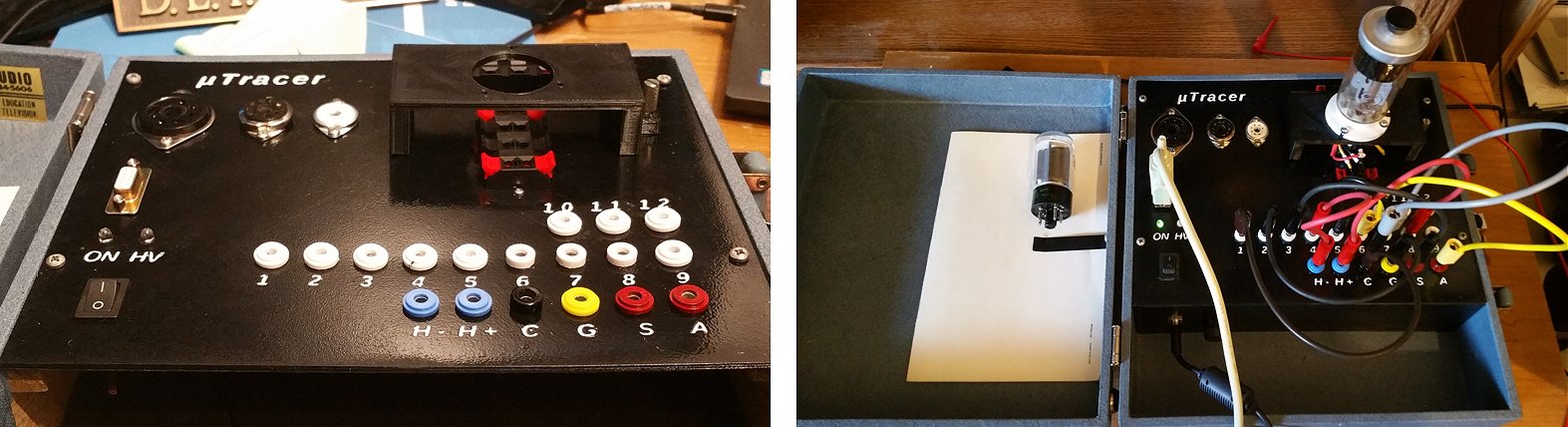

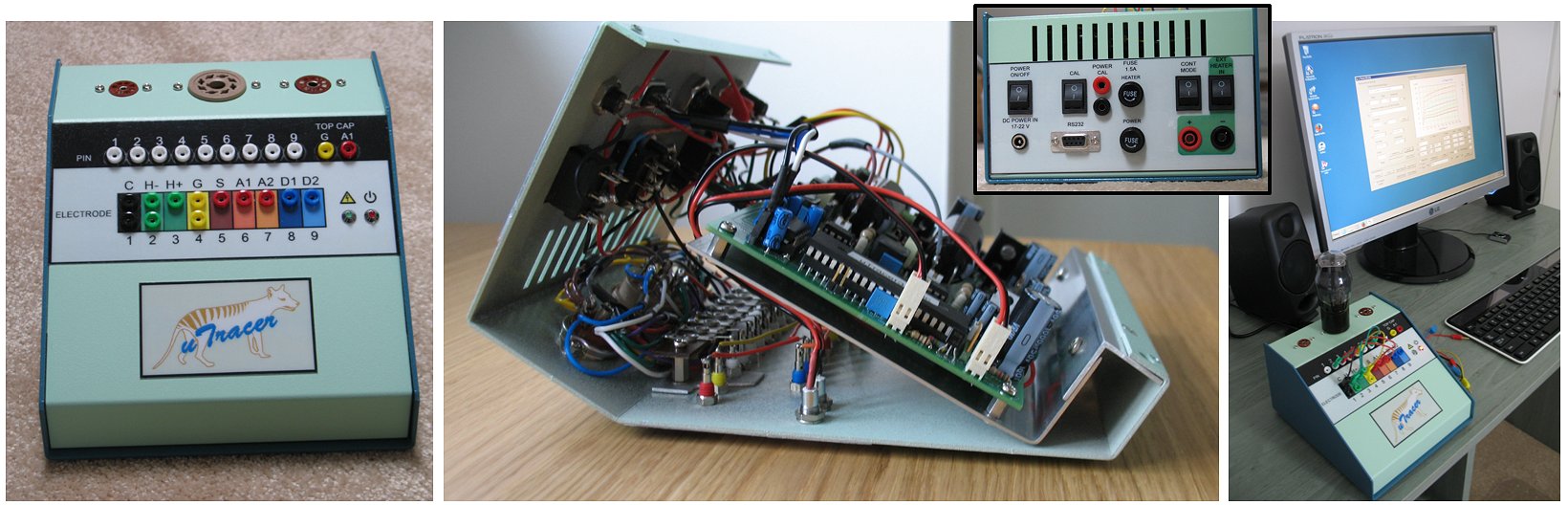

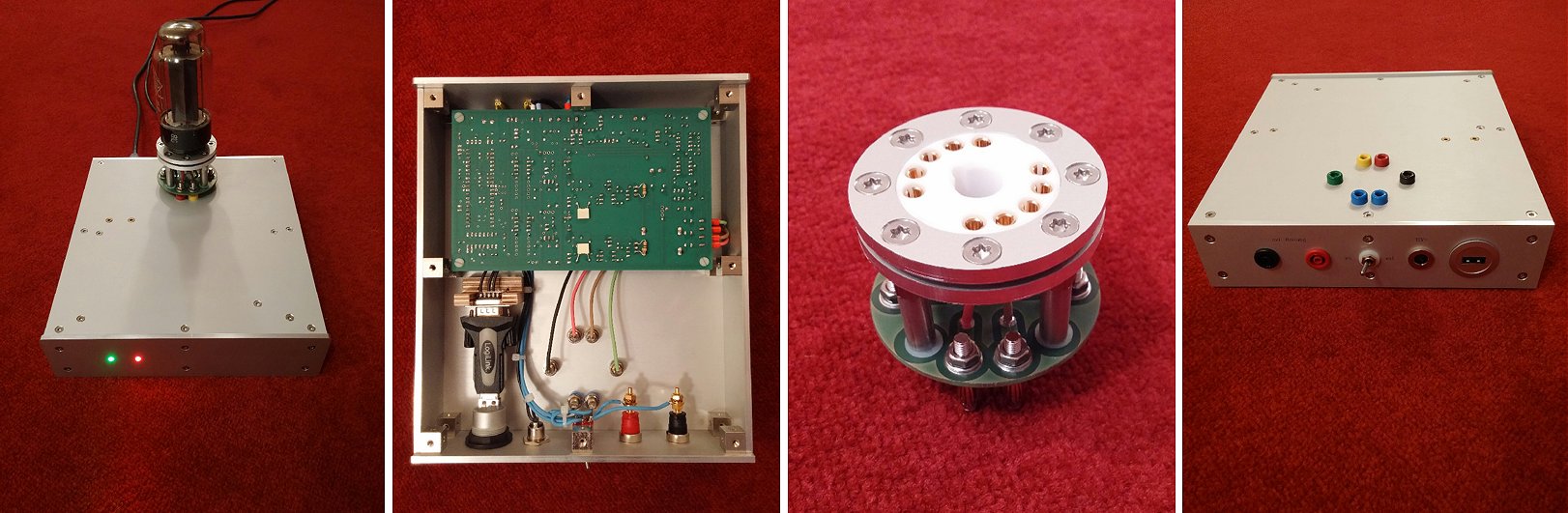

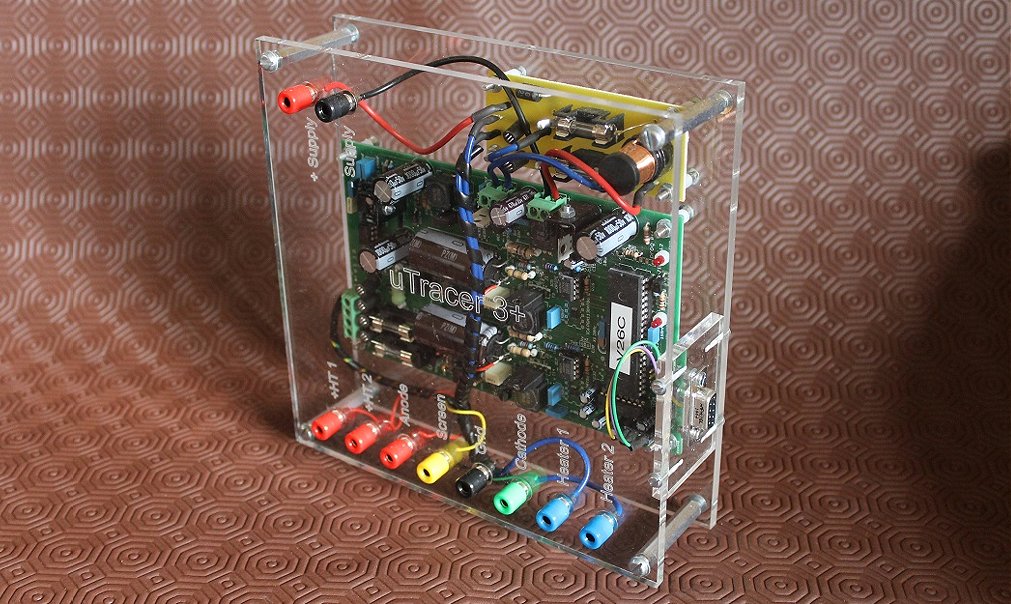

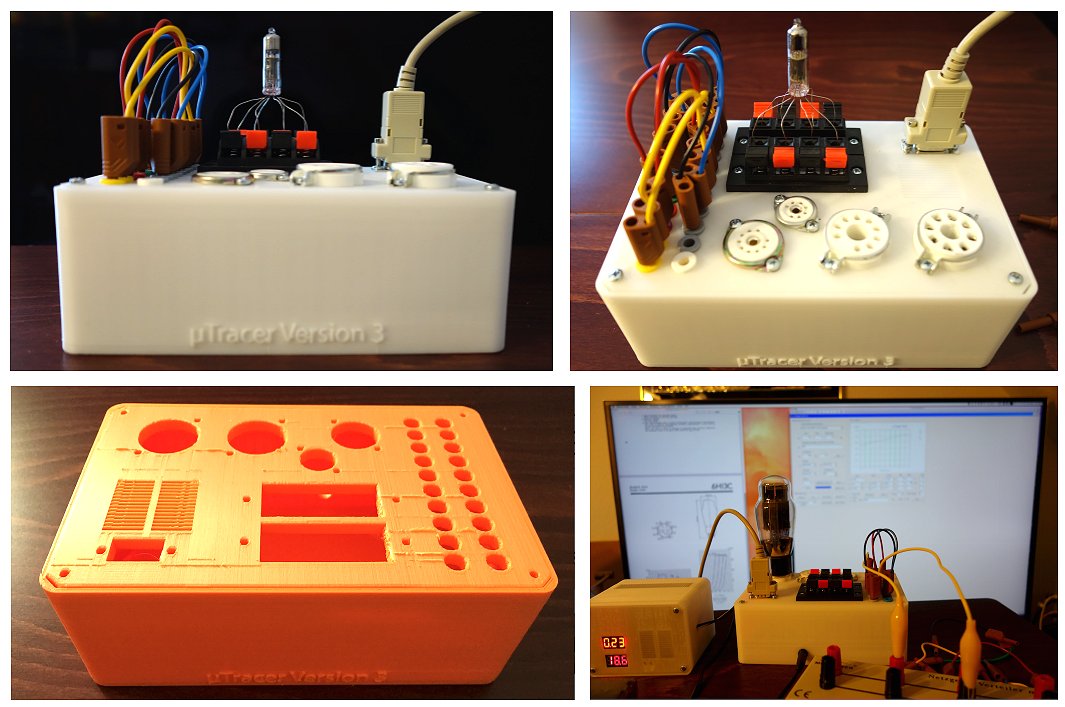

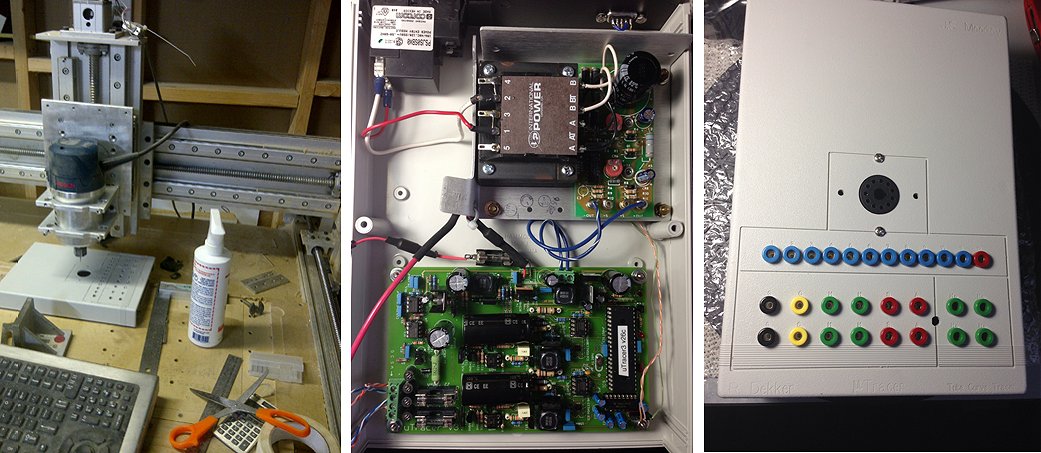

21st of Oktober 2025, Chris sent me a few pictures of his beautiful 3D printed uTracer!

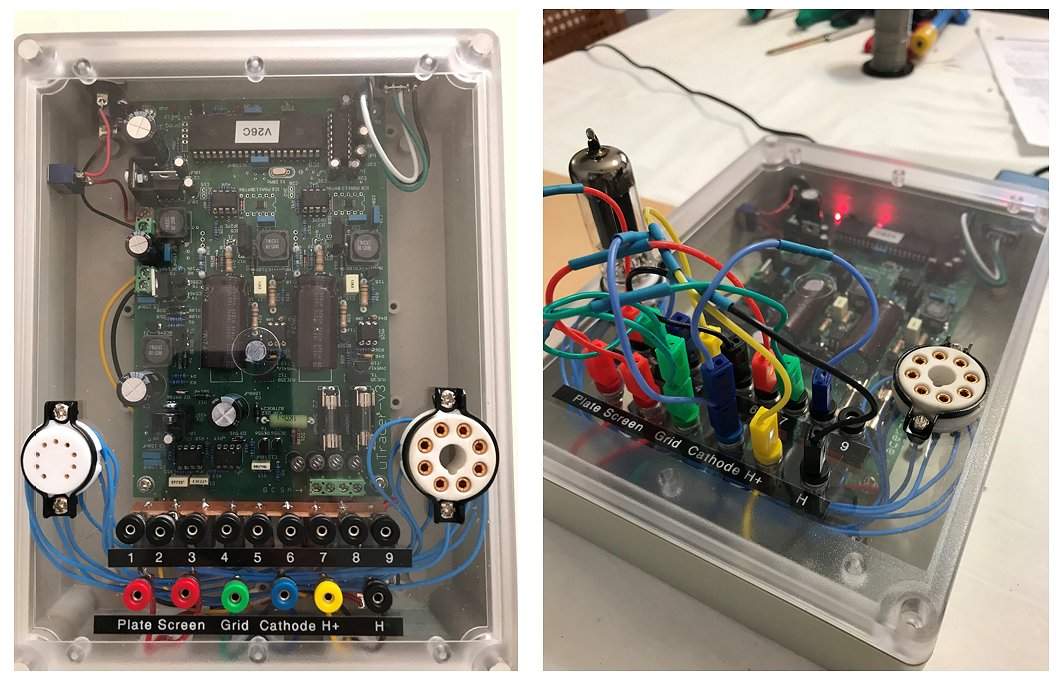

Hi Ronald,

I would like to thank you for your brilliant uTracer design and for making the kit available to enthusiast like me. The kit and instructions are top notch.

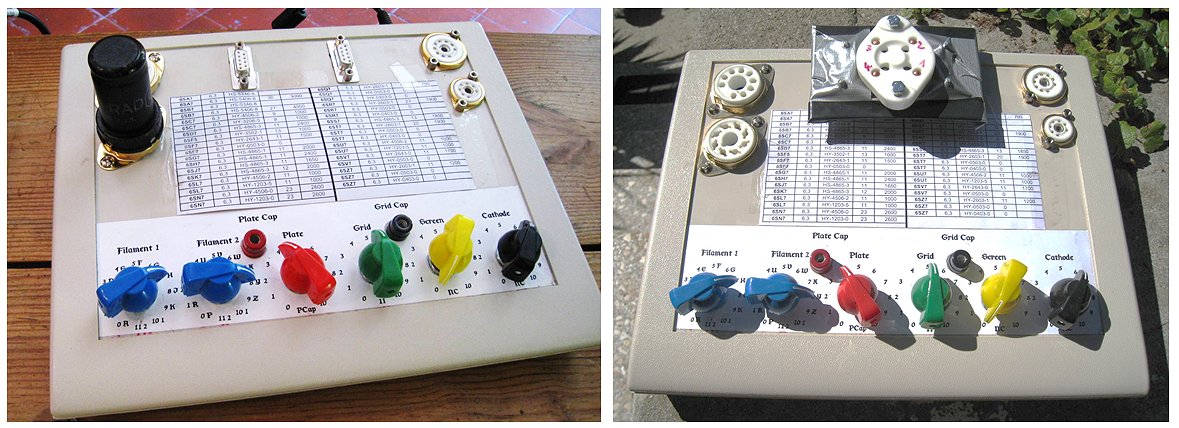

I attached a few photos of my project. I 3D printed the case and machined the top plate on my CNC mill. For the artwork I just printed the legend on self-adhesive vinyl sticker paper.

Thanks again for your great work,

Chris

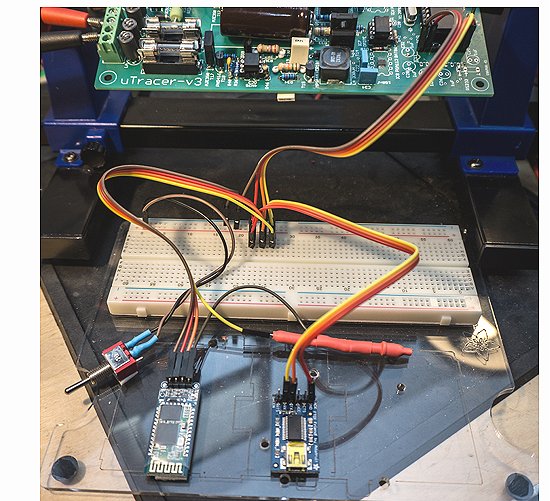

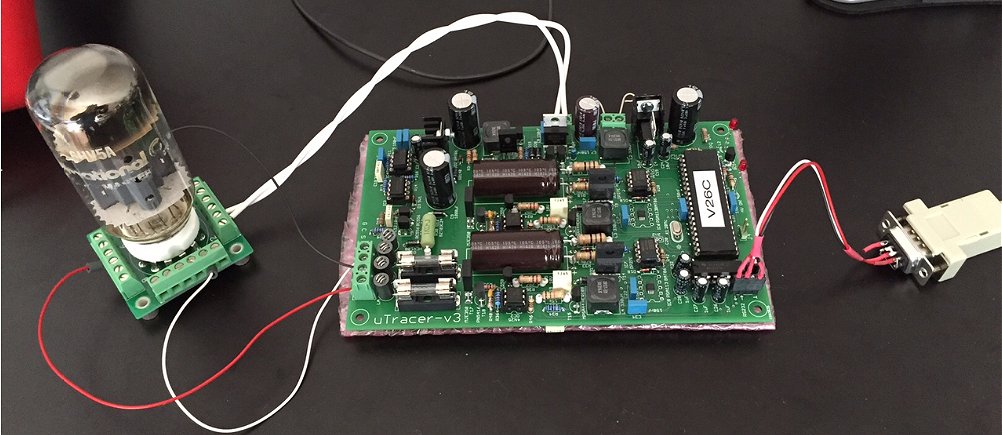

4th of Oktober 2025, Jedidiah reports steady progress on his uTracer!

I’m sorry to hear of your illnesses! I hope you find good health in the future.

I’m enjoying my build of the uTracer. I plan on using it for testing 01A dht’s. I see your note about placing a low resistivity pot in parallel to the heater with cathode connection to the slider. What does that allow to happen? I have my external heater supply set up with a 5k pot on an lm317. Does your suggestion give further control somehow and how would I monitor it?

Thank you again for all your work on this project and the gift you’ve given to the tube/valve community!

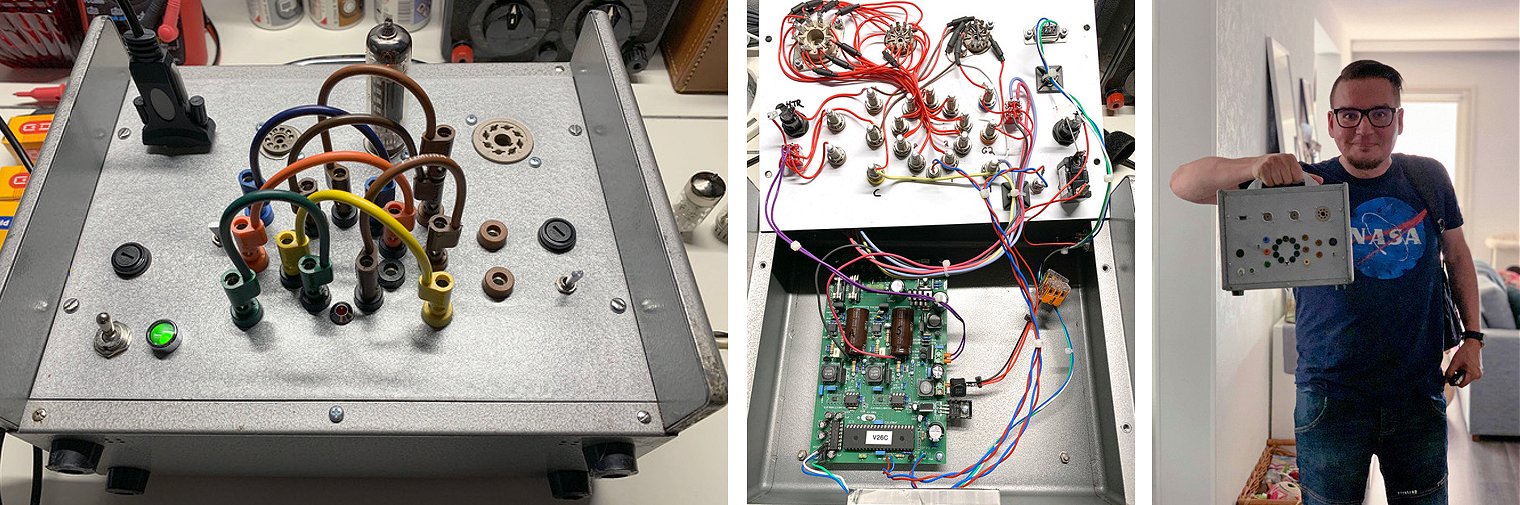

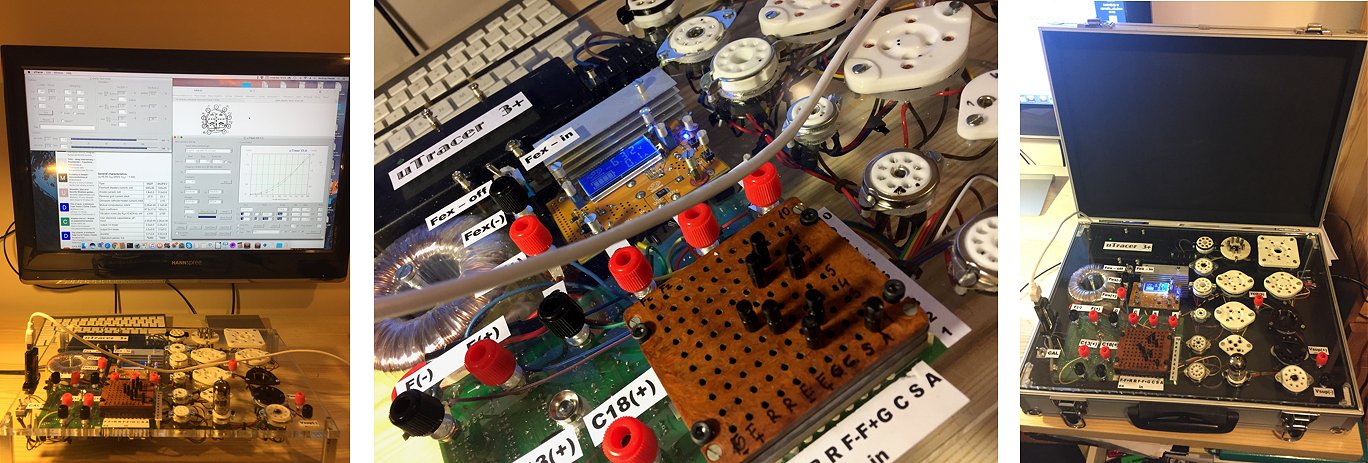

30th of September 2025, Tuukka sent me a few pictures of his fine uTracer!

Hi Ronald & Marie-José

Sorry to hear about your illness, good to know you are both OK now!

I have been very satisfied with the old version uTracer, anyway not having very much new tube projects lately it has not seen very much use.

I feel for you about the copied concept - and will surely let you, and buyers know about it if I ever see one.

Don't know if I ever sent you pictures of my uTracer build - here they are. Many tube radios and some amplifiers have been restored with it. Some "hot" tubes tend to oscillate while testing, I guess some more ferrite beads are needed.

Best regards,

Tuukka

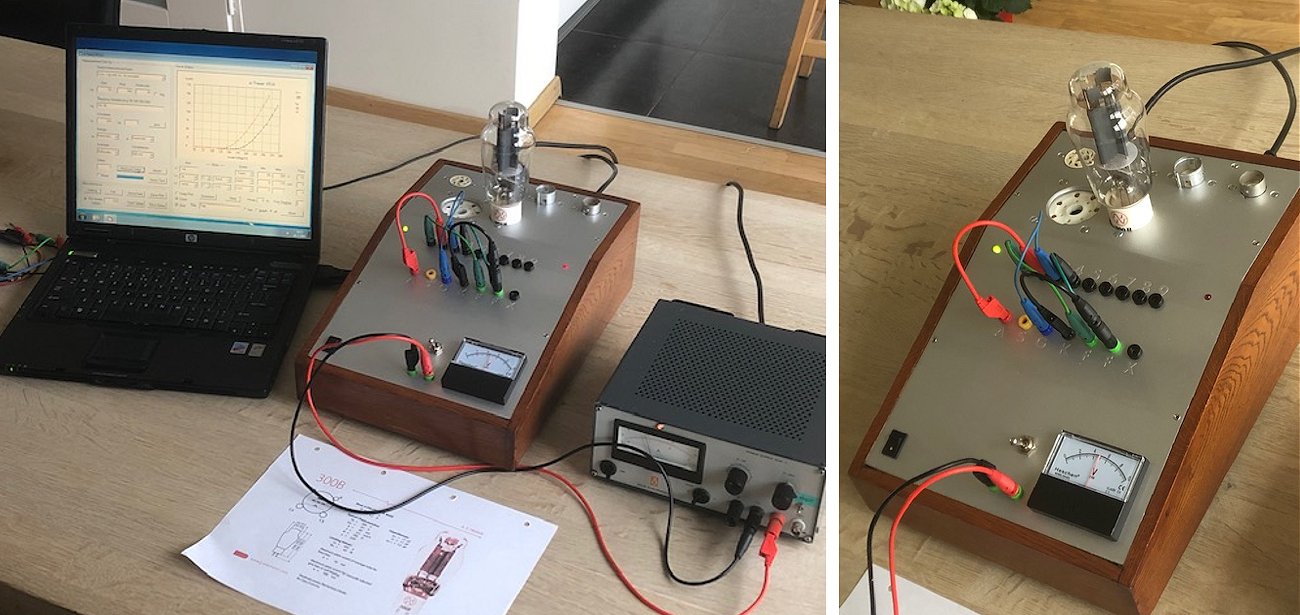

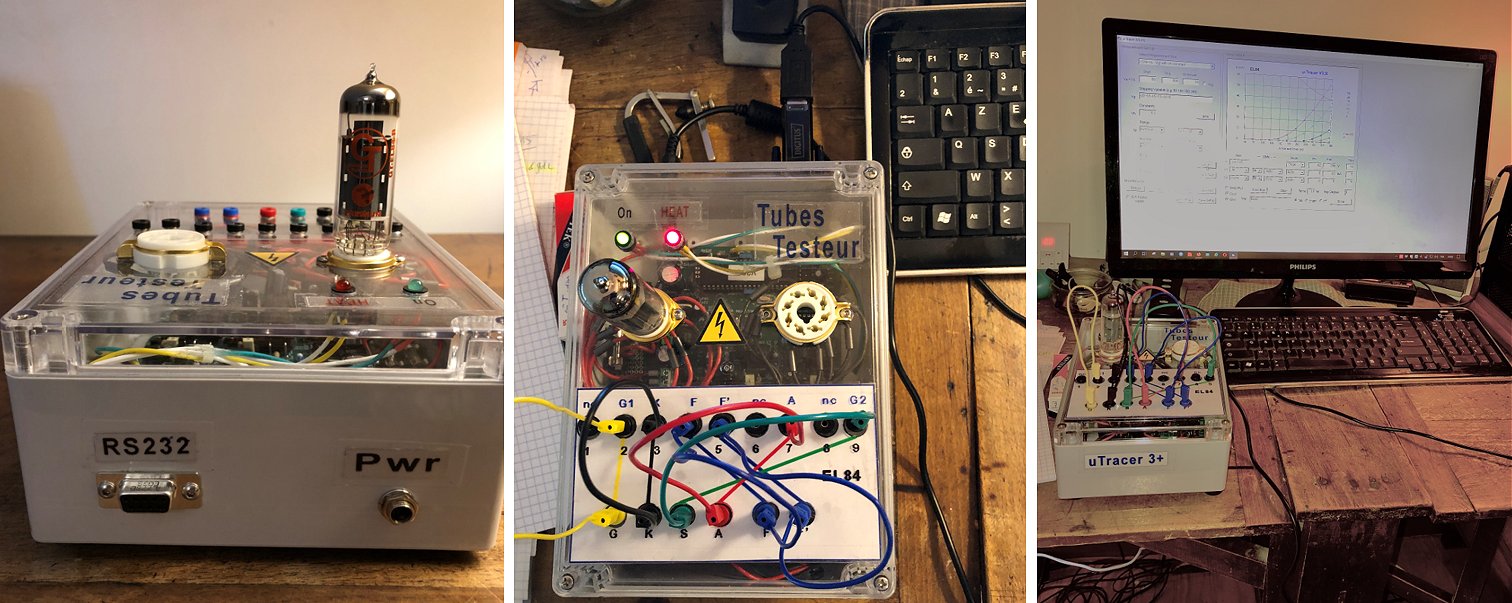

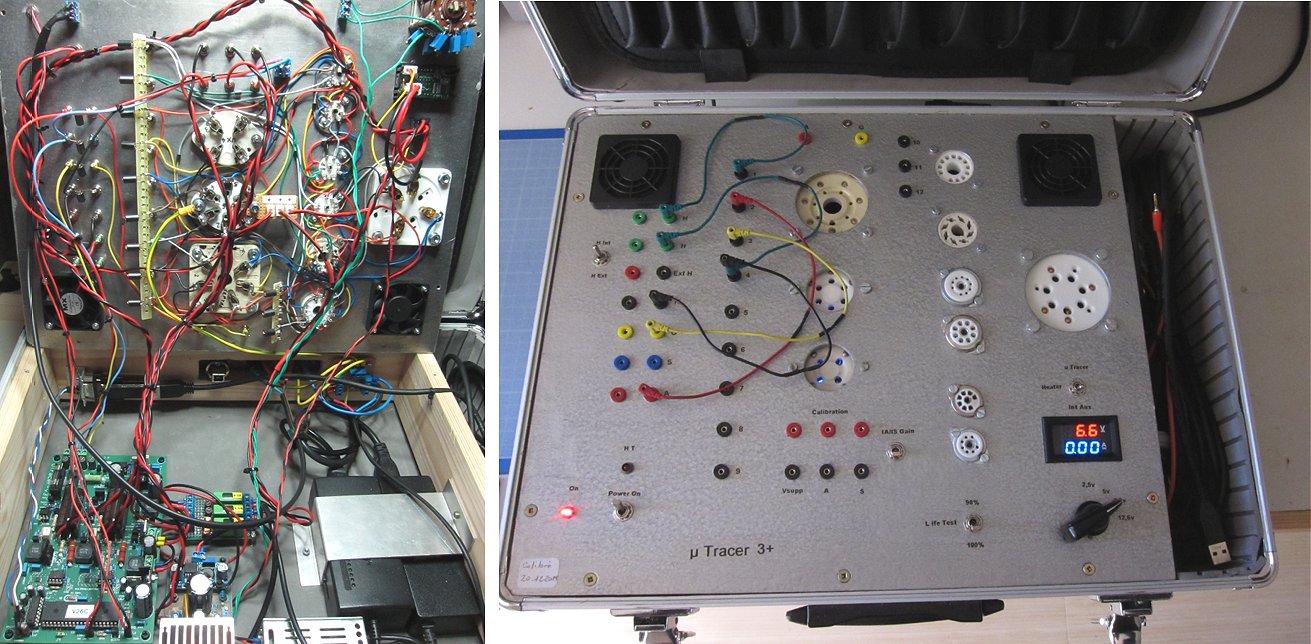

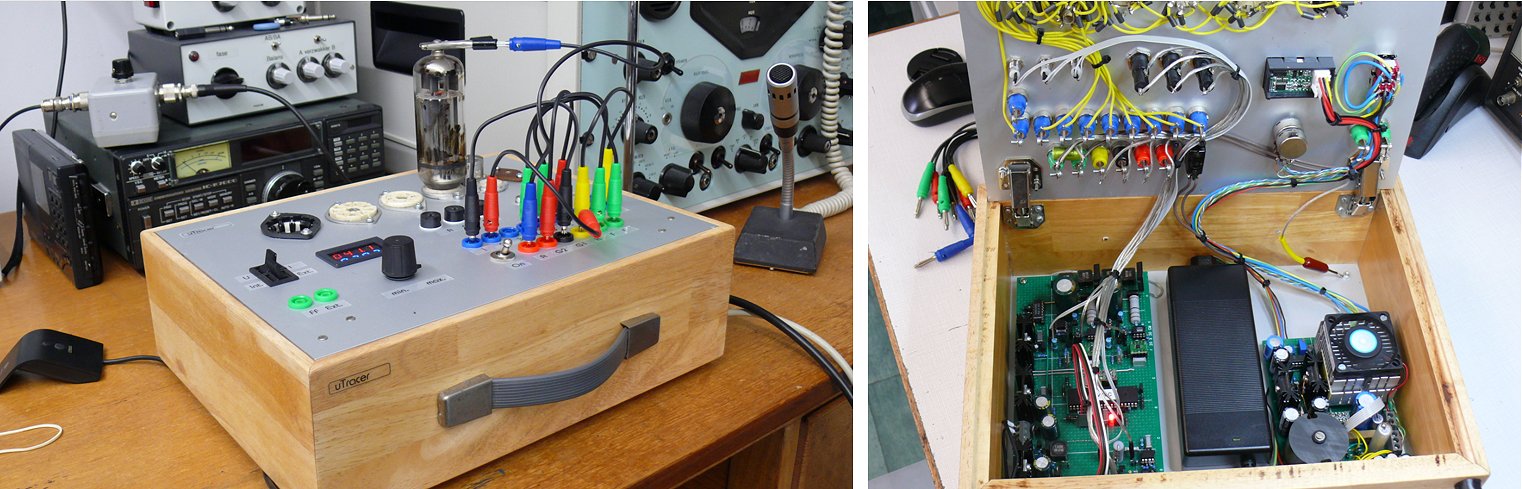

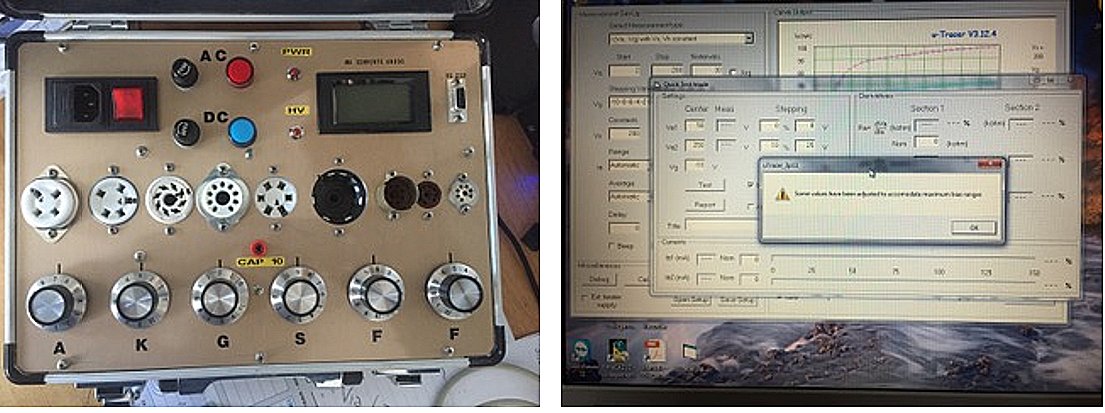

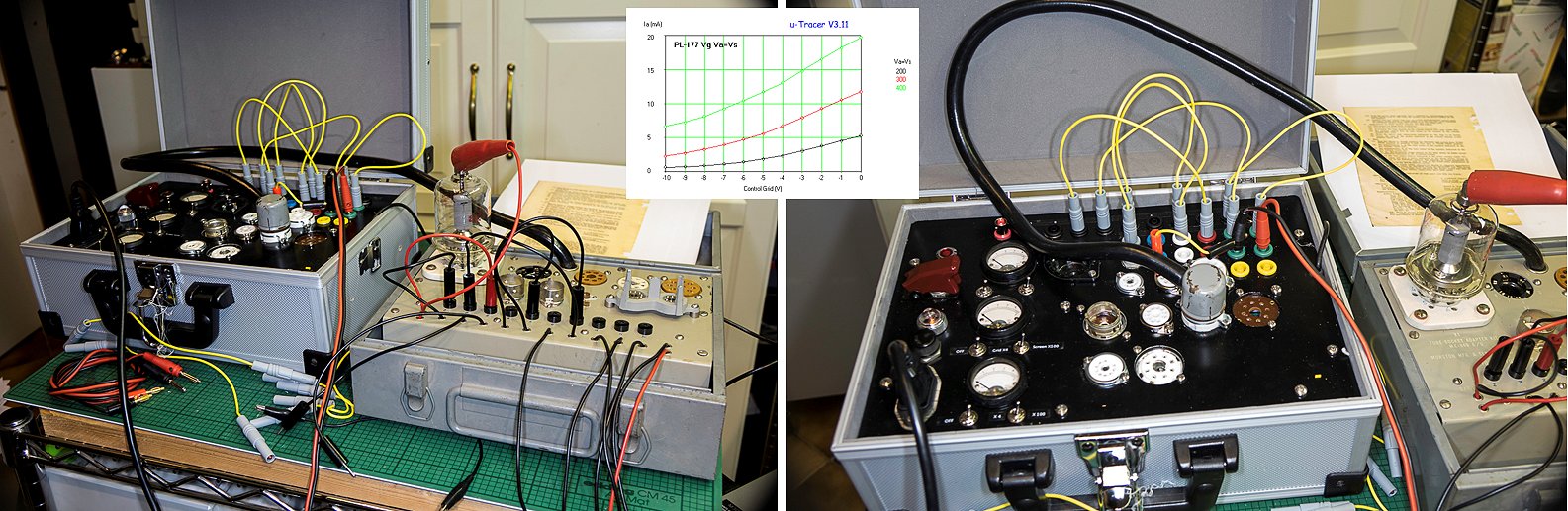

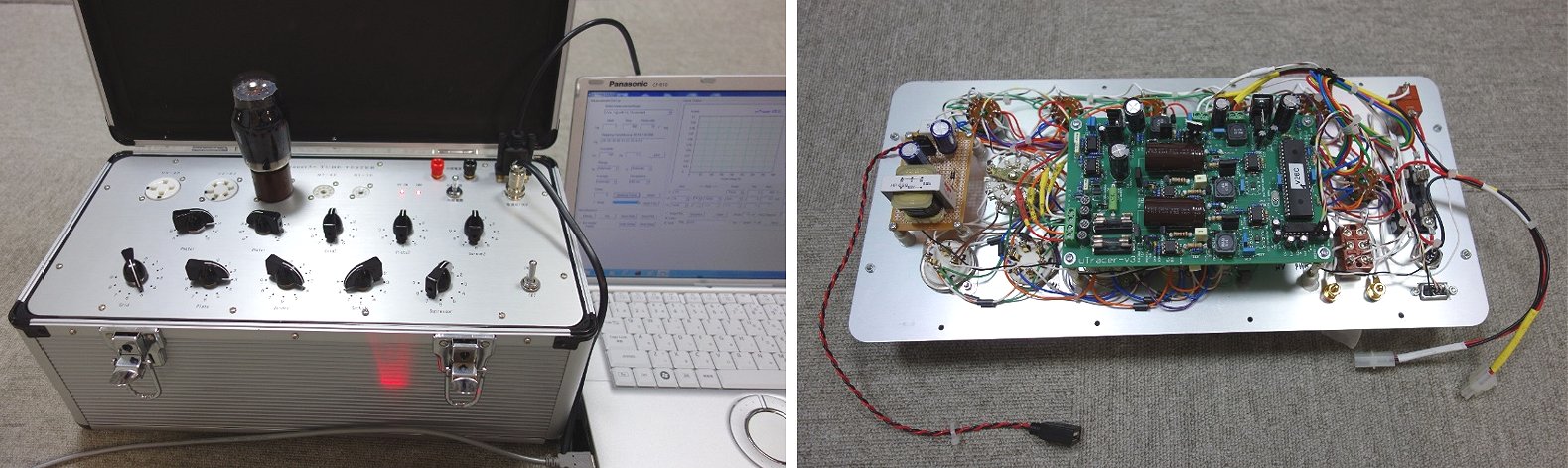

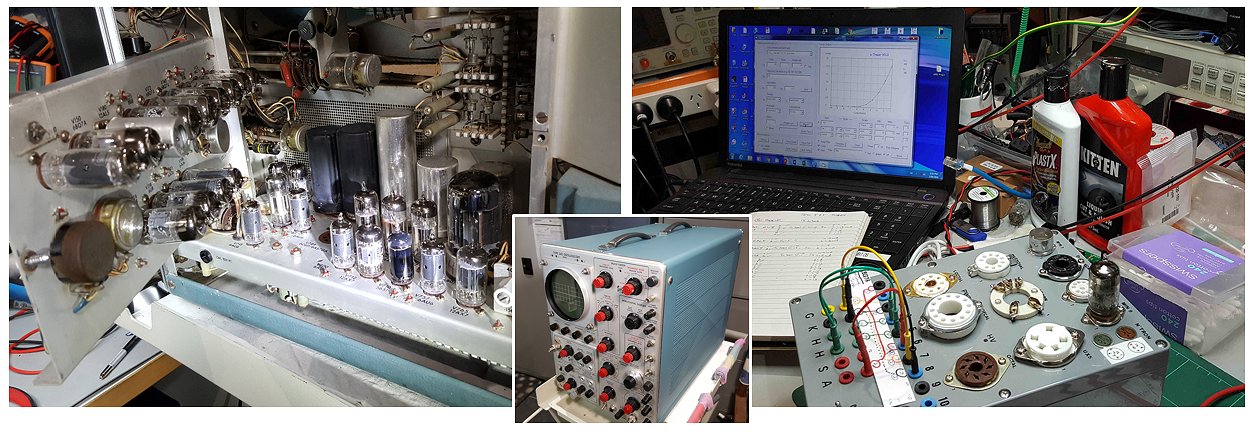

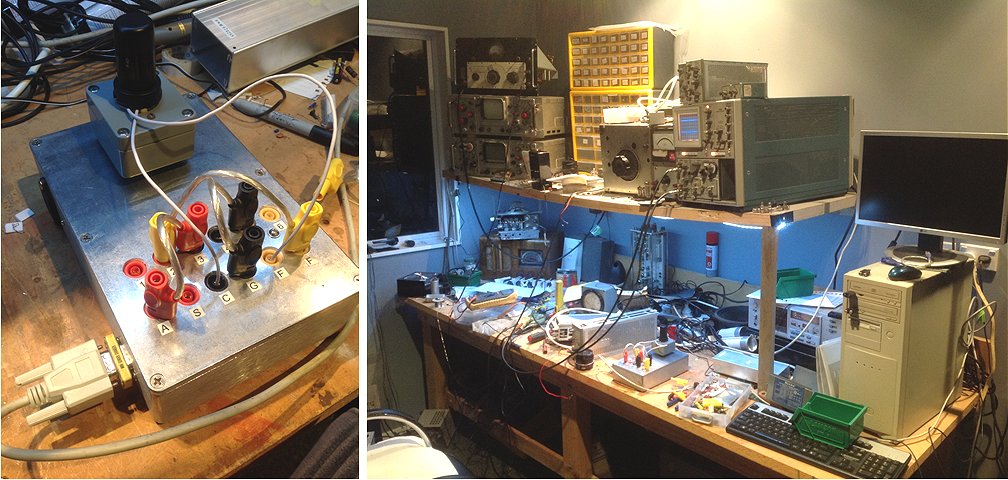

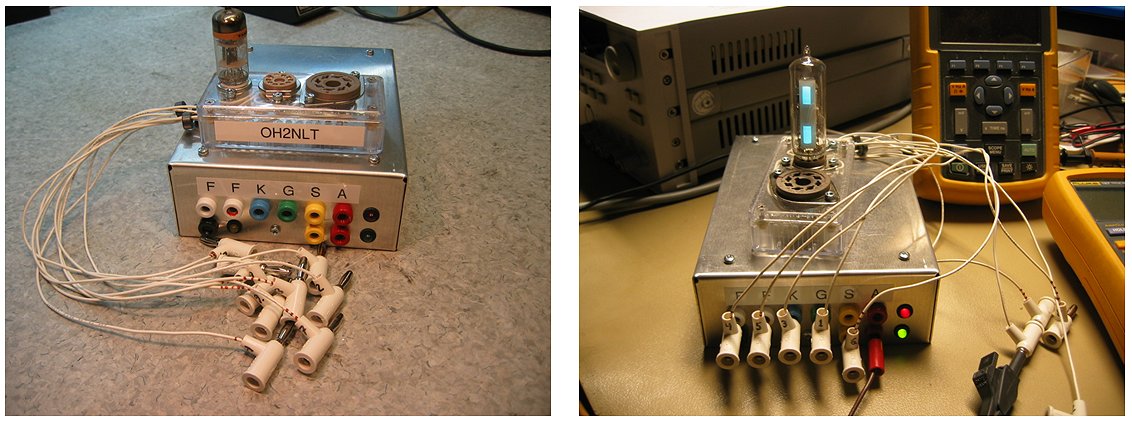

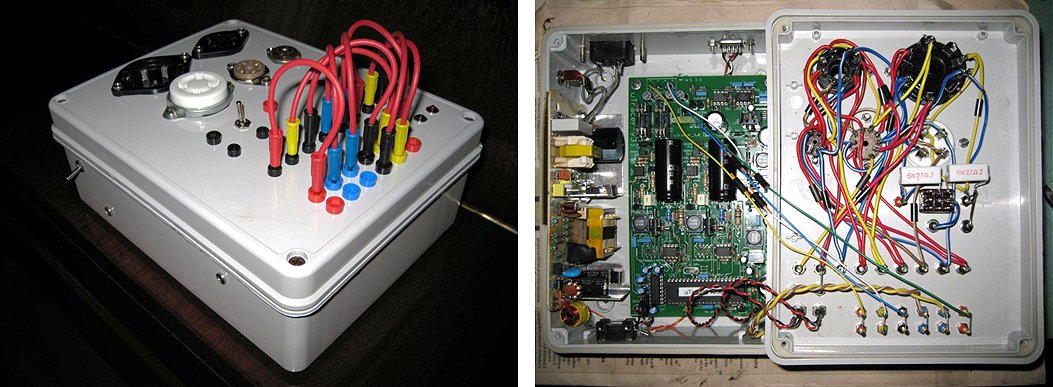

30th of September 2025, Have a look at Philippe’s great uTracer and magnificent workshop!

Dear Ronald and Marie José,

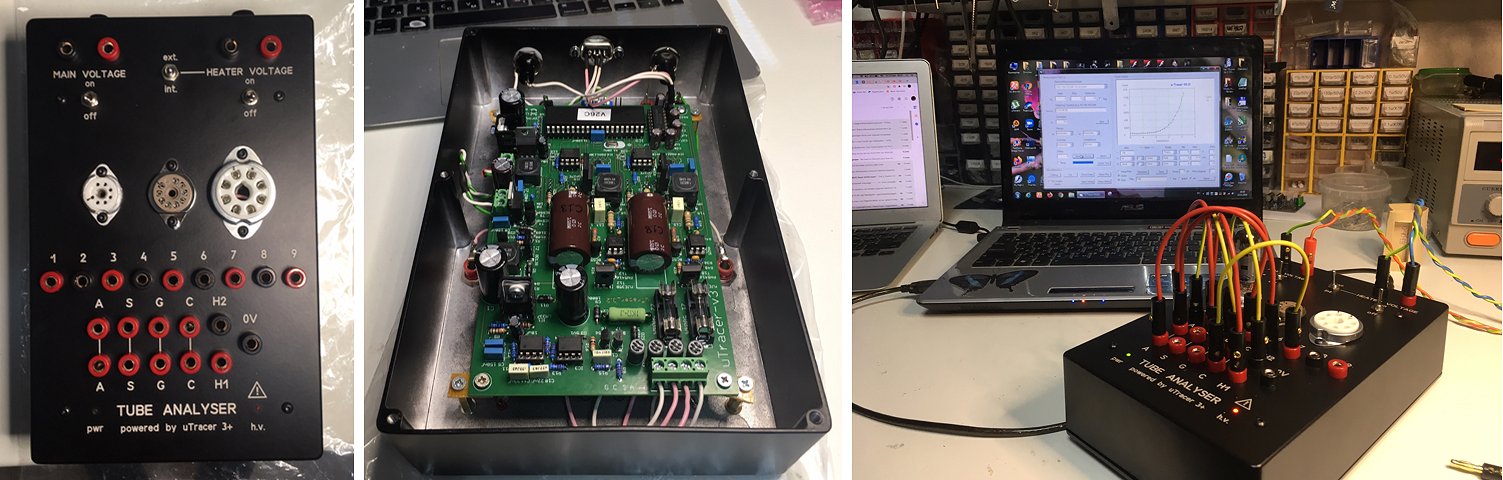

First of all, I'm very happy that you and your wife have overcome these health problems. I wish you the bests in the future :-) I received your newsletter message just as I was about to send you some news about my own u Tracer, which I just finished à few days ago ! I owned the kit since January 2025, but I hadn't yet devoted the necessary time to complete assembly and integrate it into a "box"...

The assembly went perfectly thanks to the very comprehensive documentation and the test procedure, as the assembly progressed..., which helps avoid errors and makes adjustments very easy. I'm sending you photos of the device fully finished and operational...

For the "box", I chose to assemble it in a small toolbox purchased from a hardware store. I find this makes it very easy to carrying with all its accessories and cords ... You'll see it in action on my bench on the photos !

It will be used mainly for maintaining and building tube audio amplifiers.

I'm just getting to use the software and haven't encountered any particular difficulties so far...

I was just wondering if it would be possible to add an LED to signal when the heating is enabled. The indication on the software is present, but I think it would be a nice added value to have it on the front panel of the enclosure.

If I wanted to add this indication, where would be the best place to connect this LED on the board? In parallel with the heating output, limiting the current in the LED accordingly? You'll also see that I've planned to be able to use an external power supply for the heating, but at this stage, the wiring modification you suggest in your documentation hasn't been made yet.

The photos and my short comment can of course be used for your website.

Best regards.

