|

The making of the E1T or The making of the Z550M/ZM1050 or The importance of the emergency landing of a German seaplane in 1917 For the early development of Philips Research. |

|

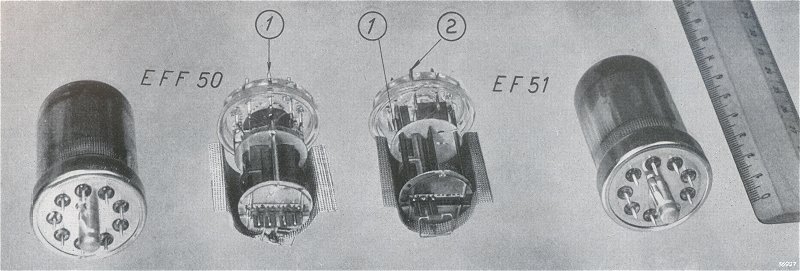

The EF50 RF penthode constitutes a landmark in the history of the radio tube. Before the EF50, all radio tubes were fabricated using technology which was directly derived from the technology for making light bulbs. The EF50 in contrast had, like all “modern” radio tubes, a base made from pressed glass. This enabled the designers at Philips to combine superior performance with a low-cost high volume production technology in a single tube. Several accounts of the history of the EF50 have been given, both in literature as well as on the Web [1]. On this page I have tried to gather all this information, and to go as much as possible directly to the sources. I have tried to sketch the context of the development of this tube and included an account of the history of Radar and the history companies like Pye, Mullard and Philips in as far as it is relevant to the story of the EF50. Using unique Philips sources, special attention will be given to the novel fabrication technologies that were used for the EF50. Finally, and for me personally most interestingly, I have tried as much as possible to reveal the people behind the technology.

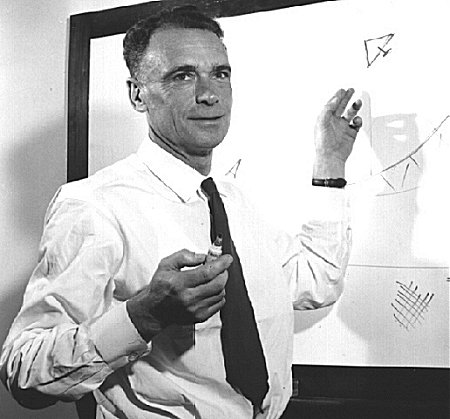

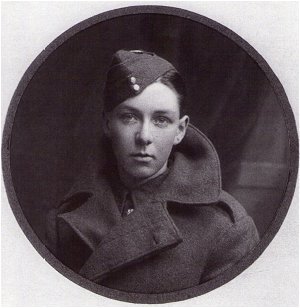

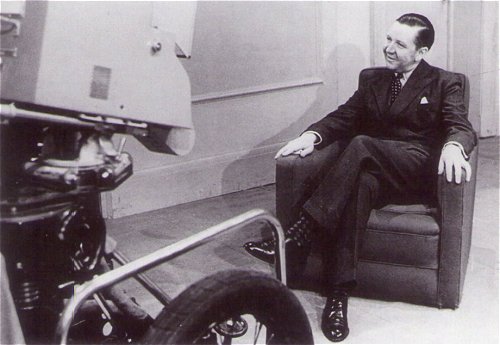

Figure 1.1 Edward George “Taffy” Bowen.

| to top of page | back to homepage |

Edward George “Taffy” Bowen was born the 14th January 1911 in Cockett near Swansea, Wales [2]. Being highly intelligent, he was able to get a good education by winning scholarships. From a very early age he developed a strong interest in radio (and cricket). He studied physics at Swansea University College and graduated with First-Class Honors degree in 1930. He completed his doctorate under Professor E.V. Appleton at Kings College London. [3] In 1926 Appleton had proven the existence of the first ionospheric layer (now called the E-layer) by the reflection of radio waves. In 1947 Appleton was to receive the Nobel prize for his contributions to exploring the ionosphere.

As part of his research, Bowen spent a large part of 1933 and 1934 at the Radio Research Station at Slough. In the early months of 1935 an advertisement for a job position at the Radio Research Station was issued and Bowen decided to apply. After a very relaxed interview with Watson-Watt, the superintendant of the institute whom he already knew from his PhD work, he was given the position. He joined the staff of the Radio Research Station towards the end of April 1935 as a Junior Scientific Officer. By then he was still completely unaware of the fact that the Radio Research Station harbored a great secret. But that was soon to change: on his very first day he was introduced to the provisions of the Official Secrecy Act, which stated the penalty for the slightest deviation from the most meticulous standards of security: “to be hanged by the neck until life was extinct!” After he had signed the contract, a highly impressed Bowen was told of the secrets of Radio Direction Finding (RDF), better known as Radar.