Philippe

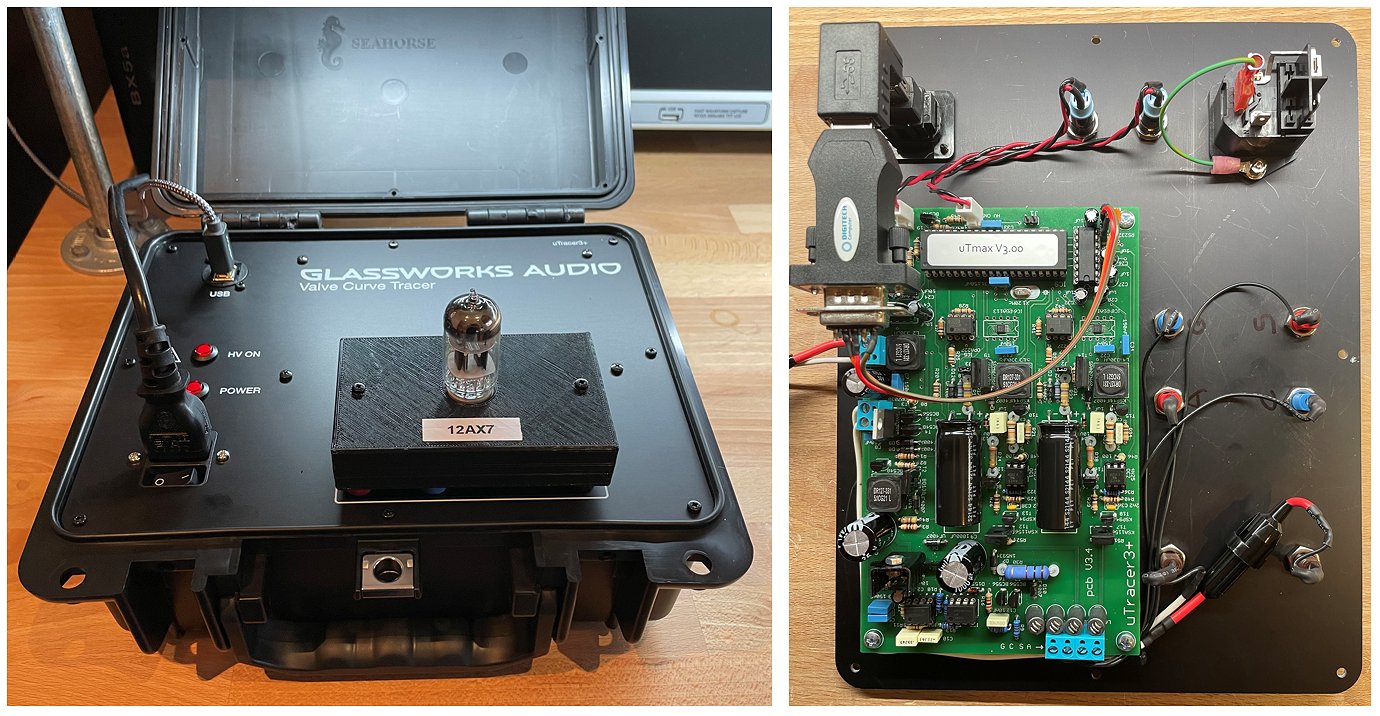

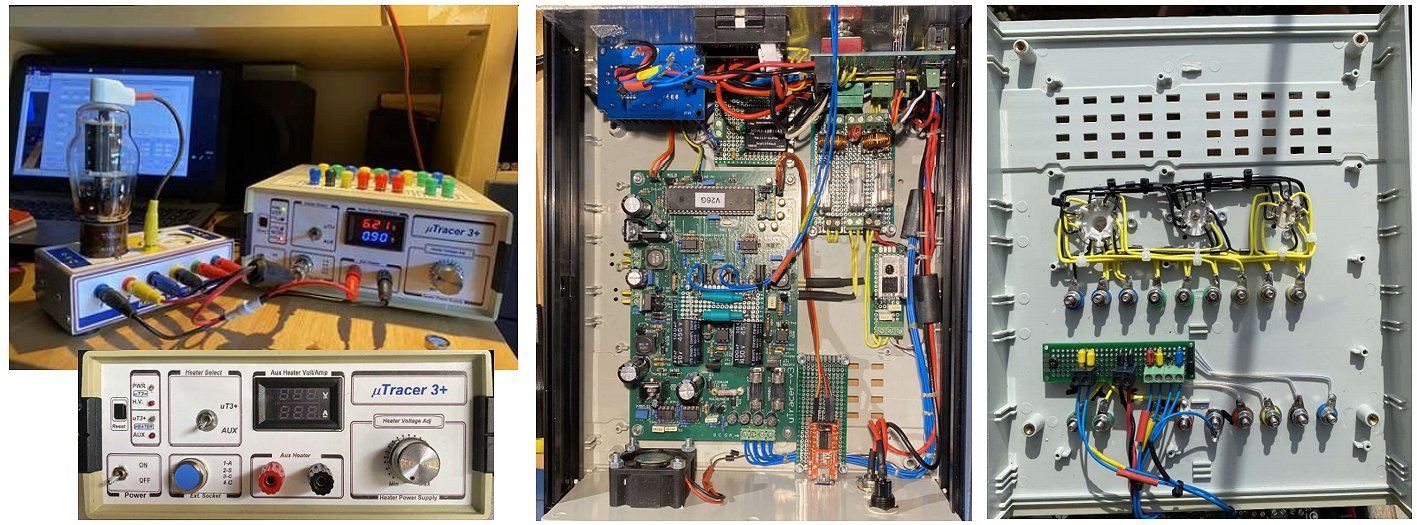

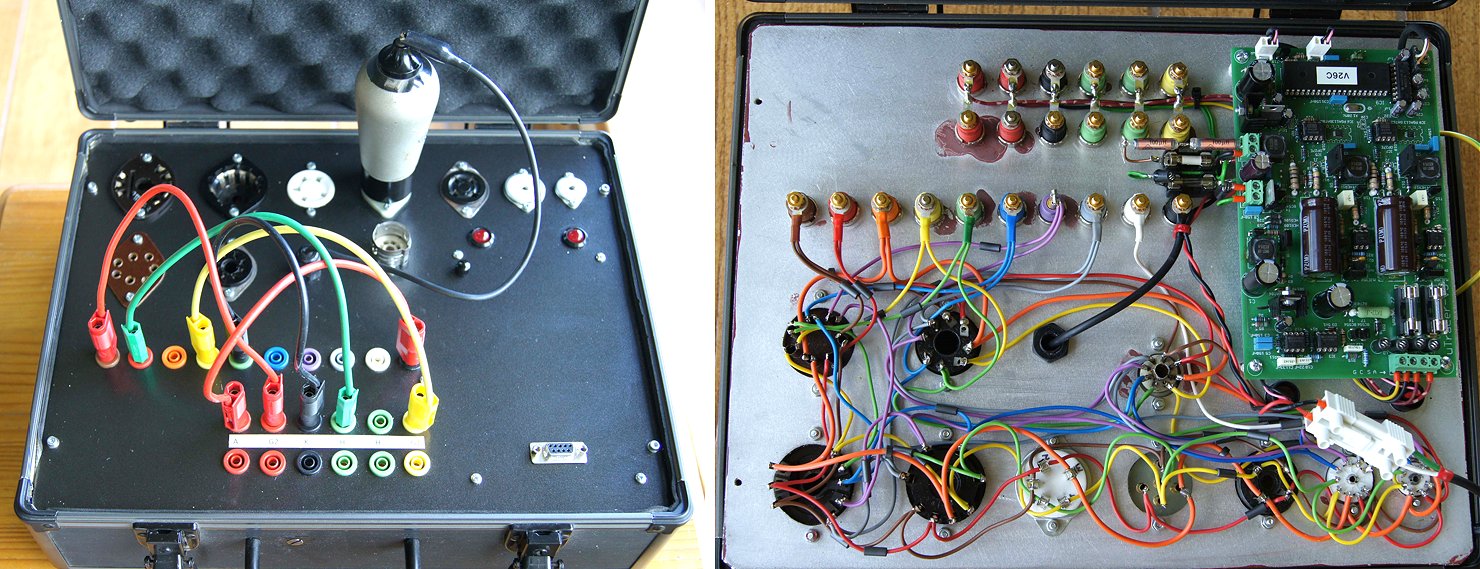

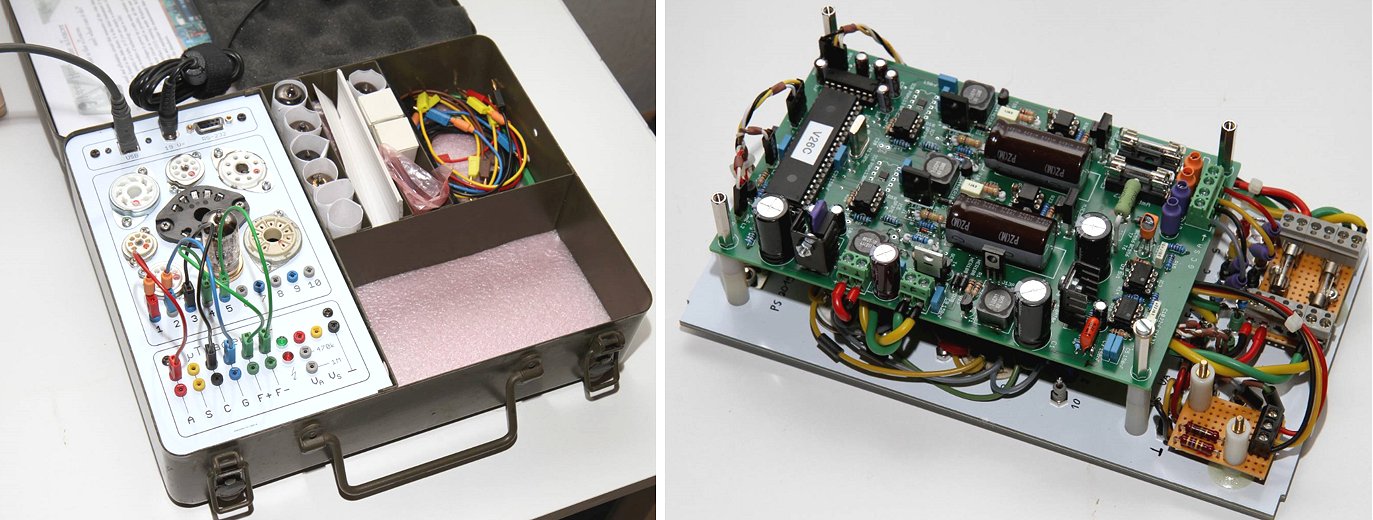

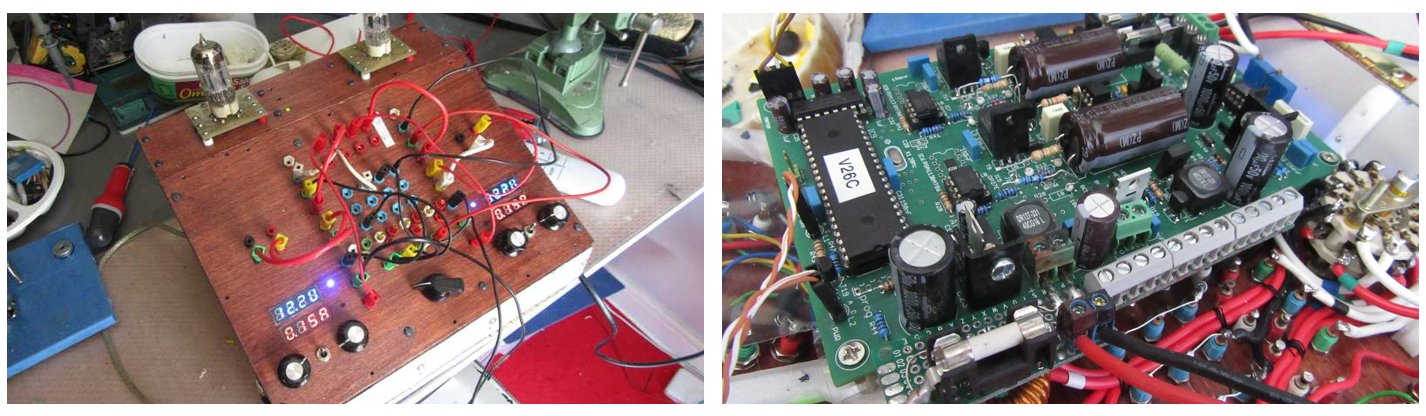

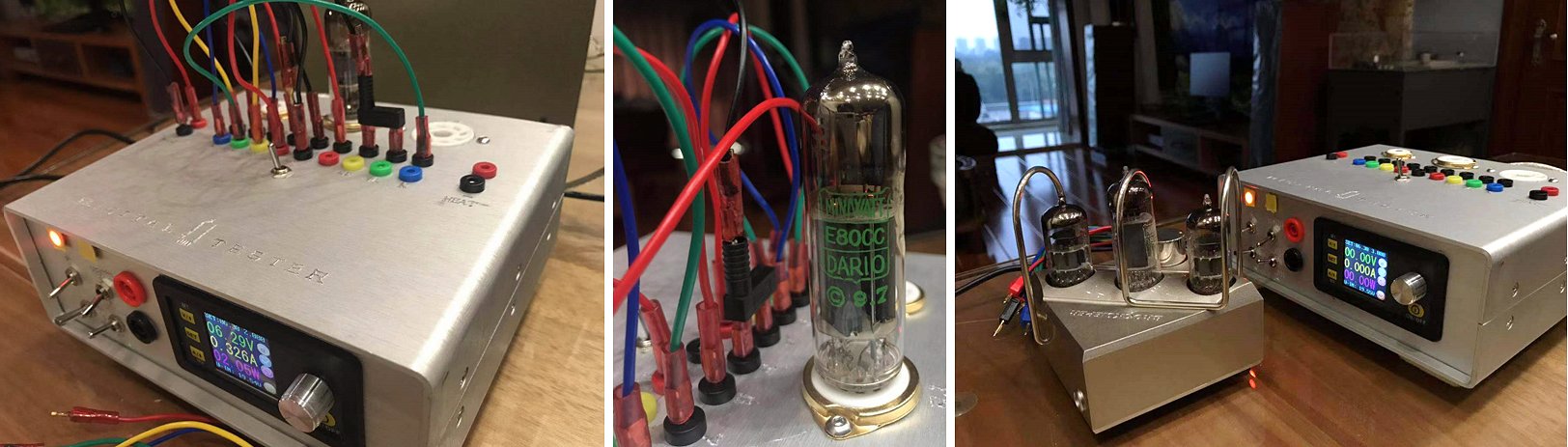

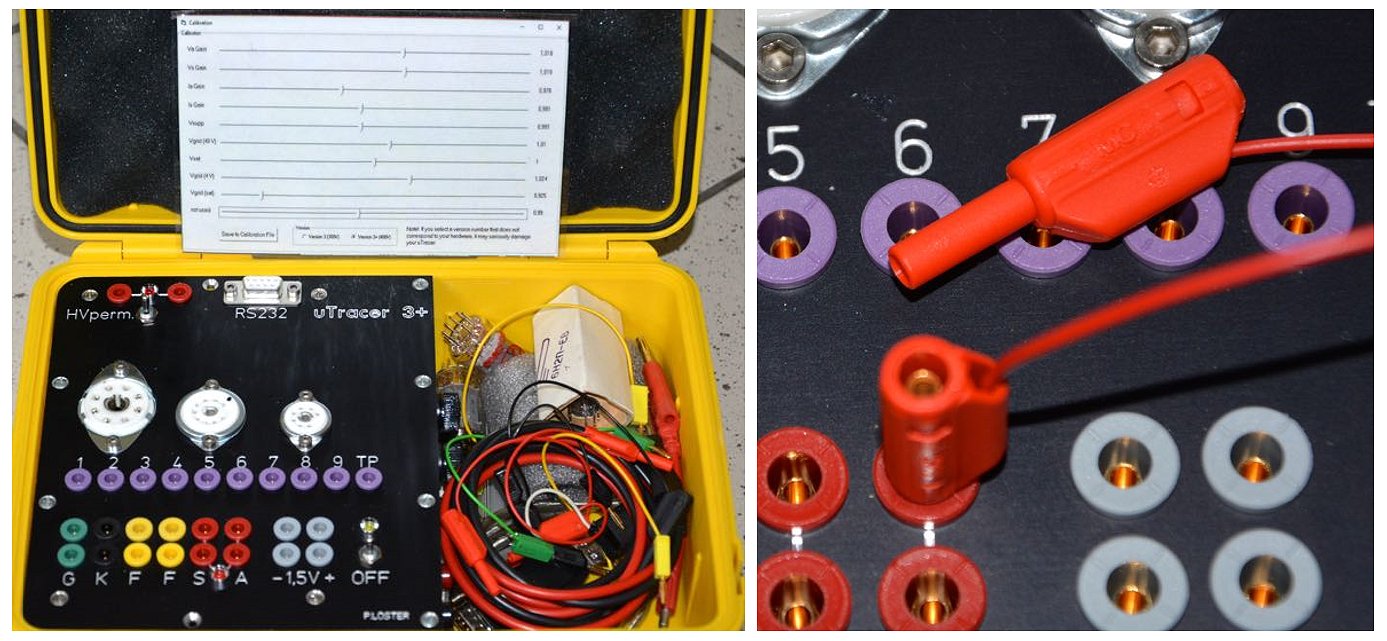

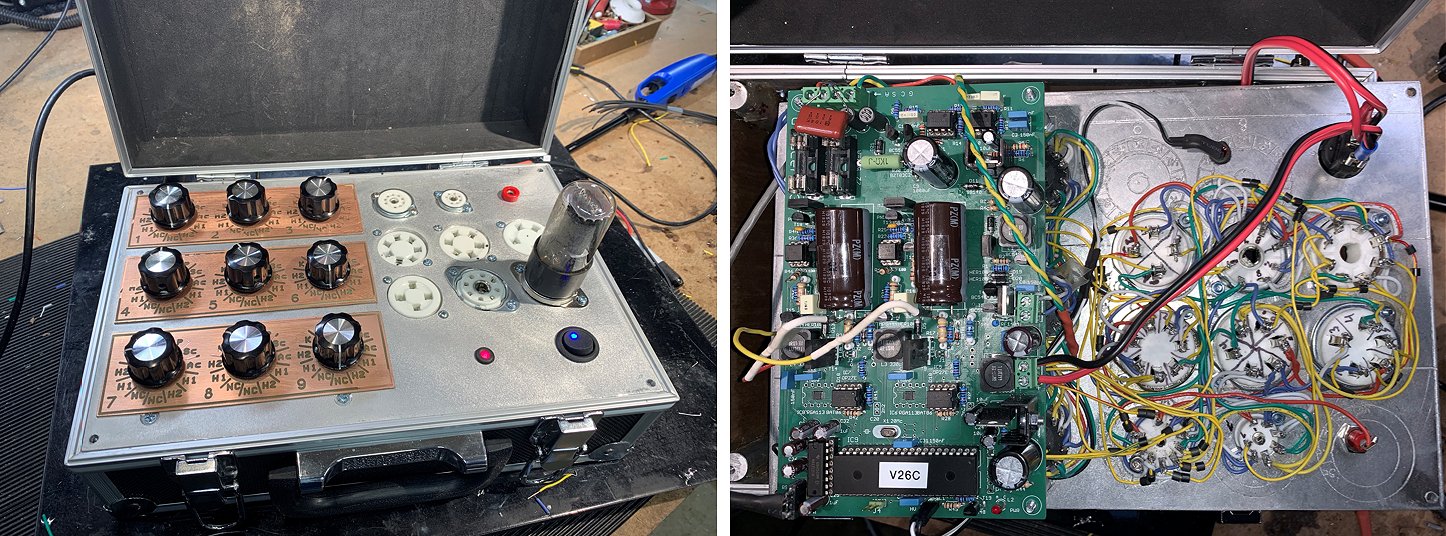

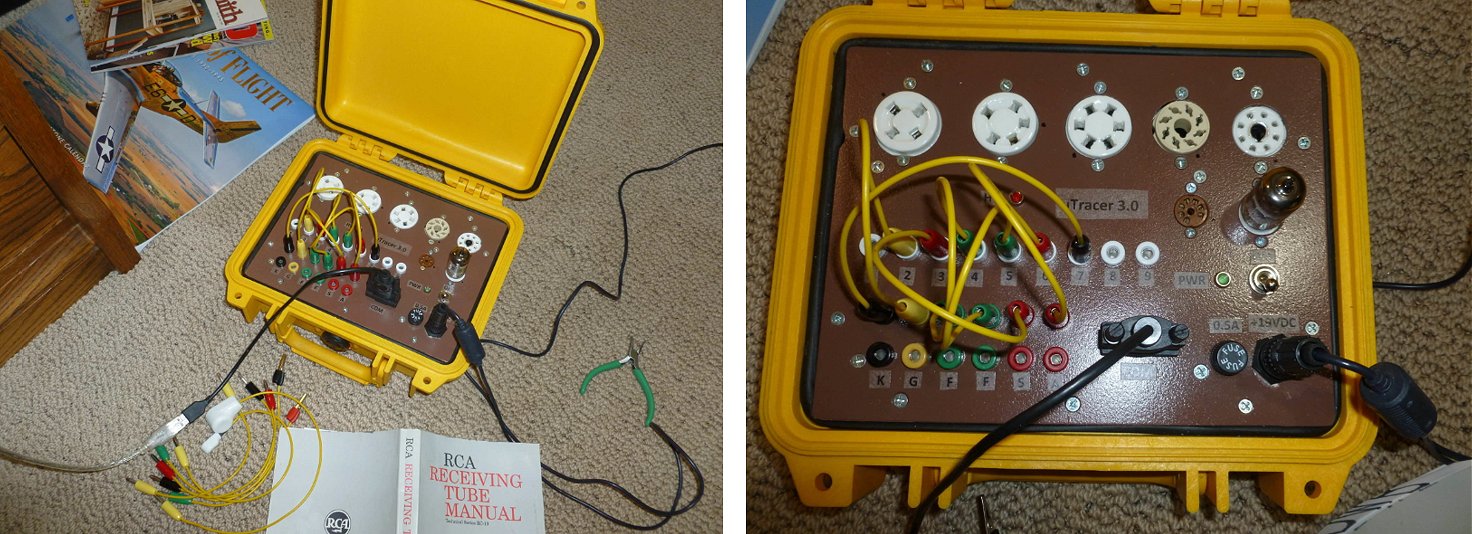

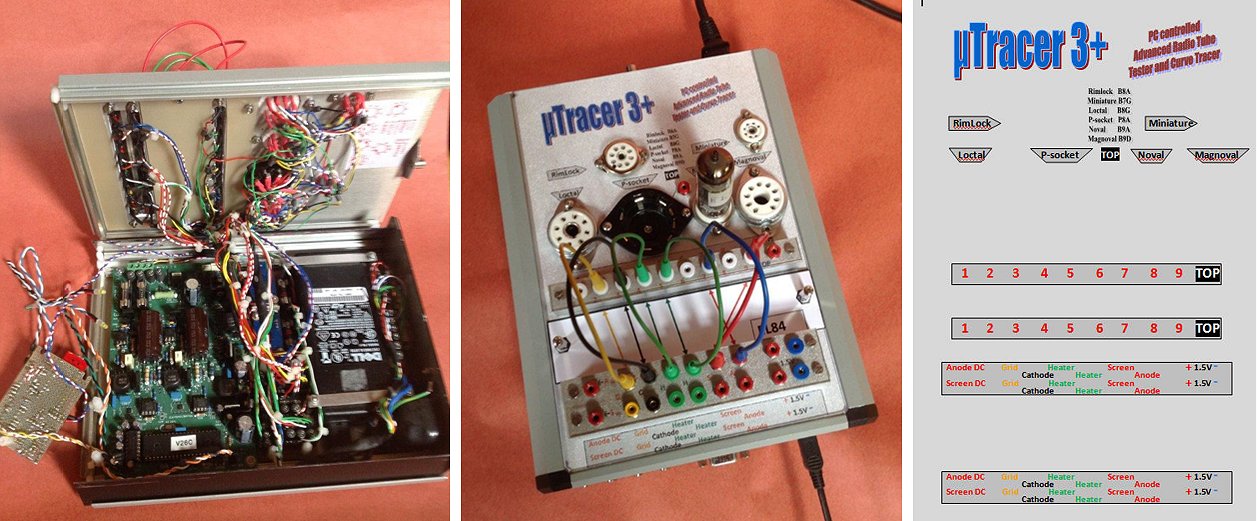

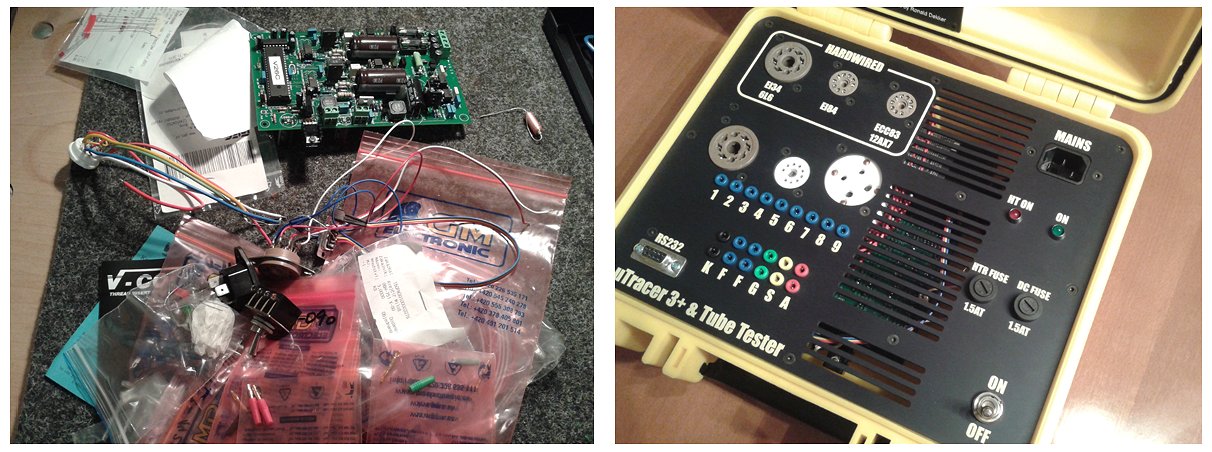

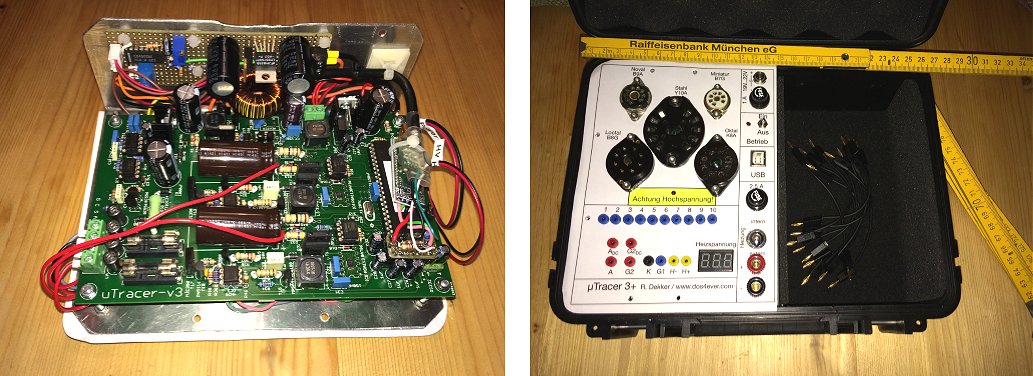

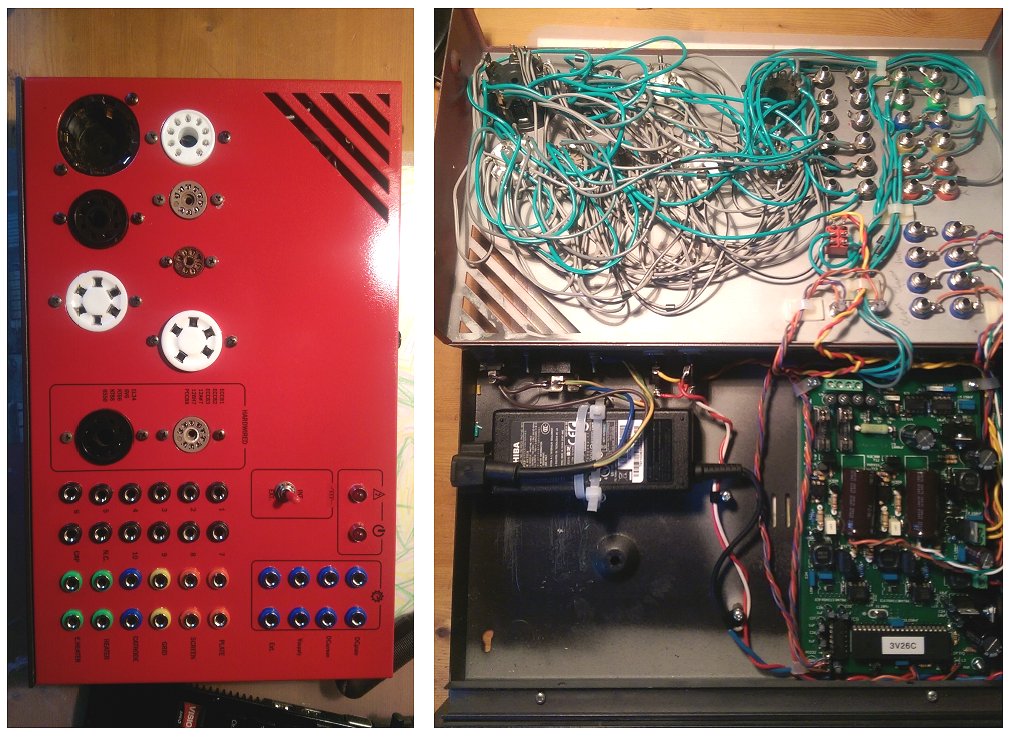

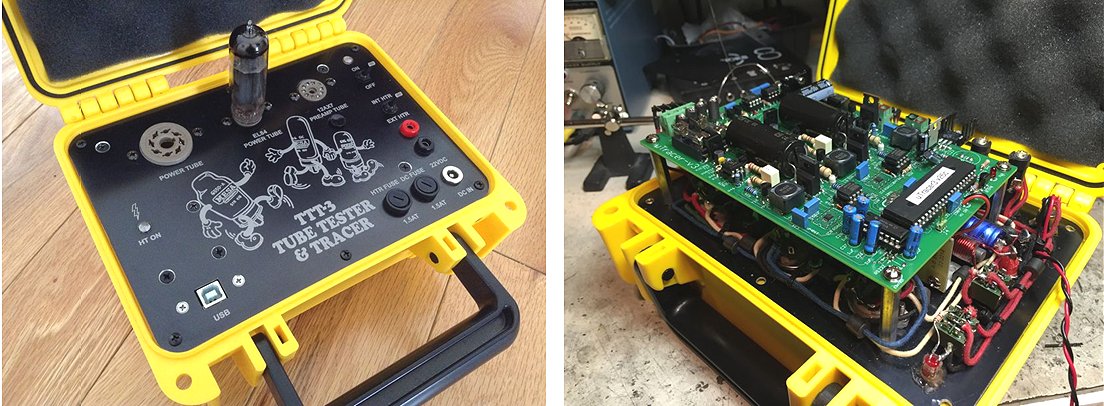

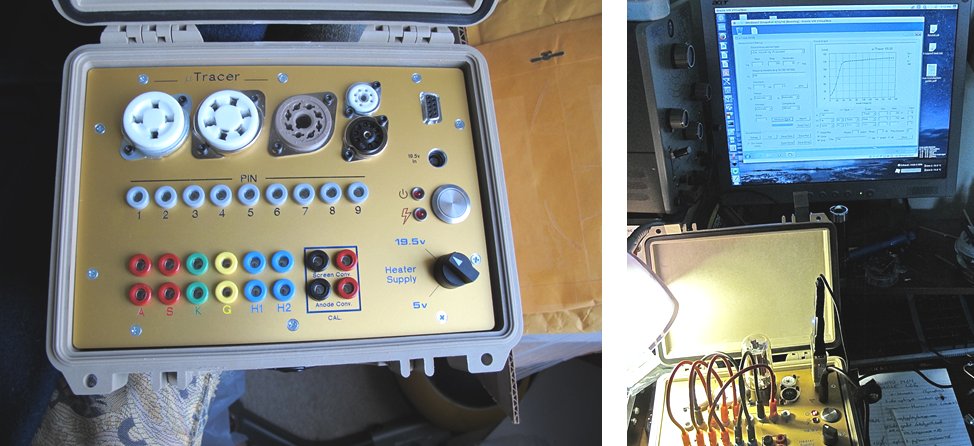

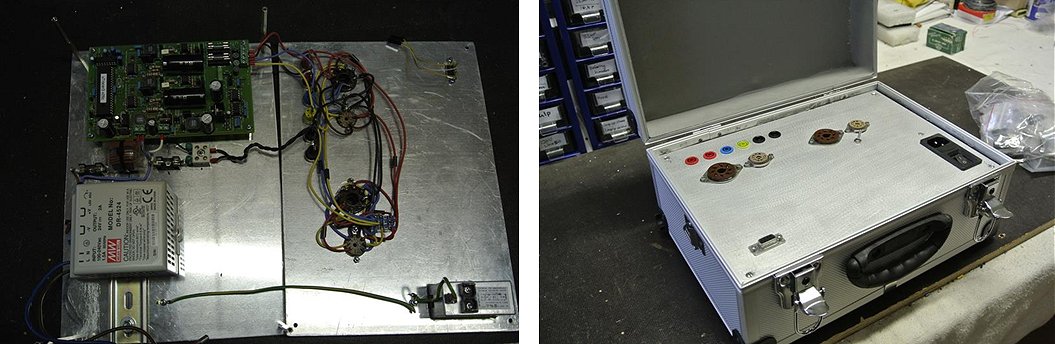

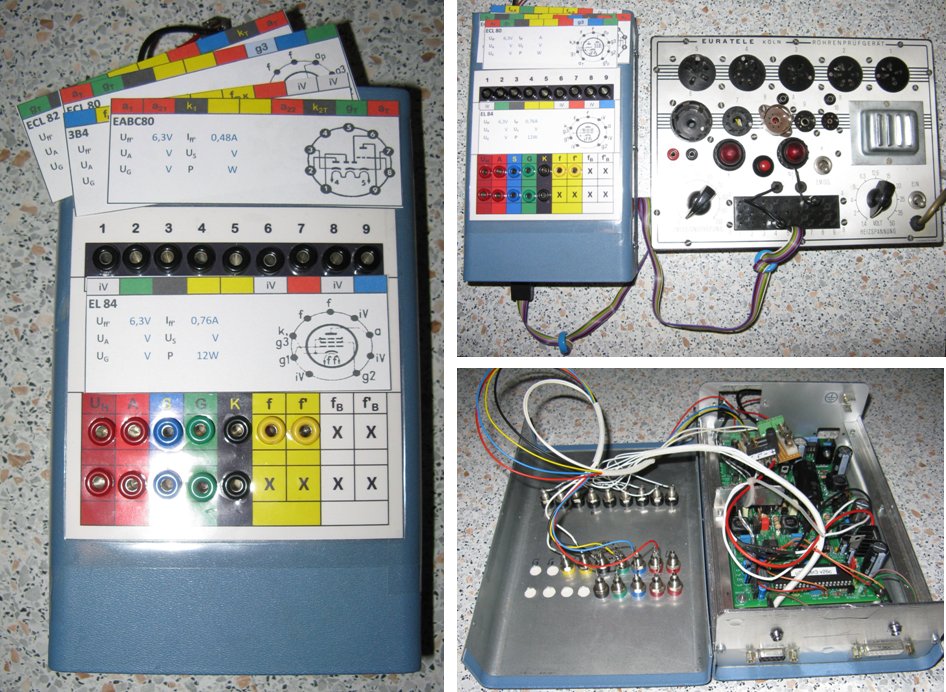

30th of September 2025, Jean-Philippe made a beautiful compact uTracer!

Hi Ronald,

Bought in december 2024 and build in January 2025, my uTracer 3+ have been updated to be able to support 600ma.

It have been integrated in a small suitcase “Peli” like, with laser cut/engraved faceplate.

An external filament supply have been integrated. Thanks to the two presets allowing to choose between 6.3 & 12.6V.

Thanks also to the current limiting function allowing to heat tubes carefully… It’s however always possible to use internal heating (see int/ext switch).

I’ve only integrated wired tube supports for ECC8x, EL84, and EL34/6L6. Two additional sockets with associated micro bananas allows free wiring to test others octal and noval tubes. I never used them for the moment since I’m primary use uTracer for maintain guitar and bass amps…

There’s room for adding one more socket. It will probably be populated with a rectifier tube support in the near future.

Usb conversion have been integrated (with FTDI232) allowing to connect directly to modern PCs. I’ve already tested hundred of tubes.. works really fine.

Thanks a lot for the marvellous design of uTracer!

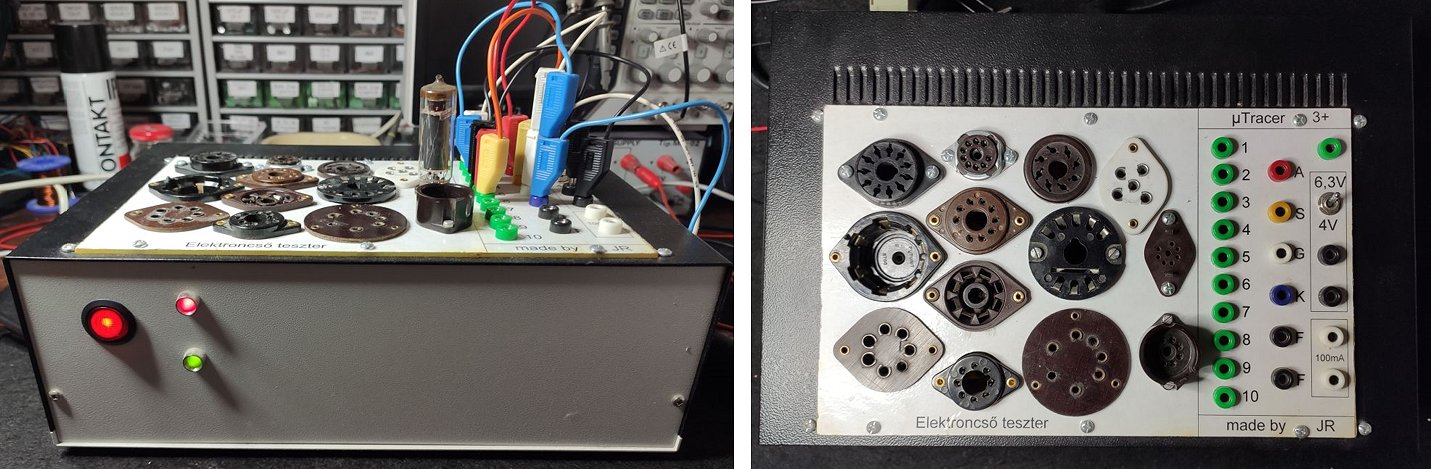

30th of September 2025, Have a look at the beautiful uTracer of Marian!

Hello Ronald and Marie-Jose!

I am very happy that your health problems have passed. I know something about it as a 77 -year -old young man.

My loss works perfectly and I am very happy. However, I think that for me there will be a more appropriate version of 1000V.

I will gladly order such a losing kit (uTracer6) as it is available.

Photographs of my device are available at www.facebook.com/marian.ryczan

I wish you a lot of health and serenity.

Marian Ryczan

Mrelektronik

30th of September 2025, Koen already tested hundreds of tubes with his nice uTracer! (in Dutch)

Hallo Ronald & M-J,

Hierbij alvast een mooie uTracer !

Ik had je finaal resultaat nog niet gestuurd denk ik -- want ik ging het nog beletteren -- maar dat is er dus nog niet van gekomen. Maar zo vind ik ‘m ook al heel presentabel!

Ik er heb al 100den lampjes mee gemeten.

Dankje voor het prachtige product en al de inspiratie & ondersteuning.

Gr

Koen

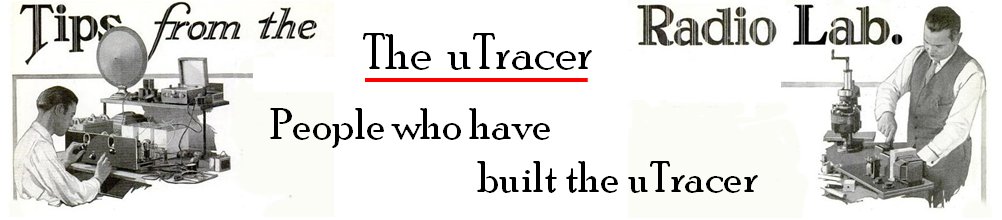

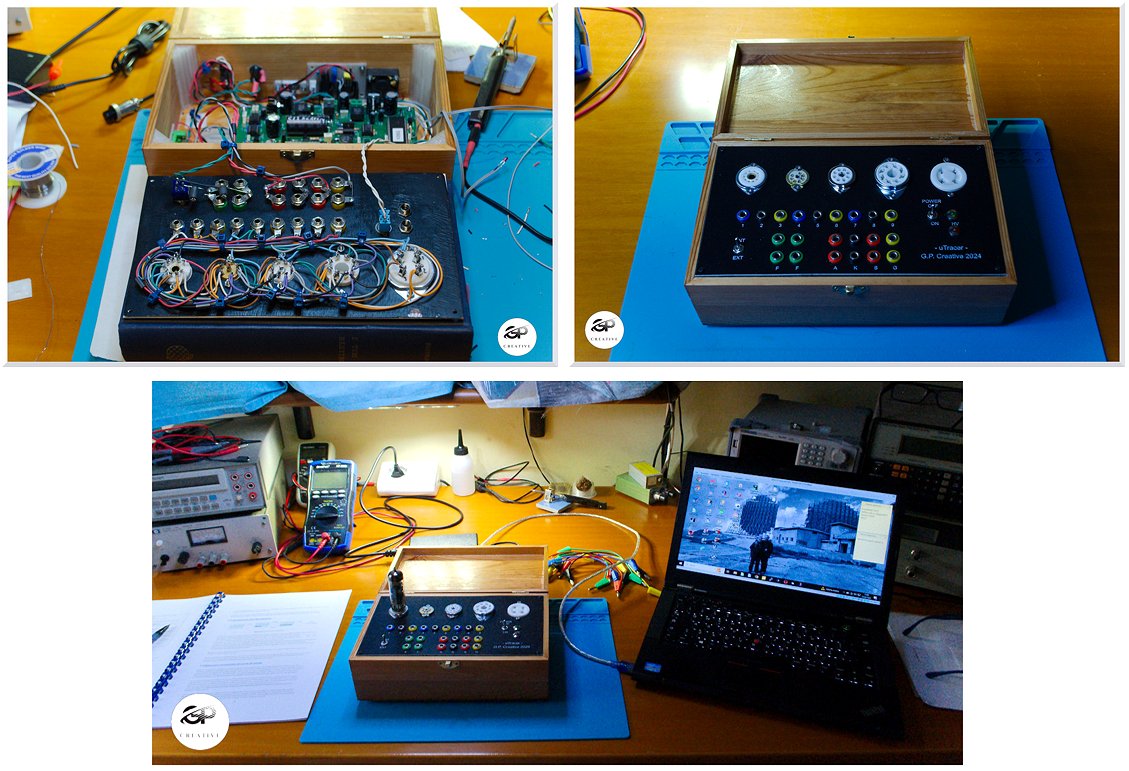

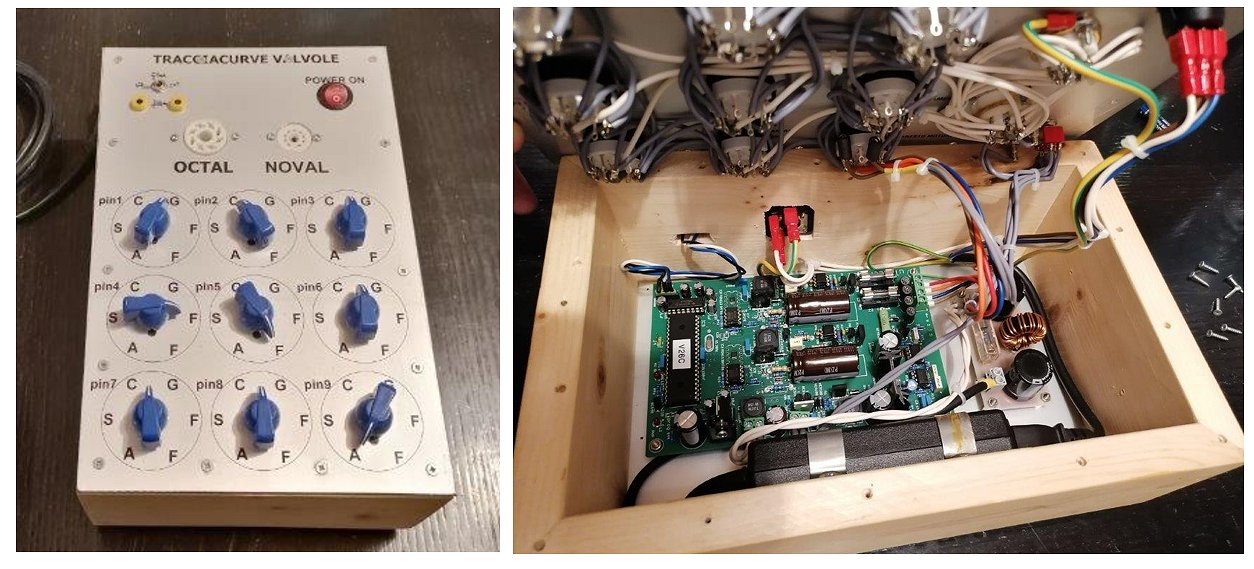

2nd of September 2025, Carlo finished his very beautiful uTracer and has a lot of learning to do!

Thank you very much Ronald!

Next step is to learn all to interpret well all the datasheet… moreover today I started to quick testing some ECC83 an ECC82 with the right parameters and all is Ok!! I had some surprises, some of my tubes will go to garbage, but I already have a queue of friends who would like to try their tubes.

Viva the Utracer!!!

Viva Ronald!!

17th of July 2025, Hans is very pleased with his uTracer!

Dear Ronald.

I attach a picture of it as it looks now. It's not really pretty - I am no graphical artist, but it works. As you can see I have added an external heater. Not so much because of the concerns others have had about the built-in heater, but because I sometimes need to test 6C33C-B and 3.6A at 12.6V is a bit much for the µTracer.

There is a small switch for the external heater - so when the meter is on, it is active. Power for the meter is a 9V battery switched on by a relay. The power consumption of the meter is so small that I suspect the battery will expire because of old age rather than use. Moreover, the meter works with as little as 4 volts. I wanted to avoid too many switches so the internal and external heaters have their own connections (a DC-jack). Not shown is the jack with two leads to connect to the heater.

I have prepared it for the -100V screen voltage extension. This also connects with a separate banana plug. The -85v supply is probably going to be a 555 based boost converter stabilized by a zener (actually a variable "zener" with a low voltage zener and to transistors - this is a much more temperature stable option than a high voltage zener). I have experimented a little with it, but boost converters are totally new territory for me - your pages helped a lot, but I may have some questions when reality kicks in.

As I said in a previous mail, I also plan to test the 600mA option. You mention that, although it seems stable enough, it has to prove its worth on the battle field. Have you had any responses?

Again: Thank you very, very much for your help!

Best wishes

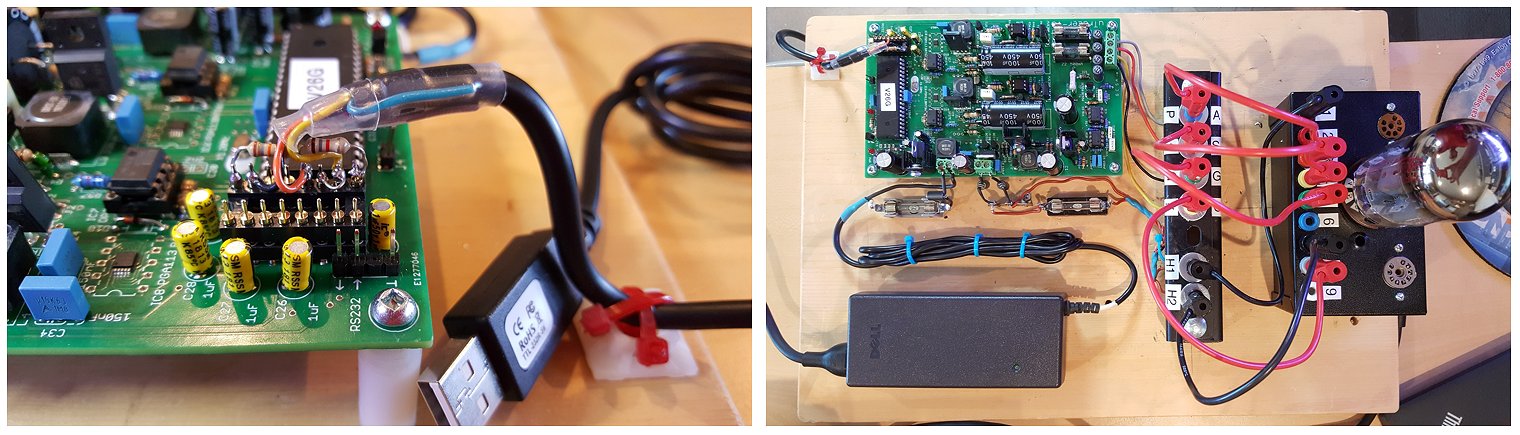

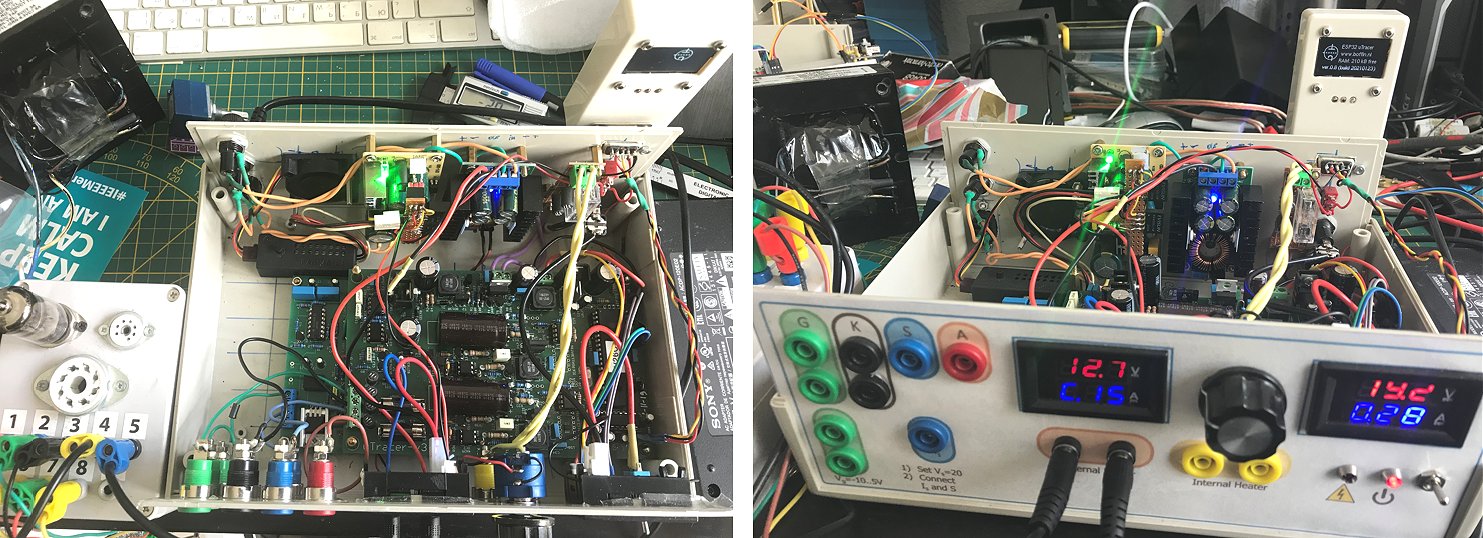

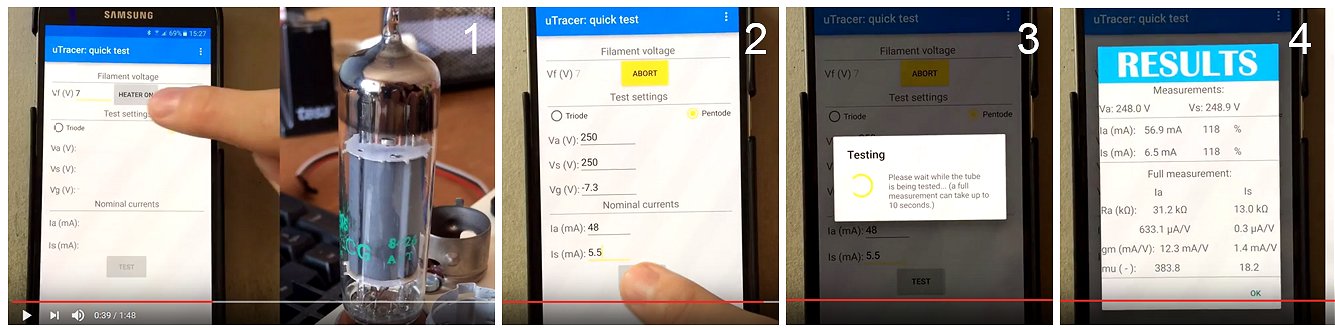

23rd of April 2025, Wow! The first portable, battery operated uTracer!

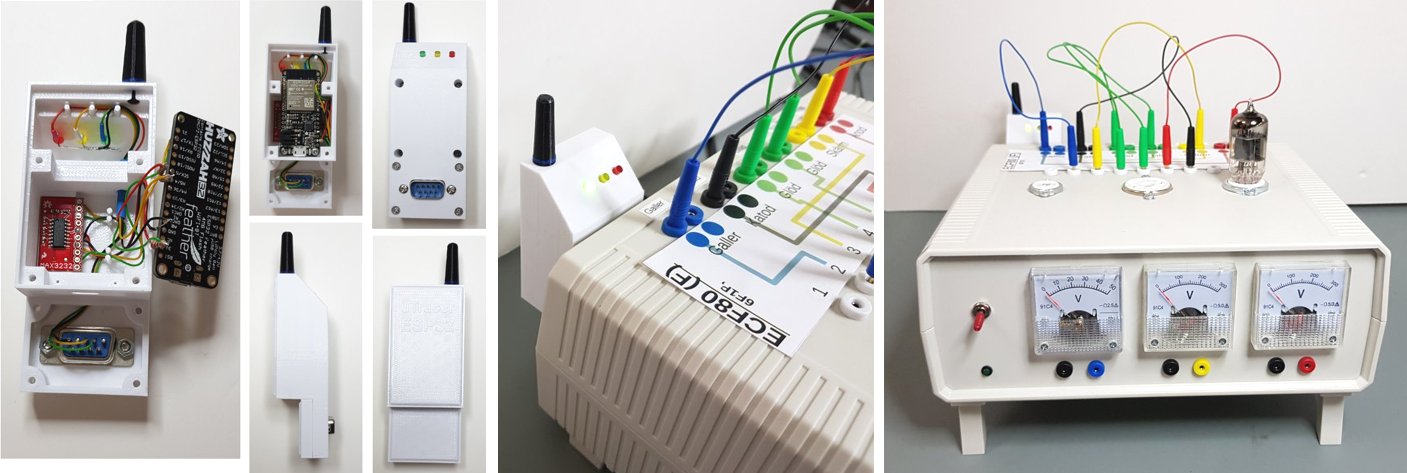

Good morning mr Ronald,

I attach some pictures.. sorry but i'm really bad taking photos... also speaking English. Basically, it's a uTracer3+ with a dc/dc boost to provide 19.5V with 3A, from 4 couples of 18650 Liitokala (3.7V 3500mAh, measured). Bms is placed under the metal plate where i glued the battery holders. A digital voltmeter/amperometer tells me the voltage of the battery pack and the current before the boost converter.

The XT60 is due to power the tube tester from an external power supply. A fuse and a diode are for battery pack protection. On the corner added a small USB C 4S liion charger, it takes some hours to charge the pack, but it will last for tens of teste, enough if i have to check tubes before buy them.

To have a fully portable system I added an ESP32 board with Boffin's software, so i can use it from a web browser both from a phone or with my pc at home (the ESP32 starts an acces point if the saved network is not found). Finally, i swapped the 7805 with a Murata OKI78 regulator due to supply the ESP32 and the PIC16 of the uTracer3+. An ugly 3D printed enclosure protects everything even if i keep the instrument inside a bag.

Best regards

Denis Brioschi

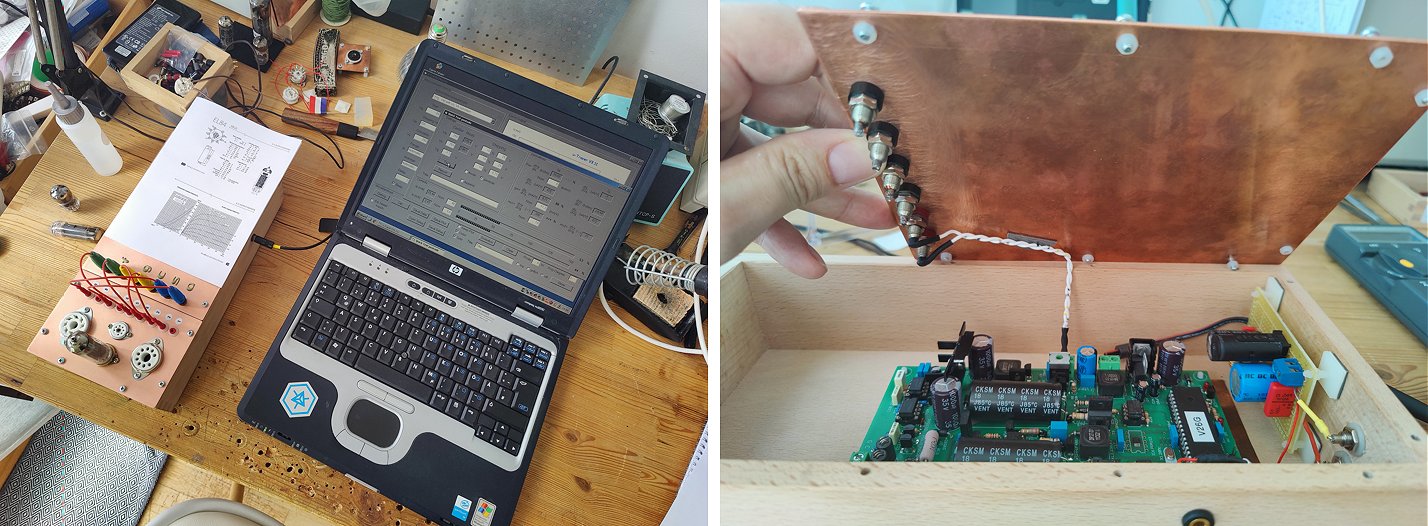

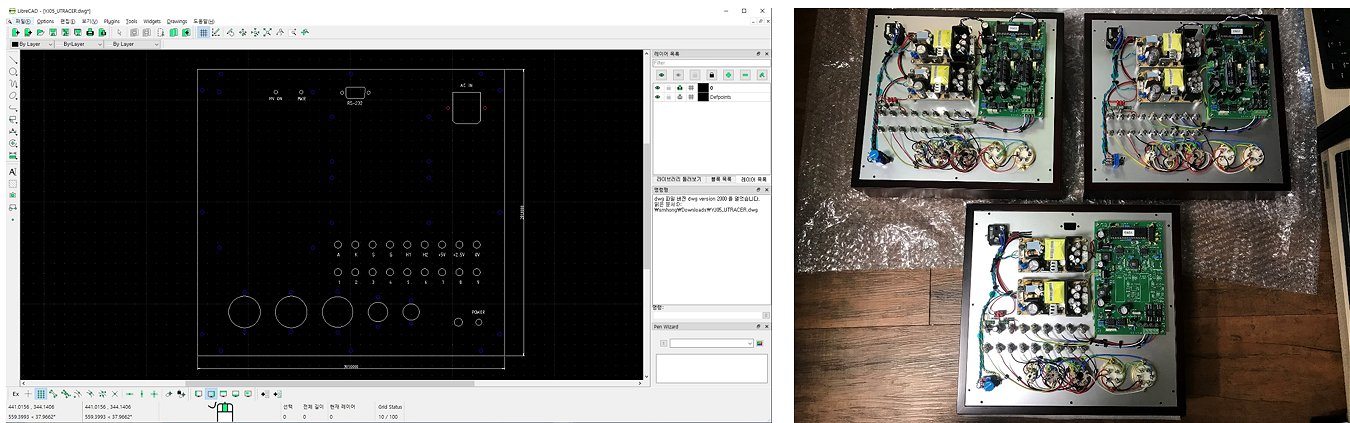

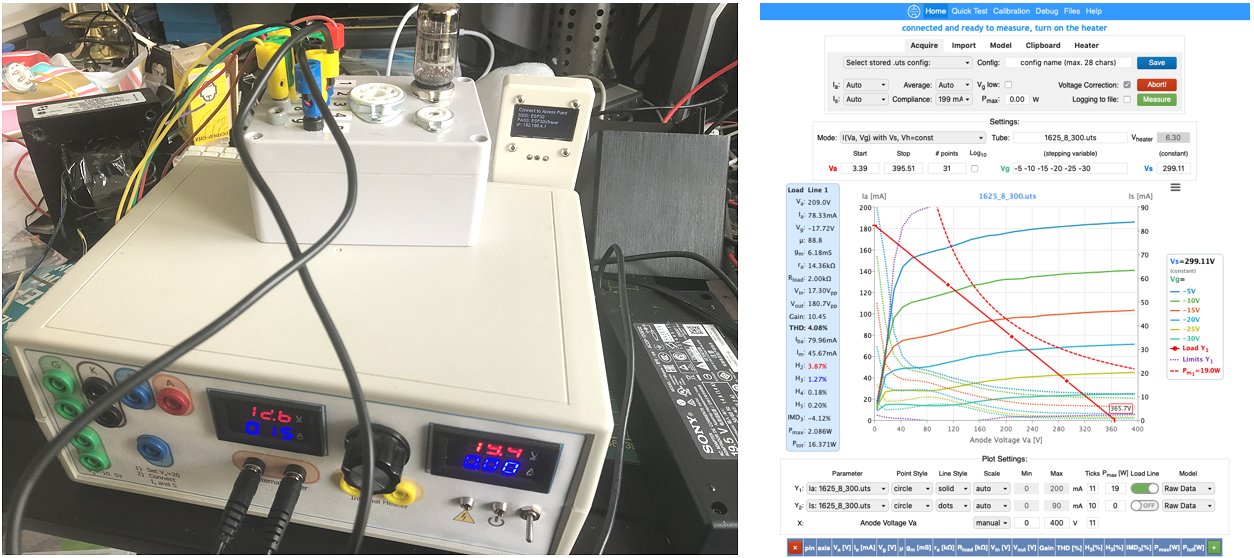

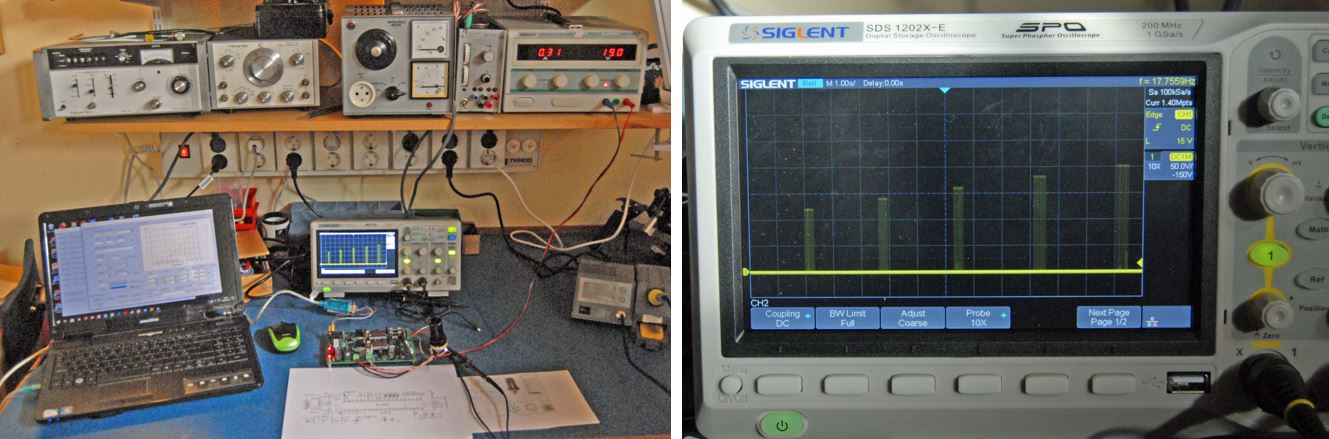

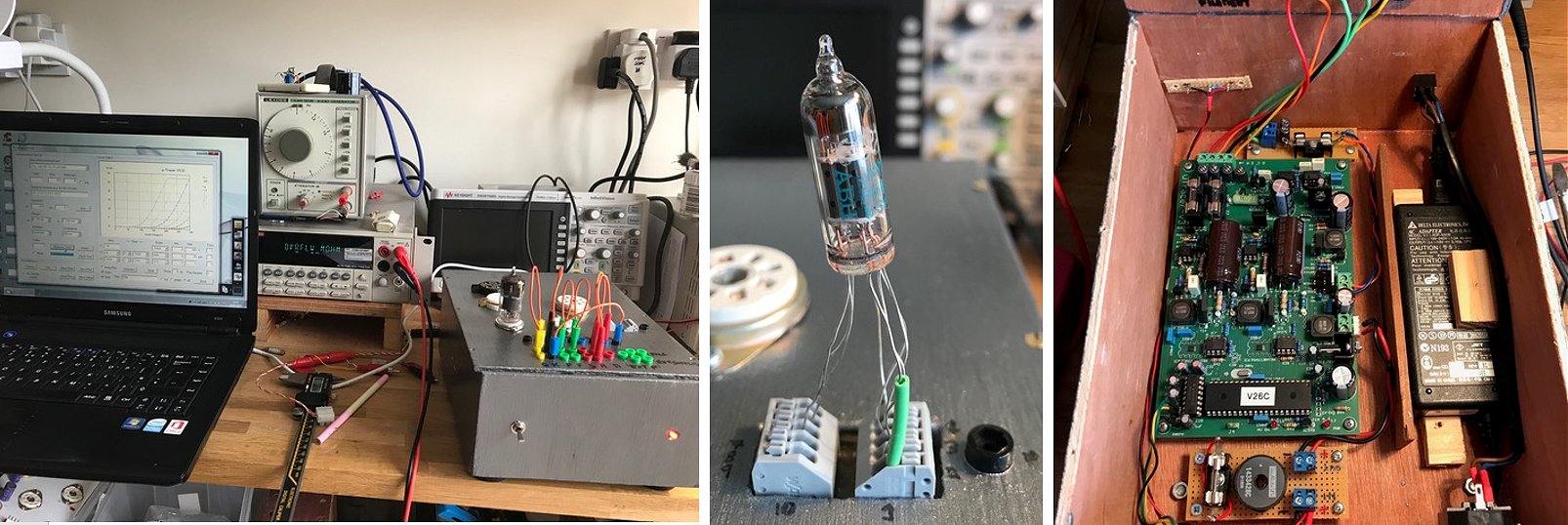

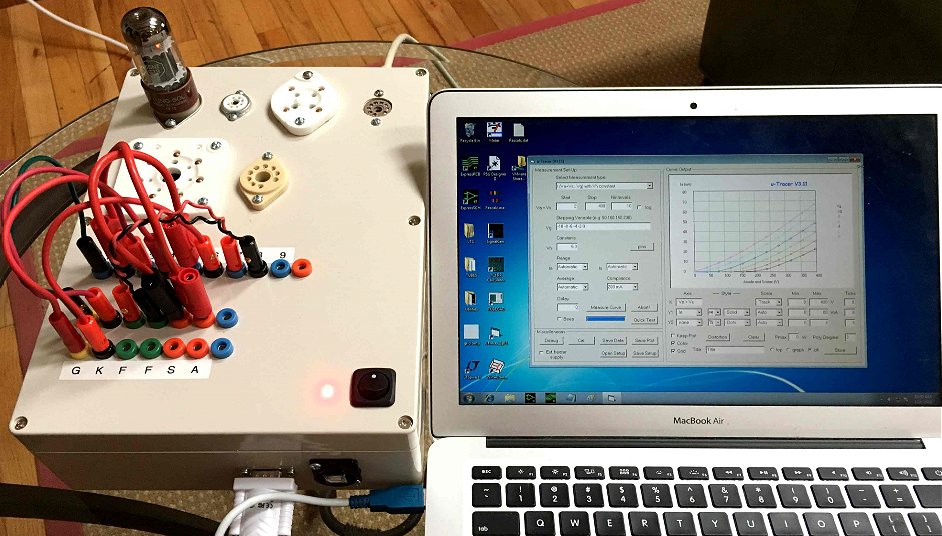

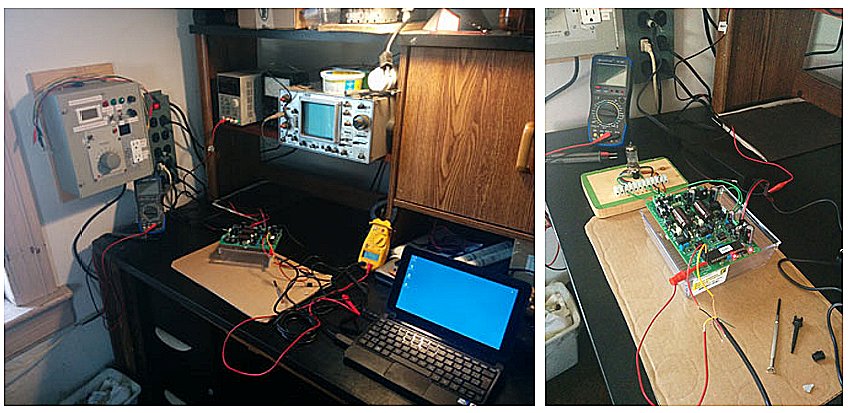

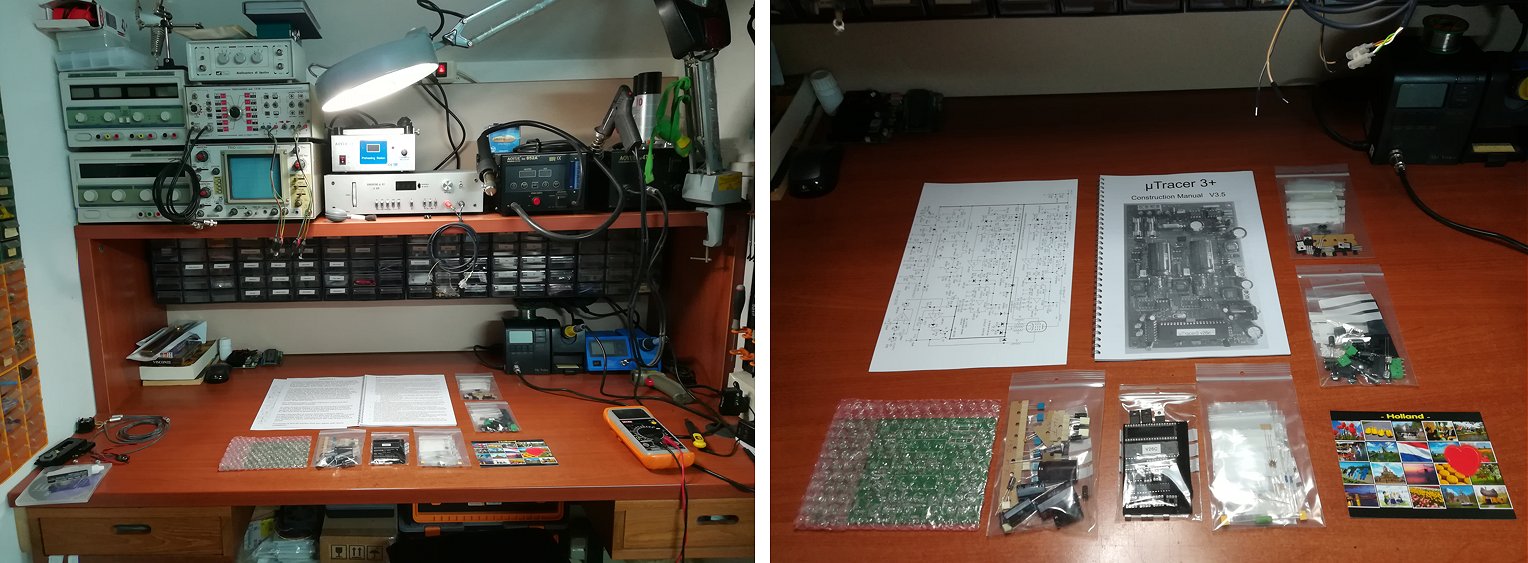

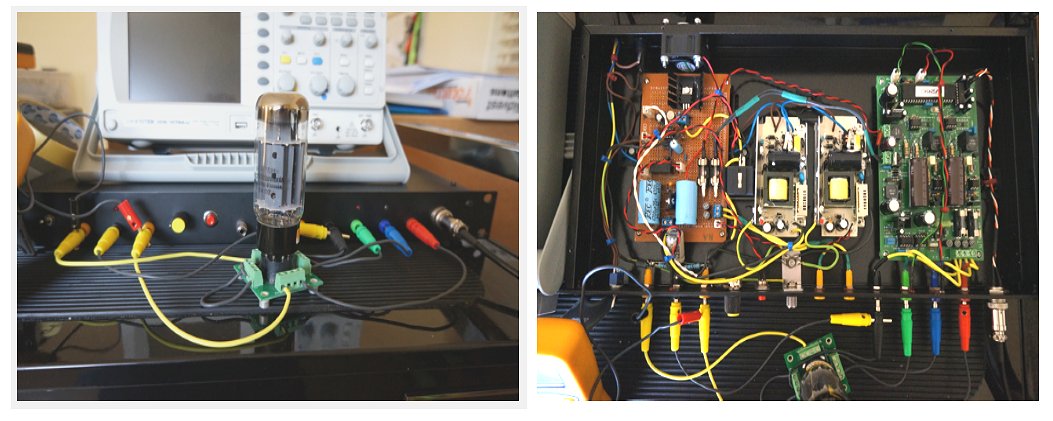

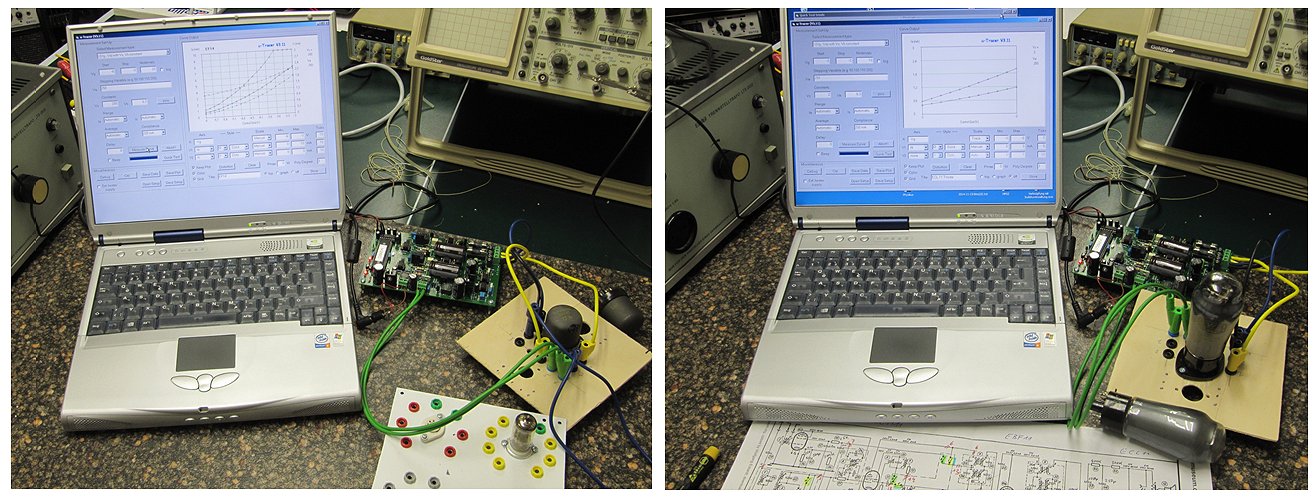

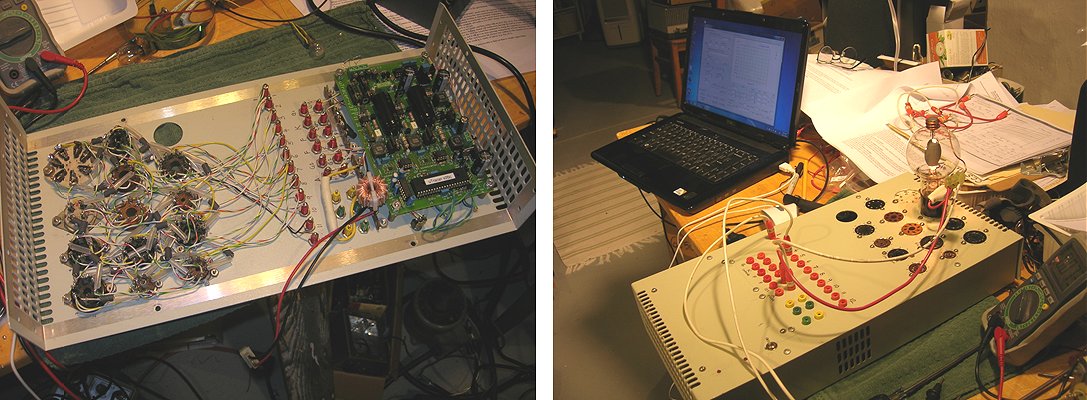

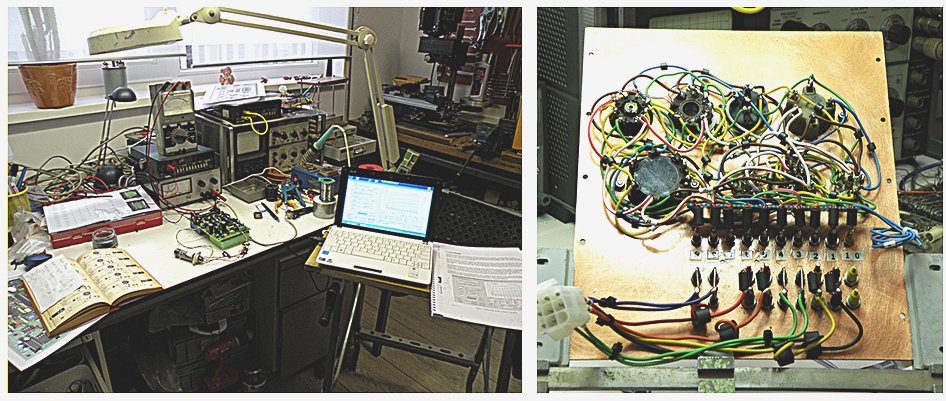

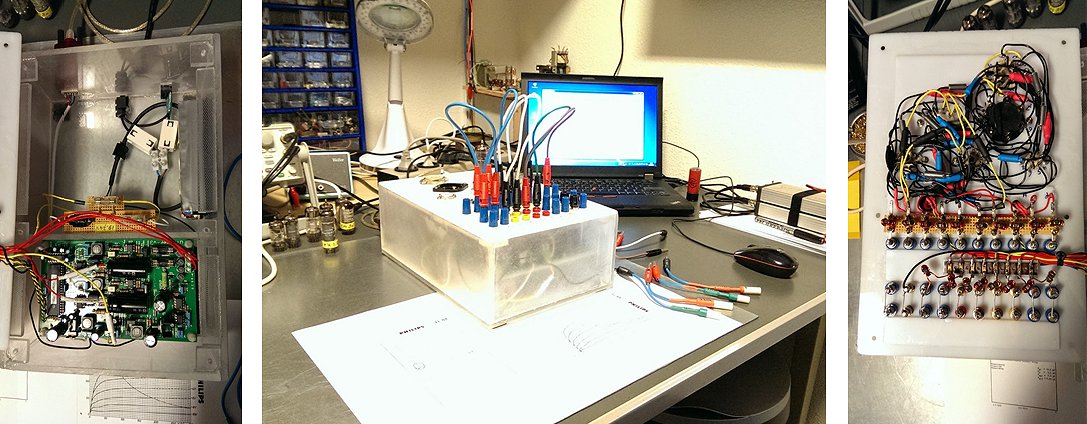

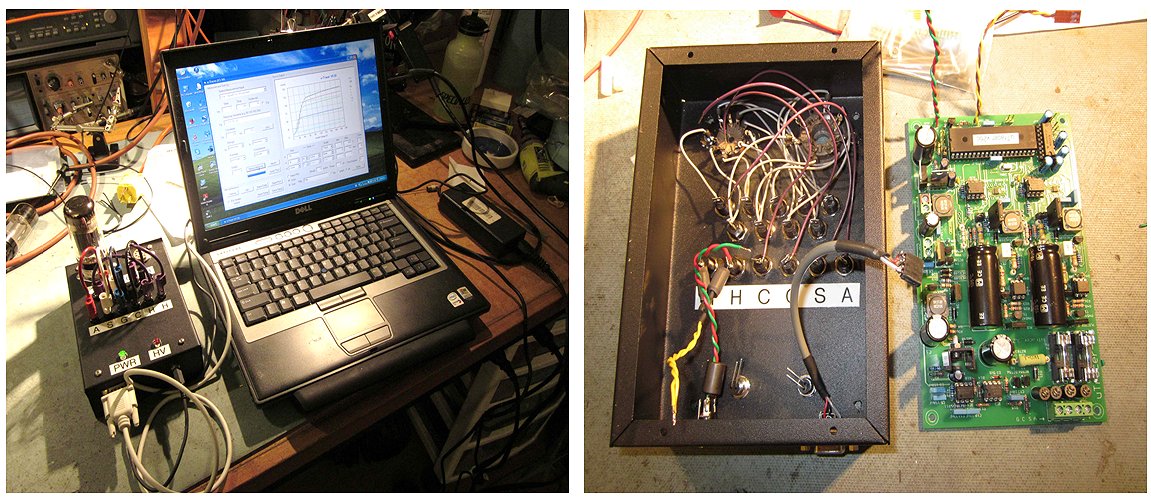

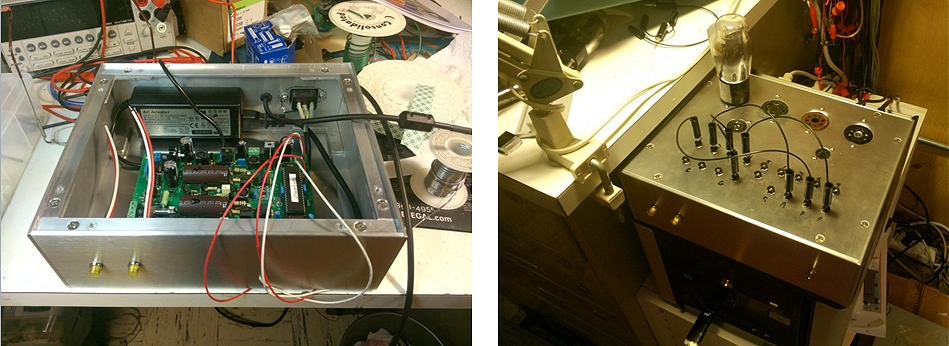

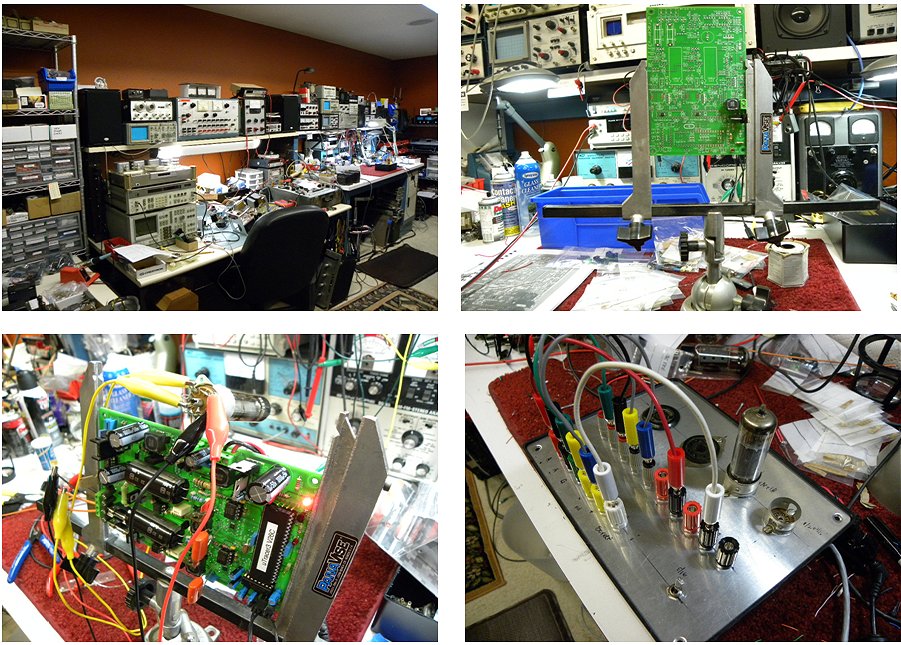

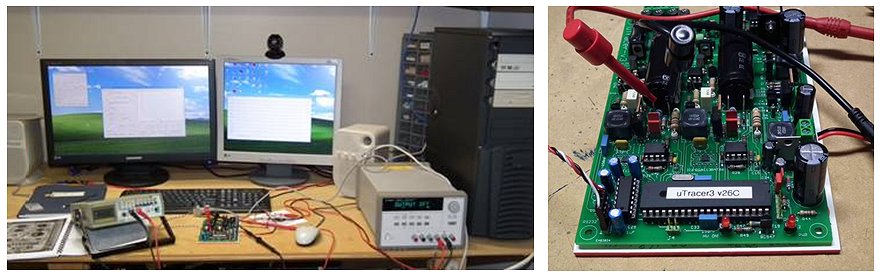

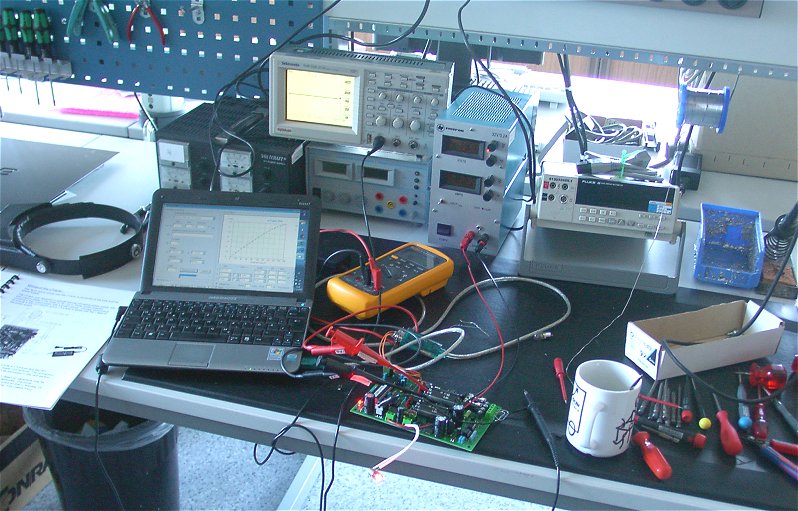

19th of April 2025, Christoph’s uTracer is operational! Always nice to see somebodies working place!

Dear Ronald & Marie-Jose,

Thank you very much for the letter and the informations about the uTracer. I am very sorry to hear that your health has caused serious problems. As we get older, health is not everything, but without health everything is nothing. It is really shameless to come onto the market with copied replicas, whoever does this. Unfortunately, there seem to be more and more people like that, even from China, who are masters at it.

Please find attached photos of my status. I'm testing the “resistance straight” today. I have problems with the GUI with the 20mA setting of the measuring field, which prefers to display 25 mA max vertically. But I have only just started to try this out. Unfortunately, there were no illnesses, but house repairs and renovations in the way, so here are two pictures of the laboratory table, which also contains some other developments. Anyway, so far everything is in the green Zone.

I wish you both a Happy Easter and very good health and :: Carpe Diem.

Kind Regards

Christoph

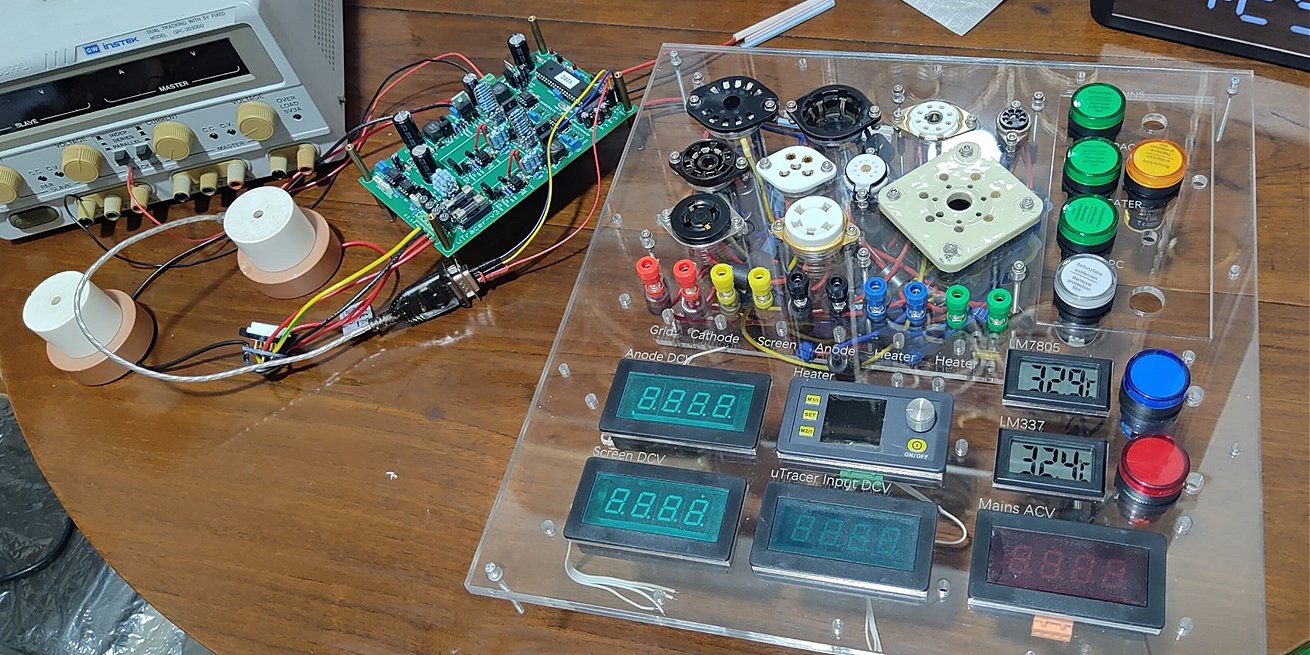

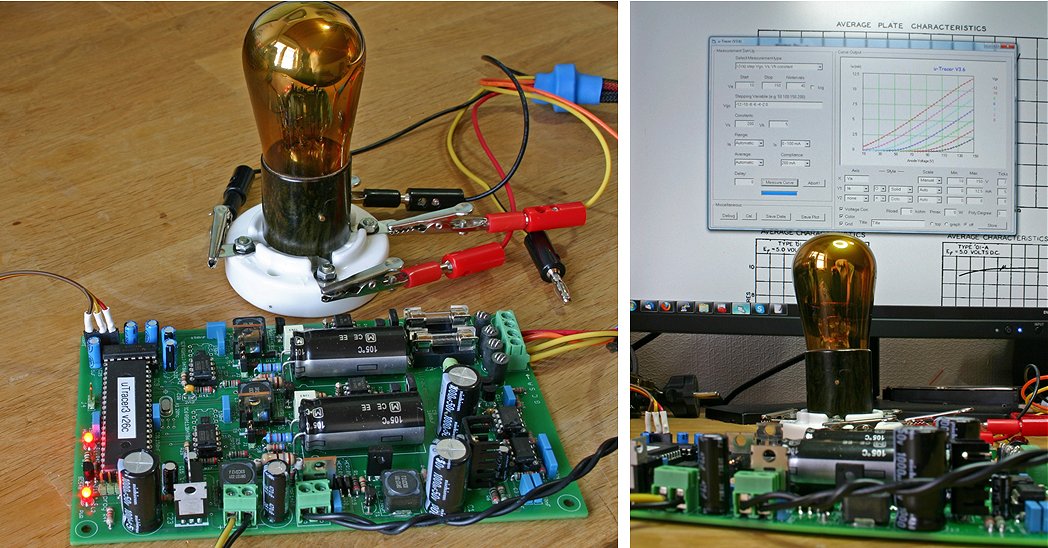

24th of May 2025, “Mr Q” from Finland sent me some pictures of his magnificent uTracer!

Hello Ronald!

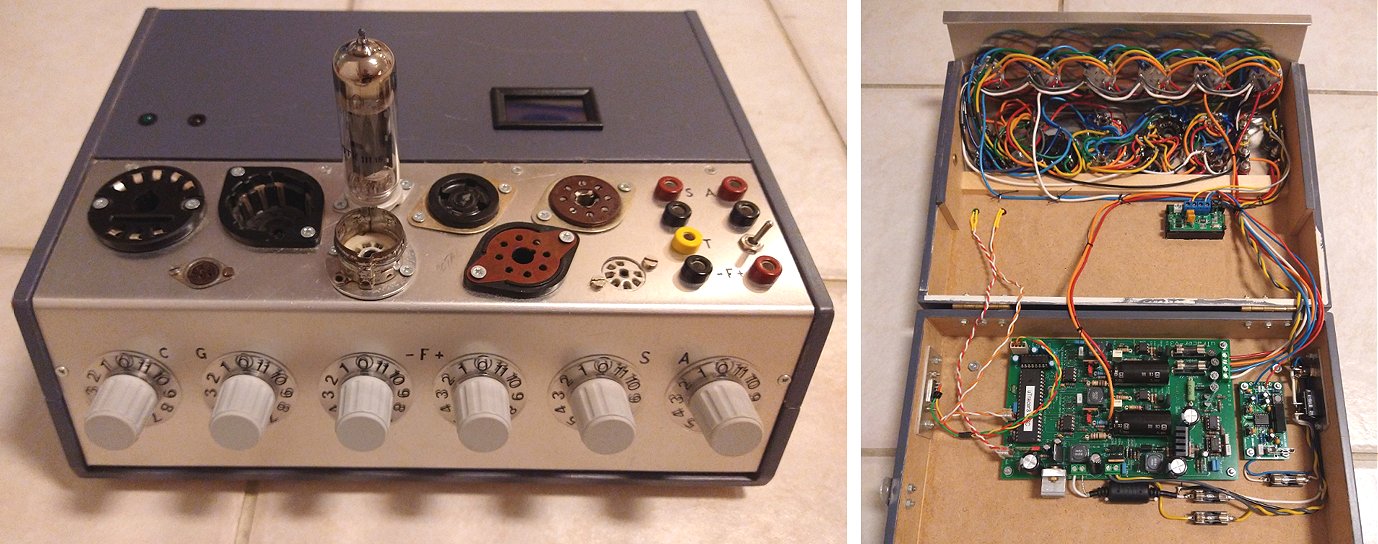

Casing for uTracer is finally finished and I'd like to share these photos with you. My workmate Jani (who made those fine silk-screen printings) said this looks exactly like different "gadgets" in -50's -60's agent-/ science movies ?? I'm happy to see my goal to captive some aesthetics of that golden tube-era is succeeded!

As a "cherry at top of the cake" we are currently making changeable charts for most usual tube types to guide correct rotary switch positions. Jani makes them with laser engraving using 2mm plastic sign material with black body/aluminum top layer. Currently we have only this ECC- proto finished...

If you find my/our work any good, please feel free to use these photos anyway you like.

Happy summer to You & Your family!!!

Sincerely,

Mr. Q

British Intelligence Agenc...(ok, Simo from Finland)

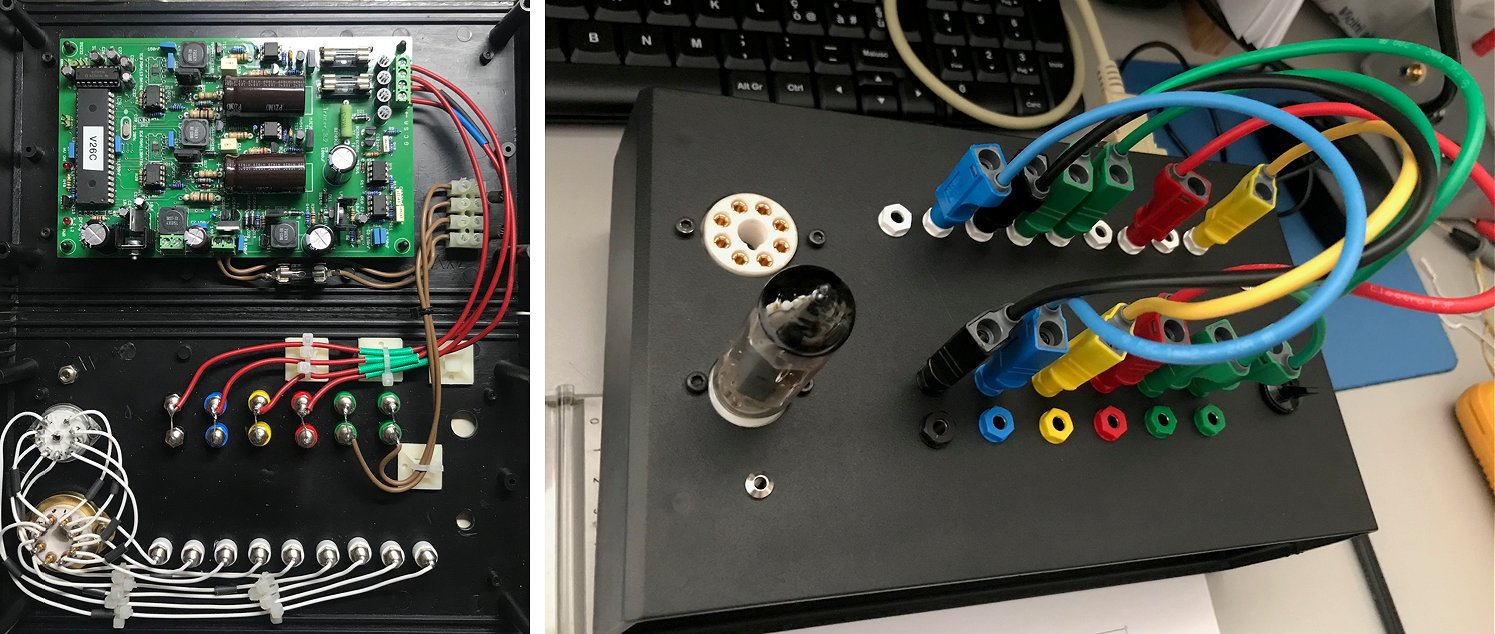

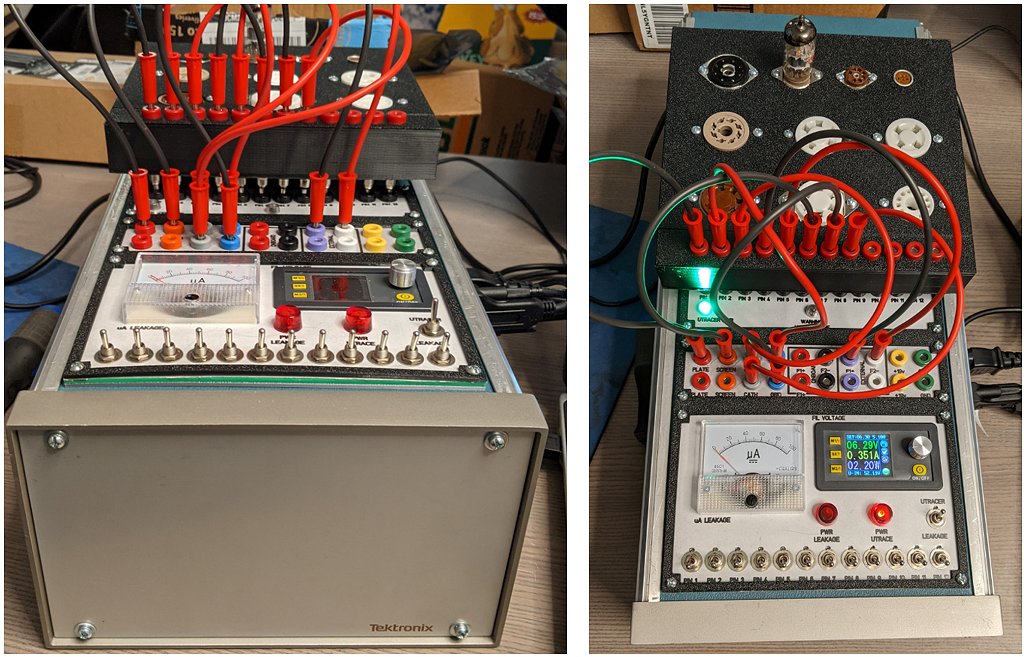

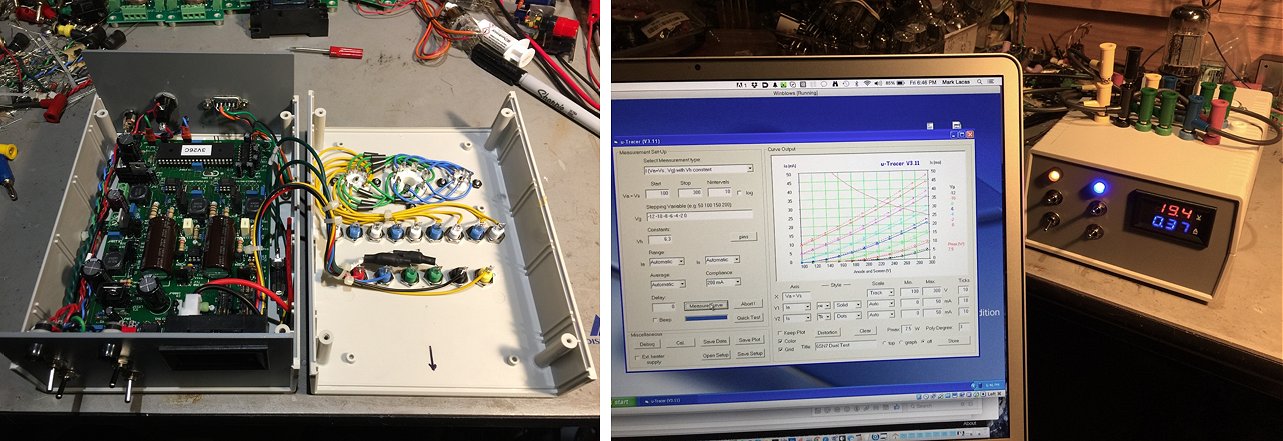

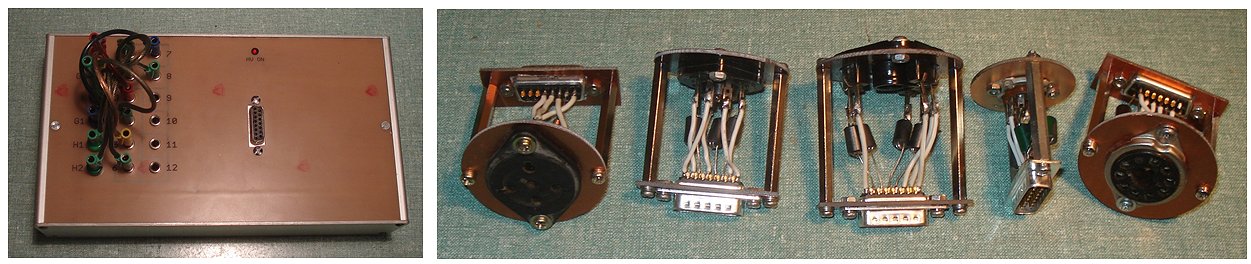

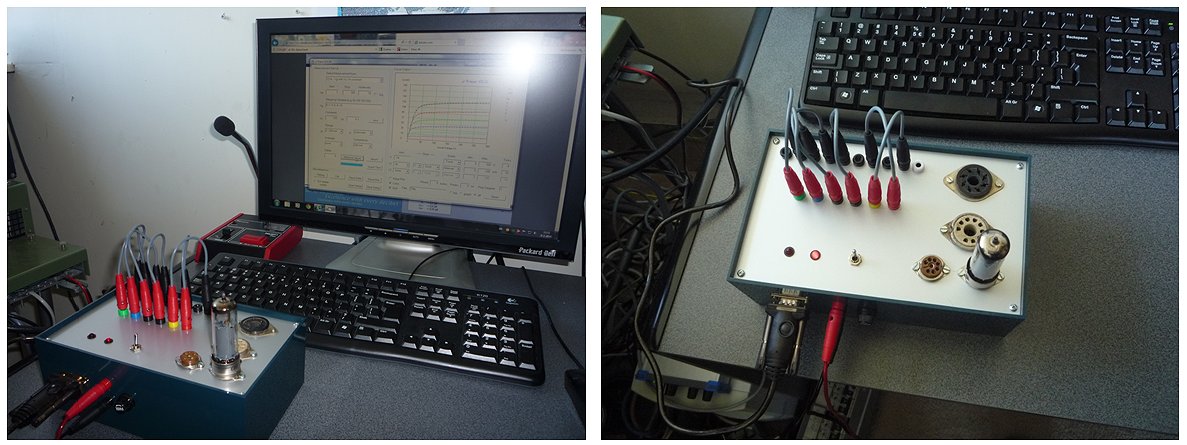

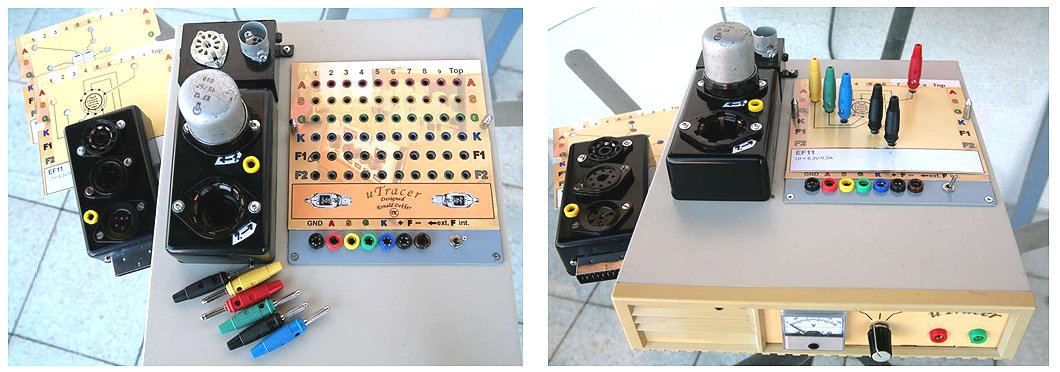

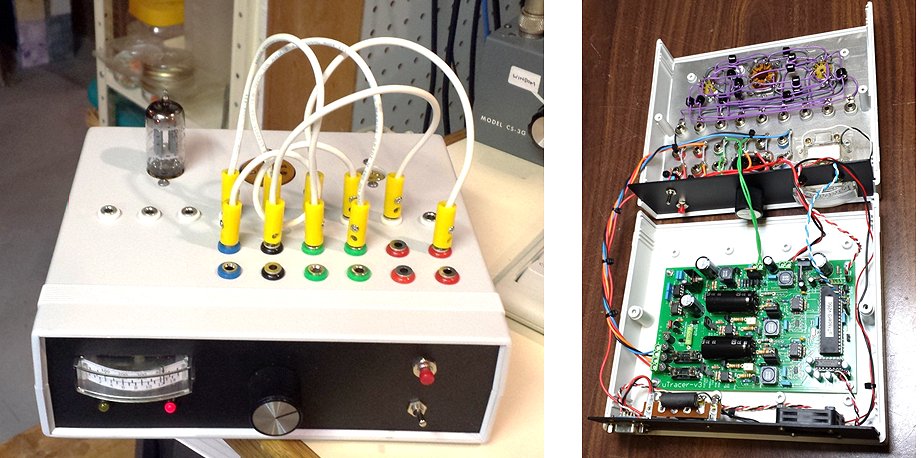

9th of May 2025, Terry sent me a few pictures of his practical uTracer3

Hi,

I had snapped a couple of pictures of my uTracer3 build but I forgot to include them. I thought you might be interested.

I had an old Tektronix case to house the tester. I found a large supply of vintage, 12” banana jack cables (I think from a phone switchboard unit) to use for the interconnects and also constructed the external socket board for testing two tubes at once. It all works very well.

I tested a lot of tubes on this uTracer but drifted away from vacuum tubes for a number of years but am now back testing and selling a large stock of vacuum tubes that are stored in my garage!

Terry

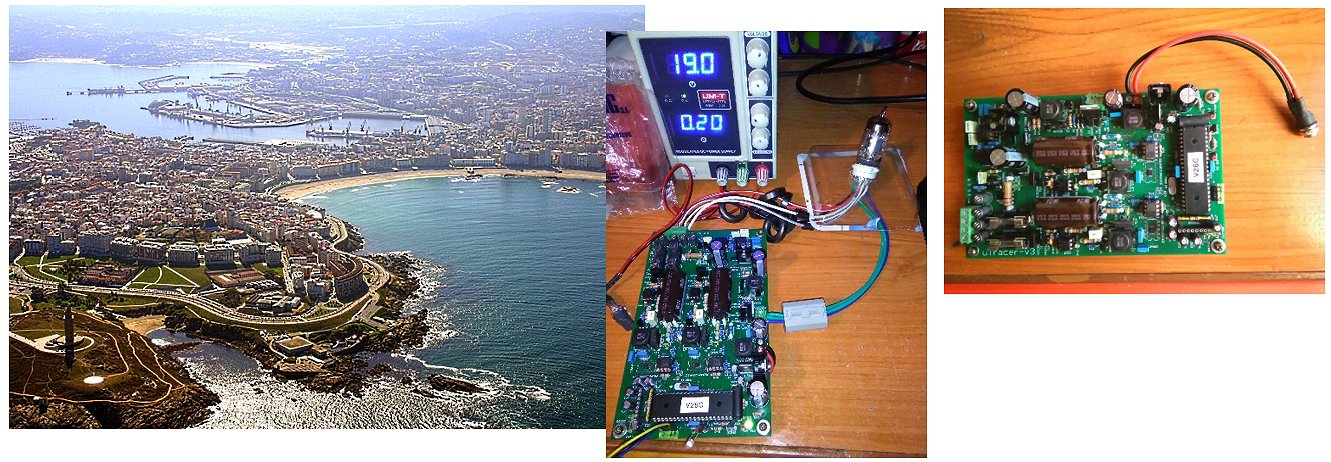

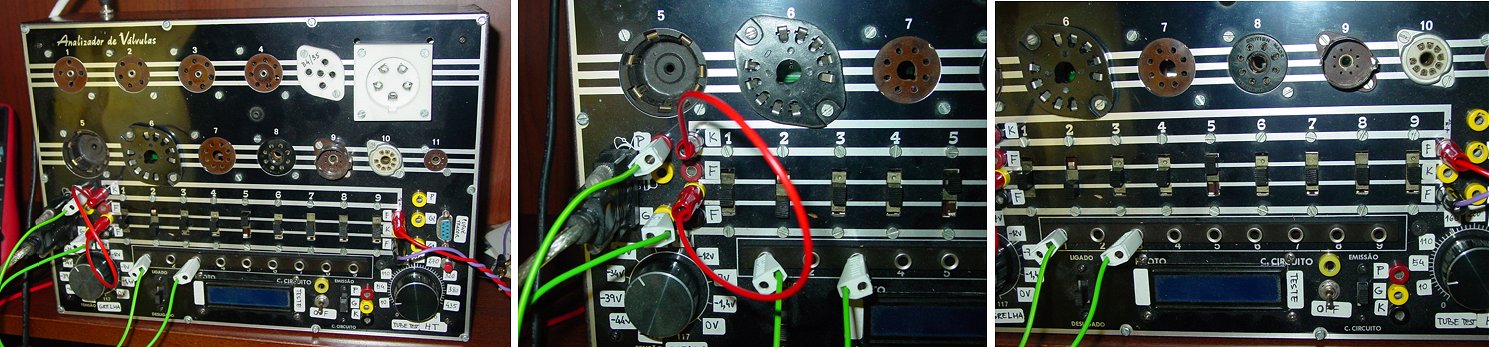

25th of April 2025, António from Portugal sent me a few pictures of his magnificent uTracer!

Hi Ronald,

I hope you and your wife are in better health.

The uTracer arrived on April 14th.

I put it in its final box and it is "Alive & Kicking", after the repair, you so carefully done.

It works perfectly.

I added some features:

- A voltmeter to monitor Vg, Va and Vs, with two scales.

- Additional voltage source in series with Vg (0V, -30V and -60V)

- Separate power supply for the filament of the tube under test.

- A switch for Va and Vs voltages, pulsating or continuous.

- A switch for cathode with direct or indirect heating.

- Diodes/rectifiers test (D1/D2/R1/R2) “a la Metrix”

- Bluetooth connection.

It uses the AVO codes in the rotary switch to select the eletrodes in the pins, except the filament,

that it is connect via two banana cords, because I dont trust the rotary swicth to hold to much current.

Just added a few tube sockets the ones I use the most, but will use na add-on box with others sockets.

Thank you for your wonderful project and for your enormous patience and generosity.

Kind regards and best wishes for a speedy recovery,

António Gomes

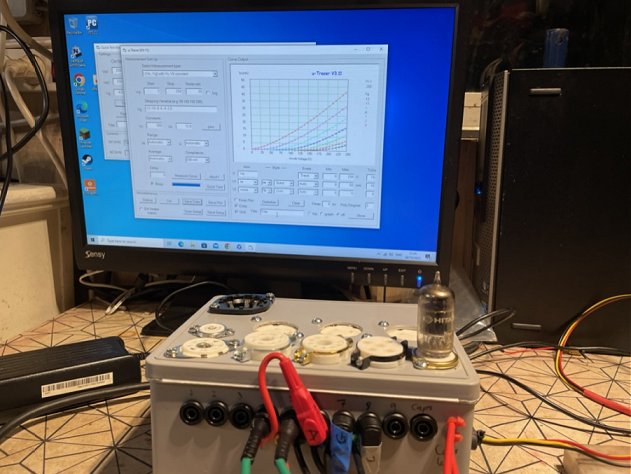

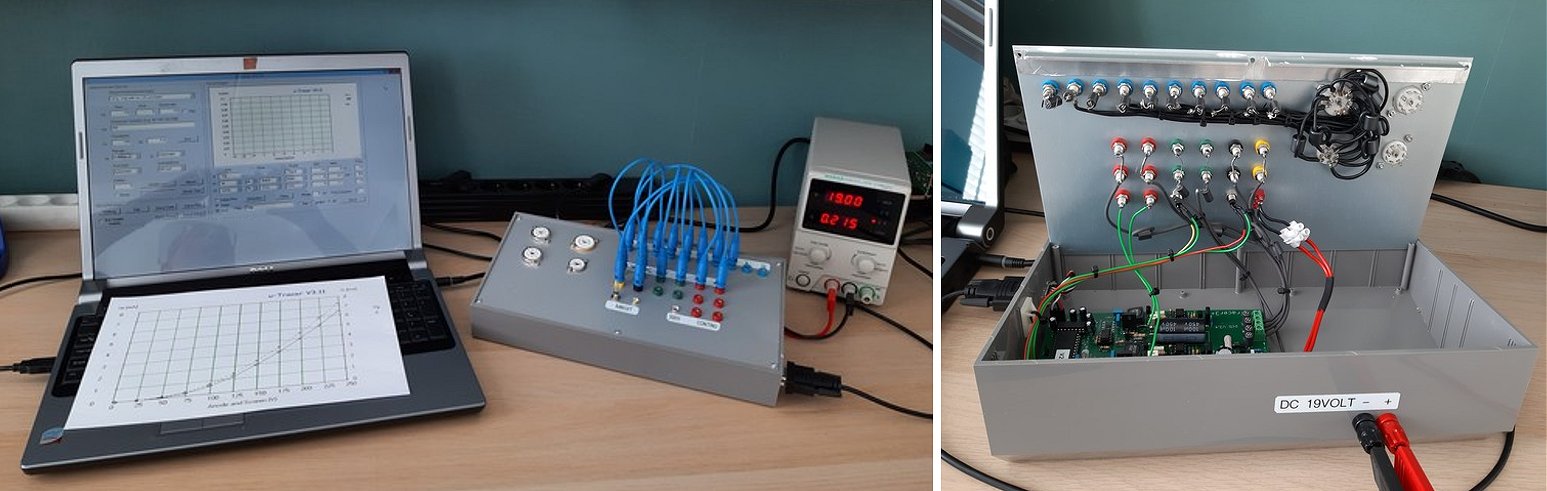

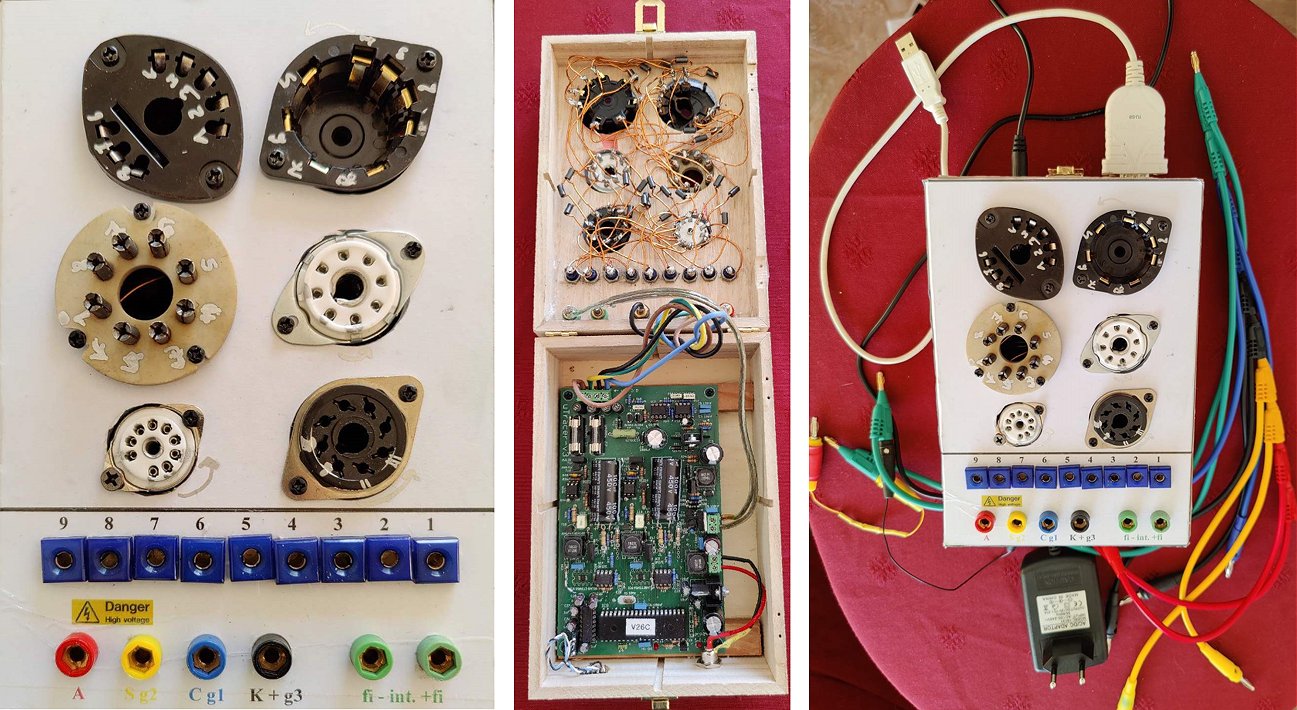

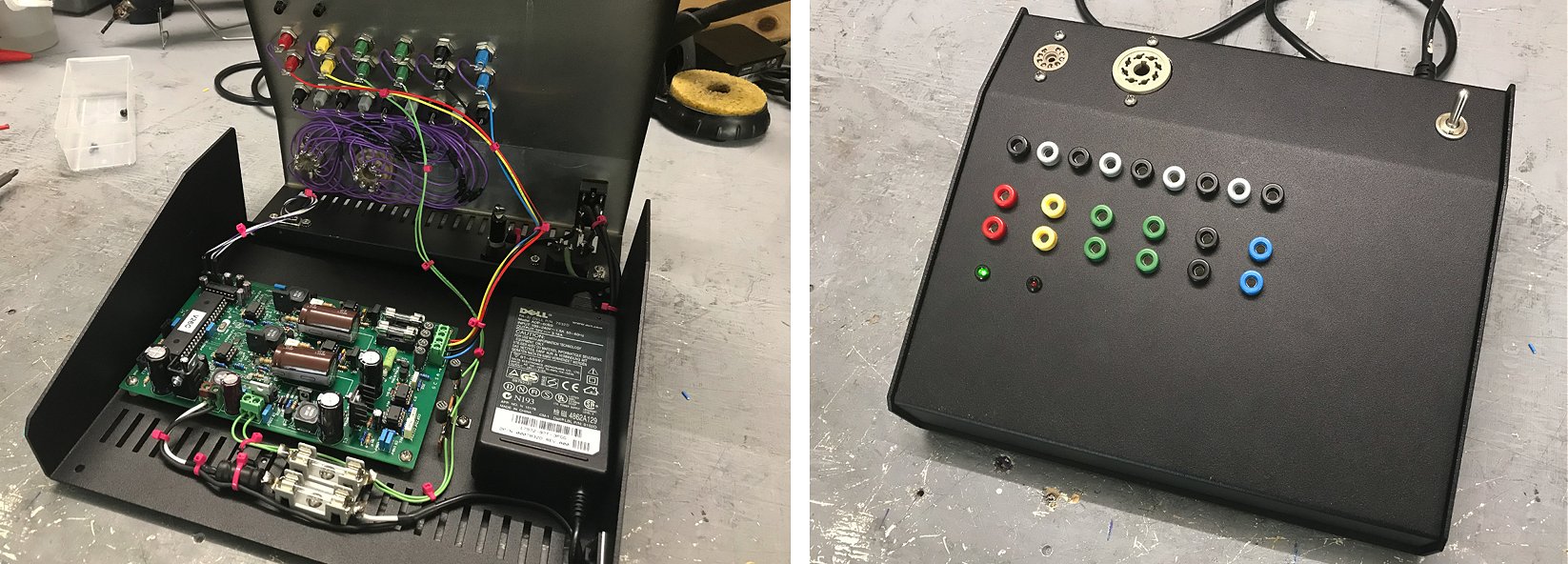

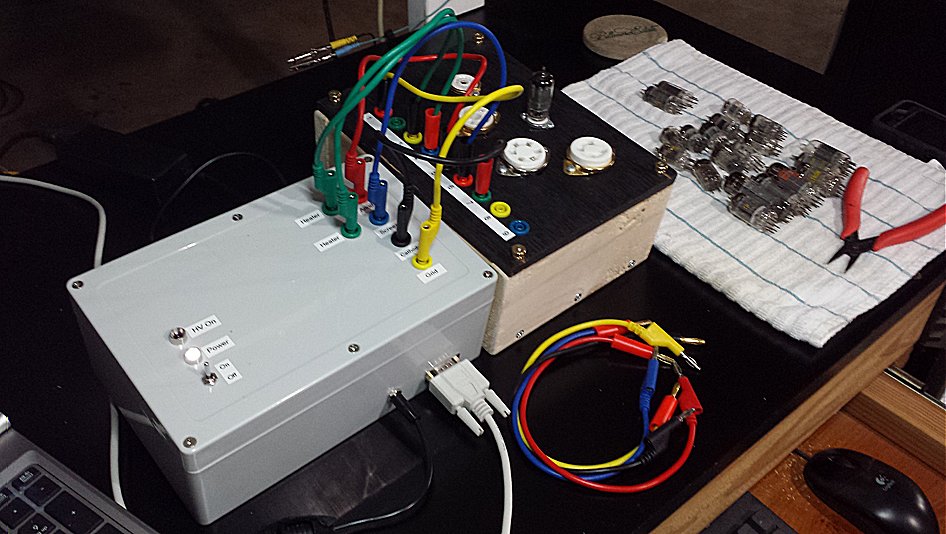

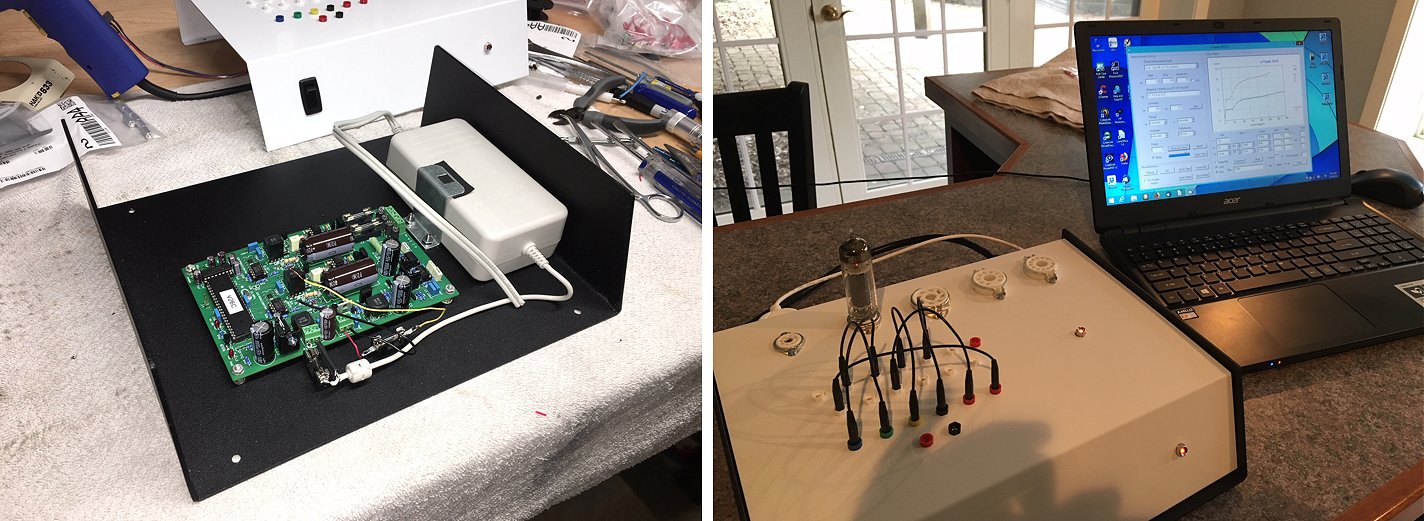

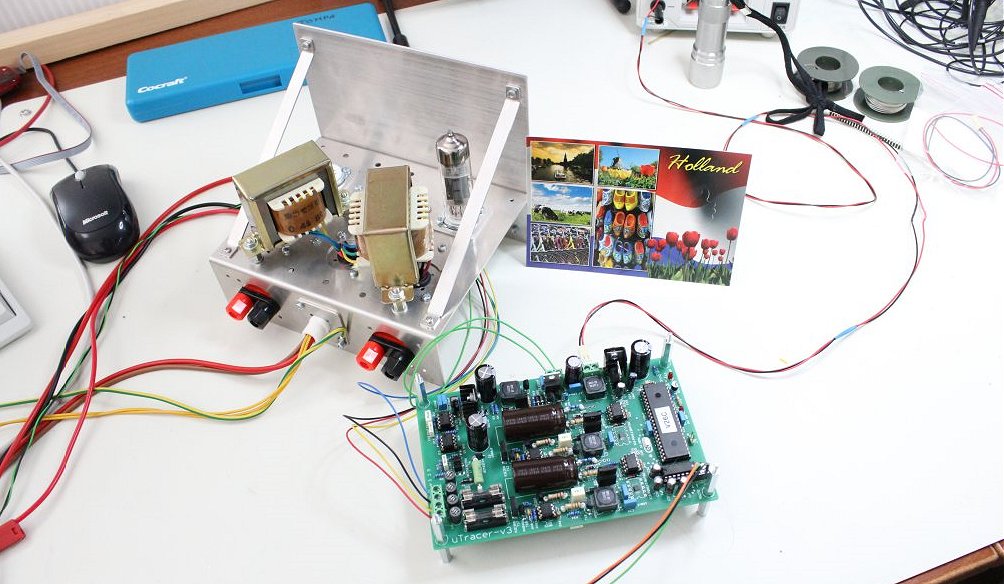

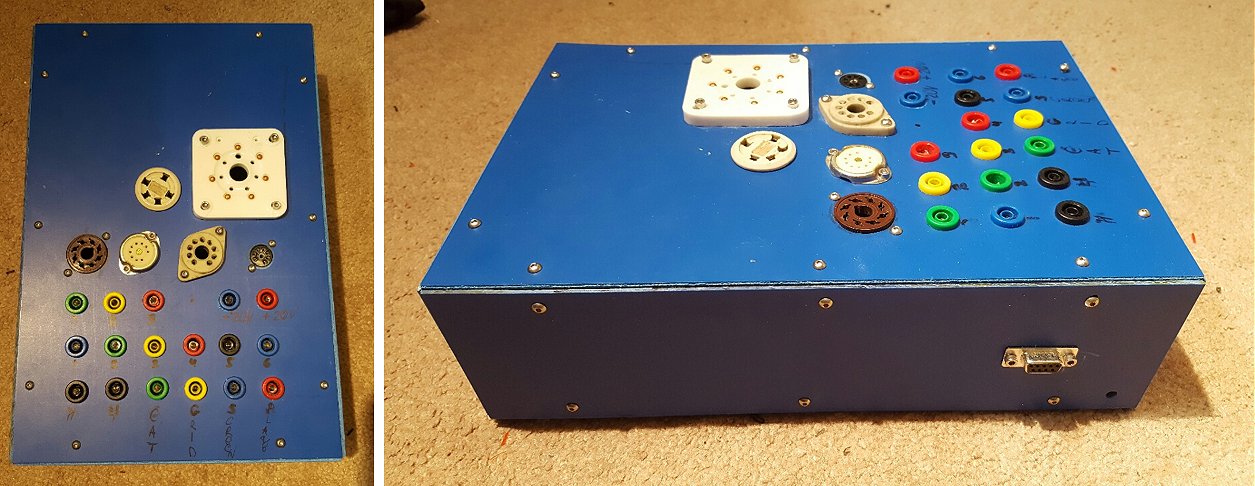

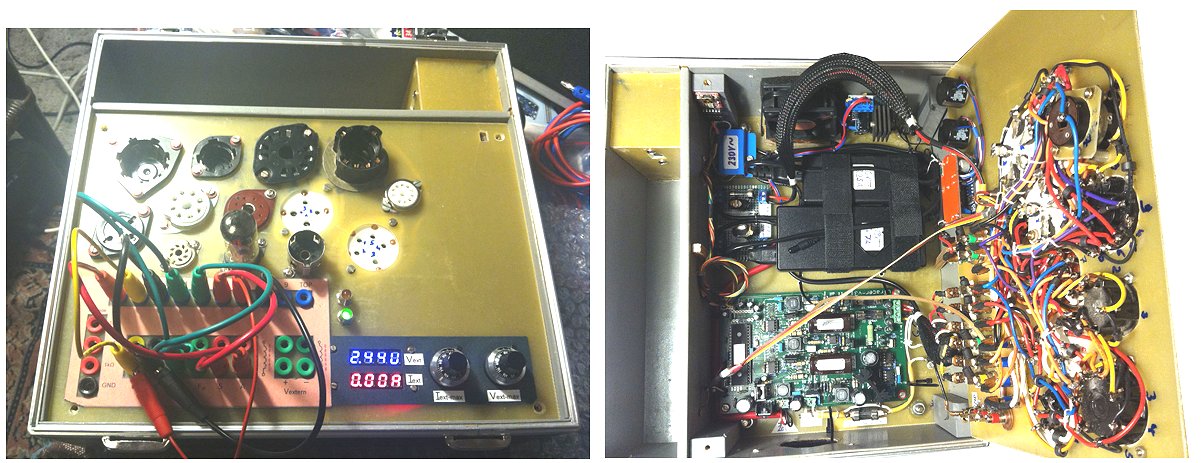

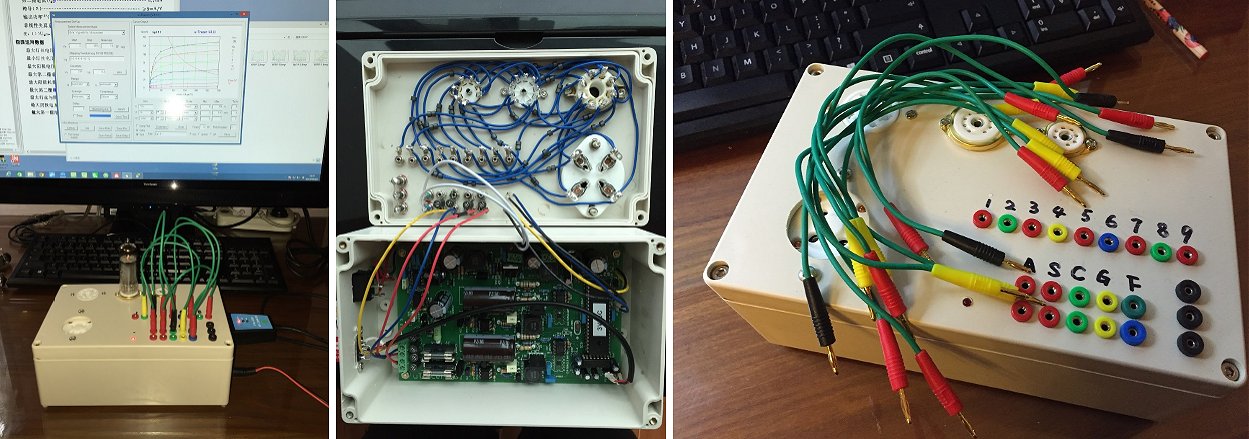

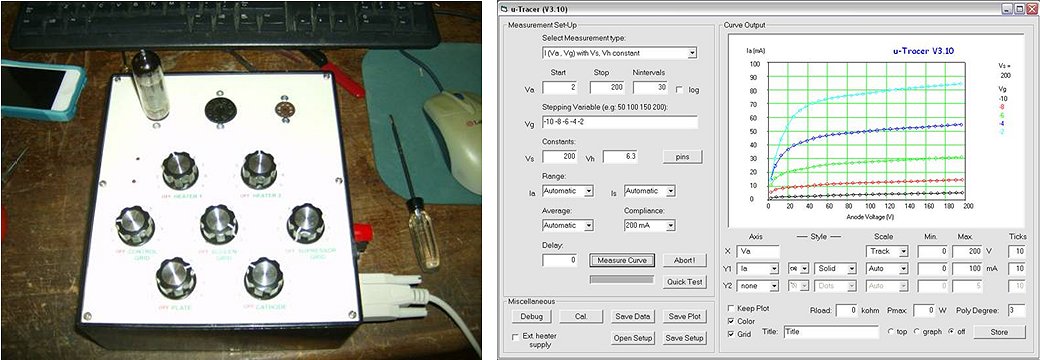

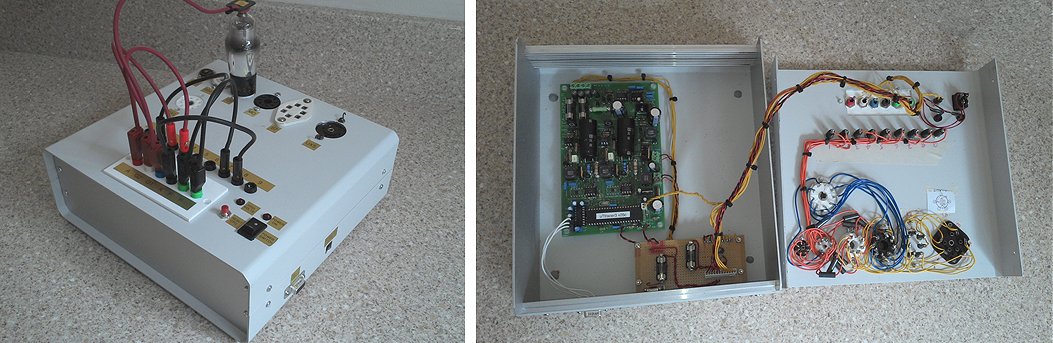

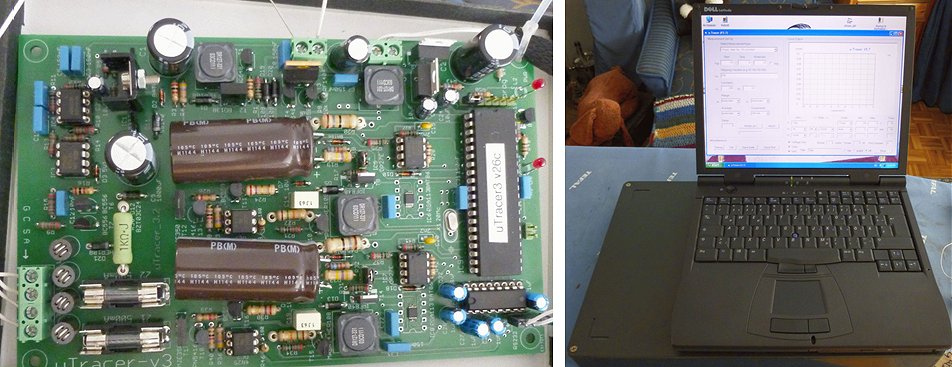

25th of March 2025, Mariano finished his excellent uTracer!

He Ronald,

I have finished assembling the uTracer, which was delayed due to the flooding in Valencia.

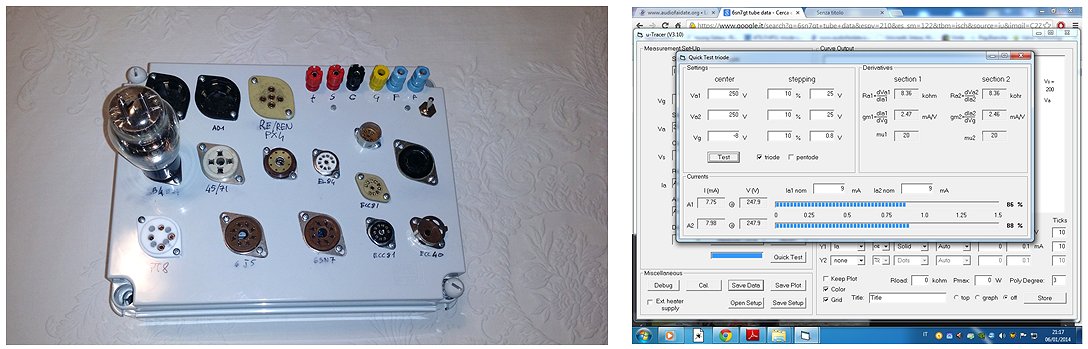

I have assembled the uTracer separately from the valve sockets, which are in a separate box and can be used for both the uTracer and analog tracers.

I attach some photos of it in operation.

Thank you,

Mariano

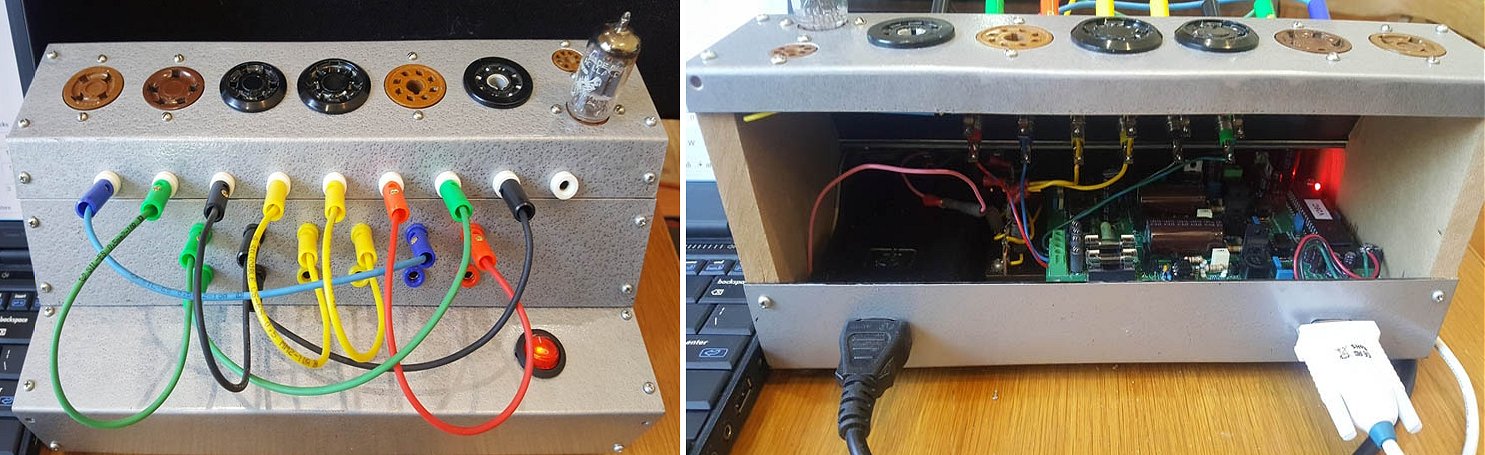

21st of March 2025, Jordy reported his uTracer finished and working!

Yes, the Utracer has now been finished for about a month. I wanted to have one because of a broken Ampeg SVT amp, where I suspected the problem was with the power tubes. However, due to the amp’s construction, I couldn’t easily measure or test them as I did before owning the Utracer. At the same time, I was getting tired of testing tubes by ear, eye, DMM, and chopsticks, so it was about time to build a proper tube tester.

Building the Utracer, including soldering and calibration, went pretty smoothly, and I didn’t encounter any uncertainties thanks to the well-written construction manual. However, I did run into a very frustrating problem: the Utracer worked on an old PC with a COM port but not on my workshop laptop (where I was using a cheap adapter). I emailed Ronald about this, and he responded very quickly (absolutely great). Unfortunately, Ronald didn’t have the exact solution, so I decided to take the device to the ICT department of the school where I teach. The issue turned out to be that the header I used caused interference and/or bad connections. Important to mention: this was not the header provided in the kit, but rather an 8-pin IC socket with some poorly soldered wires.

Once I soldered the wires directly to the COM port, the problem was solved immediately and it worked with the 5euro’s adapter/converter. Once the PCB was finished and the COM port issue was resolved, I put everything in a housing. I used ferrite beads that were larger in diameter than the solder wire (since I couldn’t find the exact size I needed), but I solved this by looping the wires through them. So far, I haven’t encountered any issues like oscillation.

I installed four tube sockets, while I probably only going to use the 8-pin and 9-pin ones. I haven’t come across 4-pin and 7-pin tubes (yet?) when repairing guitar amps, but I included them anyway because otherwise, the panel looked too empty—and you never know what kind of tubes you might run into.

In hindsight, it might have been better to build it in a plastic enclosure instead of a metal one. The housing is grounded, and if a banana plug accidentally touches the case, something gets shorted an the adapter disconnects. At the same time, this was a housing I already had lying around, so it felt like a free enclosure.

Lastly, the housing clearly shows that I’m very impatient when it comes to using a drill. The plugs are not level, and if I need to drill anything other than a simple round hole with the right drill bit, I just start hacking into the metal.

All in all, I’m very happy with the Utracer.

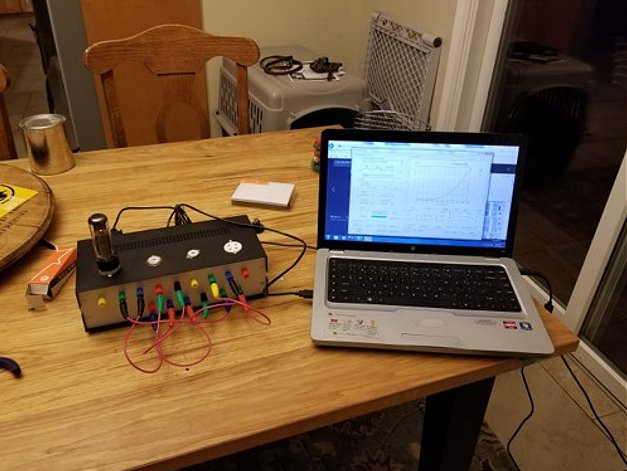

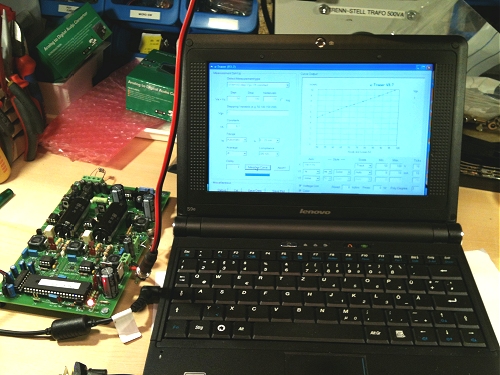

21st of March 2025, Lucky from Australia got his uTracer working on a very full kitchen table!

Hi Ronald and Marie-Jose,

Even though my tools were locked away in another house I was able to get an enough tools to get the job done, just wanted to report I have 1 µTracer built and calibrated. I had no problems with Win 10 Home edition just need a case and how to arrange it, haven’t tested and tubes yet but hard bit is done.

Yes I know its a mess done on my kitchen dinning table but it worked

Regards Lucky from Australia

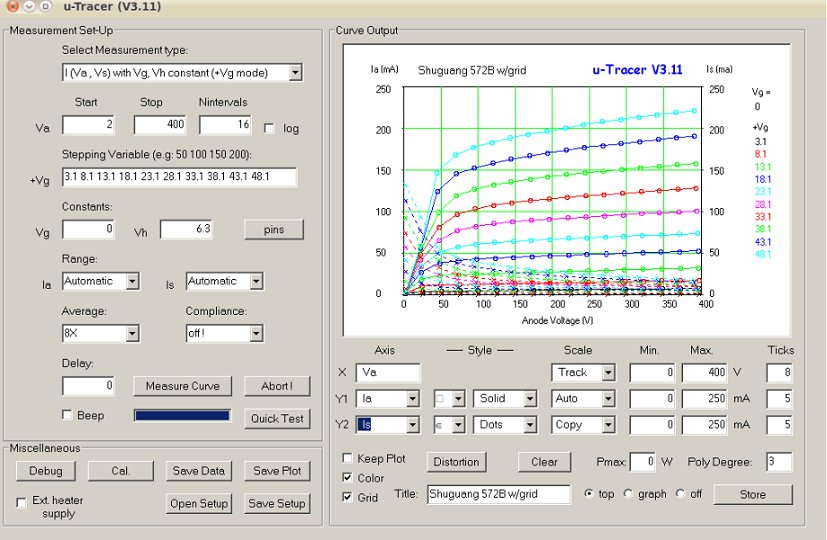

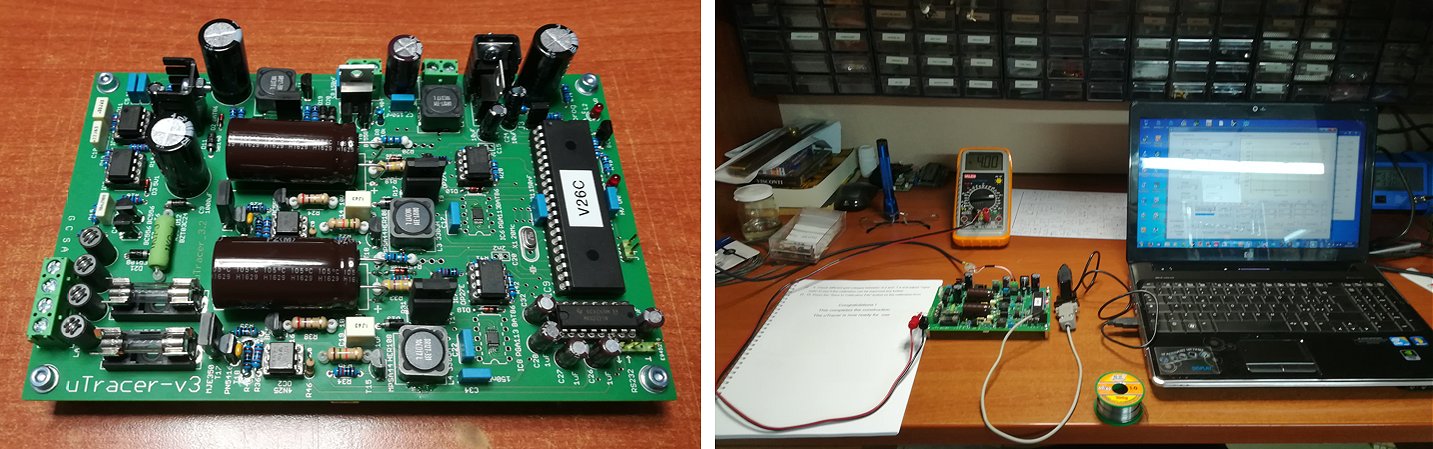

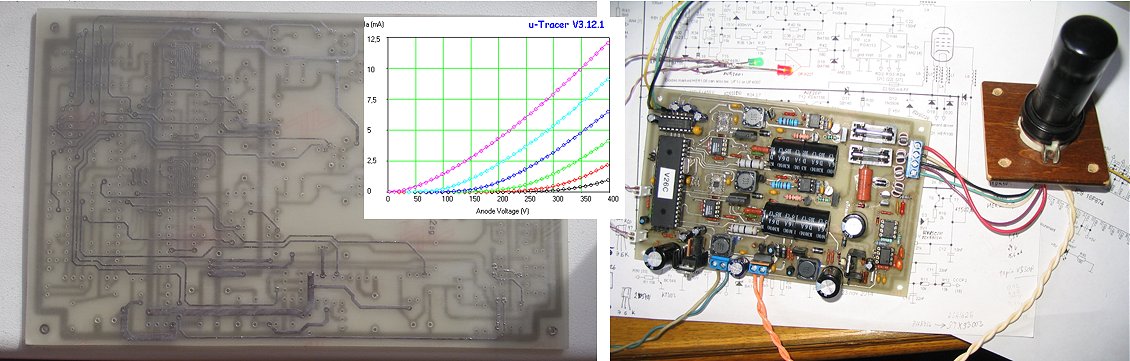

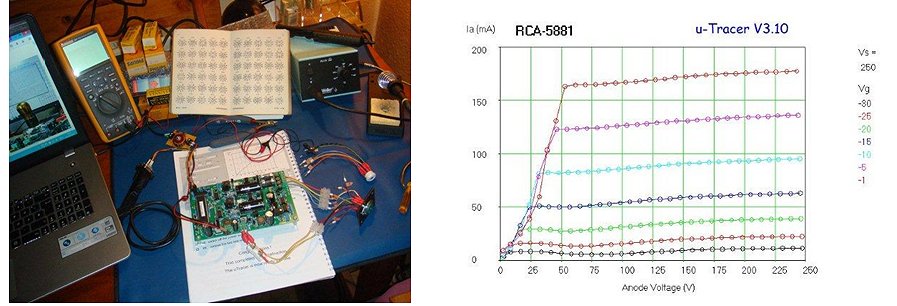

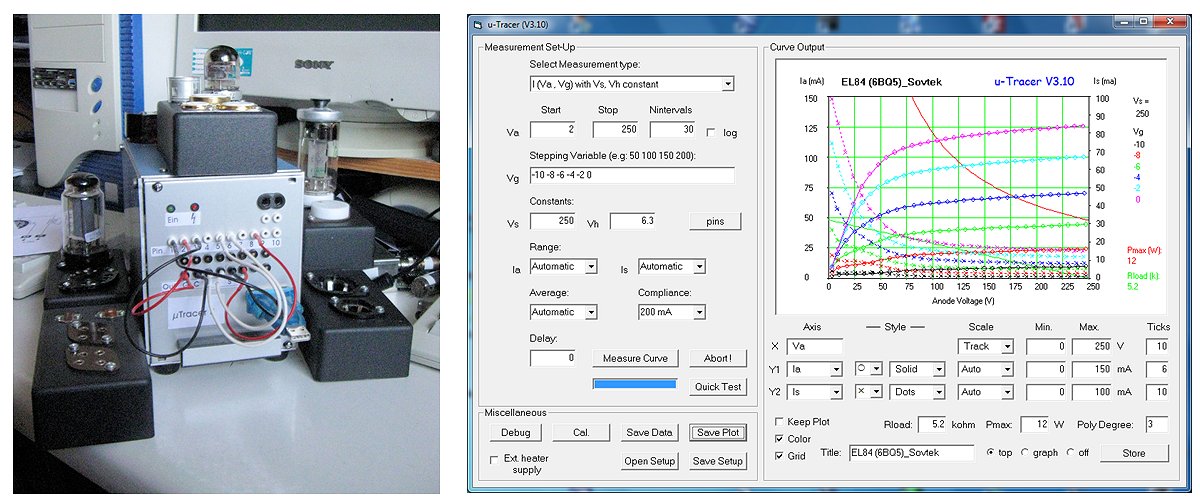

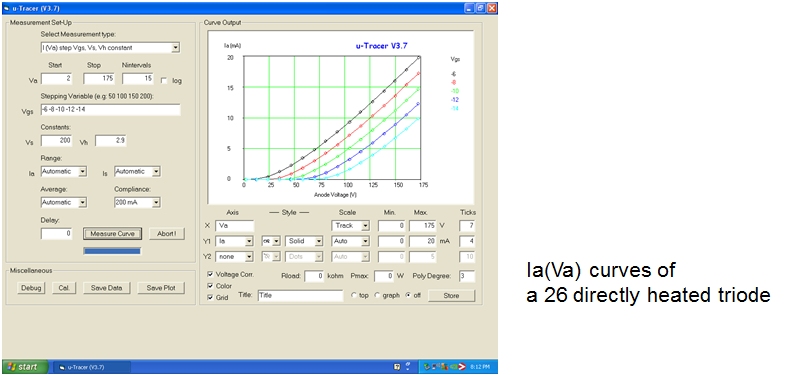

23rd of Januari 2025, Simo is very happy with his uTracer and managed to silence his wife!

Hello there!

I just finished soldering/ testing your 3+ kit. It works PERFECTLY because of your fine&detailed instructions. Building was a great fun, too shame this board is ready now. One of the finest aspects in your kit is having construction manual in a physical PAPER form! Please don't ever forget this nice handshake with these "old timers" like me.

You should have seen my wife's face when I tried to demonstrate uTracer in action for her.. She didn't say a word, but I could very clearly read: "How in heaven, a grown 58 year old guy is first sitting quiet for 15h of soldering, just to get so excited about three idiotic curved lines on laptop screen" Oh, man!

This old 12AT7 from junk-box is my first attempt to learning to use the tracer. I think I will be pretty ok after few more hours of training...

Nice to have some real data after 40 years of just GUESSING condition of tubes!

Close-up of EL34 is especially for you, I could not resist to warm up this beauty because of it's legendary brand (Yes, I have read about your work history!)

-simo

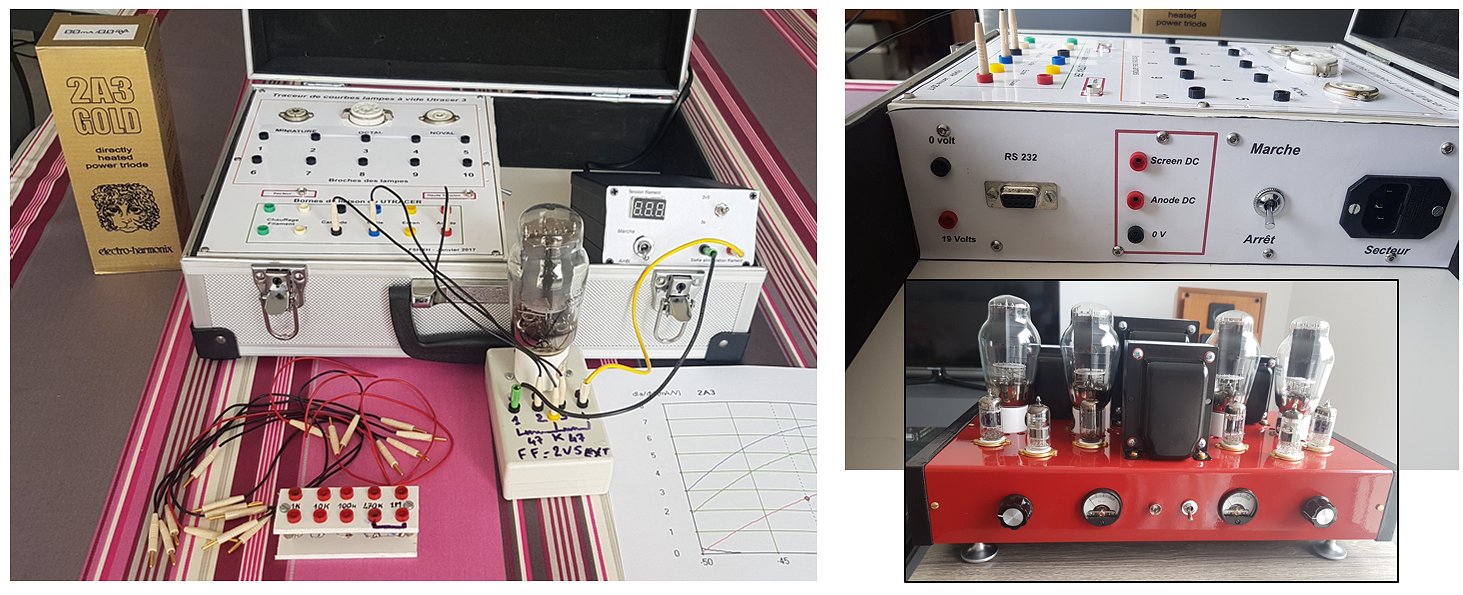

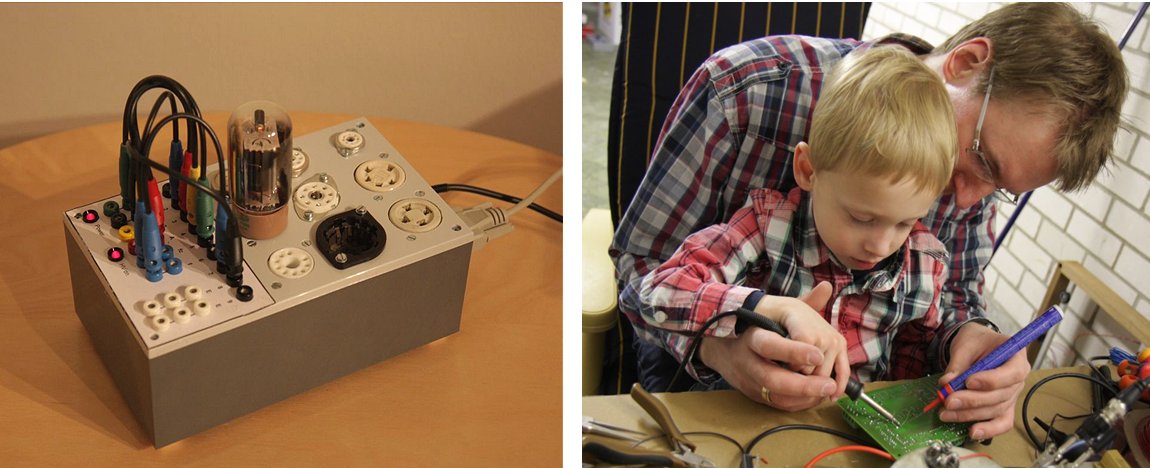

21st of Januari 2025, Matthieu from France has become a happy customer!

Hello Ronald and Marie-José,

I'm very pleased to announce that I've finished my STEP1 Temporary box µTracer 3+ :-))

I'm planning to build a nice chassis with rotoswitches like my Metrix 310B, but for the moment I'm okay with this little and compact enclosure made with my 5 years old boy!

No ferrites for the moment... and the results is quite good. I will add them when I receive the next components order. I put an external power supply for the heater.

I use WAGO interconnect for the matrix (cheap and effective for the moment).

The quick test is perfect for ... quick test! Great feature.

I like the works at boffin.nl for the load line tool.

I've reached the 200mA compliance limitation with the EL34 at VG=0 / -5, maybe a µTracer V6 one day...

It's a nice tool, the construction manual is perfect! (Maybe just put the two 10k/1% in the kit for the calibration)

Congratulations for this work, your skills are awesome!

You can follow the construction of the kit on my website:

https://www.projetg5.com/phpbb3/viewtopic.php?t=6577&start=15

Have a great week.

Best regards,

Matthieu (an happy customer)

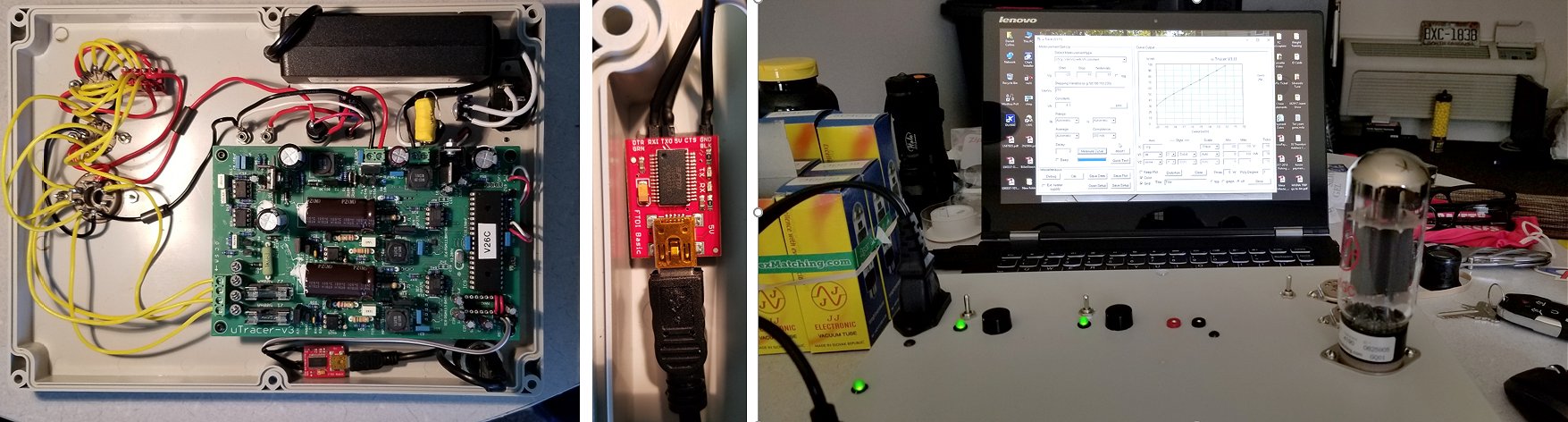

13th of Januari 2025, Walter reports another uTracer3 in service in Italy!

Hi Ronald, how are you doing?

A few years have passed since the last email exchange!

Just to inform you that my uTracer3+ was actually completed a few weeks after I received the kit (April 2022). Four months later I relocated abroad, and I had no longer a chance to play with it... Recently I spent Christmas holidays in Italy, and I decided to take a couple of photos. As you can see, I recycled the metal case of an old UPS (very convenient to save space on my crowded bench!). Everything fits inside, including an extra PCB for the external filament power supply and its separated power brick.

I removed the MAX232 chip (parked on the black foam) and I connected a RN-42 module (it is not visible in the photo, since it is between the front side of the metal case and the plastic "panel". This way I connect to uTracer via BlueTooth.

The external filament power supply board sniffs the data sent to the PIC and automatically switches to a programmable DC-DC converter when a modified command is detected. This command is sent by a custom version of uTmax GUI, simply replacing the unused zeros in your protocol with FF (this modification is ignored by uTracer). In brief, I can choose between internal and external filament voltage source without the need for any mechanical switch!

Thank you for creating and supporting uTracers!

Have a nice day and ciao,

Walter

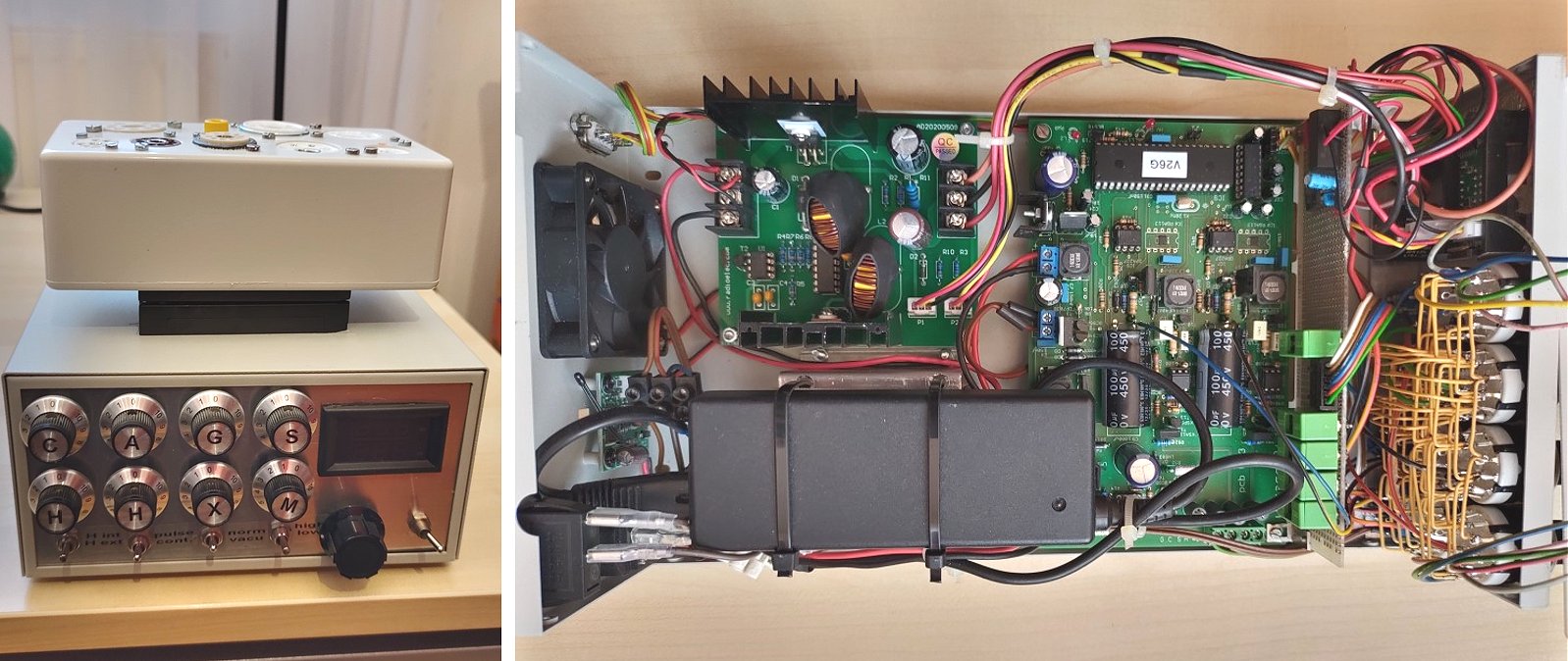

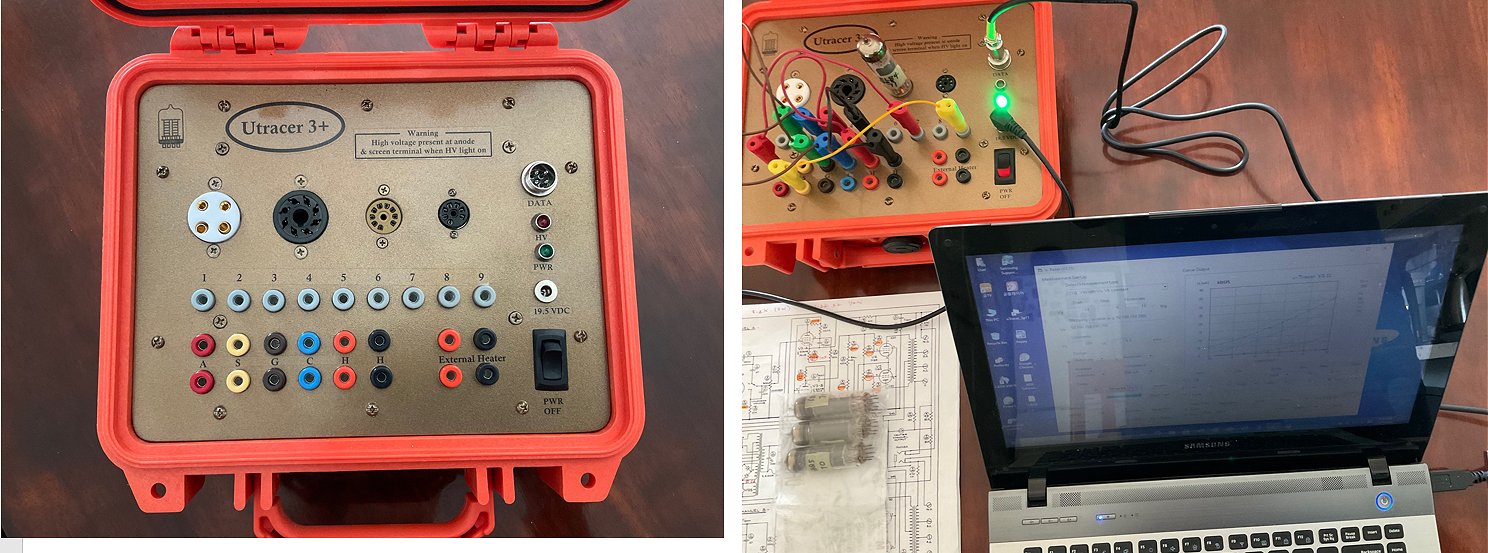

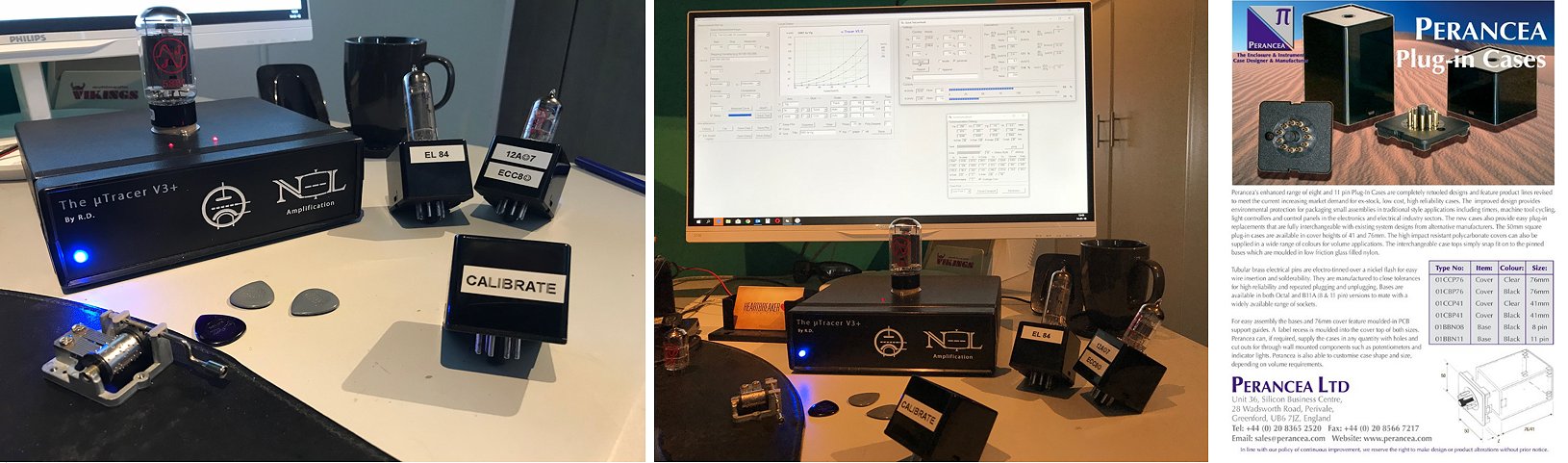

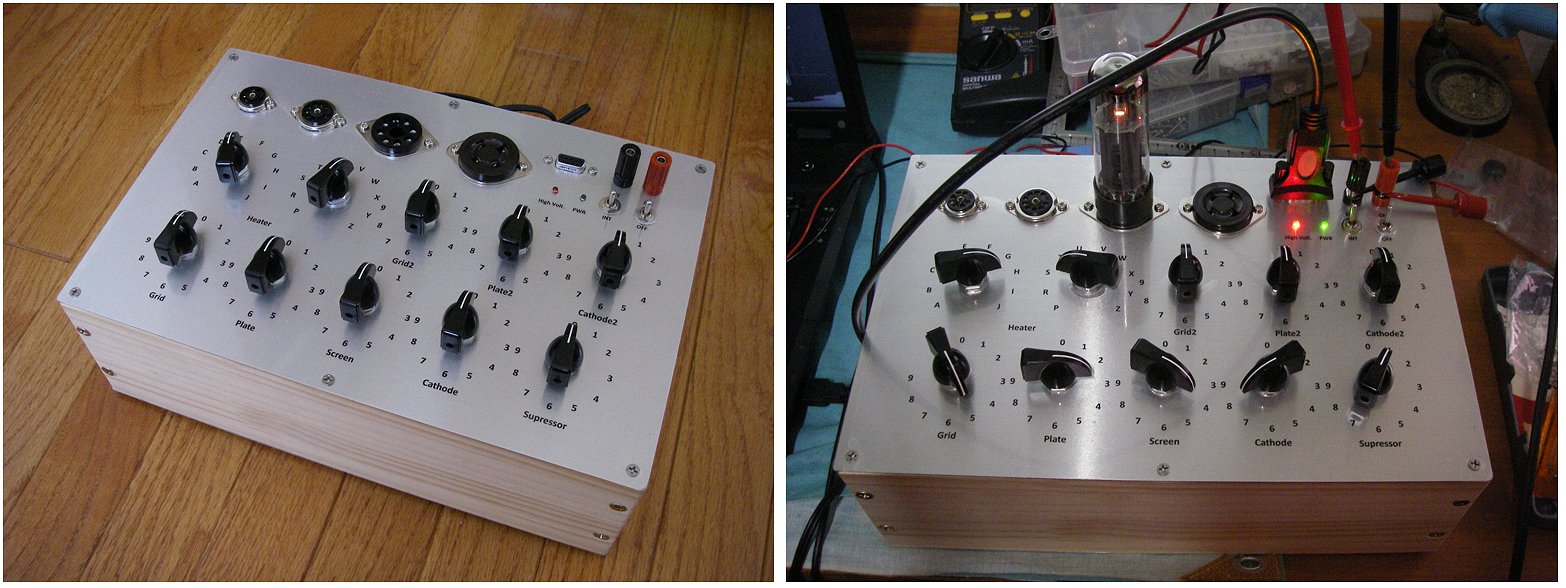

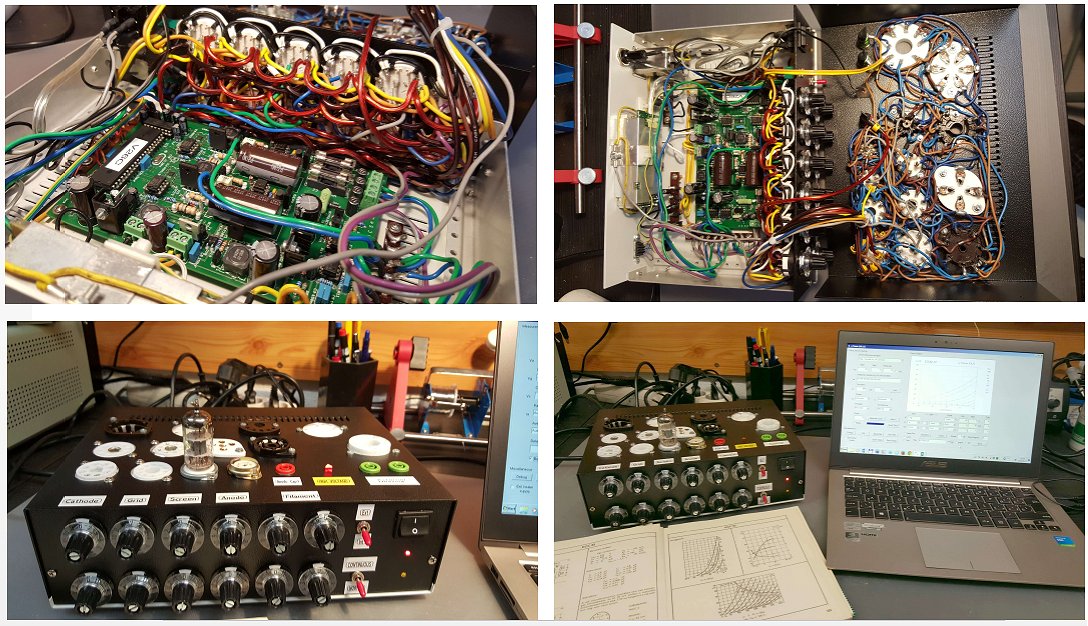

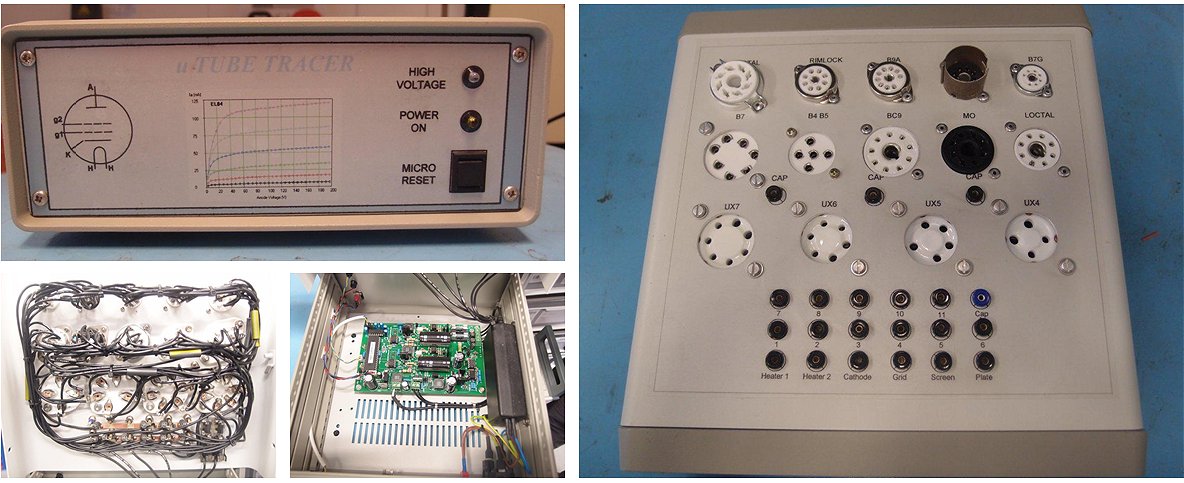

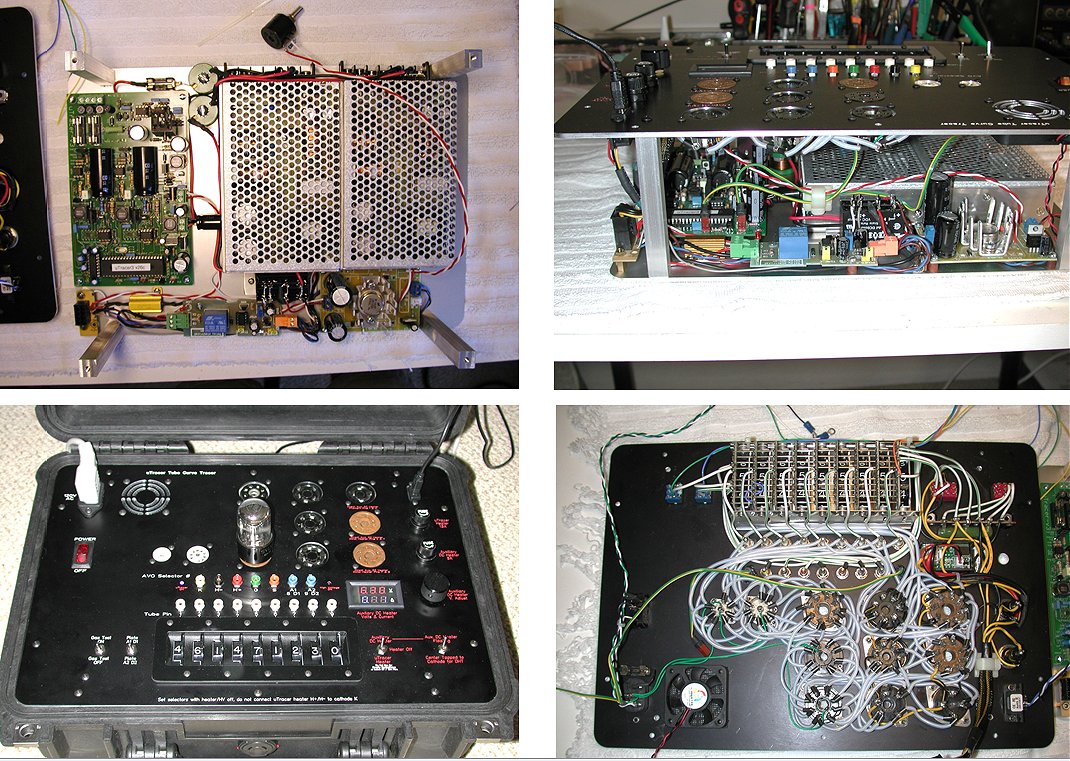

27th of October 2024 Andrew from New Zealand sent me a picture of his stunning uTracer with rotary switches!

Hi Ronald,

I thought I better send you some photos of the finished product!

It's a tight fit in a Nanuk 909 case with two laptop PSU's (one for the utracer and the other for the external supply).

I used ferrite beads liberally and everything is working well.

Kind Regards

Andrew Parsons

New Zealand

1st of October 2024 Jonathan from Holland sent me a few pictures and a testimonial (in Dutch) of beautiful and professional uTracer!

Beste Ronald,

Een tijdje geleden heb ik de Utracer 3+ kit bij je aangeschaft. Inmiddels zit hij in elkaar.

Het was een erg leuk project om hem in elkaar te zetten. De kwaliteit van de print en de onderdelen zijn erg goed. De handleiding is geweldig! Het solderen verliep perfect en alle tests heb ik succesvol doorlopen.

De behuizing maken was ook een leuke uitdaging. De bovenplaat heb ik met een lasersnijder laten uitsnijden via een collega, een koffertje (B&W type 3000) scoorde ik via Marktplaats en met een paar 3d prints kon ik alles netjes monteren.

Ik ben erg tevreden met he uiteindelijke resultaat. Zie bijlages. Erg leuk dat oude buizen techniek samen komt met moderne techniek zoals lasersnijden en 3d printen.

Als voorbeeld heb ik de behuizing van Nebojša gebruikt.

De buizentester werkt erg goed. Eindelijk heb ik goed zicht op welke buizen nog bruikbaar zijn of welke buizen echt op zijn.

Ik had al wel een Amerikaans buizen tester (Hickok 600), maar daar kon ik lang niet alle buizen op testen en die gaf lang niet zoveel informatie over de staat van de buis.

De Hickok mag dan ook met pensioen. (nee hij gaat niet weg) ??

Inmiddels werkt de uTracer ook via Bluetooth.

Mvg,

Jonathan

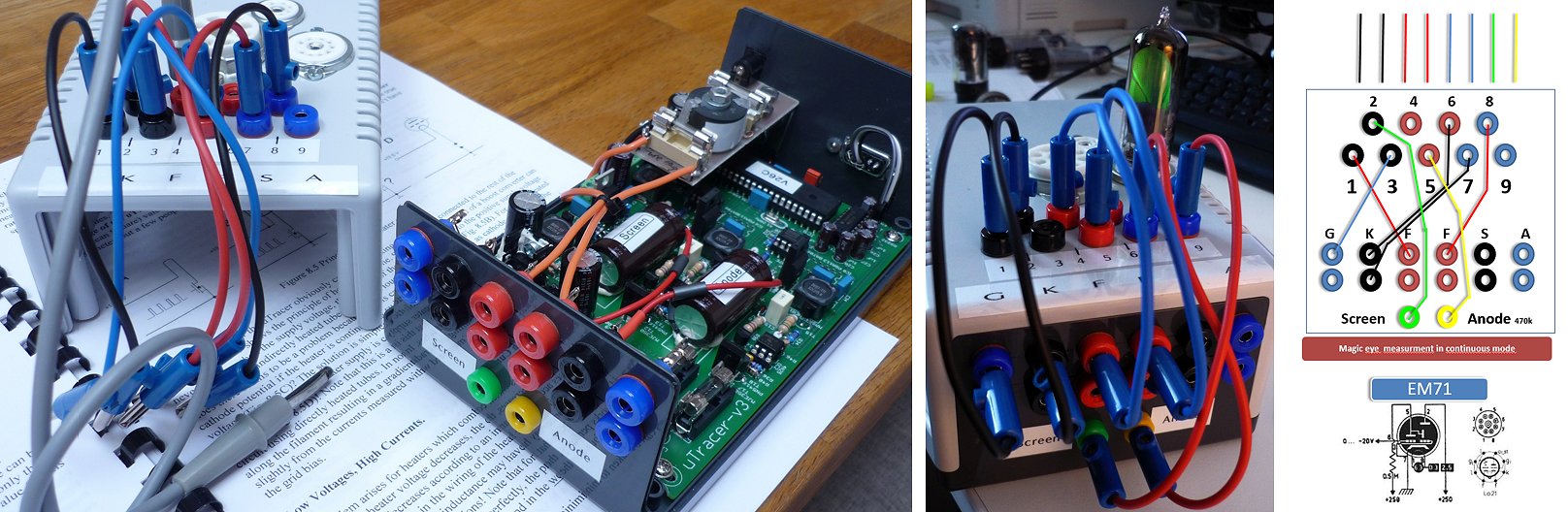

30th of July 2024 Erik from Holland sent me a few pictures and a testimonial (in Dutch) of his fine uTracer that one way or the other reminds me of the Enigma coding machine!

Dag Marie-José en Ronald,

Ik heb mijn u-Tracer 3+ in elkaar gezet en hij werkt prima!! (Teleurstellend te zien dat ik best veel zwakke buizen heb ? ??)

Ik heb een paar foto’s van mijn creatie bij gevoegd.

Ik heb gekozen voor een “stekker” optie die ik in principe kan afsluiten. Alleen wanner bv. Een externe voeding of dat er een weerstand gebruikt moet worden voor het testen van gelijkrichter kan ik die gebruiken. Ook zijn hier de Hoogspanning direct van de Elco’s naar buiten gebracht voor het testen van een “Magic-eye”.

In de andere gevallen gebruik ik de duimwiel optie die eronder zit. Ik heb voor elk type buis een 10-cijverige “code” die ik daar aangeef. Buis in de juiste socket en meten maar. Werkt super!

De stroom door de schakelaar gaat nog binnen spec, echter voor de hoogspanning niet. Wat ik hier heb gedaan is dat voor de hoogspanning aansluitingen ik altijd 1 contact heb overgeslagen tot de andere contacten en de het midden contact. Hierdoor is de kans op overslag minimaal. Niet schakelen onder spanning en tot nu toe geen problemen ondervonden.

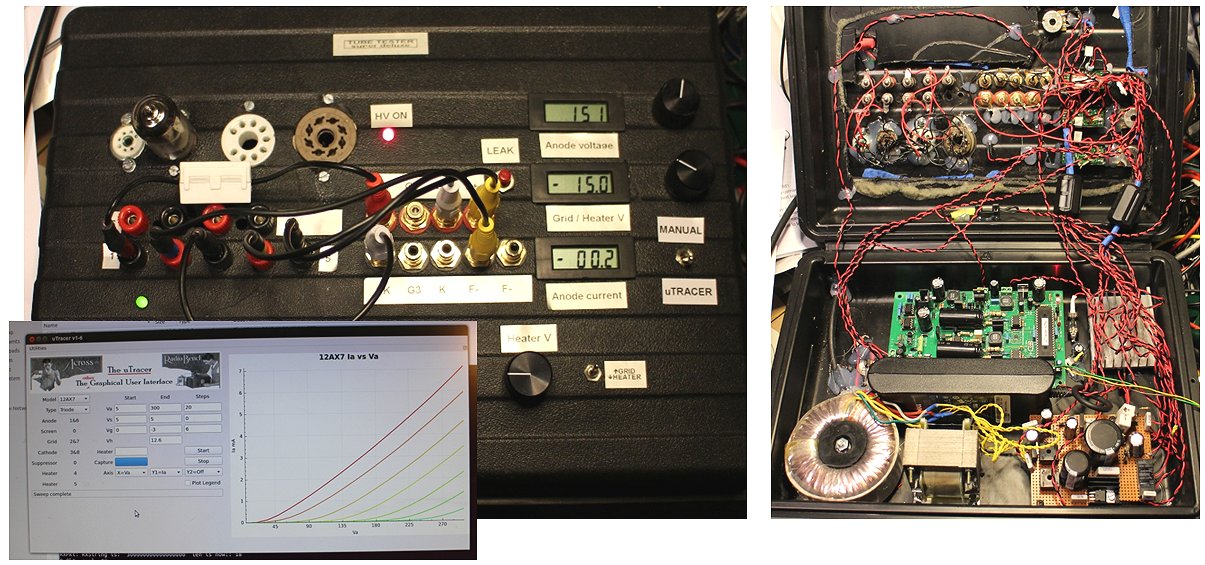

15th of July 2024 Joe, “the tube amp guy” is very pleased with his uTracer3!

Hello,

I thought you might like to see another uTracer curve tracer completed and in service. I love this machine and really enjoyed the process of building it and learning how to use it.. I didn't try to reinvent the wheel and copied the idea for the chassis box and layout from another one of your customers that you had previously posted on your webpages.

It doesn't replace my Hickok 752 or EICO 667 for most amplifier service work. However, I think many of my clients will find this easier to relate to and understand rather than a 60 year old tube tester.

Thanks very much, enjoy your summer,

Joe

The Tube Amp Guy

www.thetubeampguy.rocks

1st of July 2024 Jim sent me a few pictures of his fine uTracer!

Hallo Ronald,

Eindelijk is m'n tracer volledig klaar. (wat een leuk project!) De inbouw heeft wat meer tijd gekost dan het bouwen van de kit zelf. Uiteindelijk gekozen voor een plastic fligtcase met een PCB frontplaat. Ik ben zeer tevreden met het resultaat.

Bijgevoegd enkele foto's.

Met vriendelijke groeten,

Jim Coun

10th of March 2024 Gianni finished his superb uTracer!!

Good morning Ronald,

I wanted to inform you that I have successfully completed the construction of the 'uTracer'. I am pleased to report that the entire process was enjoyable and smooth. The GUI worked flawlessly, and the assembly was carried out meticulously following the instructions provided in the manual. All tests were passed with satisfactory results.

I have already recommended this tool to numerous valve enthusiasts. Now, I will dedicate some time to thoroughly study the user manual in order to become familiar with the measurement procedures.

Thank you once again for your availability and support.

Best regards,

Gianni

24th of January 2024 Danny from Belgium is very satisfied with his very beautiful uTracer!

Beste Ronald,

Na een paar hickups ( BC559 in de grid defect ) is mijn uTracer3+ volledig klaar!

Ben er uiterst tevereden over , intussen een paar EL84 , 6V6 , 12AT7 , ECC82.

Ik had eerst problemen met oscillaties bij het testen van EL84 maar als je eigenlijk alles goed volgt bij het bouwen en de tips over o.a de ferriet buisjes enz… kan het niet fout lopen.

In bijlage een paar foto’s ;-)

Nogmaals dank !

Danny

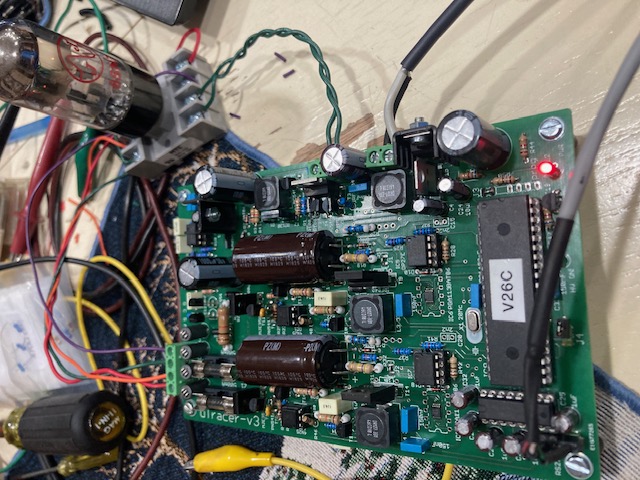

2nd of January 2024 Mike from Tennessee was the first to finish his uTracer3+ in the new year!

Ronald, it’s a thing of beauty.

Let me get it into a proper enclosure and by Feb I should have an order in for the version 6 model.

Excuse the workstation. First two tubes tested following calibration. JJ 6sn7, first showed both halves literally dead matched up to 400v. Another showed a fair separation of the halves. It is awesome to see overlays of 4 triodes!

The only hiccup I had was I believe R45 had a deceptive hole, I mistook a via in line for the correct hole. While visual QC as I completed a module, found it. While reworking I broke the already installed BAT86 adjacent. Thankfully you supplied ONE Extra! Many thanks.

Additionally, was working on New Years Eve and (not drinking!) got tired early AM and installed t14 backwards and t9 correctly. Found dying a secondary visual, no harm, no power applied. I reworked the FET no issues.

It dialed in like it was factory assembled. Zero defects, the manual is stunningly complete and precise. I only wish I had a small percentage of your Solid State skills!

Happy New Year sir to you and yours. I have started 2024 with a uTtracer!

Mike in Tennessee

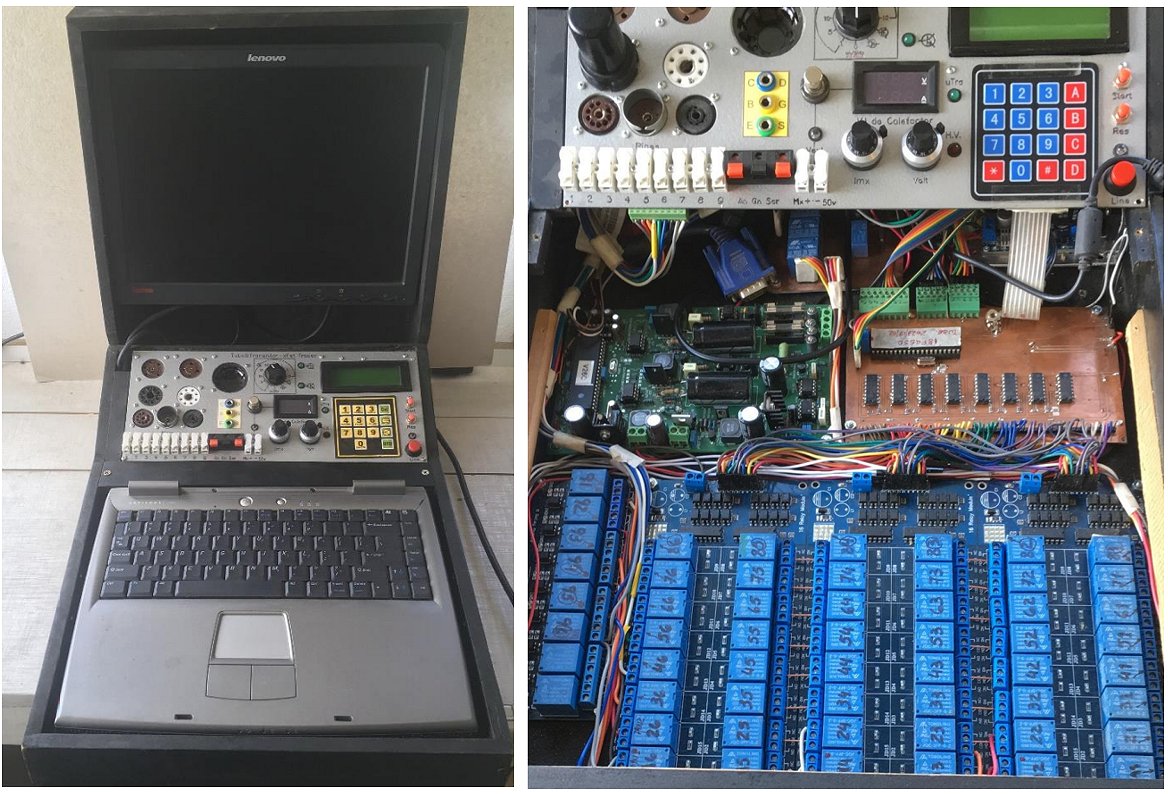

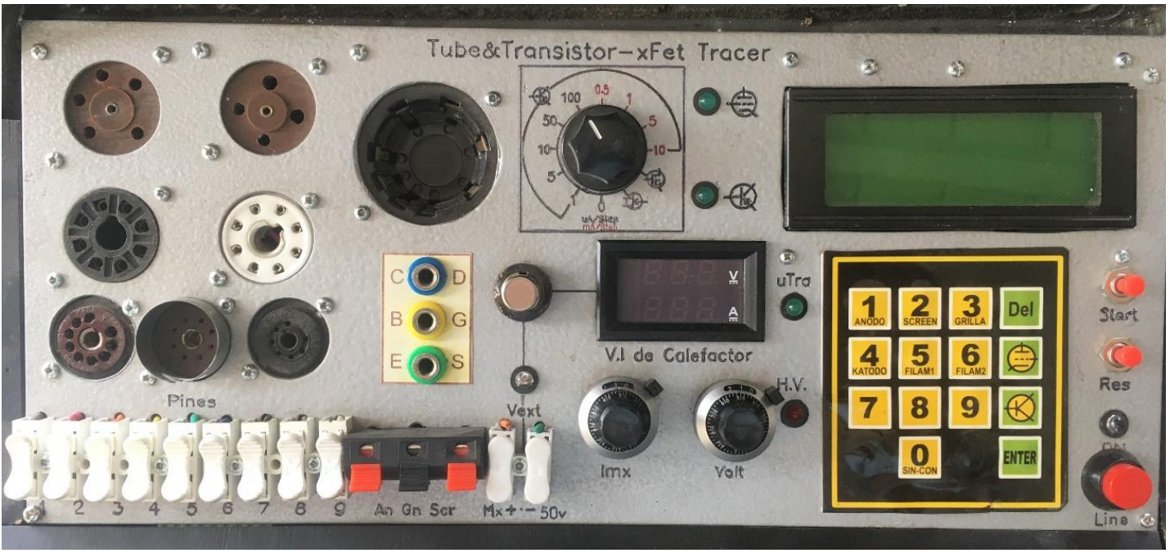

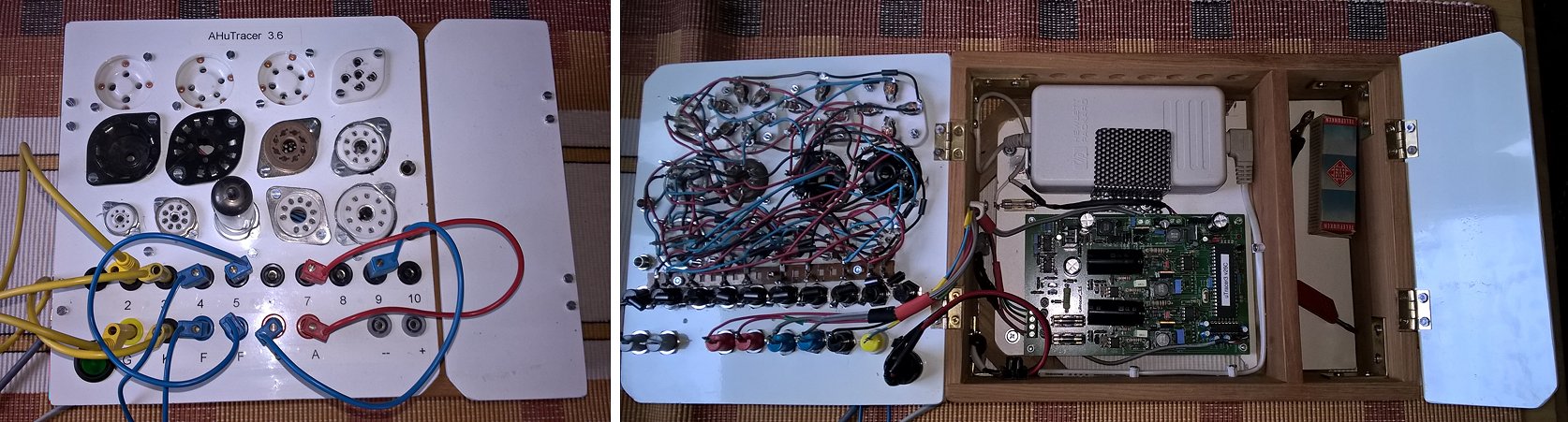

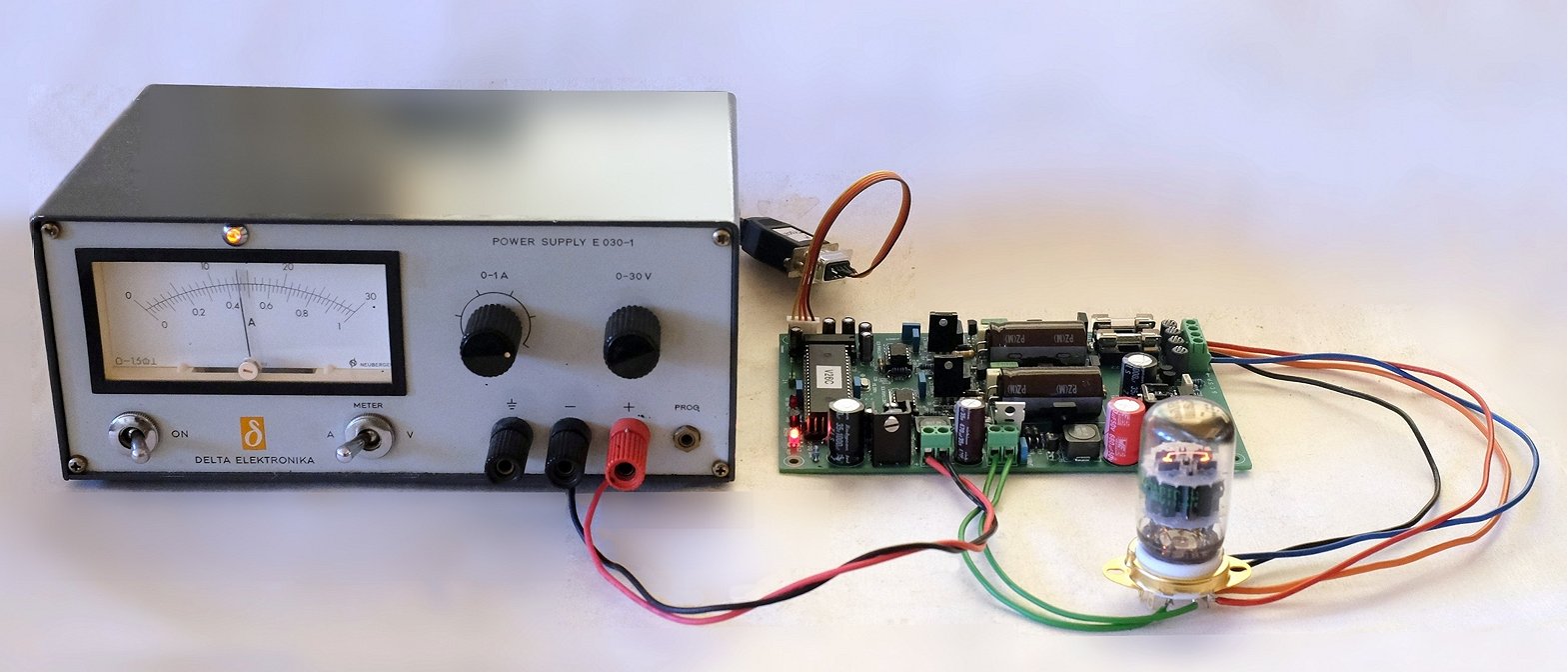

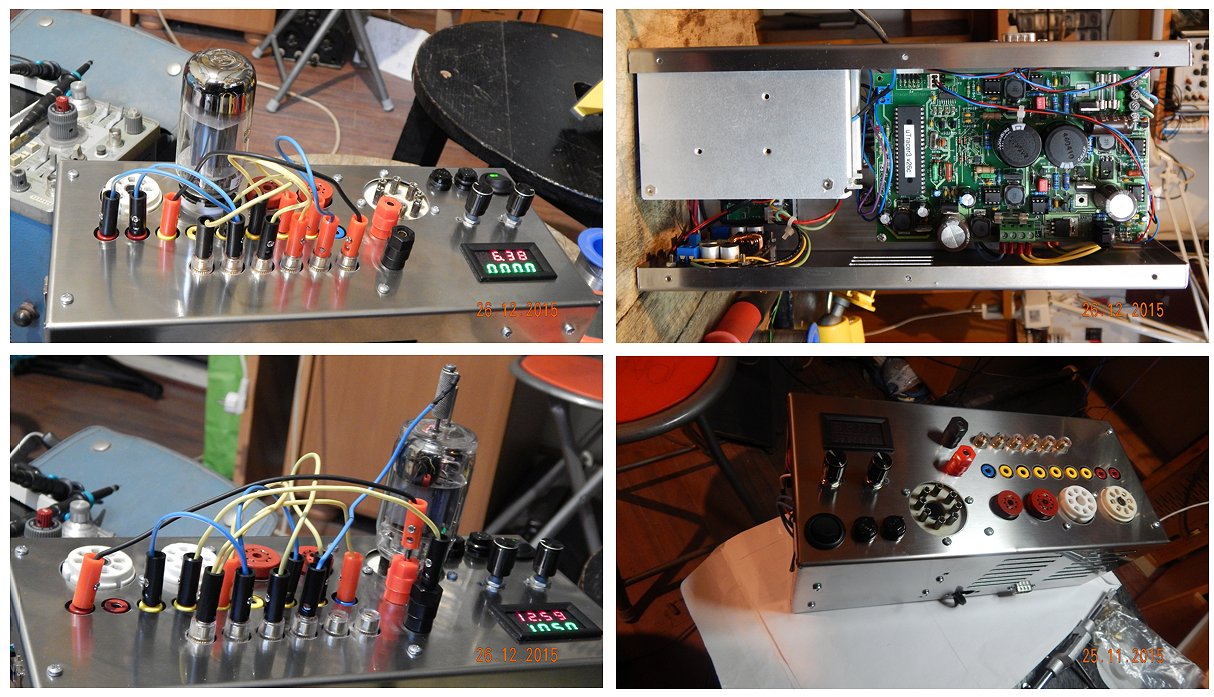

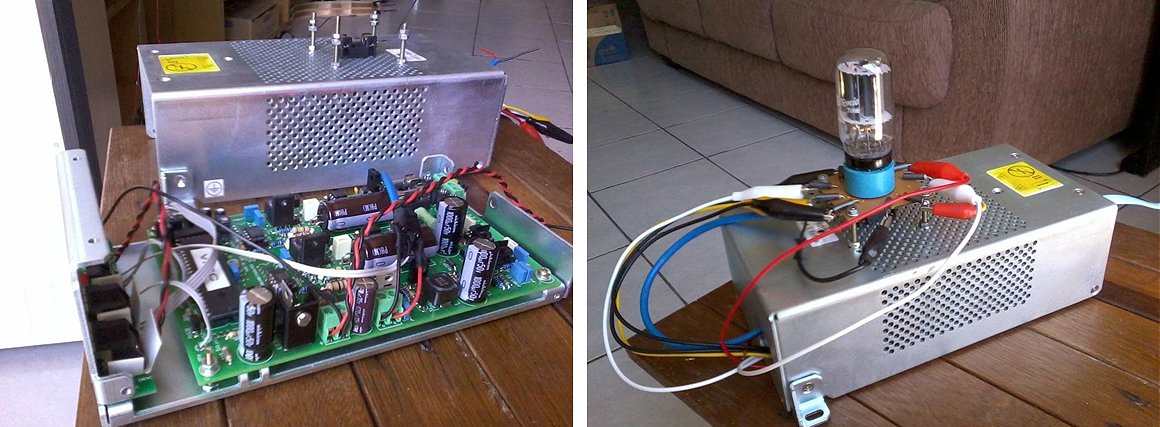

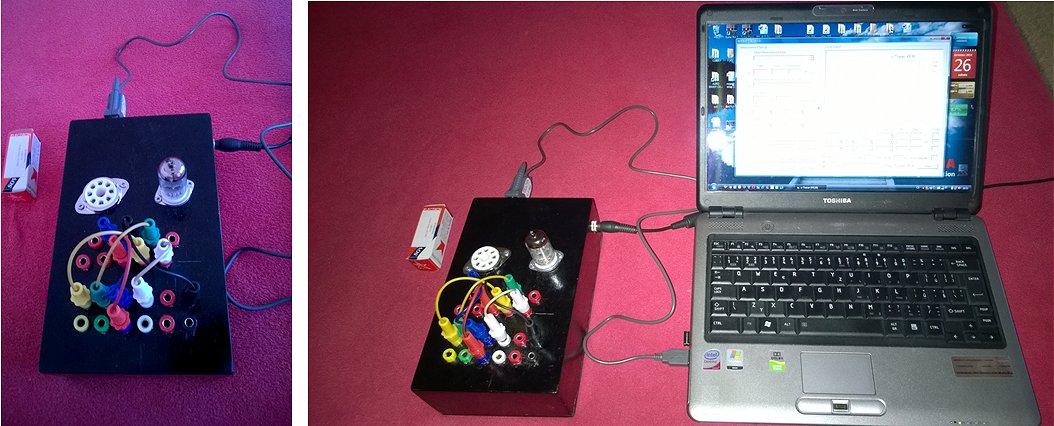

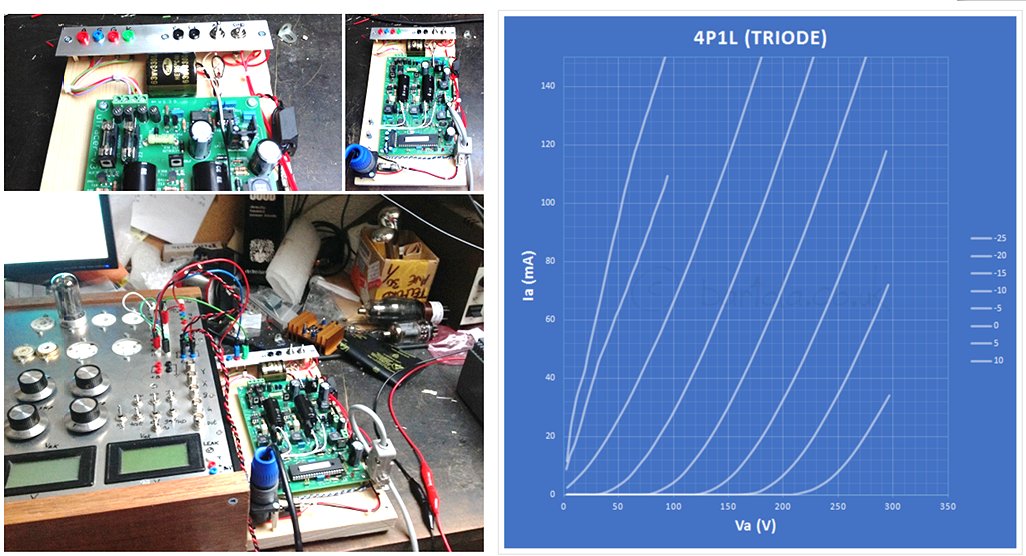

30th of December 2023 Roberto from Argentina sent me a fantastic report of his amazing uTracer!

Hello Ronald.

I was finally able to finish my tube tester-tracer. I integrated an old laptop, the uTracer, and an interface that I built based on a 18F4550 Microprocessor into a single equipment. This performs the function of assigning each of the pins to the uTracer buses. It is operated from a 4x4 keyboard, with a 16x4 display. The program starts by requiring the heater voltage to be reduced to a minimum to avoid possible damage to the next tube under test. Tubes and transistors can be tested. Everything is selected by keyboard. Once the type of measurement, tubes or transistors, has been chosen, we proceed to define the heater voltage and the pin assignment for tubes. Once this is done, it is passed to the uTracer function, which must be parameterized to start the measurement. I used a matrix of 54 relays for pin assignment, variable power supply for heater (I do not use the uTracer one), a 5 VDC supply for the relays and the interface Microprocessor. I have arranged several sockets for tubes and terminals for transistors. There are also terminals for the 9 pins if the tube under test does not have a socket on the equipment. The regulated and current-limiting heater power supply, with variable voltage from 1.1 VDC to 30 VDC. A central button allows you to use an external source. A rotary key is used to select Transistor tests.

The interface is in Spanish, I am from Buenos Aires Argentina. On YouTube there is a video about the operation of the equipment in tube testing. Everything done for this project is available to anyone interested.

Just have to write to my email rlopezsantoro@gmail.com

The video is in : Roberto Lopez Santoro, Buenos Aires Argentina https://www.youtube.com/watch?v=4tQHaiSvo3U

Roberto Lopez Santoro, Buenos Aires

Argentina

27th of November 2023 After a few hick ups with a faulty COM cable, Tim from Holland is happy to report his beautiful uTracer3 working !

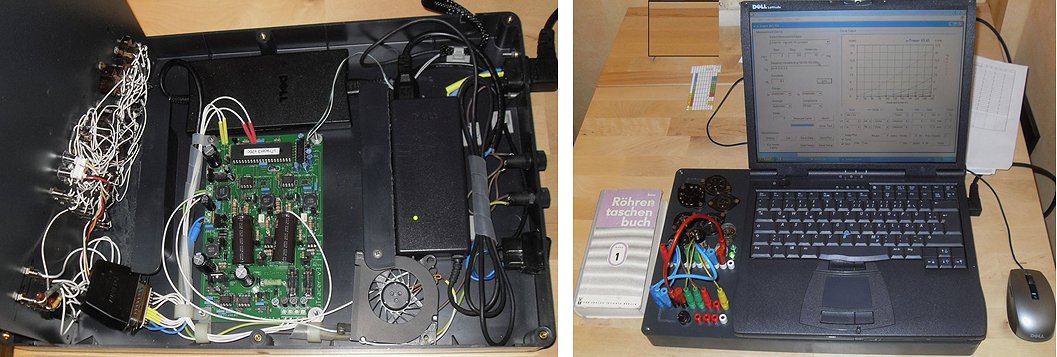

10th of October 2023 Dave from Denmark, in all modesty, reports his uTracer working!

I am happy to report that there is yet another uTracer3+ in operation here in Denmark! It's working fine - although mine is not pretty it is very functional.

Many thanks for creating such a wonderful device.

Dave

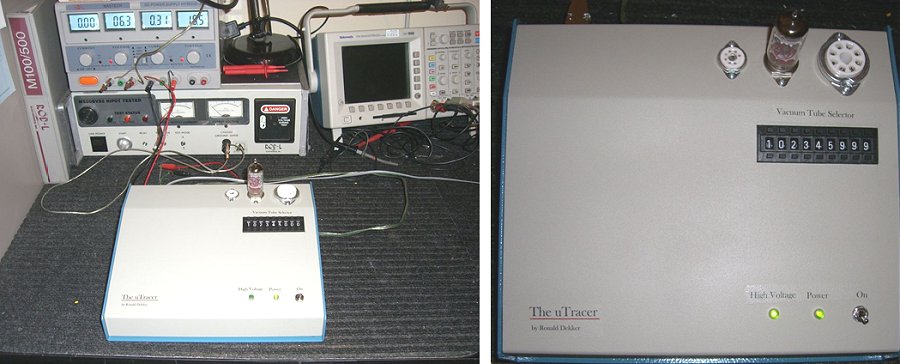

6th of September 2023 Peter from the U.S.A sent me some pictures and an enthusiastic testimonial of his beautiful and compact uTracer!

Dear Ronald and Marie-José,

Your first-class µTracer 3+ kit and excellent manual arrived well packaged. I enjoy the "Greetings from Holland" card you enclosed. You have done such a great service for all of us by designing this amazing device! It was a pleasure to build, test and calibrate it. Everything tests as written in the manual. I used a case from an old 5-port VGA switch. It was just the right size to fit the PCB and tube sockets that I need. The box even had a stamped hole in the back made for a DB-9 connector (10 of them, actually!). I covered the front rotary switch hole with a decorative piece of IC perf board. A modification I made was to move the -40V IC regulator to mount on the back panel to help cool it since the box is so small.

The µTracer GUI program runs very well in my HP Chromebook computer using an FTDI USB serial converter. I used the dnschneid/crouton script from GitHub to make a chroot environment to install Linux, Debian 10.13 (Buster) i386 architecture (32-bit). Then I installed 32-bit wine 4.0 to run the µTracer 3+ (32-bit) GUI. I also tested it to run successfully on Windows 10 as a backup computer. My next step is to begin analyzing my collection of about 400 vacuum tubes.

Best wishes to you and Thank You!

25th of July 2023 Paul sent us a few pictures of his very nice uTracer!

Marie-Jose and Ronald,

I wanted to say thank you so much for this great tool.

I finally got mine together in an enclosure and started measuring/sorting some of the surplus tubes I have.

The uTracer works great and produces fast, quality results.

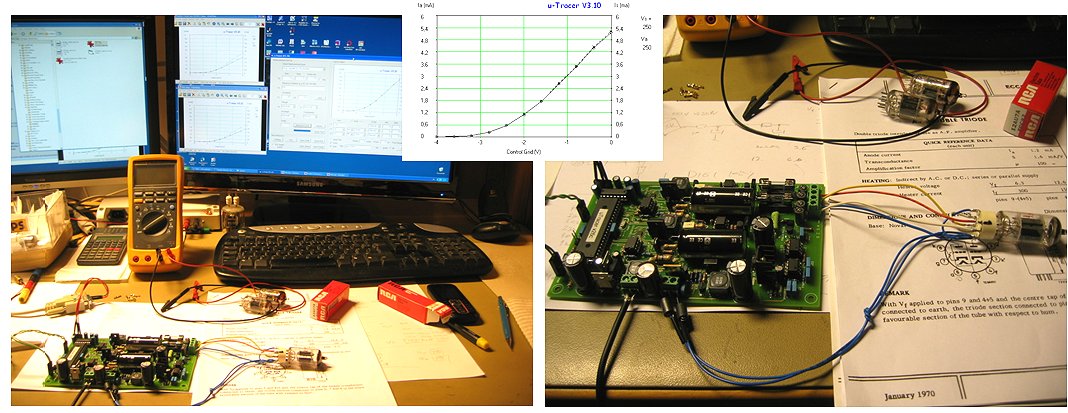

I've attached some images of the final build and a shot of an I-V test of a really nice 1958 RCA 6AK6.

Thanks again!

Paul

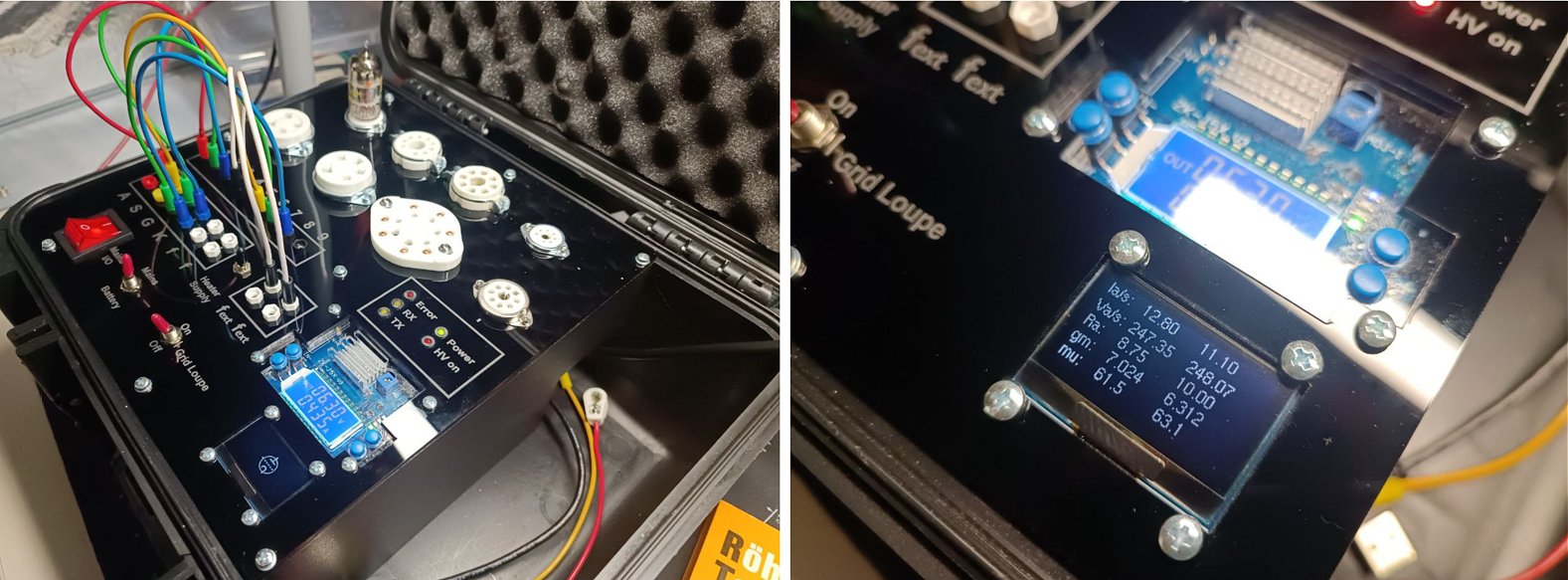

25th of May 2023 Milad sent me a few pictures of his truly amazing uTracer!

Hello Marie-José and Ronald,

it's been a while since I bought the utracer3+ but I finally finished my build. I decided to take inspiration from my Müter BMR 95 that I use to test CRTs. I bought a case and designed the rest around it. The skeleton that holds the PCB and the power supply is 3d printed and the top plate is acrylic that was laser cut and engraved. I'm really happy how it turned out, although I might exchange the acrylic for something else as it's a real fingerprint magnet.

I included a separate power supply for the heater that can be activated by a switch. It supports voltages up to 30V and should be able to go up to 1A.

Instead of using the traditional utracer GUI I opted to use Ihor Smal's utracer ESP32 interface (can be found here: https://boffin.nl/wp/utracer-and-esp32/). It works well and also shows the measured values on the little OLED display. With that I don't need a laptop to do measurements as it can be done via any device that supports a web browser.

The idea was to take the whole tester with me to test tubes in the field (for example at conventions). Therefore I also added the option to supply the whole system with power via a USB-C power bank. This will supply 20 V and is plenty for the whole system to work.

There is enough space on the right side for the powerbank as well as all the necessary cables to make the connections to test tubes.

I also added a switch for the grid loupe but I haven't added it yet so it doesn't have any functionality.

Thank you for that awesome kit and the time you put into perfecting it!

Kind regards from Germany,

Milad

20th of May 2023 Ray sent me a set of pictures from his magnificent uTracer!

Hi Ronald,

I just finished the uTracer3+ project last night and started testing some tubes. So far, it seems to function as designed. going to put it to the test over the next few days! I also just ordered a uTracer6 now that it is available. Can't wait to get started on that one.

Thank you for the time and effort you put into this to make such a powerful tool available to hobbyist's at an affordable price. As a small scale amp designer/builder, this is a game changer!

Attached are some more pics of the progression.

Regards

Ray

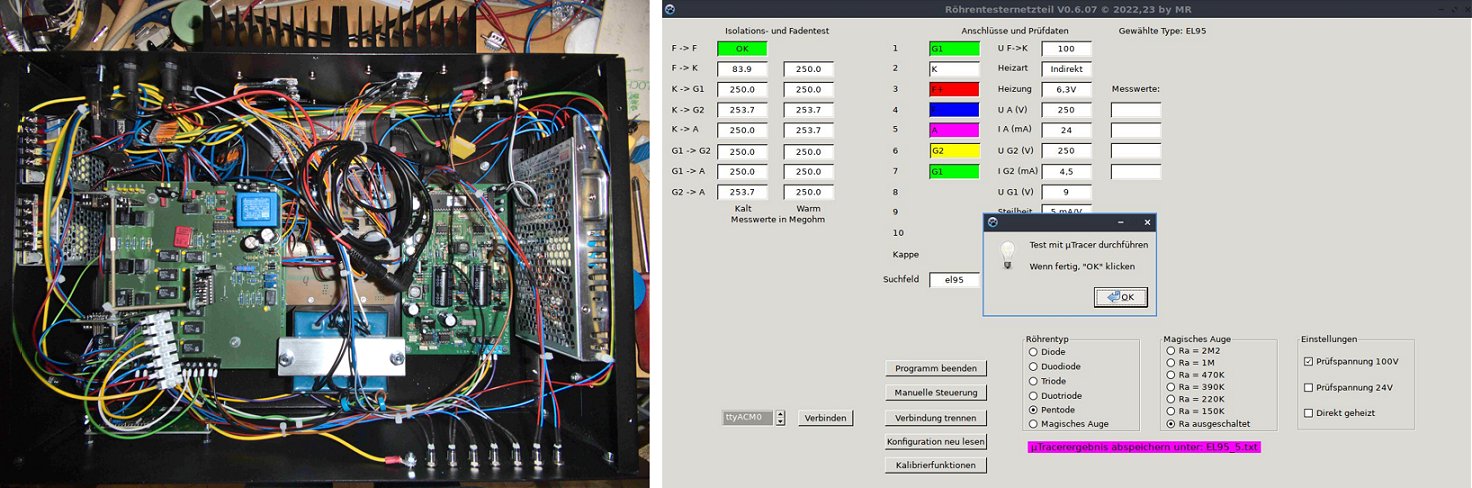

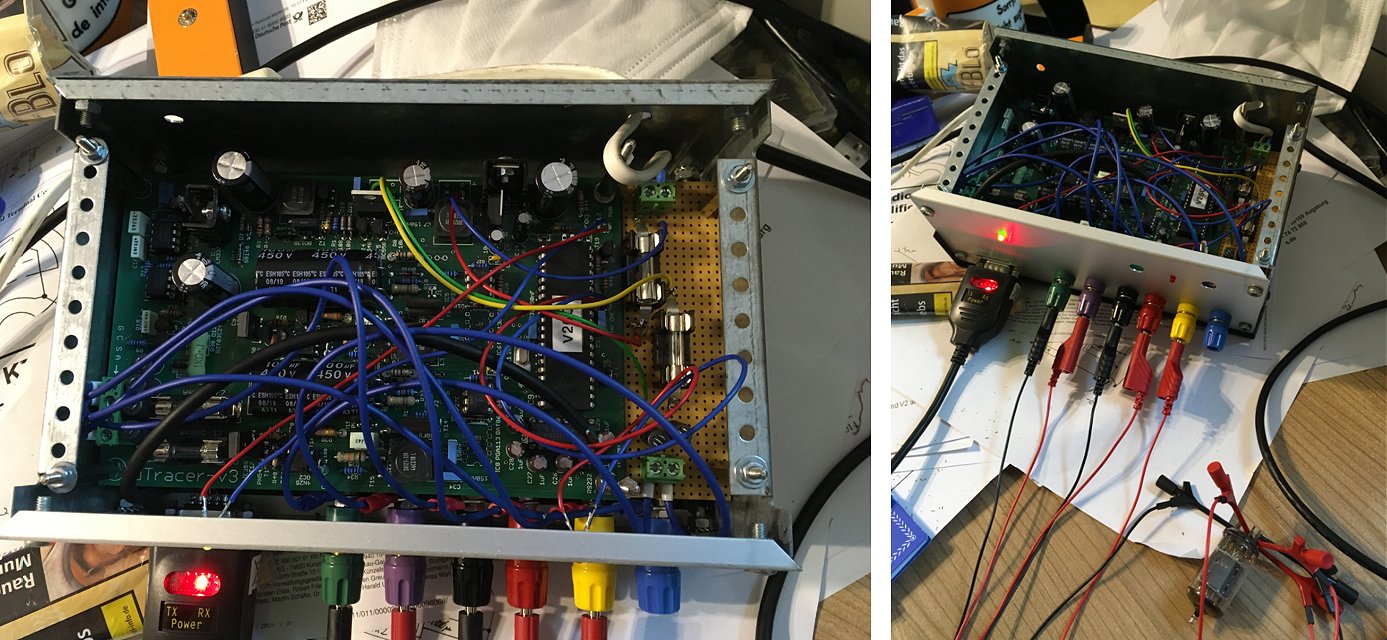

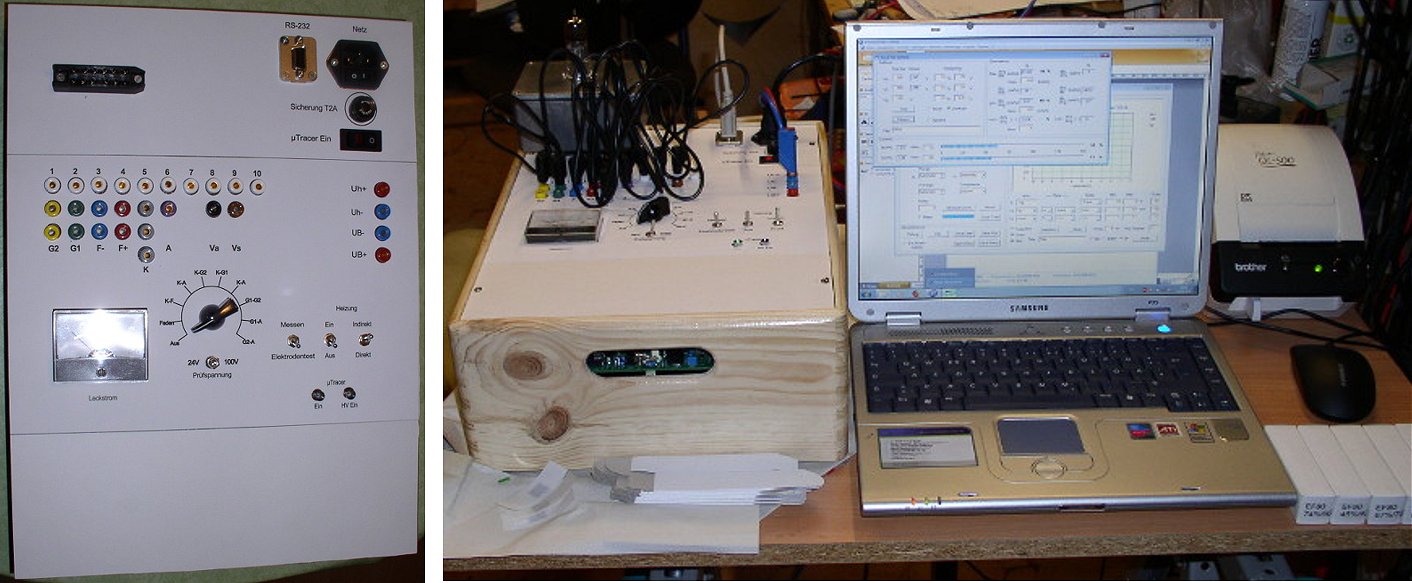

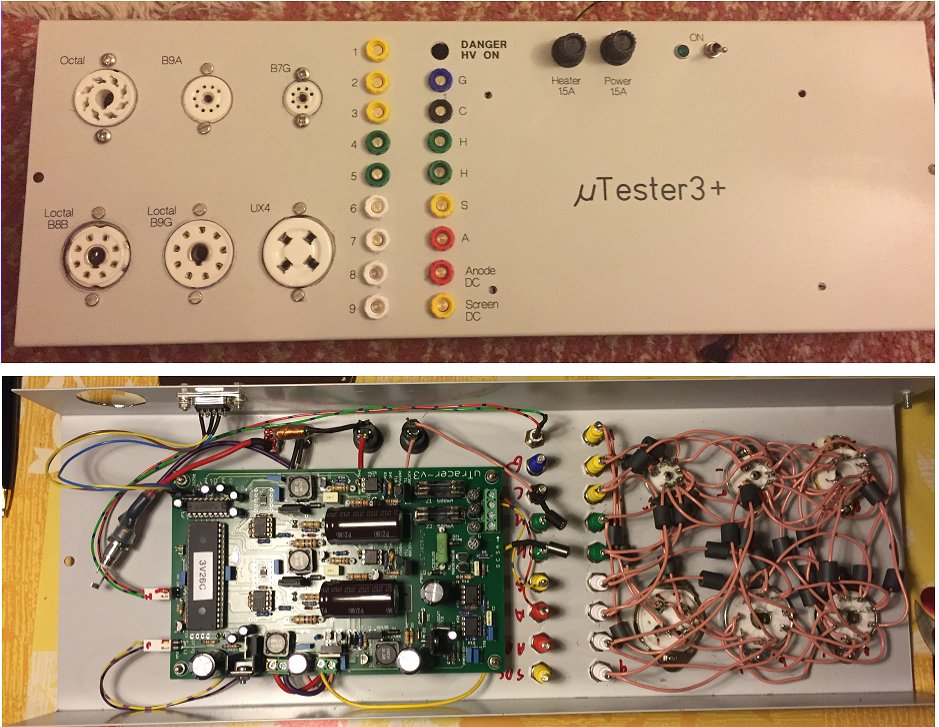

19th of May 2023 Martin sent me a few pictures of his enormous uTracer! Can you find the uTracer PCB?

Hello Ronald,

Originally I just wanted to build a suitable heating energy source for my already existing µTracer (built autumn 2019).

However, as I needed a larger enclosure than originally planned, I decided to order another µTracer 3+.

The housing is a 19" sheet steel housing with 3HE.

Since yesterday, the µTracer has been installed and in operation.

The attached picture 'Front.jpg' shows the finished unit from the front.

Inside are these assemblies:

- The µTracer itself

- A diode/rectifier measuring circuit

- 1 each heating current and heating voltage regulator

- A test circuit for checking the tubes for electrode connections

- Switching power supply units for the voltage supply of the individual assemblies.

The pictures shows the construction:

Left side panel: Auxiliary power supplies, 12V for the relays and 5V for the NEOPIXELs.

Upper left PCB:

- Change-over relay for separating the µTracer from the electrode test circuitry

- Switching to test magic eyes, G2 (screen) is then connected to the boost converter Vs, anode to the boost converter Va.

Anode resistors for the control triode of the magic eyes are also connected in the anode line.

- Test voltage generation for the electrode test (24V/100V switchable)

- Reading back the leakage current as well as the test voltages with a PCF8591

- The electrode test circuit and the other relays are controlled by 3 driver-PCBs, each with 1 PCF8574 and ULN2803.

The I²C bus is galvanically isolated from the control circuit.

Lower left PCB:

- One AC/DC module each 12V@0.9A and 48V@0.9A for power supply

- Linear regulated power supply 0 - 40V max, 0.2A for diode and rectifier testing

- Galvanically separated setpoint generation for the heating current and heating voltage controller.

- Change-over relay for switching between heating current and heating voltage.

- Relay matrix for diode and rectifier testing.

- An ARDUINO NANO-EVERY for controlling all functions as well as for setpoint output to the heating controllers by means of PWM, galvanically isolated via optocouplers and isolated DC/DC converters.

Middle from top to bottom:

- Laptop power supply for the µTracer

- PCB with the control electronics for the heating current and heating voltage regulator

- Transformer for the heating current regulator

Right:

- The µTracer

Right side panel: Switching power supply 24V@4.2A for the heating voltage regulator

Since I have some radios from the 1930s and also want to test tubes from the current series (e.g. U or P series), I use external power supplies.

Heating voltages: 0 - 12.6V max. 4A

Heating current: 0 - 300mA max. approx. 65V (approx. 105V at 50mA for the V-series)

The image shows a screenshot of my control software (written with LAZARUS).

Above left, the results of the electrode test with the insulation resistances determined in megohms.

The test data of the selected tube (here an EL95) are displayed in the centre of the screen.

I get the data from a CSV file, which is then read column by column.

However, manual operation is also possible for types not included in the table.

On the top of the unit I indicate the cable colour to be plugged in with a total of 11 NEOPIXEL.

The connector to the right of the patch panel accepts the socket adapters.

In a further step, I would like to integrate the Quicktest routine with the commands described on your homepage into my control software.

But now that spring is hopefully starting, the realisation will certainly take until autumn or winter.

It's still quite cool here in south-west Germany!

Best regards from Germany

Martin

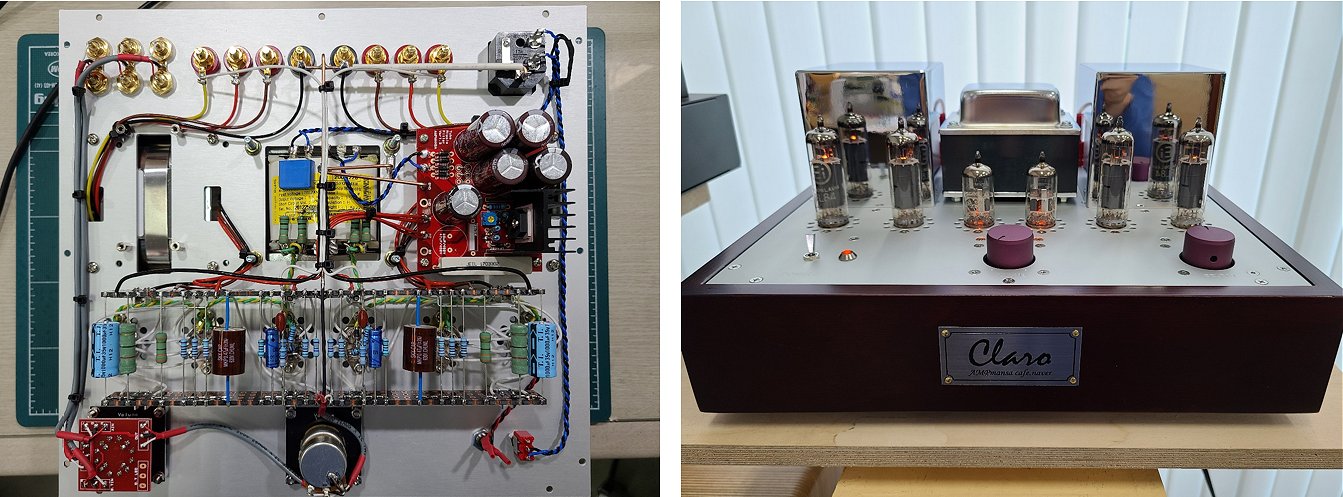

25th of April 2023 Have a look at Ray’s amazing amplifiers (and whisky collection)! In the future hopefully even better sounding thanks to his uTracer.

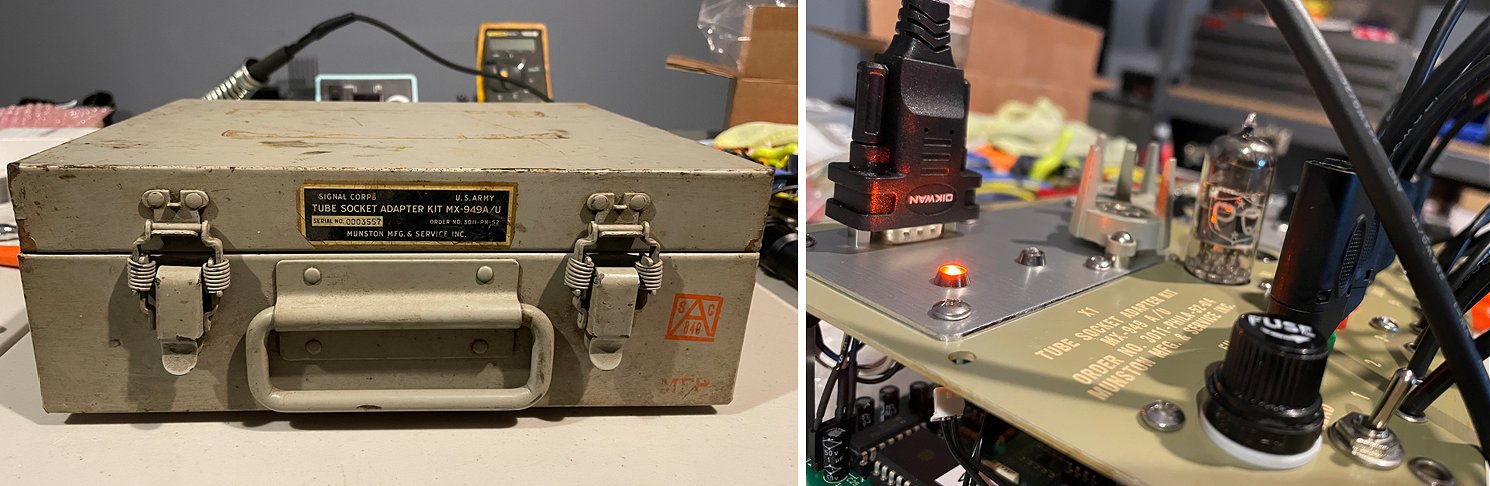

HI Ronald,

I was able to finish stuffing the board on Sunday as well as full calibration. I had no issues at all. Now onto the chassis. I attached a couple pics of an old military tube tester adapter that may be a good candidate after some socket changes and rewiring. Not sure if it's deep enough though. I like repurposing old gear like that when I can. I have a couple other military test equipment chassis that could also work, but the adapter was kind of "ready made" for this, so I hope I can make it work.

Question about PS and calibration? I calibrated with my CC,CV bench supply, but could only get 18.98 volts out of it. Will the calibration offsets track with input voltage changes, or do I need to re-calibrate if the laptop supply I have is slightly higher voltage?

I also attached a couple more pics of my latest SET amp inside and out, as well as a test amp chassis and PS that I use to test circuit ideas. It has all busbar connections for quick component changes, and removable saddles to change xfmrs.

I will update again when I have it in a chassis.

Regards,

RayL.

23rd of April 2023 Greg sent me a few pictures of his amazing uTracer (with rotary selectors)!

Hi Ronald,

Since everyone is showing off their build, I thought it’s time to share mine. Case is black walnut.

I do have a question however, how are people testing 6U5 tubes to show the function of the eye?

Cheers,

Greg Moore

14th of April 2023 Simon sent me a few pictures of his very neat uTracer!

Hallo Ronald,

Hier mal die ersten Bilder meines utracer3+

Die Änderung des neg. Power supply ist auch gemacht.

Bis jetzt läuft alles prima.

Grüsse aus der Schweiz

Simon

12th of April 2023 Way sent me a picture of his fine uTracer and an enthusiastic testimonial!

Hello Ronald,

I hope this communication finds you well. I made a couple of your suggested modifications for the grid voltage, as well as increasing the maximum current capability, and plopped it in a rather prosaic enclosure. I’ve thoroughly enjoyed using the uTracer 3+ over the last 6 weeks; it has been very entertaining being able to compare the quantitative measurements (especially with dual triodes displaying dissimilar I/V curves) and actually hearing differences in my amplifier designs (e.g. for cathode followers and cathodyne phase inverters, “rolling” different dual triodes based on the dissimilarity of their sections to “tune” them to higher gain vs. lower gain input channels, etc.). It has also been fun to match all the power tubes I have lying around. I am looking forward to using Derk’s Extract Model for all the tubes I have without existing LTSpice models.

Thank you again for creating such a wonderfully well thought out and useful instrument. Now that I have had more time to digest your lab notes blog, I especially have enjoyed seeing how you tackled all the challenges along the way. Kudos.

Sincerely,

Way

5th of April 2023 Joris sent me a few pictures and a testimonial of his magnificent uTracer!

Hi Ronald,

During the lunch breaks at work I had a nice little project for the past months. Assembly was a breeze (I must confess I did not follow the partial assembly, did it all at once) and it worked first time. After some testing and calibrating it was time for an enclosure. I wanted to make it compact and portable and at the same time make it with stuff I already had laying around. The enclosure is from an old GPS receiver development kit, the meters are from a TV pattern generator and the tube sockets from an LCR bridge. I opted for 4mm sockets to connect the tube to the tester, since I have a lot of 4mm banana plugs at hand. The 2mm version would have been nice as well, but I would have had to buy all. I included a small heater supply section based around a simple switching regulator. The potentiometers to set the voltage and current were wired to the front panel and I added the voltage and current meter. The accuracy of these is not great, but it gives an indication... I added a preset 6,3V switch as I use that most of the time. As I had a broken PCB with a USB C to serial converter on board I figured it would be a nice modern addition to include it, so I cut that piece off and added it to the rear panel. To keep the retro feel I used the Rotex to make labels. In the pictures I had not numbered the sockets for the tube sockets.

After the first assembly the uTracer broke unfortunately :) Since I made it so compact the pins protruding from the PCB punctured the insulation of the tube sockets' wiring. Ronald quickly shipped a repair kit, what a service! The second time it failed was the BD138 transistor in the negative supply. I replaced it with a BD140 and it has been fine ever since. (I had the ringing suppressor resistors installed from the beginning) When it broke I noticed that the voltage regulators got quite hot. Moving them to the enclosure eliminated any heating. So far I have tested a lot of my tubes and was able to rule out some faulty ones. It really is a nice piece of equipment to have!

I highly recommend building this. It is really nice to build something and not having to design everything yourself. You'll always arrive at a useful working product in the end!

Kind regards

Joris

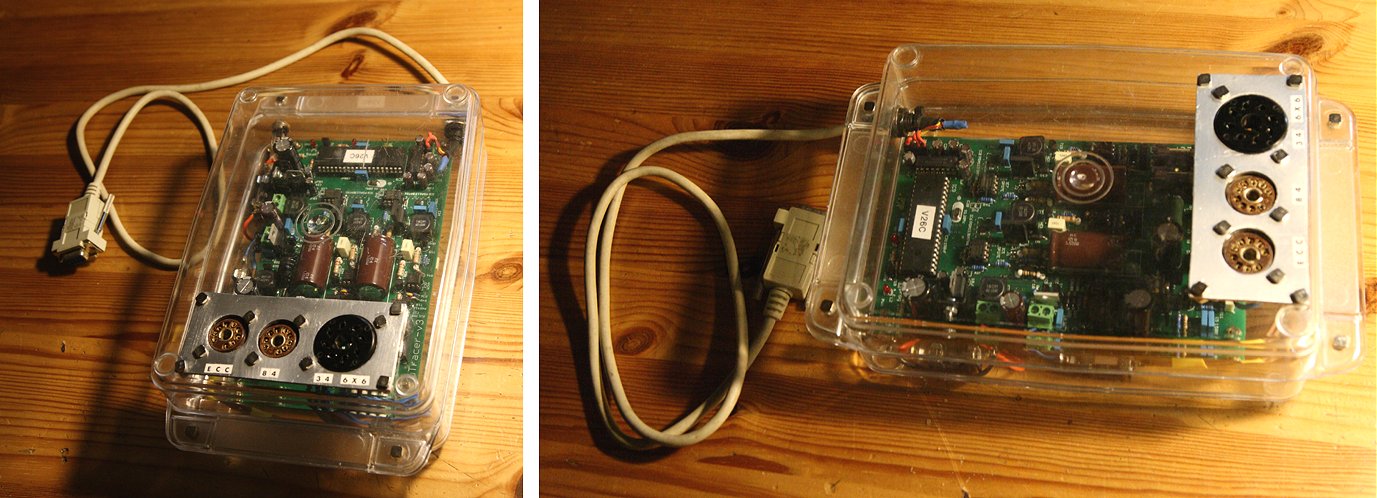

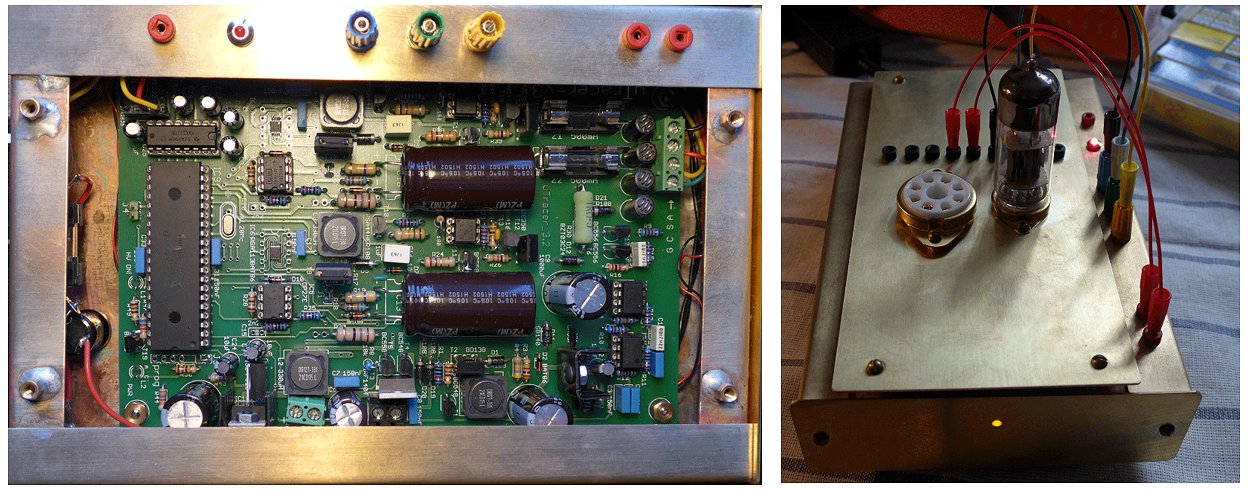

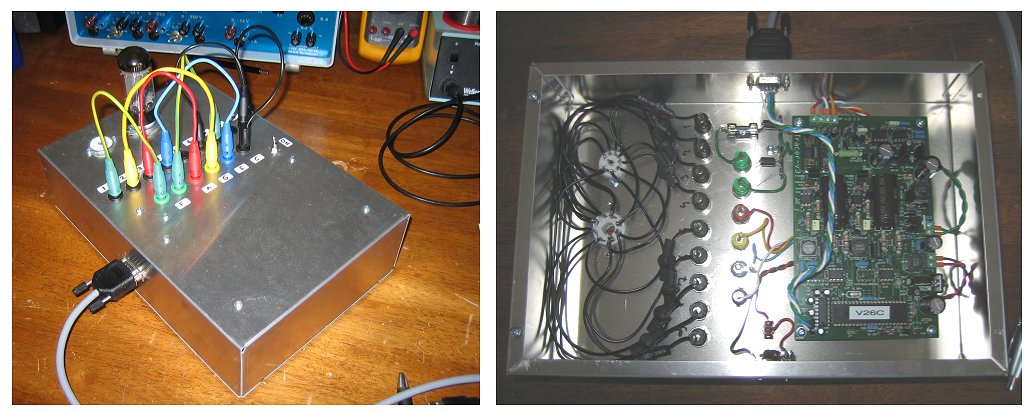

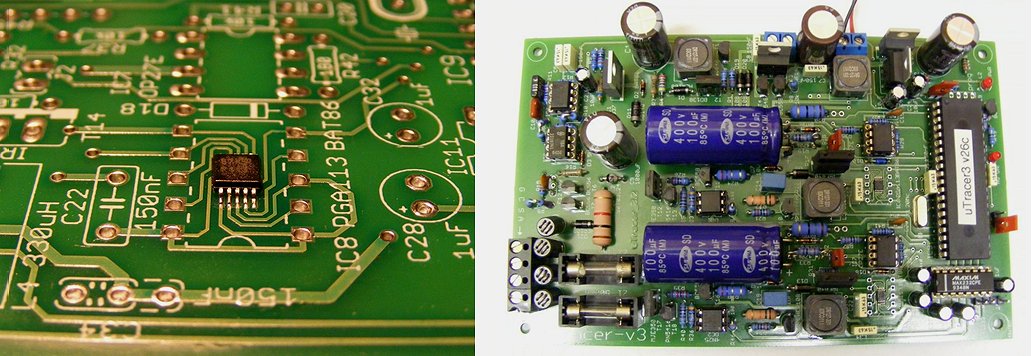

26th of March 2023 Sylvain sent me a picture of his own version of the uTracer3 PCB including some of the extensions!

Hi. I know you like to see different versions of your great project.

Here my own version 3+ PCB. I redraw all the pcb, incorporated all the revisions, mods, and added a side section with the Grid Loop and Cap forming options.

So far the main section is all working perfectly.

Thanks again for sharing such great project.

Sylvain

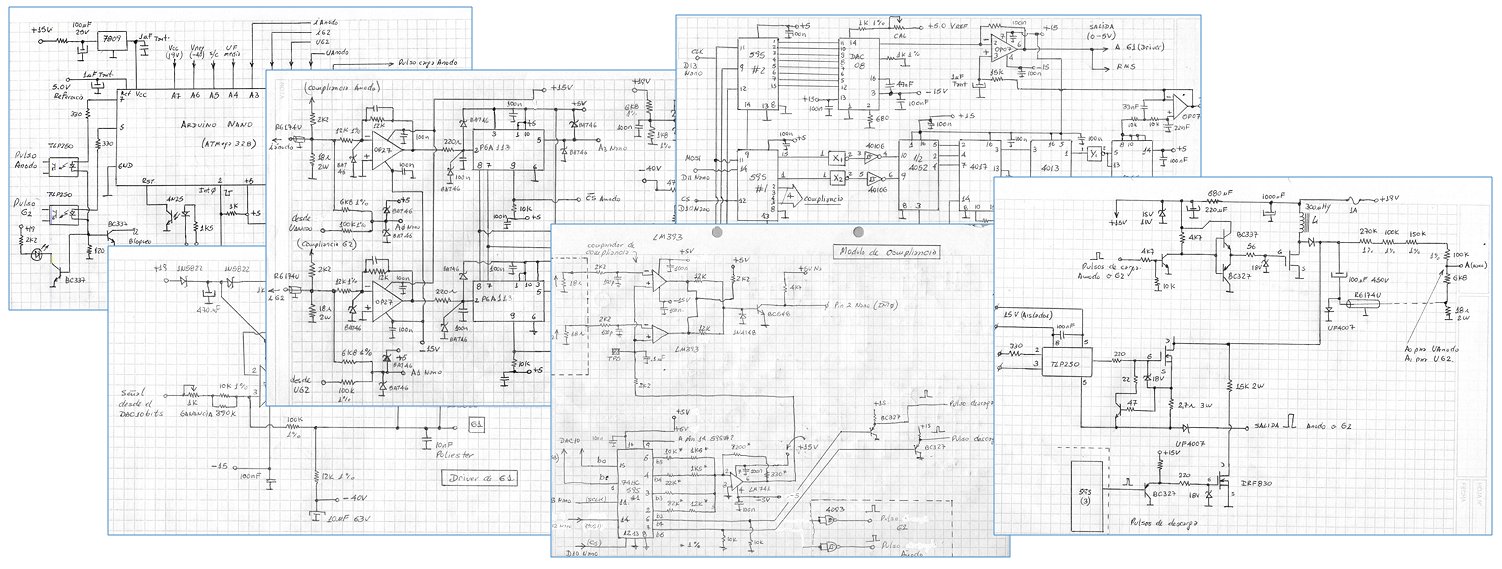

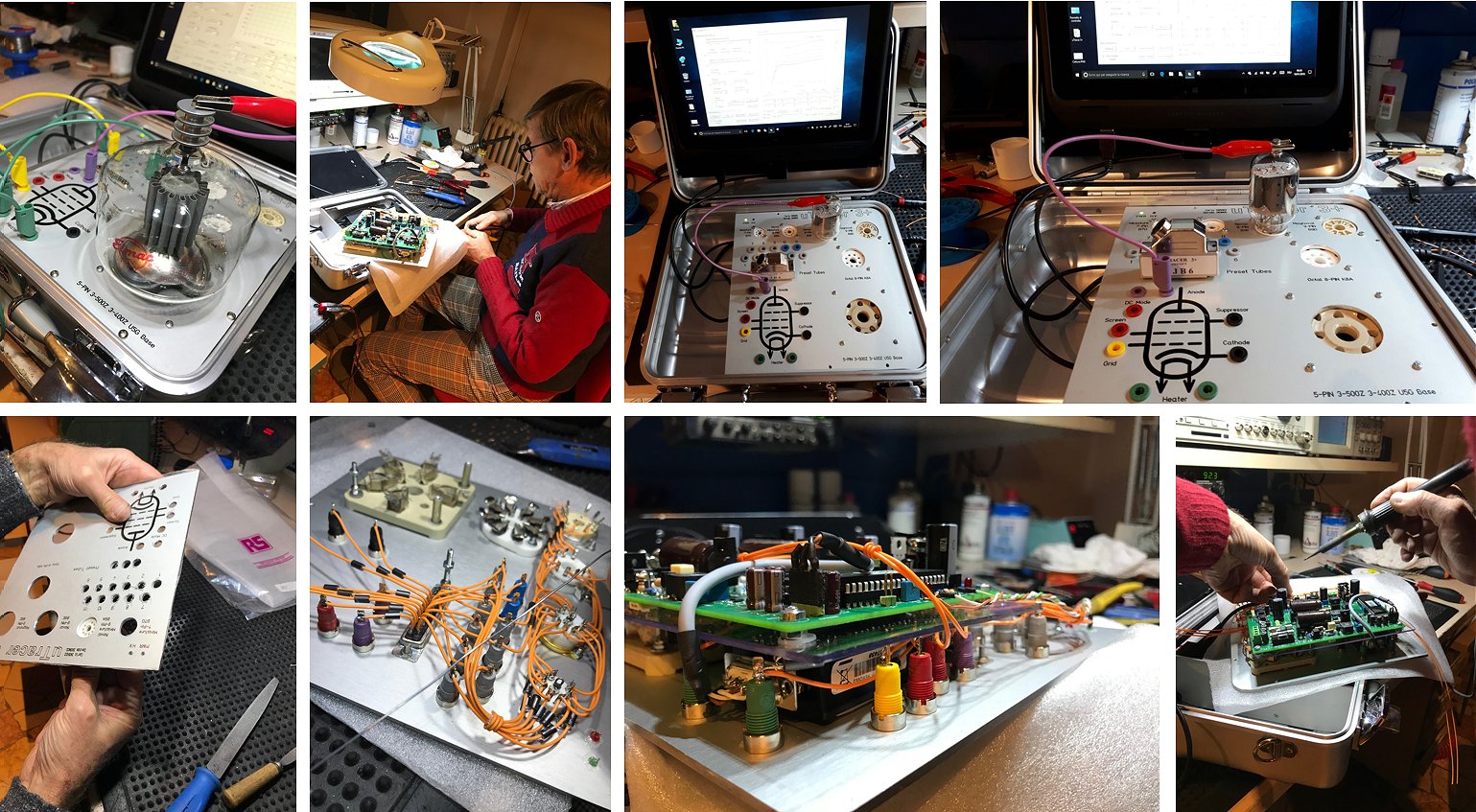

22nd of March 2023 Jose from Argentine sent me some pictures of his uTracer that he completely recreated from stuff he had available! Fantastic! I take my hat off!

Dear Ronald :

My name is Jose Luis Fernandez from Buenos Aires Argentina. I have been reading the contents of your website , Dos4ever , since around 2020. In fact , I found it by luck during the pandemy. I am an enthusiast of both DOS and old technology as vacuum tubes and the like. In my youth years ( I am 62 now) , I began experimenting in radio and electronics and at sixteen , became a licensed amateur radio operator . Tubes where common in those days, specially in amateur radio, so I think someway I developed a deep interest in tube technology ,that is alive even today. Some of my friends think I am crazy because of this, but no problem , fortunately I was able to find your website as well as another ones with people as enthusiast as myself ( or as crazy as me!....who knows) . Now , with world wide web , we have access to a huge amount of literature about tube technology, that unfortunately I did not have when I was at school.

Since 1987, I became an electronics engineer ,and until now I am working in the factory automation field. specially in power electronics ( induction heating , drives, ect) usually trying to solve the problems that no one wants to do, because is not good business, old PLC systems and industrial computers and machines based for example in DOS not to mention induction heating and soldering using high power tube oscillators I was asked to design , several years ago , a numerical controlled machine for making keys , using servomotors (Indramat) for the various operations. I implemented it with a PC running VB 1.0 that is DOS based , not very beautiful Graphics but extremely stable . In fact , this machine ( we finally made two of them) is working since 2006 without any failure related to the PC or DOS program. It has a solid state disk , but the system never hanged up since it was put in operation.

This introduction is only to try to explain who I am , and to say that , I really fit your description of one of your crazy readers! But I am proud of it!. When I found the project of the Utracer in your site , it was shocking, finally an idea of how to make an instrument to see the actual curves of the tubes that until today were only available in those old manuals. Something extremely well designed, in my opinion and very well documented. As your design progressed I became more interested in making one for my own lab.

When finally you offered it as a kit, that was the opportunity to do it, but unfortunately, some health problems and money related ones, appeared. It was not possible to afford it. So I decided to try to implement another version of the hardware, but using your nice software.It was a personal challenge. It was necessary to build it section by section, following in general your ideas, but adapting them to the parts and processor that I had available. I have used other type of switch , borrowed from the industrial power world and another type of power supply. With both, there were many problems related to noise ,difficult to solve ,but very interesting to study in detail. In the diagrams, I apologize for the poor quality, handmade, ( very in the line of Bob Pease drawings) you will see some details, for example the power for the switches is taken from an isolation transformer( with low capacity) from the power transformer to decrease the capacitive coupling to the former, without it , high frequency energy appeared just over the measurement pulse.

All the parts , except the PGA´s and some precision resistors, came from junk, old TV sets, old instruments and discarded industrial equipment. I have used extensively material from Phillips because it was and is now very popular in our country. Phillips used to have in Argentina production facilities for tubes and transistors ( with the FAPESA name) so became very popular at the time ( early 70´s) The result is very good for me, it was beautiful to see it tracing caracteristics of my old tubes , and of course , it has the Utracer name because I think that IT IS your design!. I only adapted it to a different processor. I added the name AR because it was based in an Arduino Nano ( it has 8 analog inputs available) . I used several ones for industrial projects and have one still as a spare.

It took quite a lot of time to design and build the several parts , but finally is nearly finished and ready to be used. So I decided that you have to know about it , you have one more of your Utracer´s in this part of the world. I am sending you several pictures about the appearance , the schematics of the main sections and specially the result of the measurement of an ECL80 , in order that you can tell me your opinion about how it is working ( If you agree and have the time, of course). I would appreciate it a lot.

I have a profound debt of gratitude with you , and have to say that it was a pleasure ( as is still now) reading about your projects , histories about Phillips Research , and to see some pictures of your daily life and beautiful family. Working on this project have been a healing process, for myself. I hope , in the future ,I could became one of your customers Ronald.( Maybe with the BIG utracer) In the meanwhile , I will continue reading your web pages , and enjoying your ideas and comments. The orange colour in the interconnection cables for the elctrodes are , of course in your honour.

Finally an apology , for my English, it is not my native language so , is not easy for me to write these words . Thank you very much Ronald !!, and if any time, you need something , from this remote part of the world, please do not hesitate to ask me.

Sincerely : Jose

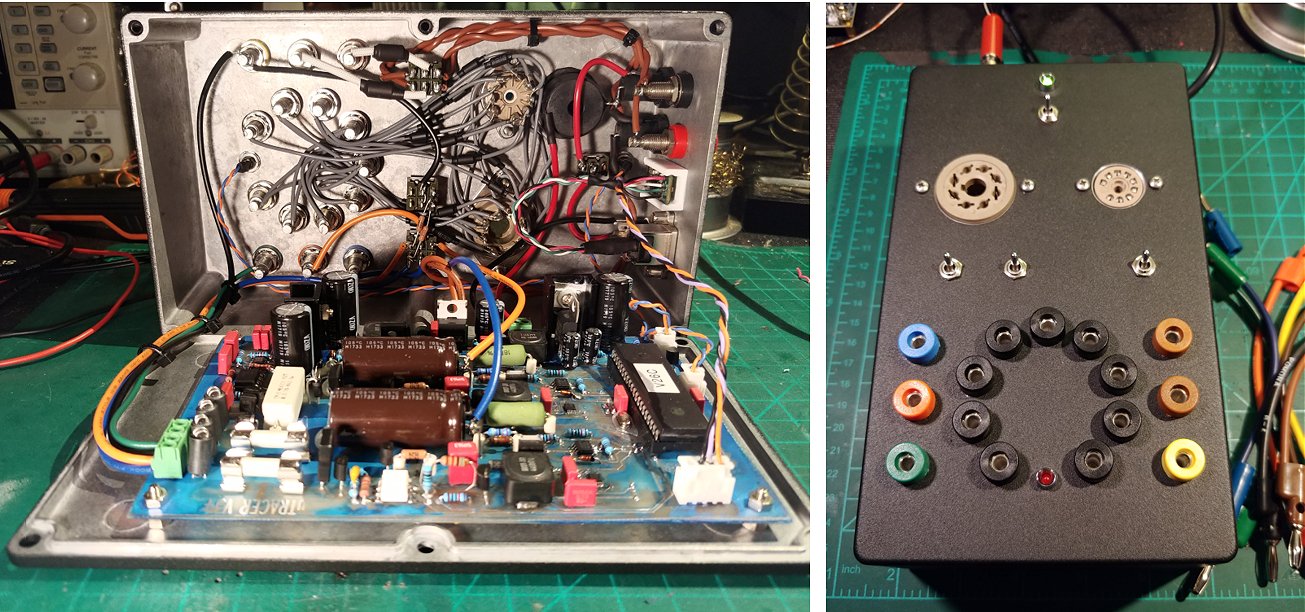

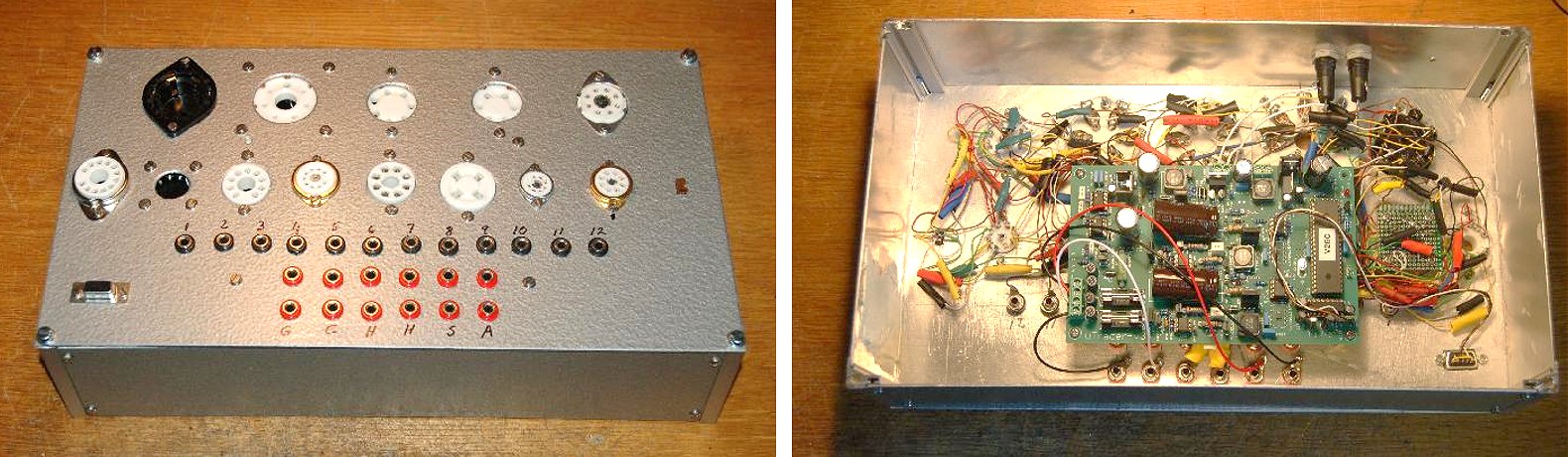

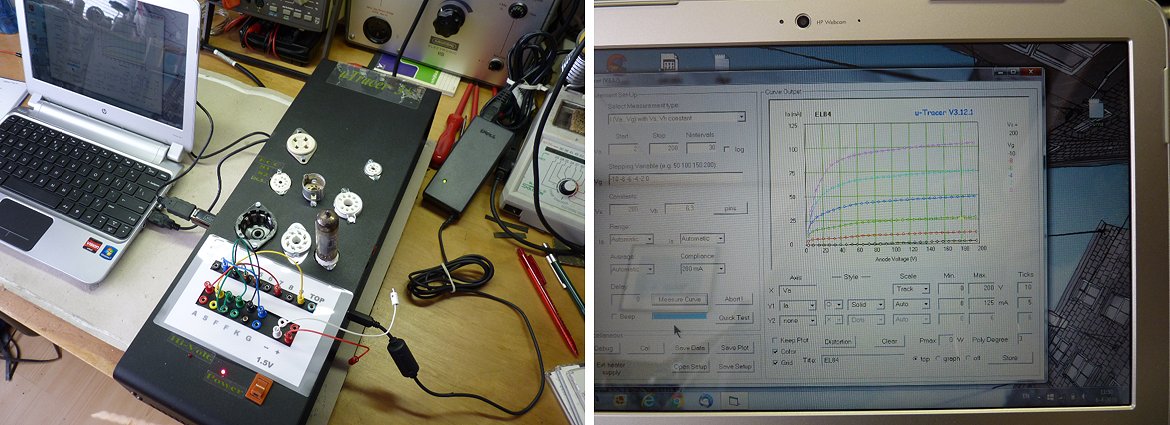

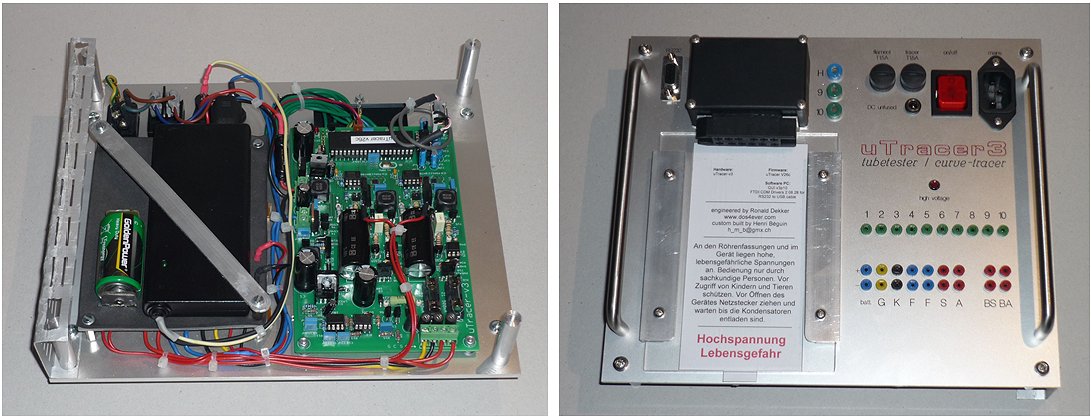

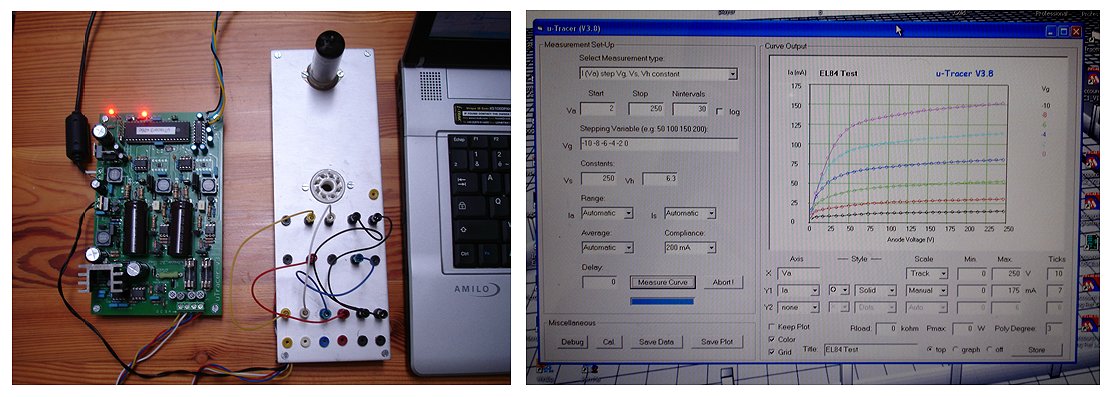

16th of March 2023 Mike finished his very nice uTracer!

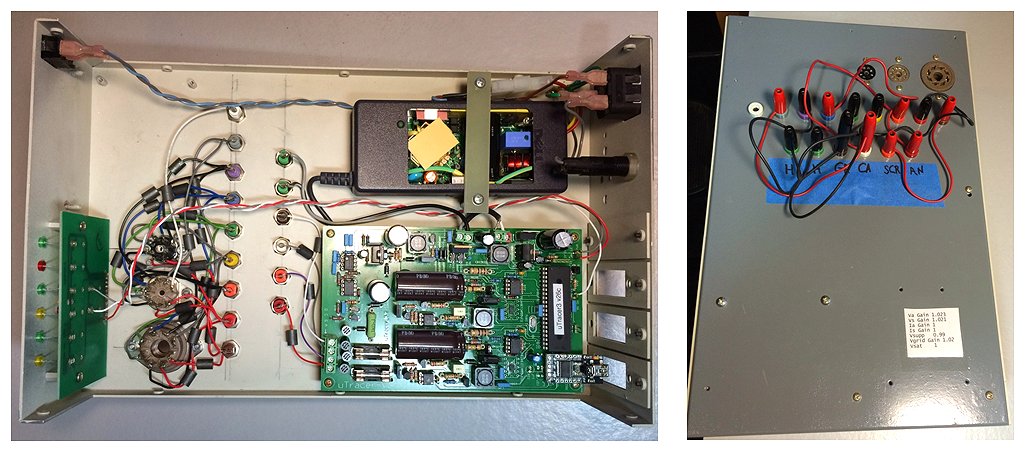

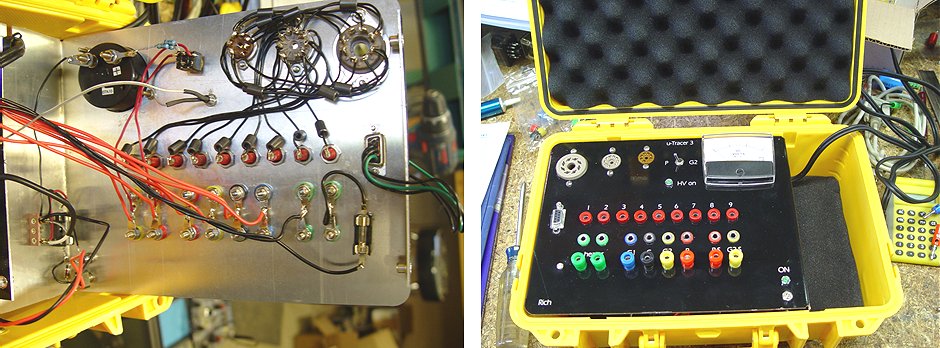

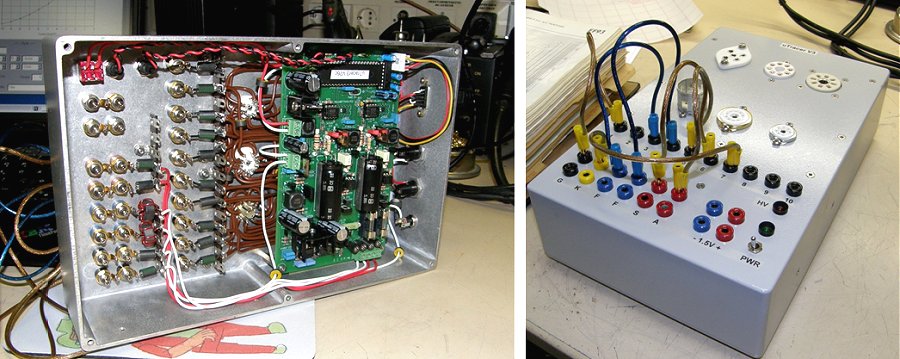

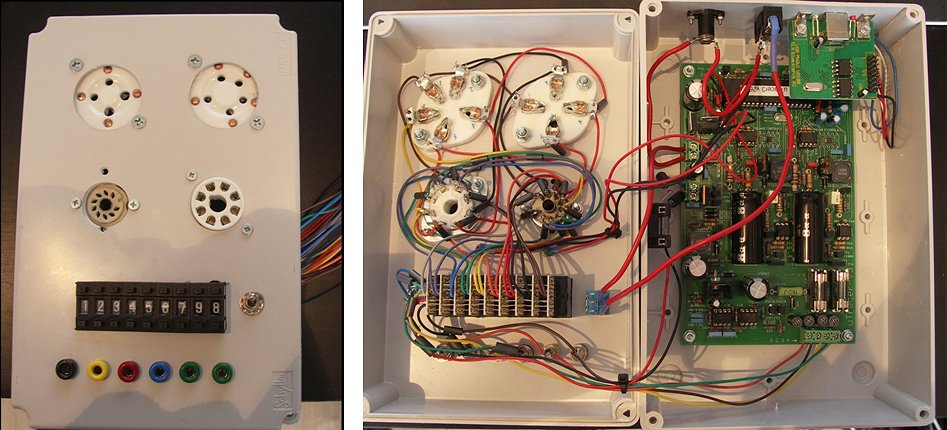

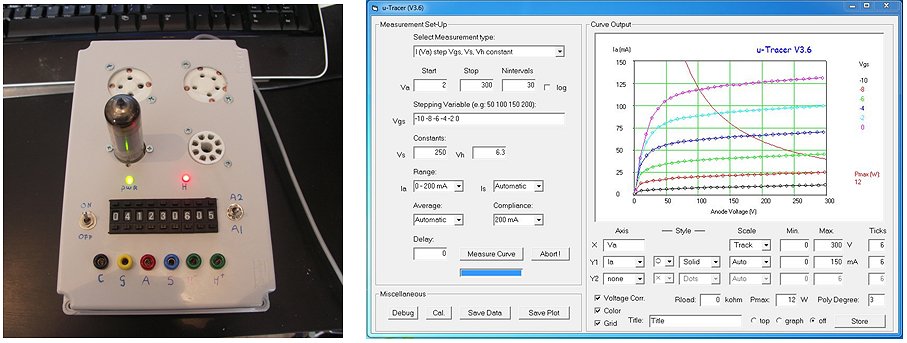

I have now finished building my uTracer 3. I am attaching a couple of photos showing its internal construction and the end result. You will notice that I have opted to layout the 9 pin sockets for the patch panel in a circle. These are numbered 1 - 9 clockwise so that they are how I see a valve base from inside a chassis - and the same as many data sheets which show the pin connections from the underside of the valve. In the second photo you see one of my first tests - an EL84. I only have the octal and noval bases for now as these are pretty much the only types of valve base used in guitar amplifiers. If I ever want more, I could build an extension box just containing valve sockets and patch across to it. I have yet to add labels to the box, but will get around to that soon.

I am beginning to see the enormous potential of this valve tester, so my next task is to understand the full range of it's capabilities! Thanks for bringing this kit to us, and for your very clear instructions.

Mike

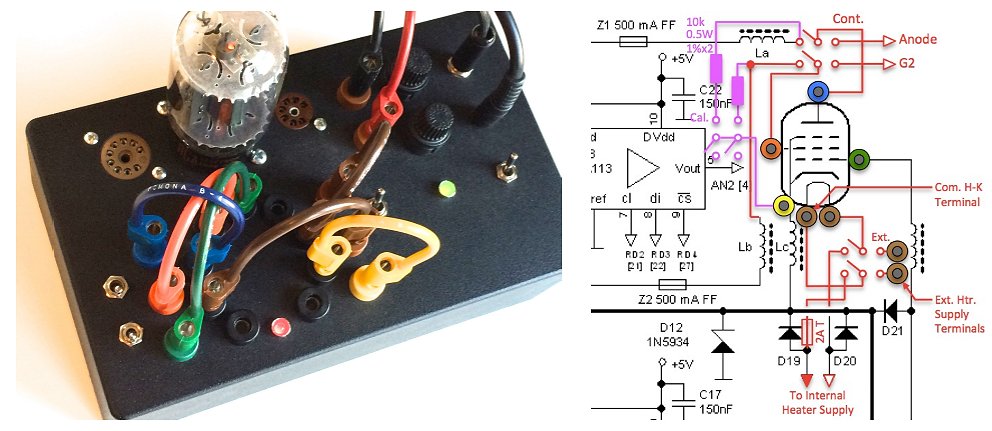

8th of March 2023 Bjørner from Norway sent me a few pictures and a report of his fantastic uTracer and the amazing additions that he made to it!

Hi,

Thought I’d share a few pictures and description of my µTracer3+ implementation, for the testimonials page. It took me a while to build this thing, since I decided to make some addons/modifications, but now it’s up and running, and it works really well. One addon is a USB adapter board that can be installed between the PIC and its DIP40 socket, to eliminate the need for an adapter cable. I also made a custom switched regulator and measurement module for heater voltage/current, with selectable voltages of 1.5, 5, 6.3 and 12V, plus continuously variable voltage between 1.4 and 16V. This module also has an adjustable current limit up to 2.5A, which gives the filaments a soft start. Though being a separate module, the heater PSU output can be turned on and off from the µTracer software. The project is built in a reused enclosure from a scrapped TV-decoder. A short YouTube video shows the unit being used in practice: https://www.youtube.com/watch?v=7Mg959vXJqE. I also recently started a blog https://retronics.no, and detailed description about construction, addons, and schematics, plus a review of the µTracer can be found there. All the related blog posts are linked from the YouTube video. If someone wants to build the USB adapter or the heater PSU module themselves, I will gladly share Gerber files for PCB manufacturing.

Best regards,

Bjørner

Norway

5th of March 2023 Scott reported his uTracer finished!

Hello Ronald and Marie-José,

I ordered my uTracer 3+ kit back in 2016 as you can probably see by the previous email. Wow, time is a fickle friend. Life kind of got in the way, and since then I've retired and moved back to my home state of Florida.

Finally built the tester, works great! The build manual is fantastic, all of my tests results along the way just as described. Thank you very much for a great device.

All the best,

Scott

www.naturecoastelectronics.com

23rd of February 2023 Way Yin finished his uTracer and he wrote me a very enthusiastic review!

Dear Ronald and Marie-José,

I just completed building, testing and calibration of your wonderful uTracer3+ kit.

After a slow start on my part (not being a Windows user, not being really familiar with some of the cool components on a PCB, and generally being an idiot) I've completed buildout, testing and calibration of the board.

I wanted to convey how much I truly appreciate the extensive work and great care you have devoted to creating such an incredible package that a hobbyist like myself can enjoy. Everything, from the meticulous and well segregated design of the PCB, the logical layout and construction with testing of each section, the excellent manual, the clever GUI, the thoughtful pre-population of the board with hard-to-mount components, and the precise and logical selection and packaging of all components, made this one of the most enjoyable projects in recent memory - and reminds me of the joy I had as a child building and flying model airplanes and rockets. The attention to detail on your part made for a flawless and uneventful buildout without a single hitch or moment of frustration.

I look forward to wiring my enclosure and enjoying your uTracer3+. The examples you have posted of other builds has been a great idea generator. Thank you again.

Wishing you the best,

Way Yin

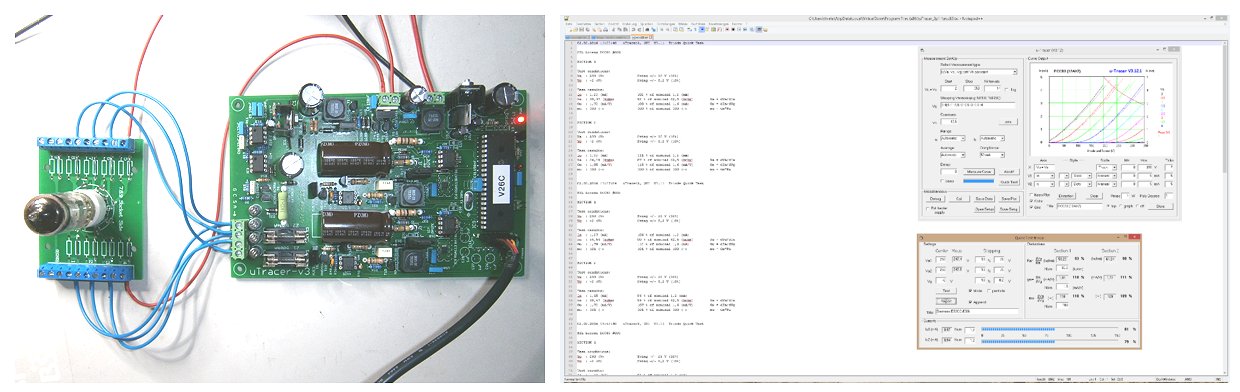

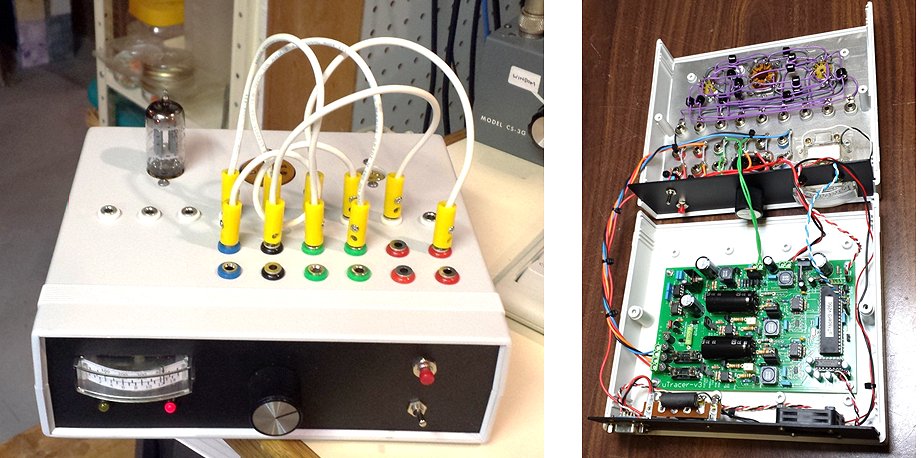

8th of February 2023 Kari from Finland finished his simple but effective uTracer

I'm glad to report that I have now (finally) built my uTracer3+

With your excellent and detailed instructions the build process was very easy and enjoyable. Everything worked first time. ( Except for a stupid mistake I made all by myself )

Here is a picture of the tester before buttoning up the case.

For the first test subject I grabbed a dusty old EL84 pentode that once served as an audio amplifier for a radio from the 50's. No big loss if it blows up..

Not only did the tube not blow up but Quick Test revealed that it is in fact in good condition!

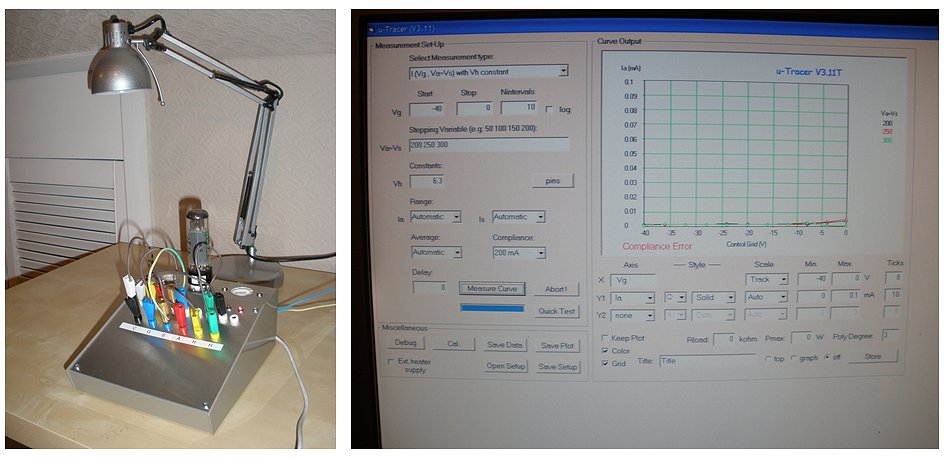

This picture shows measuring the curves from the same tube. I'm running the gui under Wine emulation on my Ubuntu 18.04 Linux computer.

Thank you very much for providing this great kit for us tube-lovers!

Wishing you all the best in the future.

Kari

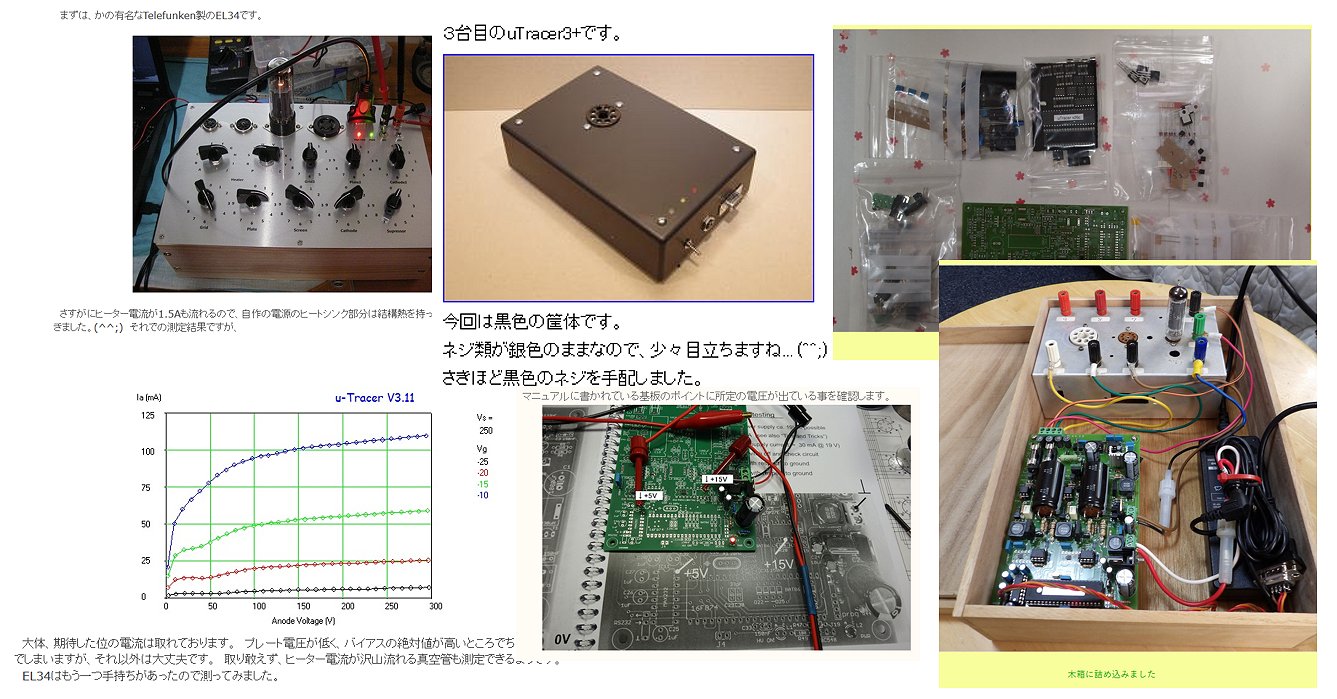

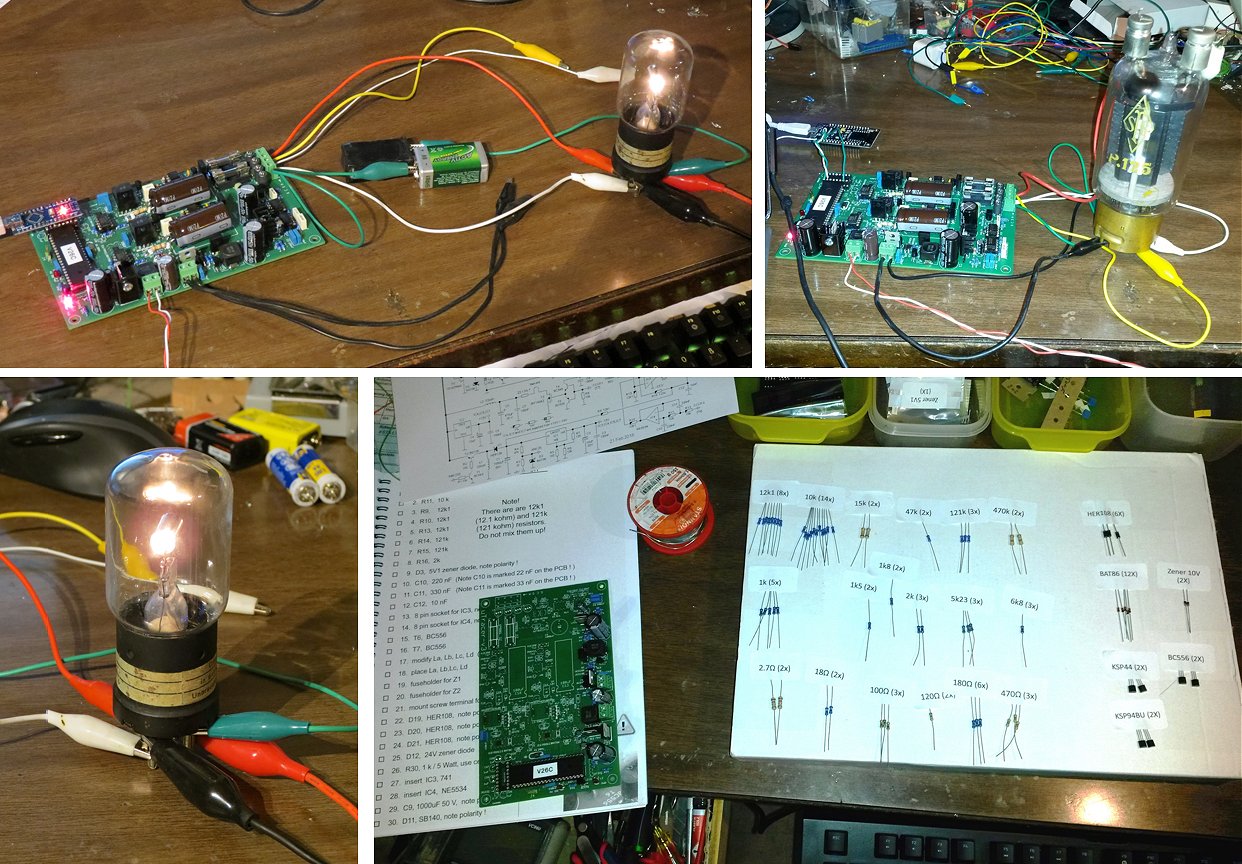

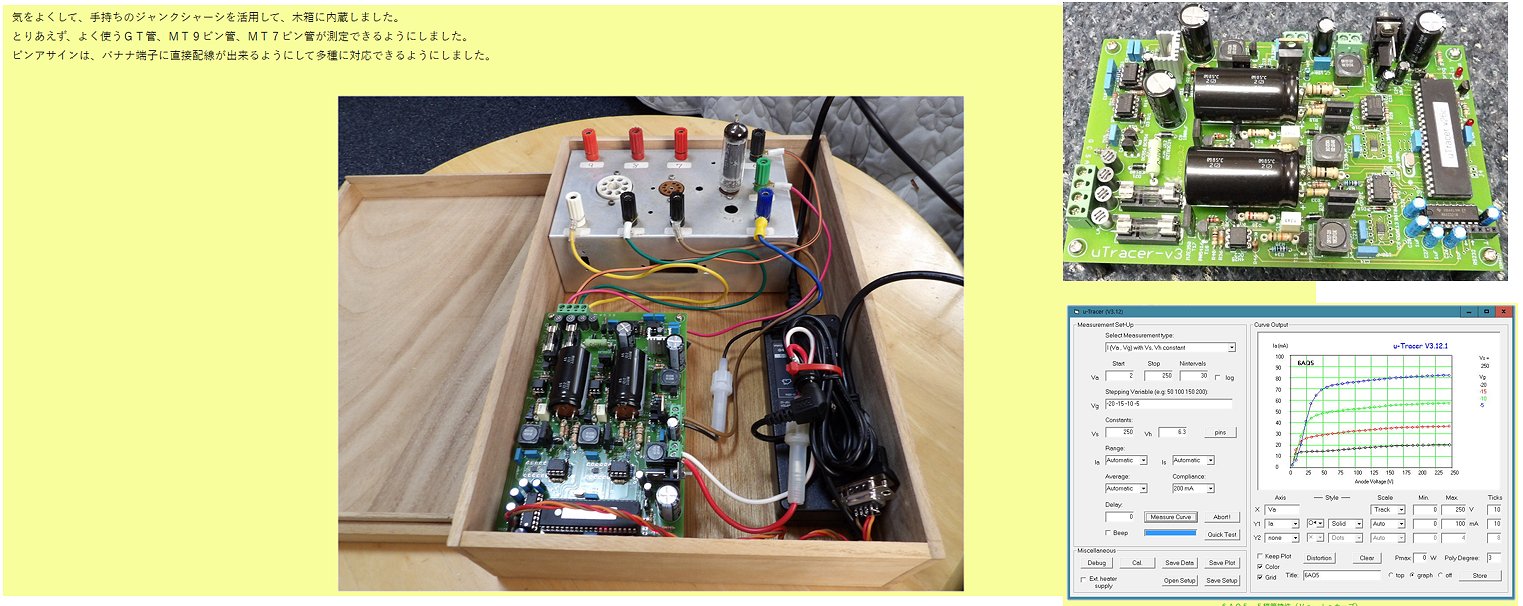

4th of February 2023 Ryuji from Japan Finished his very fine uTracer !

2nd of February 2023 Hans from Holland sent me a few pictures of his beautiful uTracer!

Dag Marie-José en Ronald,

Hierbij twee foto’s van de uTrace3. Bij de bouw vond ik het telkens toch spannend of de tussentijdse testen volgens de uitstekende handleiding klopten. Alles ging naar verwachting. Van een oude plank en een aluminiumplaat die ik nog had liggen heb ik de ombouw gemaakt. Inmiddels heb ik diverse buizen doorgemeten waaronder 300B’s en KT88’s. Mooi om te zien dat 1 van die laatste buizen beduidend slechtere resultaten gaf dan de rest. Een verklaring voor het probleem bij de bias-instelling. Ik gebruik overigens een externe voeding voor de gloeispanning, dat geeft ook bij de wat minder dorstige buizen de beste resultaten. Ik heb de uTracer aangesloten op een laptop die ik eigenlijk al had afgeschreven en ook op een nieuwere computer via een usb aansluiting. Beide systemen werken perfect. Bedankt voor de mooie bouwset, de uitgebreide handleiding en de verzorgde site waarvan ik veel geleerd heb.

Met vriendelijke groeten,

Hans

14th of January 2023 Mario sent me a picture of his finished uTracer !

Hi Marie-José & Roland.

Thank you for your best new year wishes. First of all i'd like to wish you a very good year 2023 as well. Hope you had a good, loud transition with your family and friends.

A long time ago I ordered one uTracer3. The final assembly was pretty easy due to your fantastic guideline. Even the usage of the uTracer3 is pretty easy.

Thanks again.

As of now the uTracer3 helps my to check all the tubes from my tubes seller's all over the word before using the tubes in my devices. Of cause all of the tube seller's promising a perfect quality and a tight matching. The reality differs extremely. However. Your uTracer3 is a good value for money tool to separate the tubes as well as the tube seller's. Nowadays tubes are extremely expensive. So the uTracer3 helps me to save the electric devices and finally uTracer3 saves my money. Too ugly tubes are not used and will returned to the tube seller's.

I am happy, thank you and go on with your activities.

Greetings from Germany

Mario

3rd of January 2023 Paul sent me a few pictures of his very nice uTracer!

Hi Ronald,

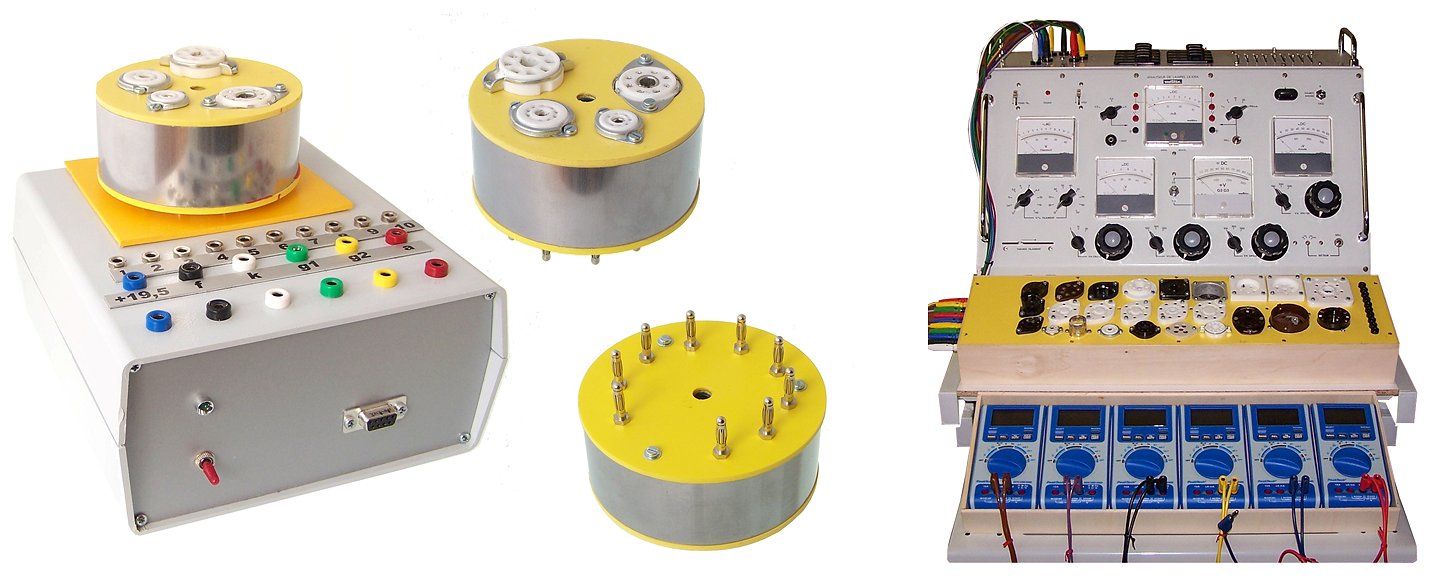

Per your request, I'm attaching a couple of pictures of my version of the uTracer3+. This version uses 3d printed "personality modules" that plug into the unit--each one for a different tube. Since my primary use is for testing and sorting specific tubes, it seemed more robust to use these modules rather than patch cords or switches for connecting the tester to the tube elements. Any time I need a new module I simply 3d print a new box, and make the necessary connections on a small PCB that goes inside.

Best regards,

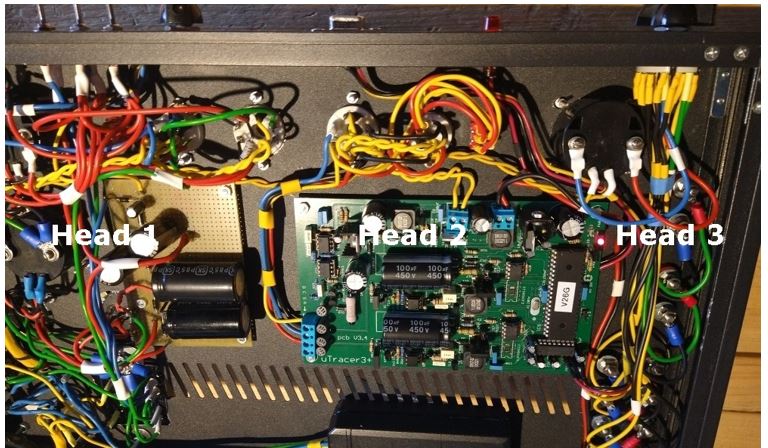

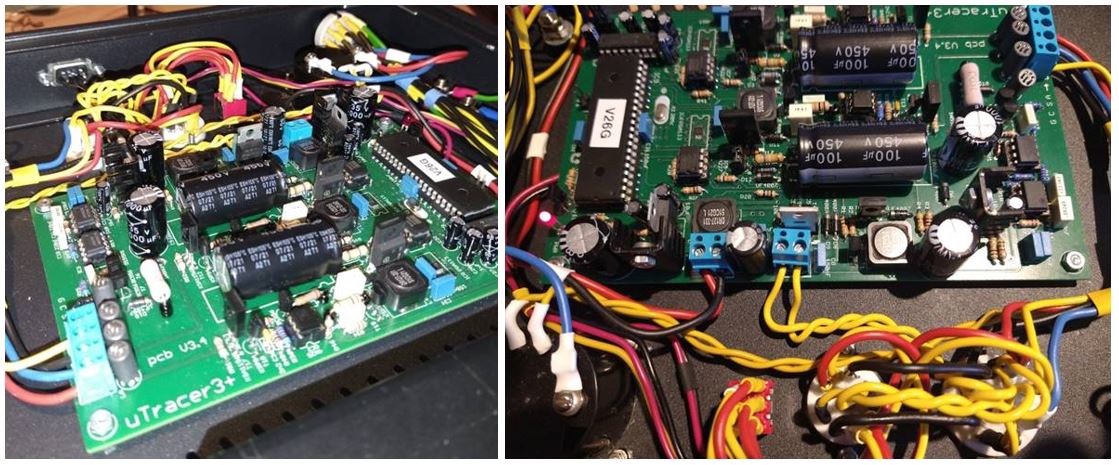

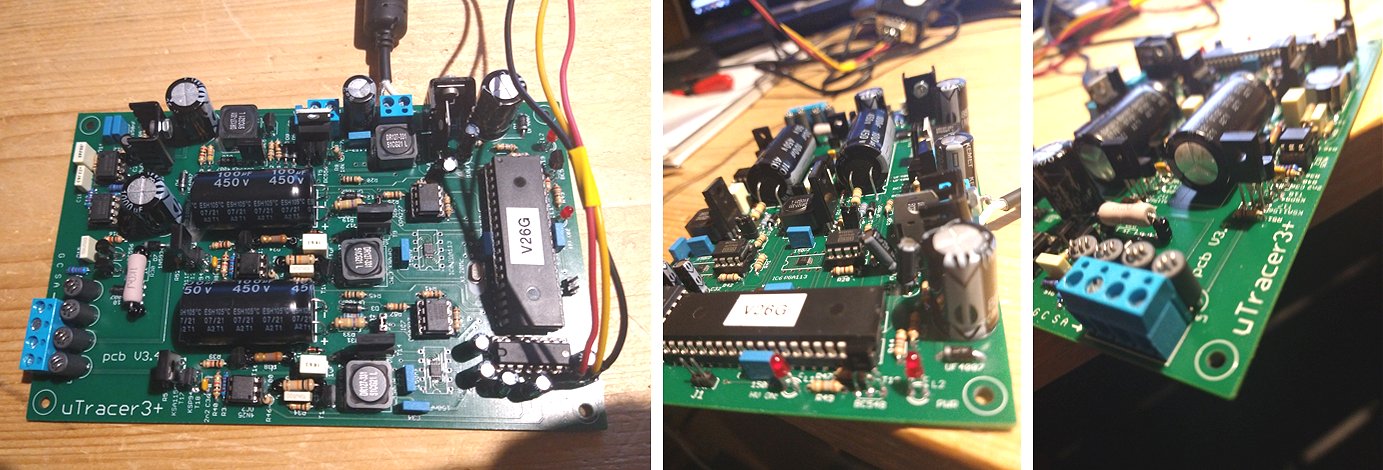

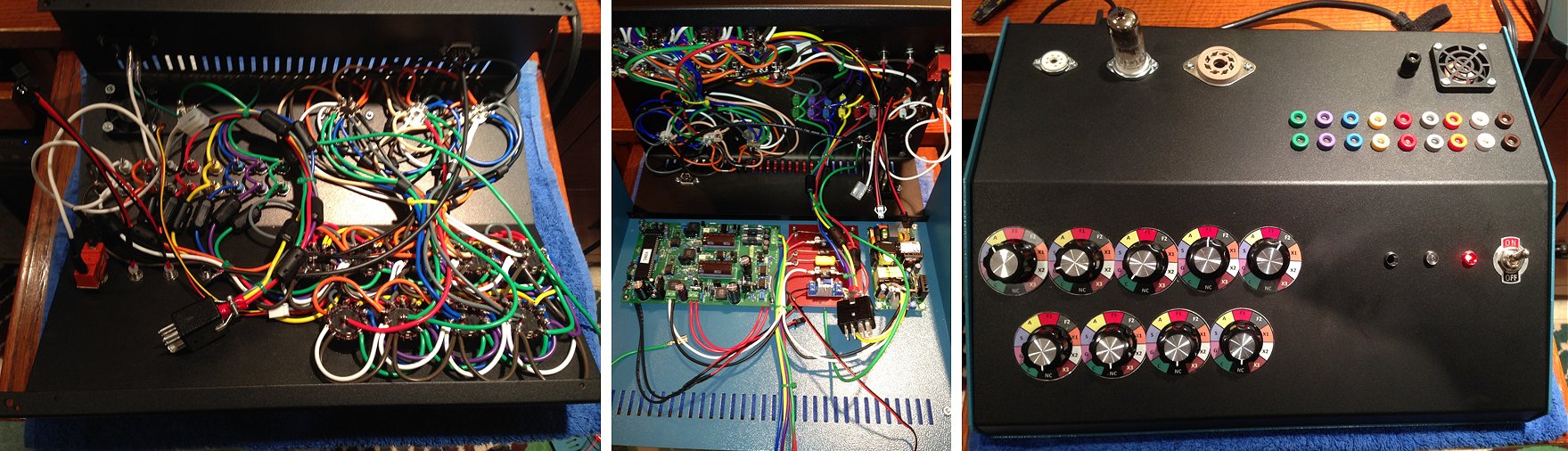

26th of December 2022 Auke sent me some pictures and an extensive account of his “three headed beast”!

Hi Ronald,

Hereby my version of the uTracer3+.

I think you might call it the uTracert3+ plus2

Now please keep in mind that my “three headed monster” is still “under construction”, work in rogress, It will change a lot… and is far from done…

First of my compliments to you.

The uTracer3+ is very easy to build, with a good step by step build and testing manual.

The KIT has all components, very well labeled and packed.

Although It took me a few months to build (due to the lack of time I could spend) the actual building time was less than 24 hours including calibration.

My needs from day to day repairing amps.

What I have done in my build is somewhat different than usual. In fact, it became a small 19 inch three headed beast! Tailored to my insights and needs.

My needs are just the most common tubes like the EL34, 6L6, ECC XX and sorts…

My main field of use is Guitar Amplification tubes. So, I set up with a fully wired 8 pins socket and a parallel wired 9 pin socket.

This left me with a problem being EL84 tubes… Luckily there are adapters that fit the 8 pin socket… Problem solved.

As time passes, I might feel the need to create some other adapters.

To my three head beast build, from left to right..

The 1st “head” is a simple DIY Emission tester, complete with Gas/Gasless test and tube short indicator and a measuring range from 90 volt up to 275 volts Very handy for quick testing of tubes of any age. This tester has no connection with the uTracer3+. It is fully analog, and results vary a bit with source feed wall outlet varying. It uses two supply transformers. One transformer 2x 6,3 volt for heating and illumination, and a 2 x 15 volts in series to create switchable 90 up to 275 volts using voltage pumps and minus 30 volt for bias. I’m planning for a digital voltmeter connection to be added to make it a bit more accurate.

The 2de “head” of the Beast is the uTracer3+. All hard wired, nothing special there. The only thing I changed was the High Voltage “on” Led placement. I mounted the LED in a small Neon Indicator fitting and mounted it on the front panel.

During mounting of the PCB, I probably bended the PCB a bit. One of the HSP Coils become loose and caused the Software to Hang during testing and getting no results. I broke my head around that problem and in the end, I contacted Ronald and he very quickly diagnosed the problem. Many thanks for that. I just did not see what was going on…and you did with all the knowledge you have on your brainchild.

As one can make up from the pictures, I used the “old school” heating wire twist mounting. Not only for the tubes but also for the useless Analog panel meter illumination. I know for the uTracer heating it has no extra value, but I might go for the external heating option. Then it will be a good idea to have the twist heating wires (and ground balance them) to eliminate hum and magnetic field dispersion. Since this 3 headed beast does not uses high gain amplification it is of no further use than easy recognizing heater wires. I used a slightly modified LENOVO 65 Watt laptop supply. It stripped it from its mains connector and wired the mains straight in. And I replaced the low voltage output lead for regular wires used throughout this build. This saved me lots of space inside my 19 inch housing. It is mounted using NANO tape on two sides.. Great stuff.

The 3th “head” is a fully passive “final” testing option. When an amp receives a new set off well matched tubes, I made it an issue to check if “surrounding components” don’t throw the set out of balance.. This is usually done by scoop and sinewave measurements at fairly high power, but I found that this not always tells the whole story. The 3rd head is capable of measuring mA per tube in the amp itself using extension adapters. A well matched set should deliver exact equal measurements per tube just running idle… If not… there is more work to do! It uses a 50 mA analog panel meter and it will get DVM connections options. It also can measure the idle ma balance of the phase shifter tube or any other double triode.

This concludes my uTracer3+ plus 2 build.

All what is left to do is getting the user manual printed and getting the hang of all measurements possible with the uTracer 3+

Thank you Ronald for providing such a great KIT.

Kind regards to you and your family

Auke Dost

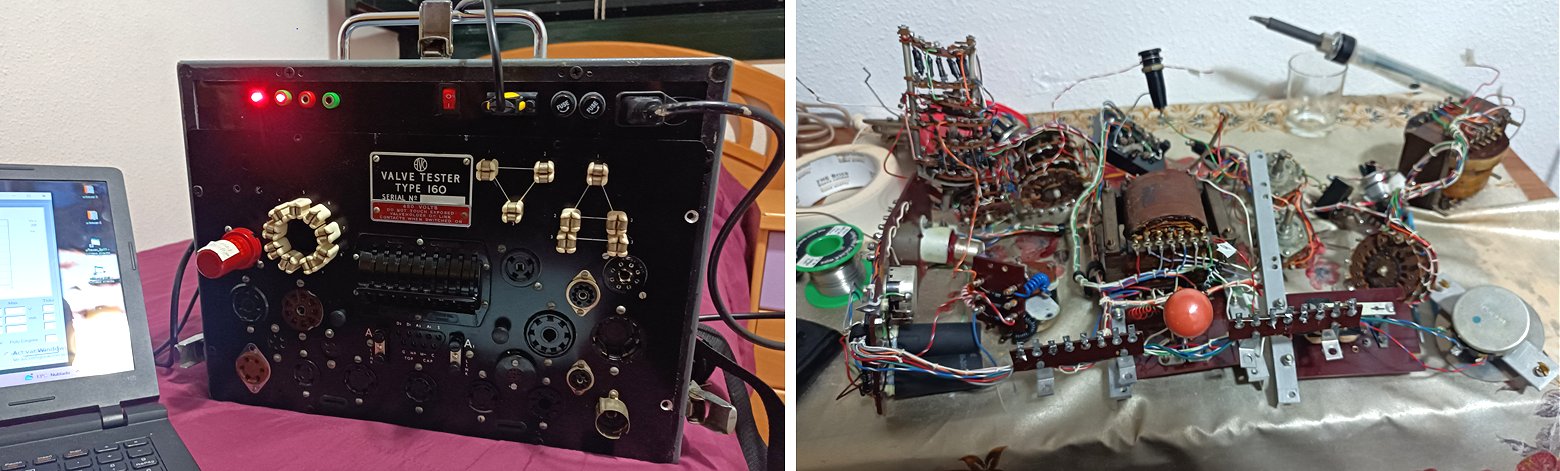

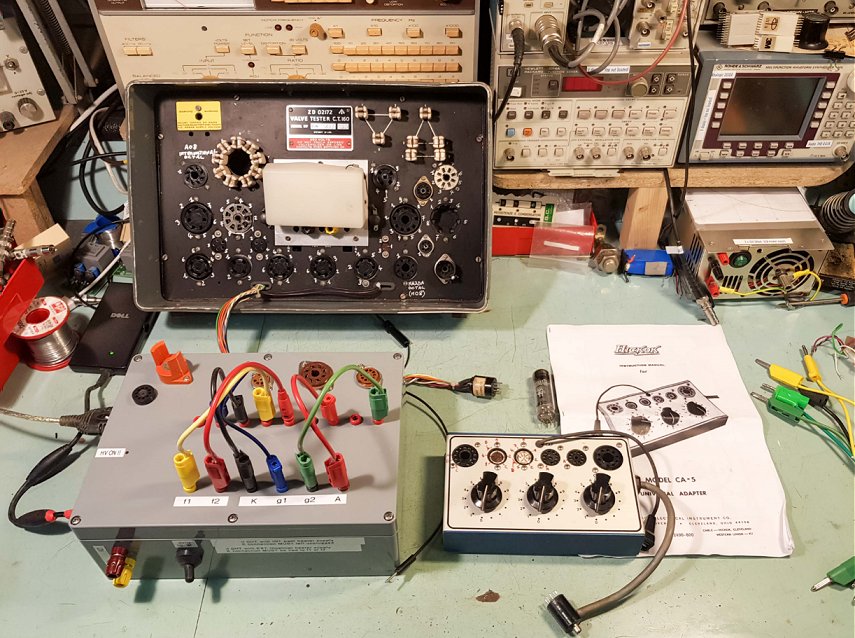

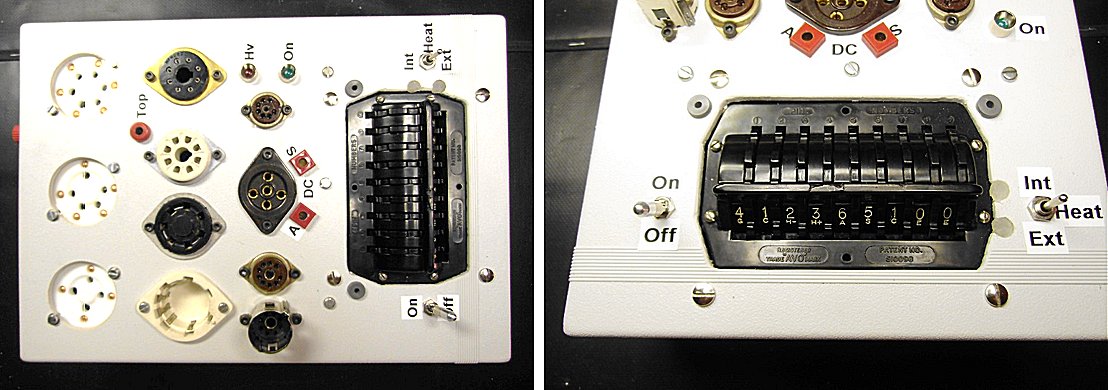

18th of December 2022 Francisco used the casing of an old AVO CT160 to make a fantastic uTracer!

Greetings from Spain,

With almost 3 years of delay I present my U-tracer 3, it is working perfectly since its assembly in 2020, (I think I bought it in 2019), but I took its construction slowly, now I am going to start the assembly of the U-tracer 6 version which I purchased from you a few months ago. I have used the remains of a magnificent Avo ct160 for the connection board (the Avo was rescued from a metal crusher about to be totally swallowed) fortunately I was able to recover many parts, although it was impossible to fully recover it, Avo ct160 and U -tracer are made for each other, in fact I am using Avo's configuration data for U-tracer. U-tracer 6 will surely be assembled using the board and cards from a Funke W19.

Greetings again and thanks for your great work at U-tracer.

Paco Perez.

Saludos desde España,

Con casi 3 años de demora presento mi U-tracer 3, está funcionando perfectamente desde su montaje en 2020, ( creo que lo compré en 2019), pero tomé su construcción lentamente, ahora voy a empezar el montaje de la versión U-tracer 6 que adquirí a ustedes hace unos meses. He aprovechado los restos de un magnífico Avo ct160 para el tablero de conexiones ( el Avo fue rescatado de una trituradora de metales a punto de ser engullido totalmente) afortunadamente me fue posible recuperar bastantes partes, aunque fue imposible su recuperación total, Avo ct160 y U-tracer están hechos uno para el otro, de hecho estoy usando los datos de configuración de Avo para U-tracer. U-tracer 6 será montado seguramente usando el tablero y las tarjetas de un Funke W19.

Saludos de nuevo y gracias por vuestro gran trabajo en U-tracer,

Paco Pérez.

13th of November 2022 Alan reported his fine uTracer3+ up and running!

Hi Marie-José,

Received the utracer3+, assembled it, and all is working great! Thank you and Ronald for this wonderful project.

Alan

30th of October 2022 Have a look at Wouter’s amazing uTracer3+!

Goedemiddag Ronald en Marie-José,

I promised to share the final result of my uTracer3+, which i have been using for over a year now.

The build went without trouble, thanks to the great manual.

I mainly use ecc82 and 83’s, so i made a dedicated section.

For housing i chose a petanque-case with active cooling.

My girlfriend has a cutting-plotter, so designing the front panel decals was fun, cheap and easy.

Ronald, i still don’t get how you came up with this fantastic device, but i’m glad you did! Thanks!

Kind Regards,

Wouter Freeman

9th of October 2022 Auke from Holland reports his uTracer3+ working!

Dag Ronald en Marie-José,

Ik wil jullie even laten weten dat er een nieuwe uTracer 3+ het gloeiende levenslicht heeft gezien! Compliment voor de super bouw beschrijving. Klopt van A tot Z.

De test en calibratie moet je even inkomen .. soms miste ik even de haak en lijn waar ik moest kijken voor de juiste waardes maar het is goed gekomen.

Binnenkort stuur ik jullie wat foto's van de voortgang en het uiteindelijke resultaat.

Groet en dank voor dit mooie product.

Groet,

Auke

10th of september 2022 Norbert from Austria realized a beautiful uTracer3+!

Dear Ronald,

I hope this email finds you and your family well.

I finally and happily can report that I finished my uTracer 3+ build a week ago. :-)

Thank you for all your time, expertise and efforts to develop such a cool tube curve tracer & tester and offer it as kit version to the interested DIY community.

After I ordered and built a uTracer 3+ kit end 2015 / early 2016 - the finished board has worked fine from spring 2016 as your construction manual is excellent - it took me until end Aug. 2022 (including a long break due to my work load in my job for some of these years) to complete my uTracer build. To explain this, to select and build a proper case and finish the mechanical work is always the most time consuming and hardest part for me, especially when the job is demanding. So, finally after my retirement on June 1, 2022, there was the time to finish my build. And it worked out :-)

Enclosed please find some photos of my completed uTracer 3+. A nice badge stating something like "uTracer 3+ by Ronald Dekker (400V version)" has still to be made and will be put on the uTracer top plate in the right upper corner. :-)

For DHT triode power tubes (45 and 2A3 in my case) I use an external heater (ie a laboratory DC power supply, I bought some years ago).

Thank you once again for bringing the uTracer project to the DIY community! :-)

Best wishes,

Norbert

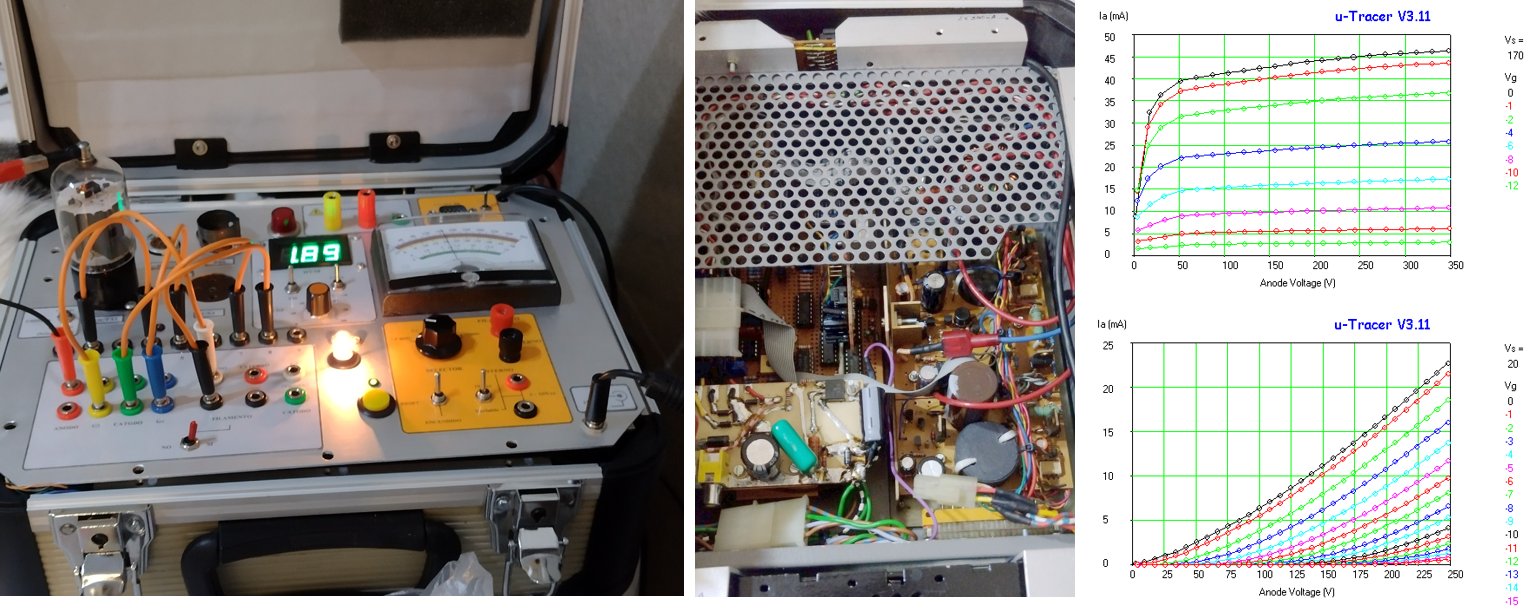

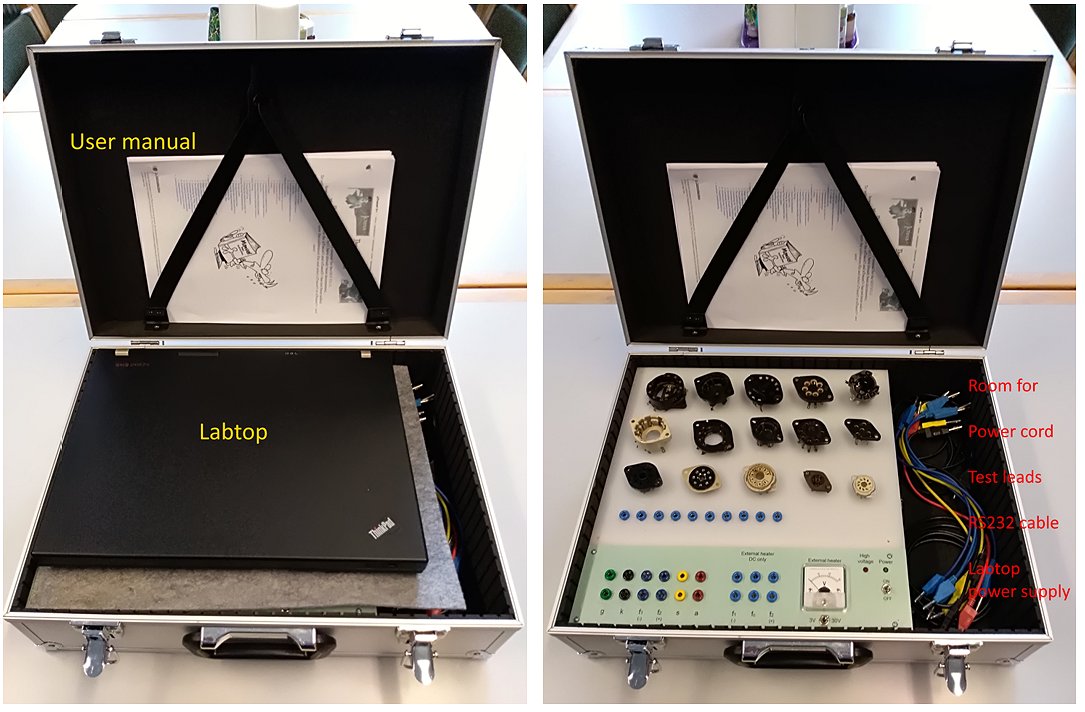

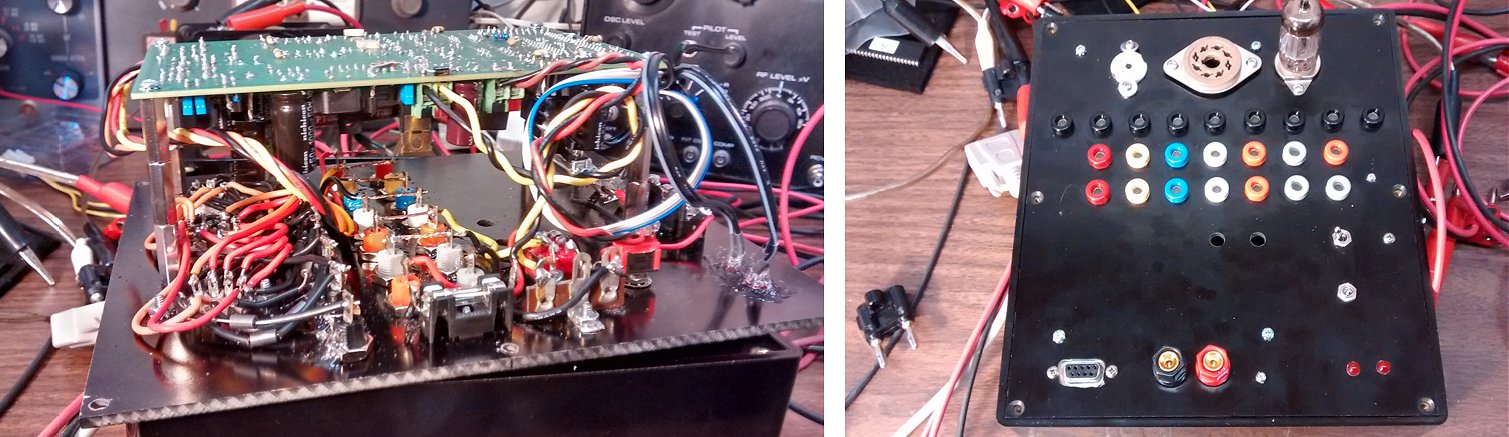

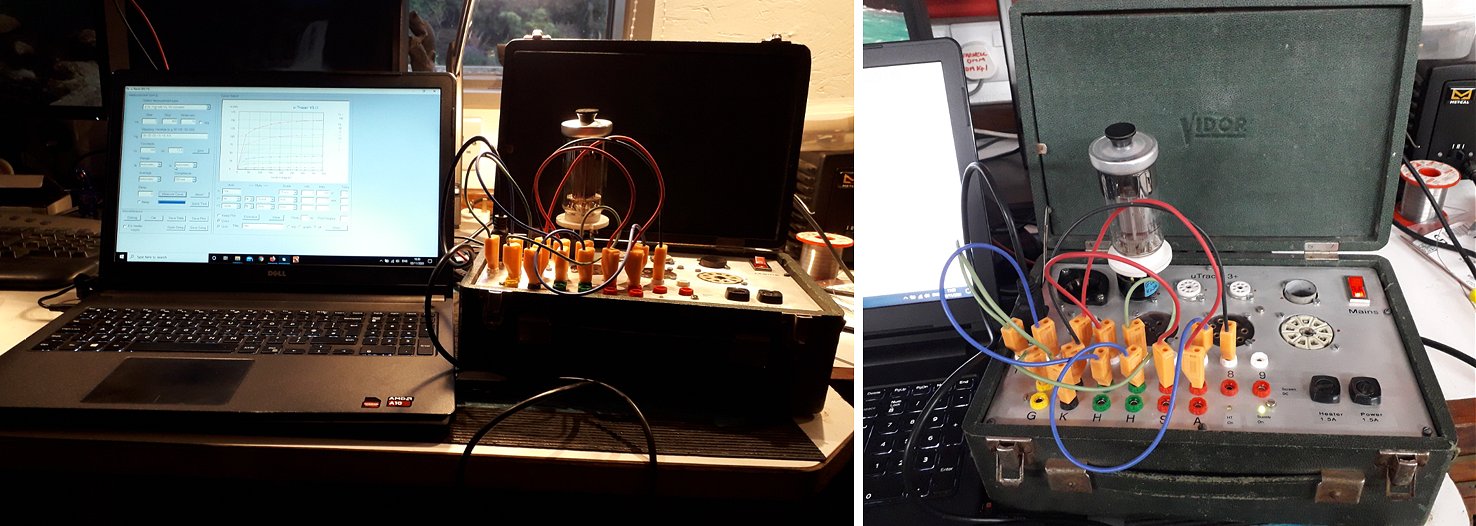

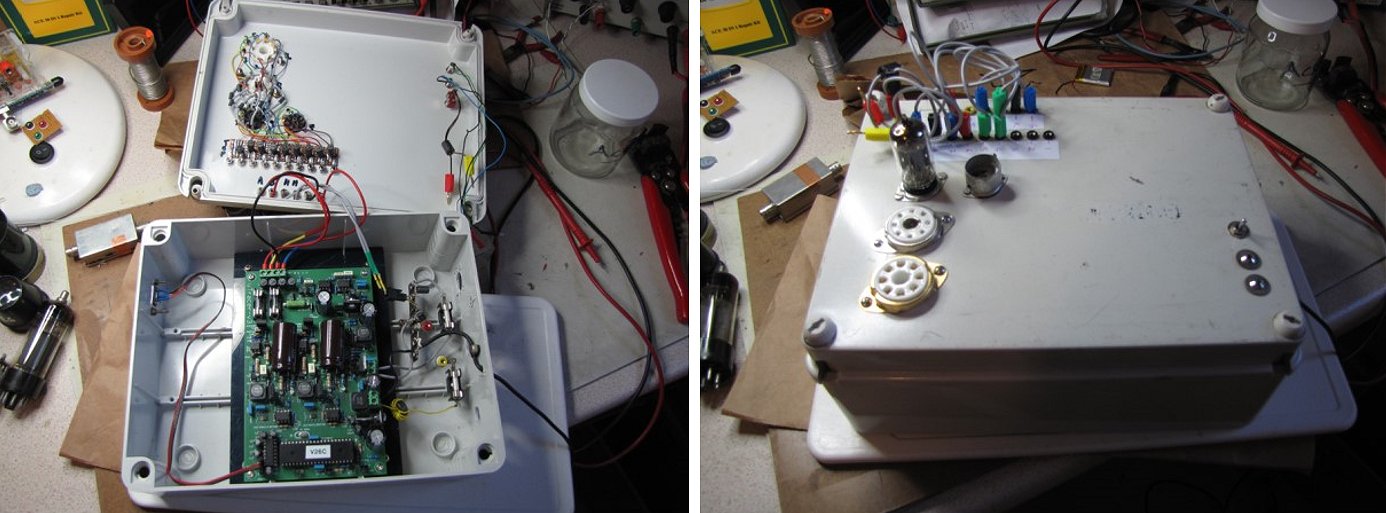

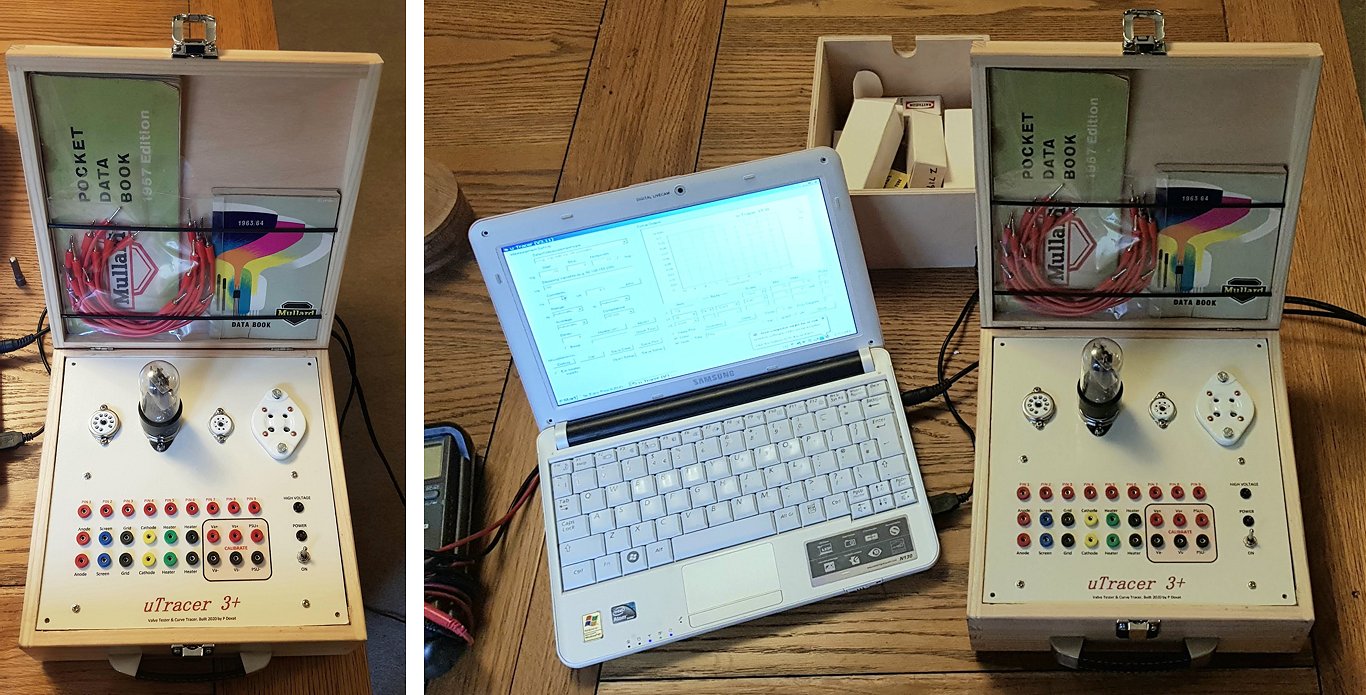

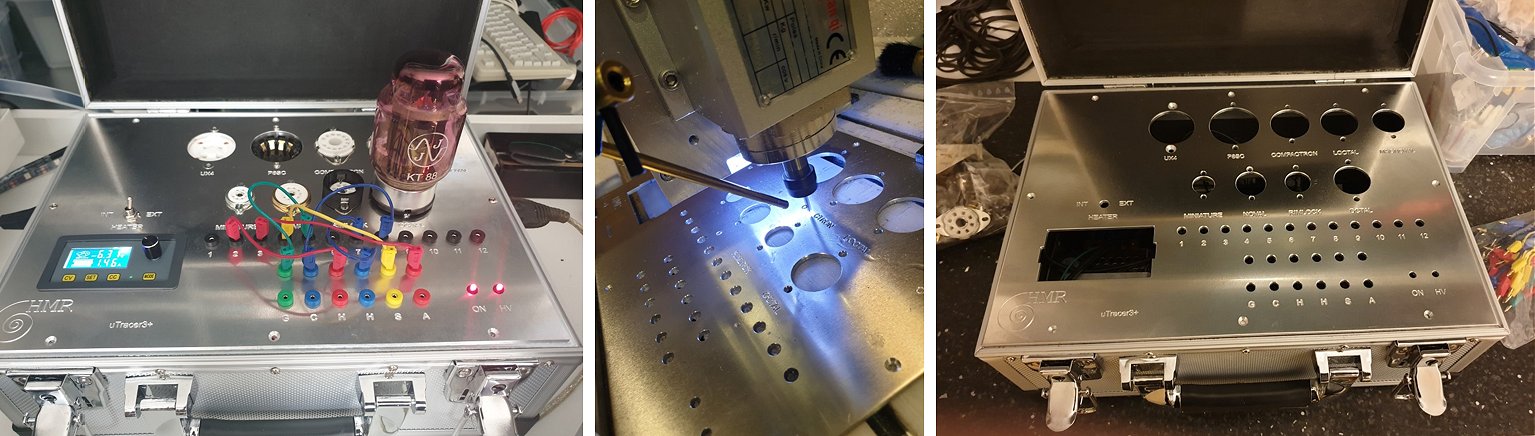

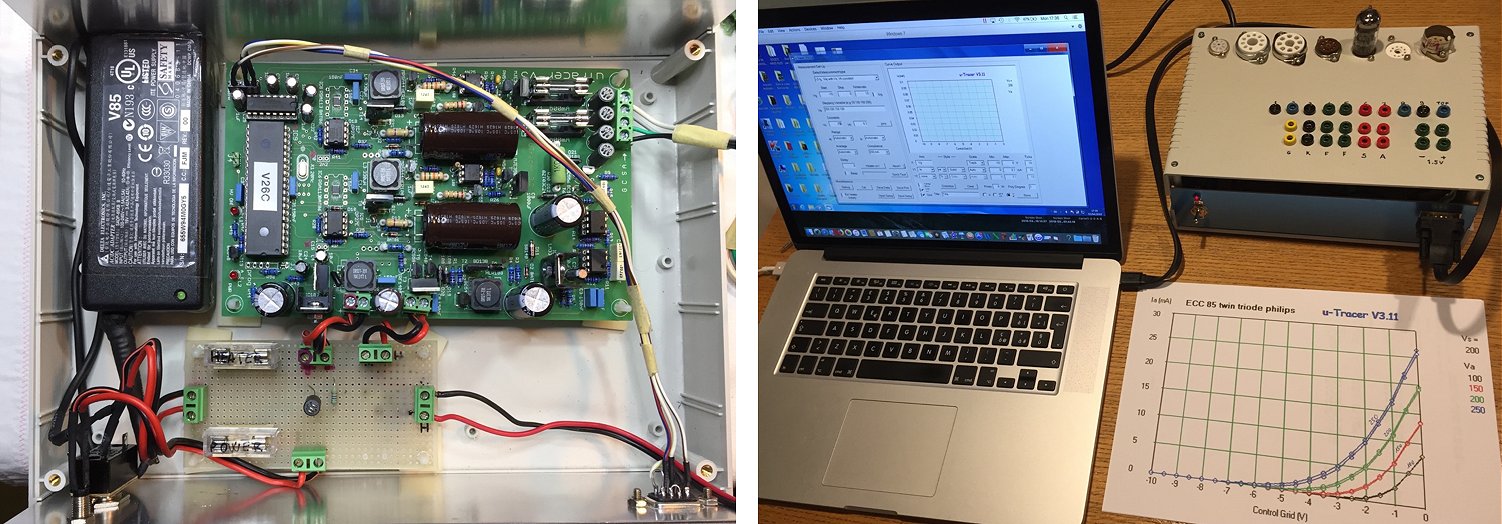

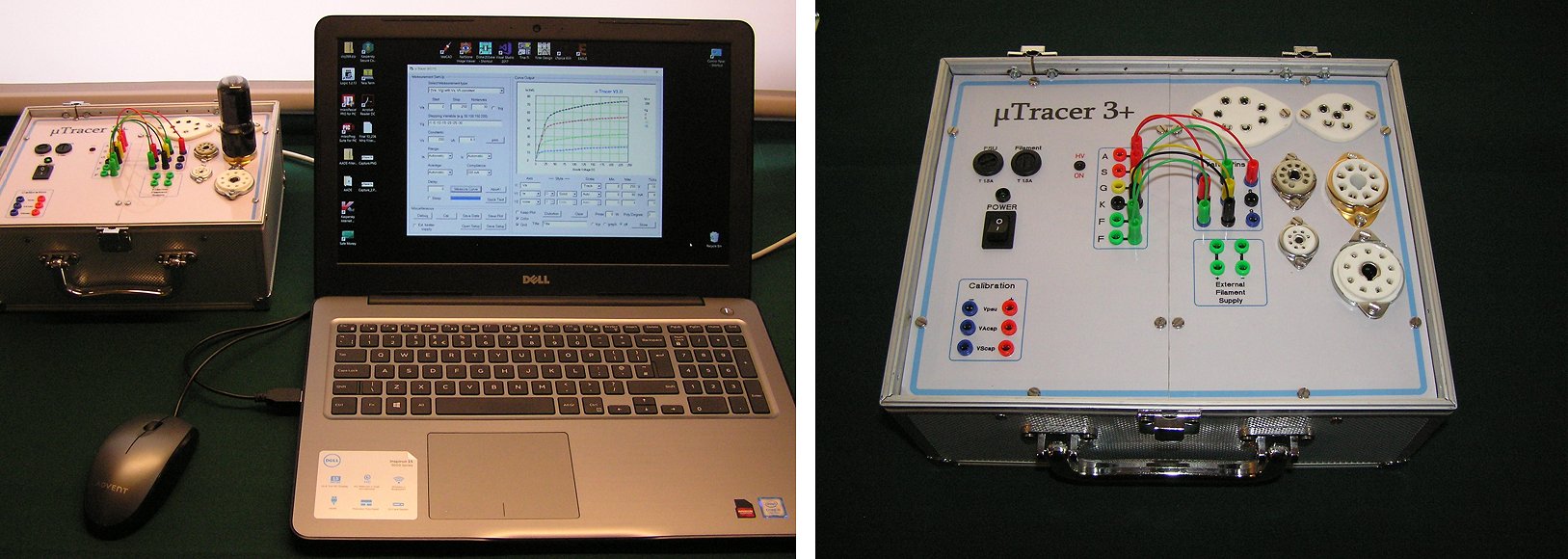

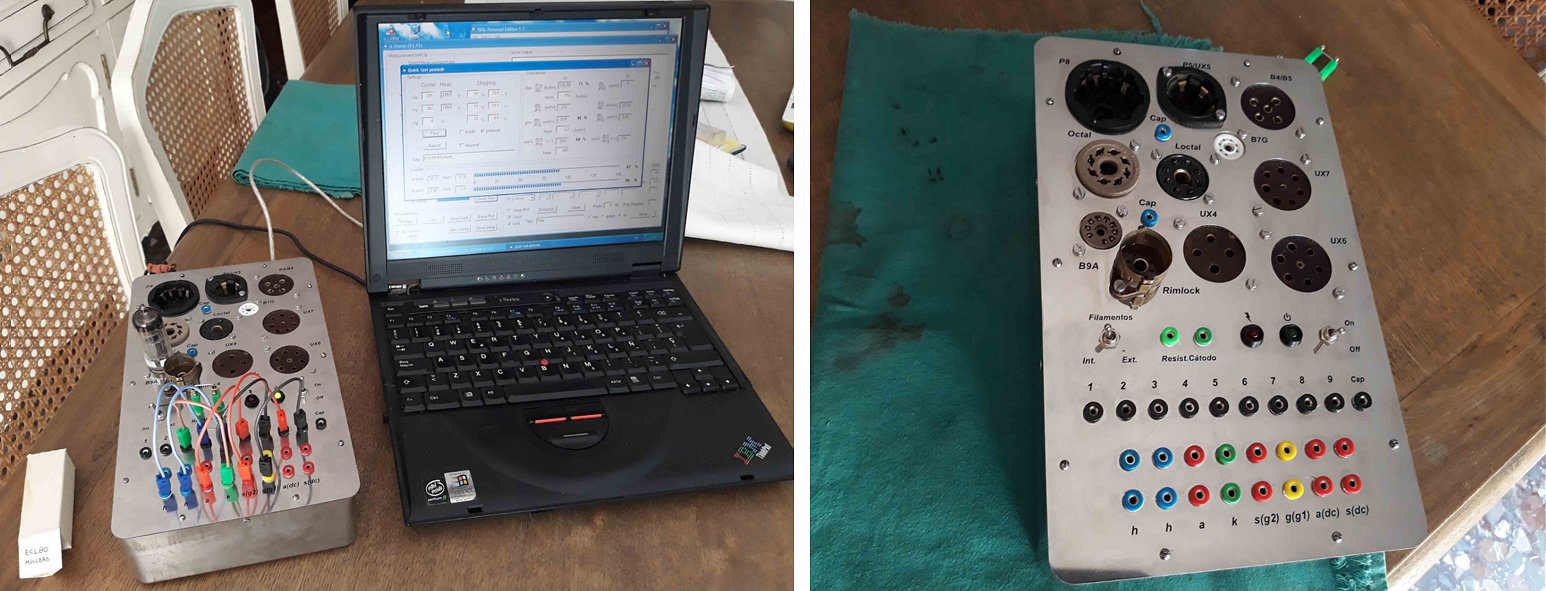

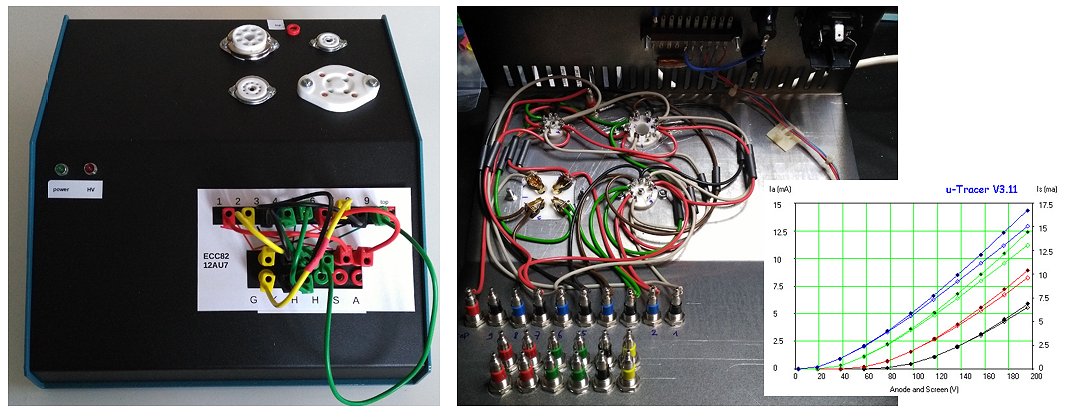

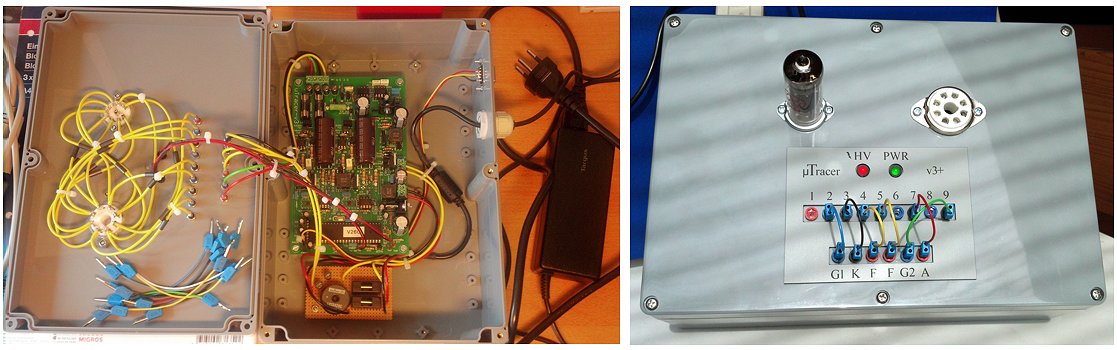

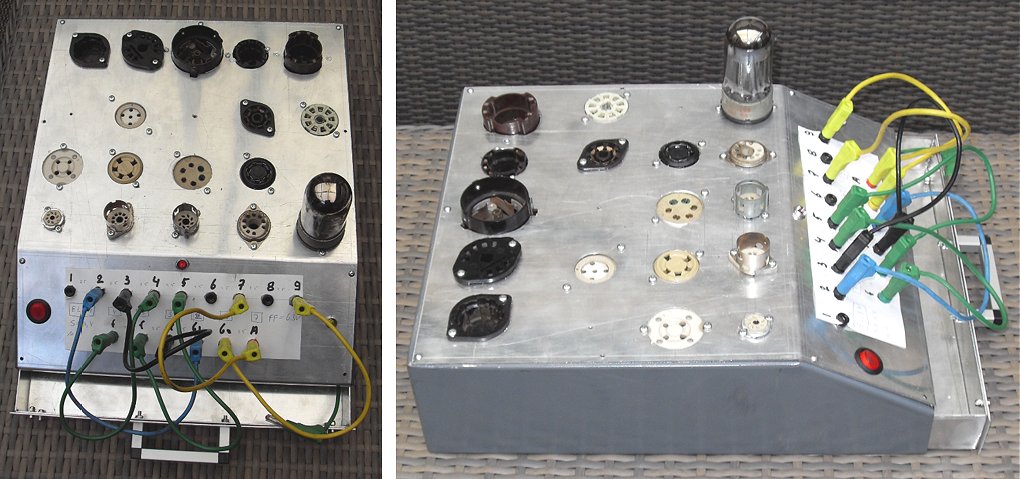

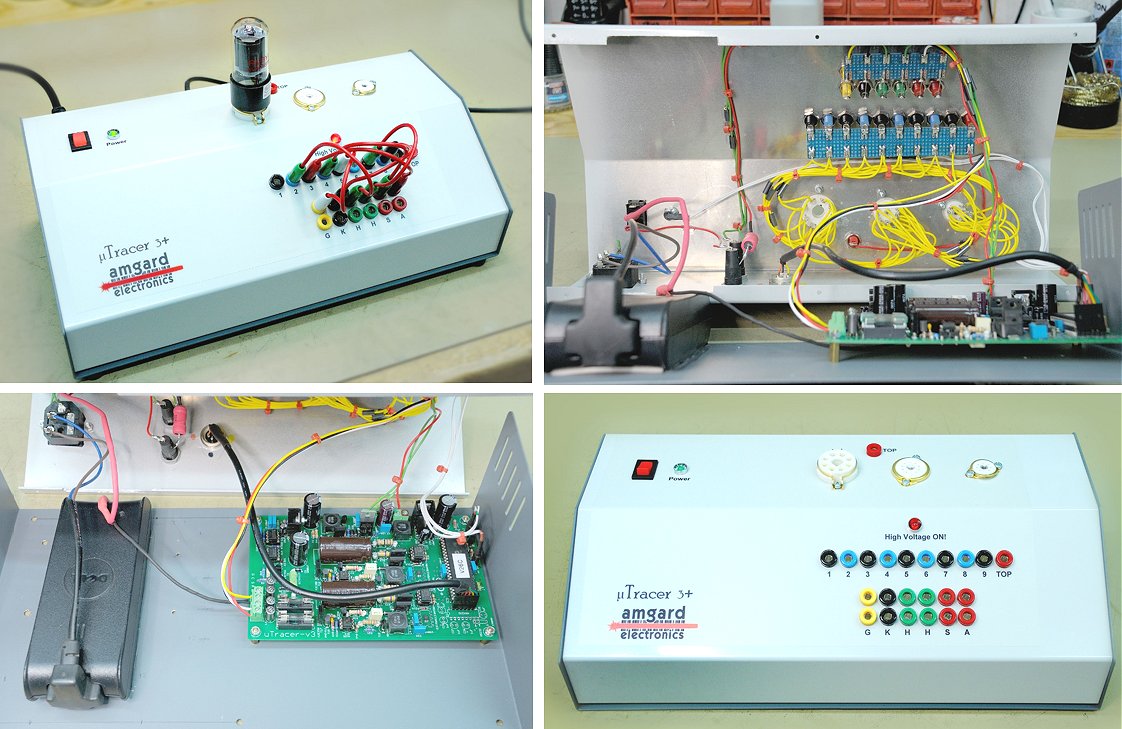

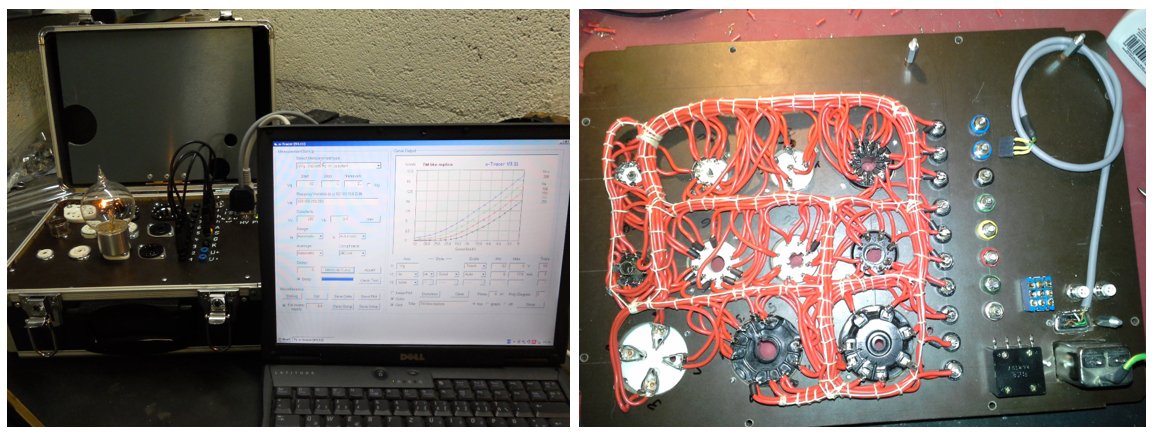

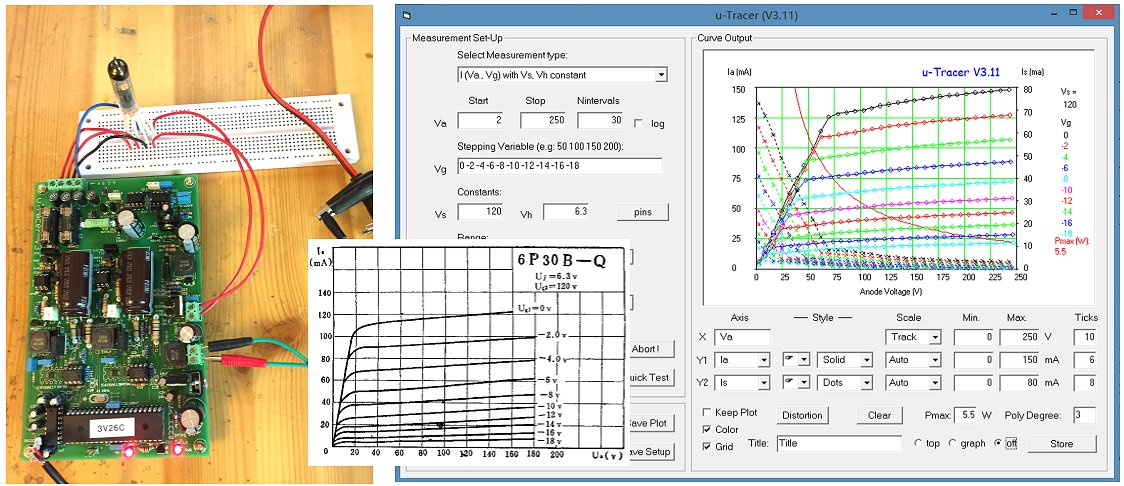

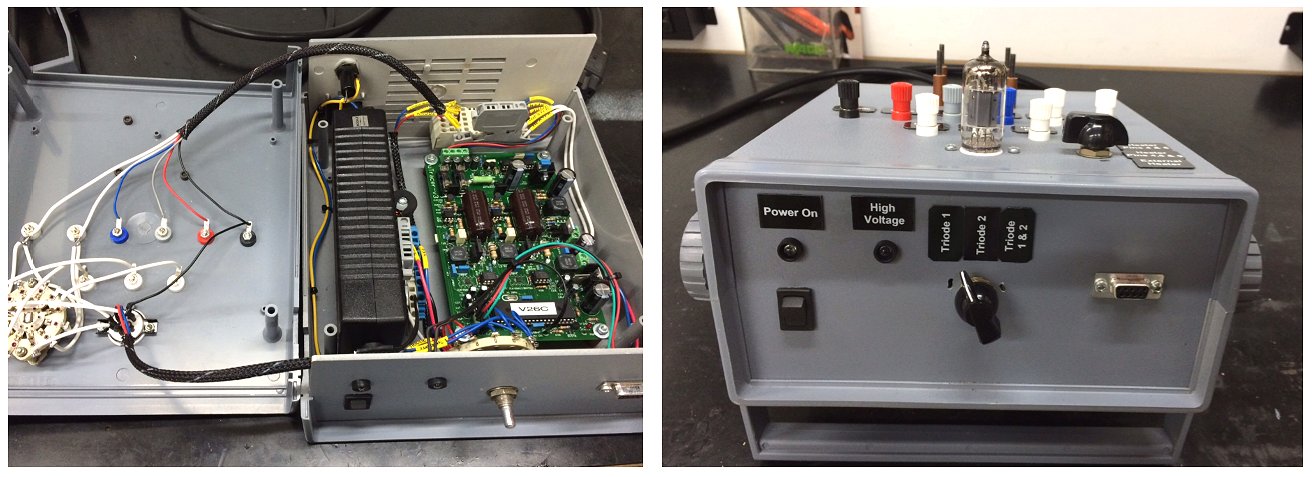

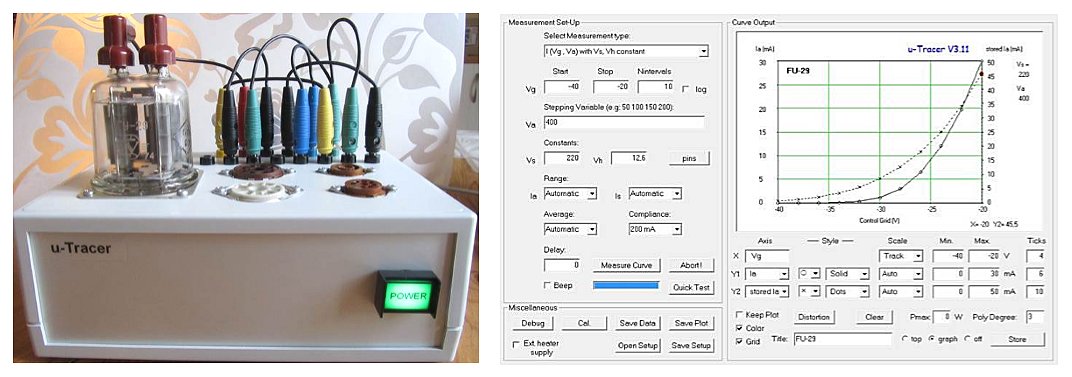

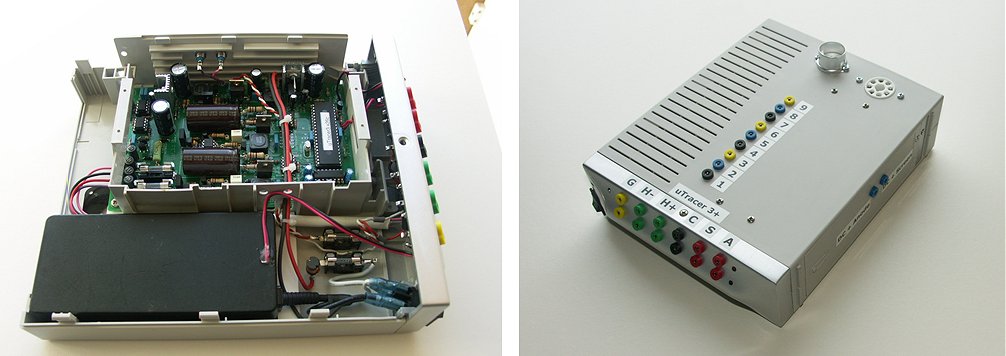

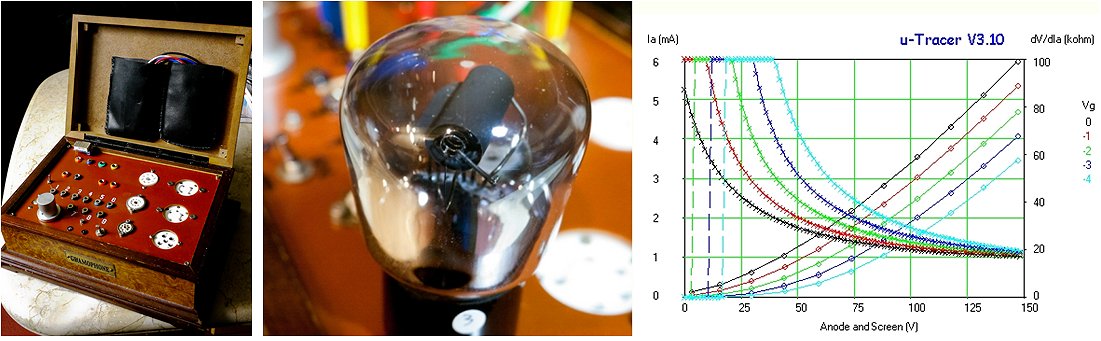

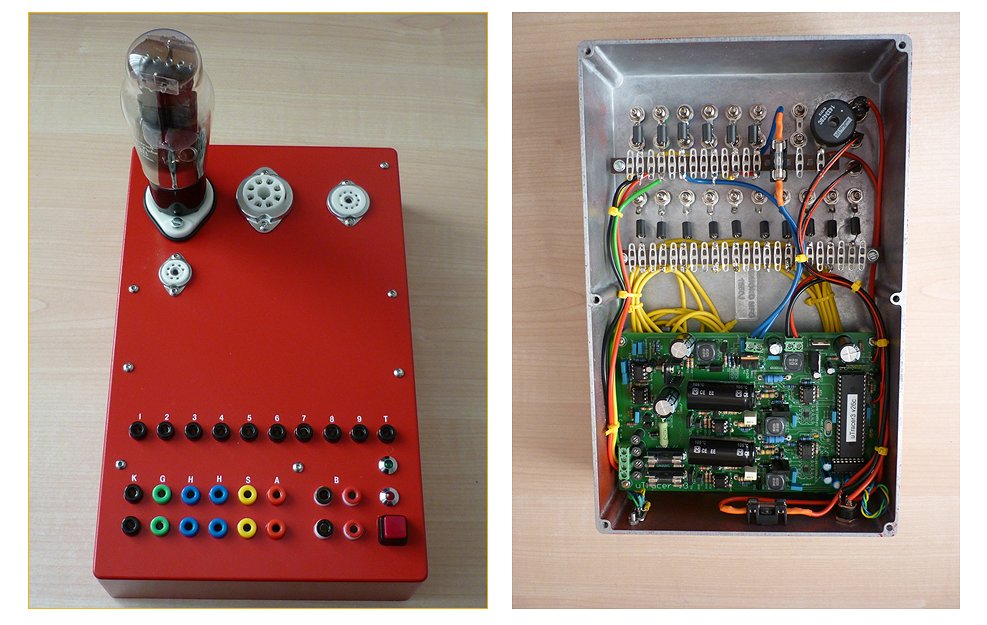

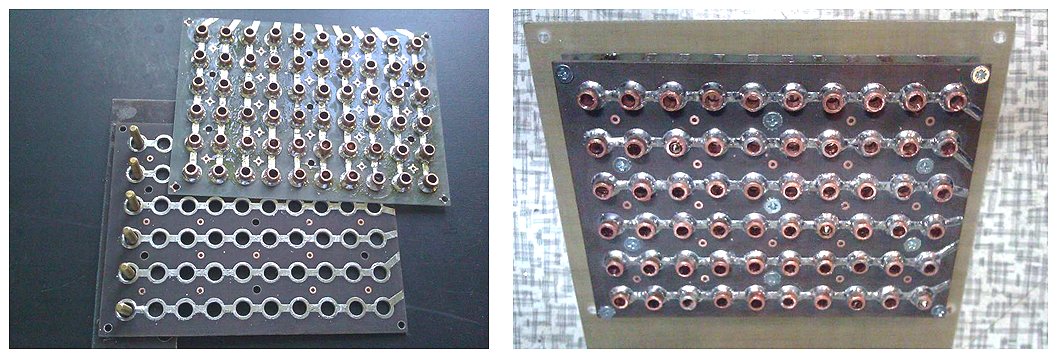

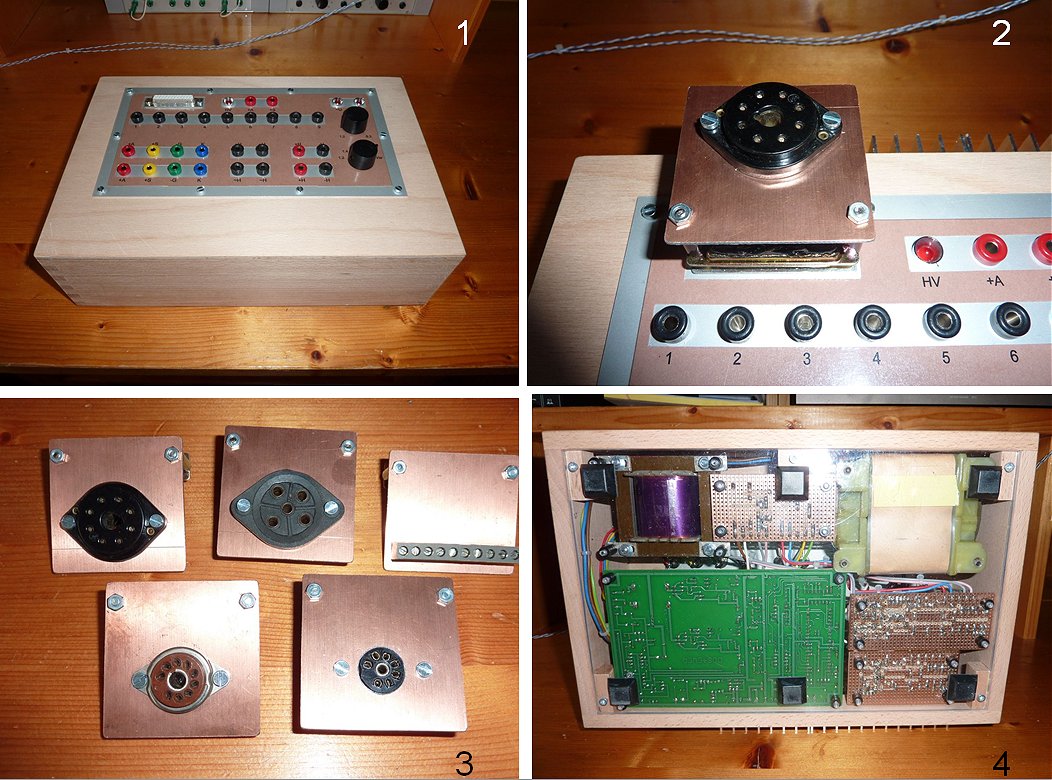

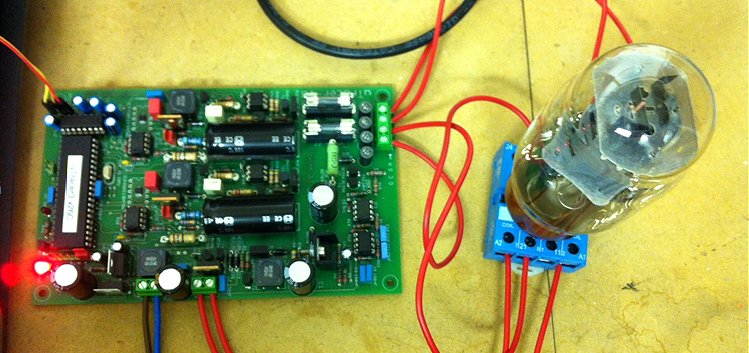

8th of July 2022 Preben from Denmark (OZ1PDE) built a beautiful uTracer for the Sønderjyllands Radiomuseum

16th of July 2022 Preben sent me an update of the construction

Hi Ronald

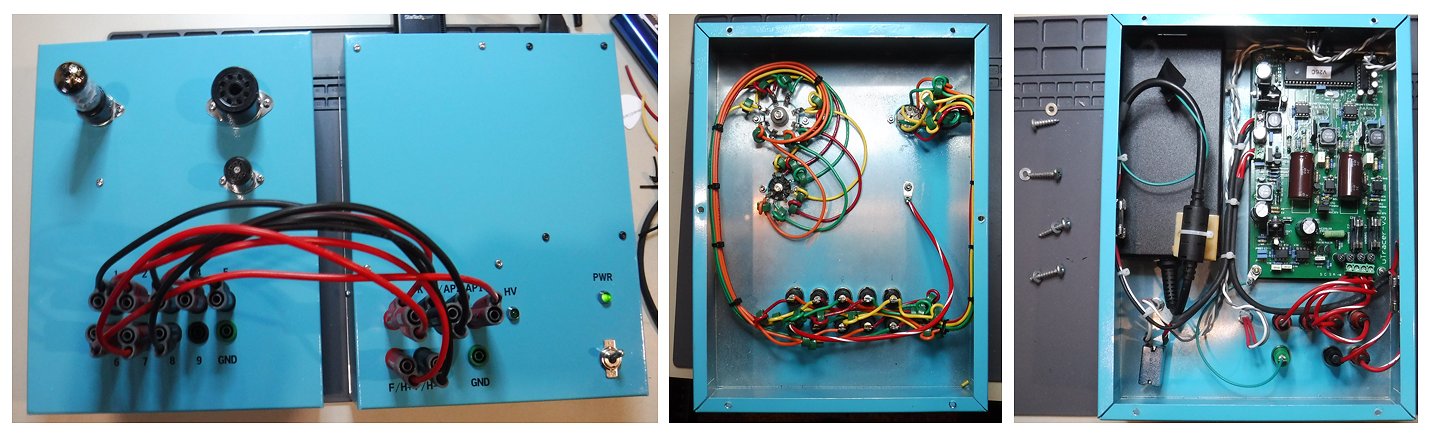

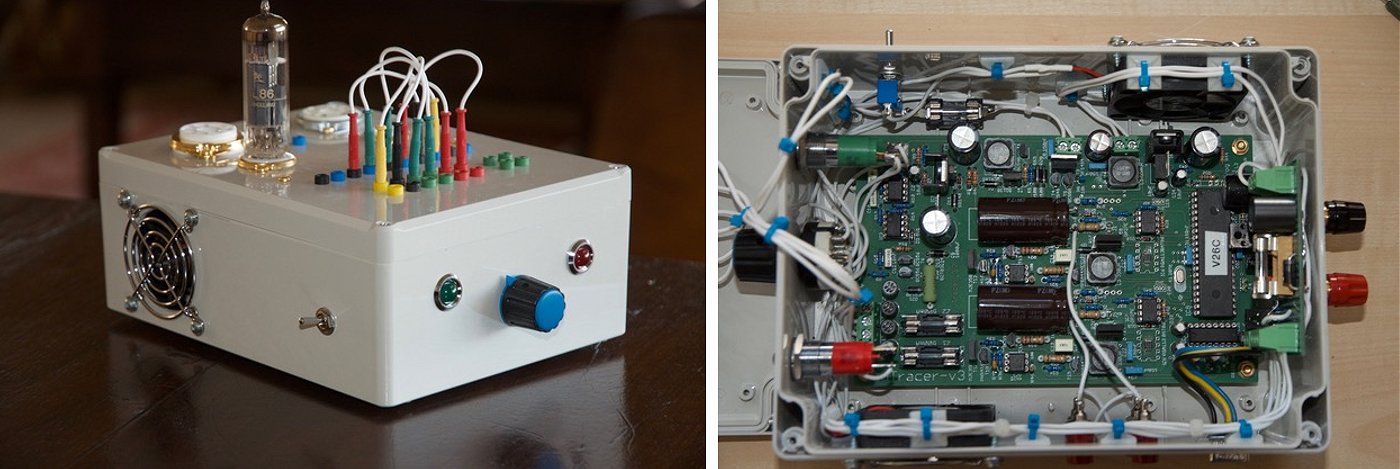

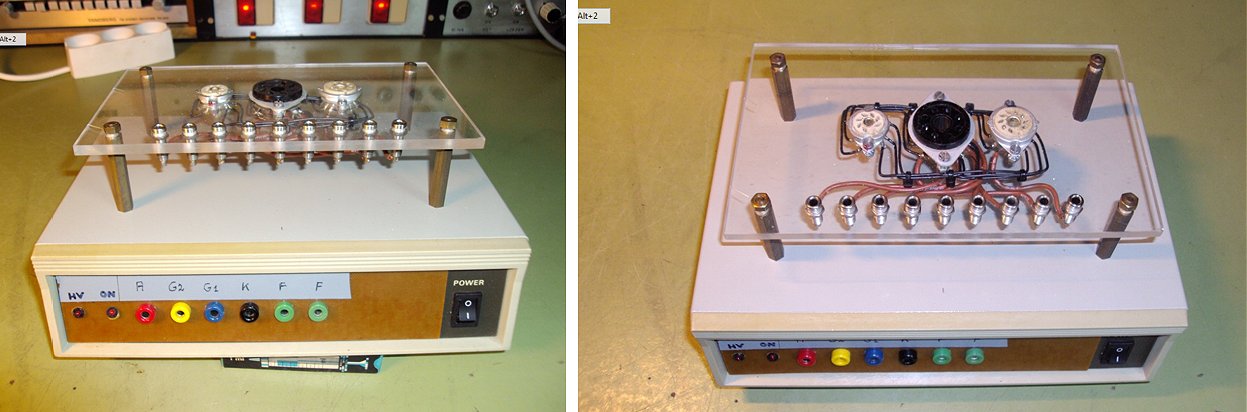

Thank you for posting pictures of our edition of the uTester on your website, and special thanks for your reference to the Radiomuseums website.

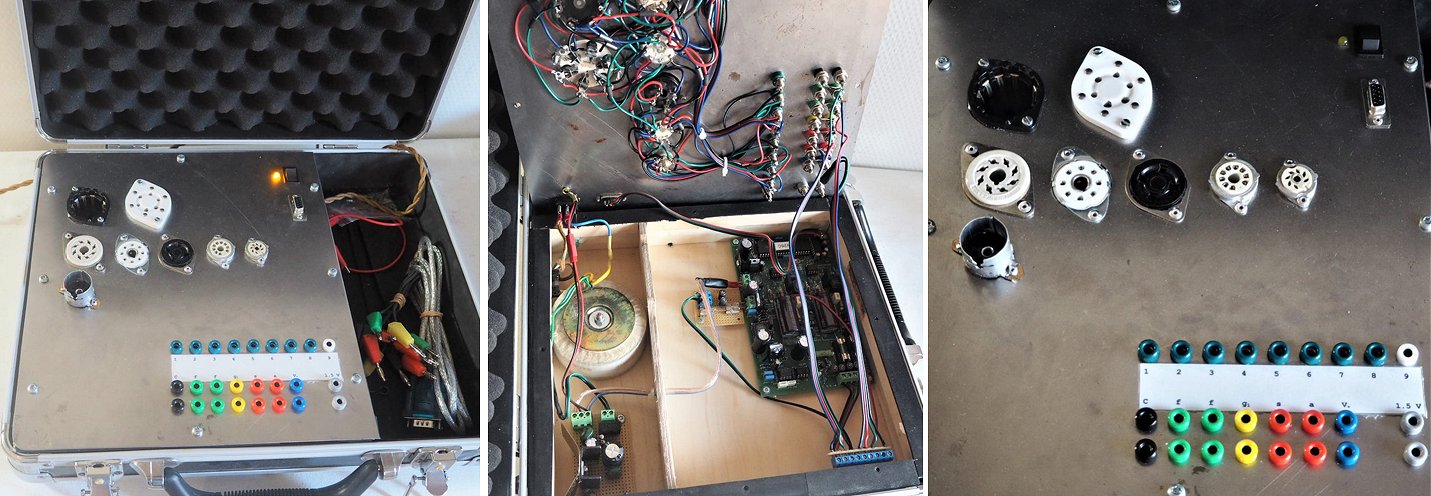

Our version of the uTester is still under construction, so I would like to attach some comments to the pictures and have also sent a few new pictures.

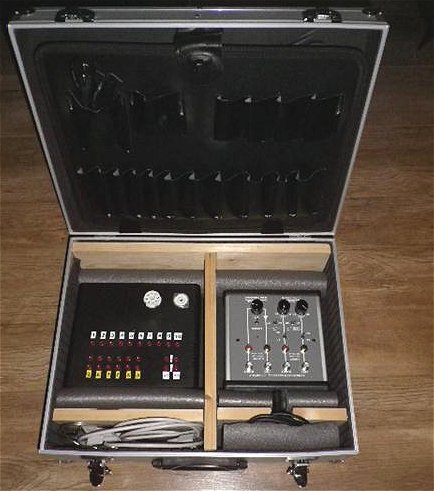

The idea of our uTester is to have everything you need in one suitcase. 15 different tube sockets are mounted on the top plate. In the compartment on the right side, the power cord and RS232 cable come out, so there is no need for connectors on the outside of the suitcase. At the same time, it is used for storing test leads and power supply for the laptop. In the lid, space has been made for the user manual. In addition, there is room for the laptop.

Best regards

Preben

26th of June 2022 Have a look at Peter’s magnificent uTracer!

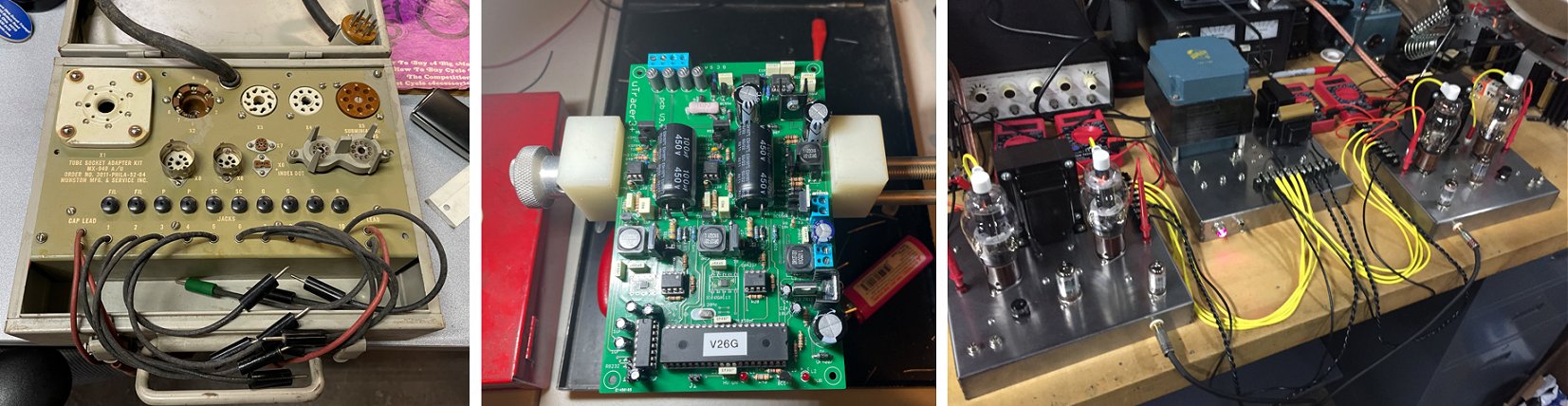

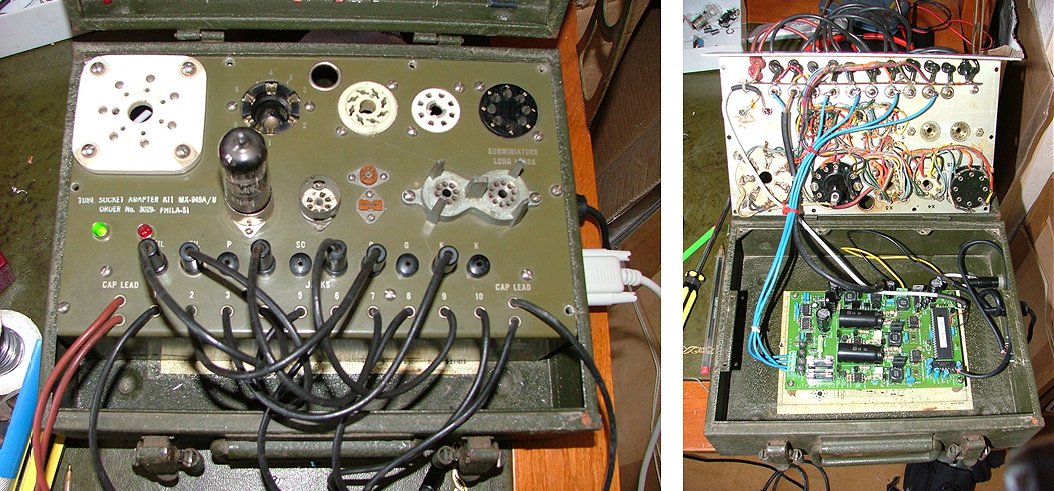

24th of June 2022 Randy send me a few pictures of his finished “military style” uTracer!

Greetings!

I've spent quite a bit of time over the last few weeks on finishing up my Utracer build.

I chose an old US military case...pre Pelican style. It perfectly matched the "theme" I was shooting for. I tried my best to make it look at home with other 1960's-1970's military tube testers.

For the tube wiring portion, I went with cannon plug cables. Each socket has designated cables to use according to the tube pinout. I chose this method over the open jumpers for a couple different reasons. No accidental touching high voltage test points and a cleaner look. As much as I love rotary switches, the associated wiring is rather difficult, time consuming, and not as clean looking. This also allows me endless expansion capabilities, and I have already 3D printed some external socket enclosures.

For communication, I went the Bluetooth transceiver route. Model is a Parani SD1000. It's a direct serial RS232 to Bluetooth adapter. That way I don't have to drag around a serial to USB adapter and a serial cable. So far it has worked flawlessly with 2 laptops, a 10" Windows tablet, my Android based phone(with the app), and a 10" Android based tablet. My goal is to mount the 10" Windows tablet in the lid of the case, so it can truly be an all in one solution.

This was quite a fun project! Thank you for designing the Utracer and making it available to the masses.

Feel free to post my photos if you would like.

Randy.

20th of June 2022 François sent me a few pictures of his fine uTracer3 !

By the way,

I never took the time to send you pictures the first version.

Nothing fancy, just plug the AC and a serial/usb adapter and you’re tracing.

It works flawlessly since I built it. All cables are silicone for security.

Thanks again to both of you for your dedication.

Best Regards,

François

14th of May 2022 Theo sent me a few pictures of his fine uTracer (in Dutch)!

Hallo Ronald,

Bijgaand een update berichtje omtrent mijn uTracer.

Na de omissie bij hoofdstuk 8 is de verdere opbouw van de uTracer probleemloos verlopen. Hij werkt inmiddels naar tevredenheid en ik heb het geheel ingebouwd in een simpel kastje. Voeding wordt verzorgd door mijn labvoeding goed beveiligd en mooi stabiel. Ik heb vooralsnog een tweetal type buisvoeten (Noval 9p en mini 7p) aangesloten om de kans op oscillatie zo klein mogelijk te houden en heb besloten om, wanneer ik in de toekomst andere typen buisvoeten benodigd ben, deze onder te brengen in een separaat kastje van ook weer max. 2 stuks. Ik ben reuzeblij met m’n UTracer en beveel jouw briljante set dan ook in heel mijn kennissenkring aan!

In de bijlage zend ik je nog enige foto’s van m’n creatie.

Dank voor alle goede zorgen het snelle advies wat ik tijdens de bouw mocht ontvangen!

Fijn weekeinde toegewenst en groet ook aan Marie José.

Theo

8th of May 2022 Andre in Berlin shared a few snapshots of his finished uTracer!

1st of May 2022 Hartmut announces the birth of a new uTracer!

Hallo Marie-José en Ronald,

It`s finished.

Date of birth: 05/30/2022, weight: 3 kg, length: 28.50 cm

Thank you for your time developing the kit and for selling it at a more than fair price.

And above all, a big compliment for the really perfect assembly instructions, which also enable someone without much technical knowledge to assemble the device.

I still have to practice measuring myself. So I measured an old, used EL84 with 110% and immediately afterwards a new JJ Electronic EL84 bought from a specialist dealer with 51%. Of course it can be true. An EABC80, for example, seems to be a particular challenge in terms of measurement technology. since I have been working with tube technology for about three months, it could be possible, that I still have to learn a little. :-)

Hartelijke groet,

Hartmut

12th of February 2022 Dirk from Germany finished his uTracer3+ and is already planning a suitable housing for it!

Hello Marie-José, hello Ronald

the Kit ist build and testet. Everything seems to be fine. The construction manual is very well made!

The next step is to build the housing, I am still thinking about an upgrade of the heating and the sockets...

All the best

D.D.

2nd of February 2022 Hans-Jürgen from Austria sent me some pictures of his excellent uTracer!

Lieber Ronald,

ich habe vor einigen Jahren den uTracer gebaut und vor Kurzem einige Funkamateur-Freunde animieren können, dieses Gerät ebenfalls zu bauen. Einige dieser Geräte funktionieren schon erfolgreich. Anbei einige Fotos meines Gerätes zur freien Verfügung.

Liebe Grüße

27th of December 2021 Geri sent me a few pictures of his very fine uTracer!

Dag Ronald

Mijn uTracer 3+ is al een tijdje klaar en ik ben er dik tevreden mee. Ik heb er wel intern een separate voeding voor de print in gebouwd en twee gloeispanningsvoedingen van 6,3V en 4V. Dat zijn voor mij de meest voorkomende gloeispanningen en de overige kan ik eenvoudig extern invoeden. Dat zijn er zoveel, ook meer dan 19V voor U-(eind)buizen. Door voldoende ferrietkraaltjes in de bedrading naar de buisvoeten op te nemen, heb ik nooit last gehad van oscillaties. Ik heb ook eindelijk een goed USB-RS232 snoer op de kop kunnen tikken (van DSD-Tech type SH-RS232AUSB met FTDI chip DB9) en nu werkt de communicatie met de laptop ook probleemloos. Het enige wat ik nog wil toevoegen is een Volt en Ampèremetertje voor de gloeispanning en stroom, m.n. voor dat laatste. Ik heb gemerkt hoe prettig dat dat is als ik een externe gloeispanningsvoeding (met V-A meter) gebruik. Dat metertje loopt in bestelling. Ik stuur je wat foto’s van mijn uitvoering. Misschien kun je er wat mee.

Hartelijke groeten en een fijne jaarwisseling, Geri

15th of December 2021 Thomas sent me some pictures picture and an extensive testimonial because he is very pleased with his uTracer!

Dear Ronald,

When I started to clean my father’s storage, I found thousands of vacuum tubes. I remember well that my experience with this technology was limited to my teenage years and quicky phasing out the years following. But I started to investigate in this technology again and as well browsed for methods to verify the function of tubes. That was the time when I stumbled on night over your home page and after a few days and testing the software I decided to go for it to make myself a birthday present.

Thanks a lot for your excellent project µtracer3+! The kit was perfectly prepared and following the instructions it took me just like 5 hours to complete the main part. The time I spent after that was more something like ten-fold ??. In the following I present my interpretation of this great project.

The base case is a complete set intended for a laboratory power supply kit. The front is a simple aluminium plate I folded and fitted. On the top a 20pin connector interfaces to the socket adapter, currently only one adapter for post-war tubes is existing.

After browsing through discussion threads, FAQs and testimonials I set my personal goal to squeeze almost all ideas I found into my setup. The look into the inside shows that the gear is quite packed and there is not much space left. The fan including fan control on the left (back) side was already part of the case. Underneath the laptop power supply there is a second independent power supply which is providing the 15V for the auxiliary heating source – a combined step up / step down converter offering all ratings between 1.4V to 14V and 14V to 60V.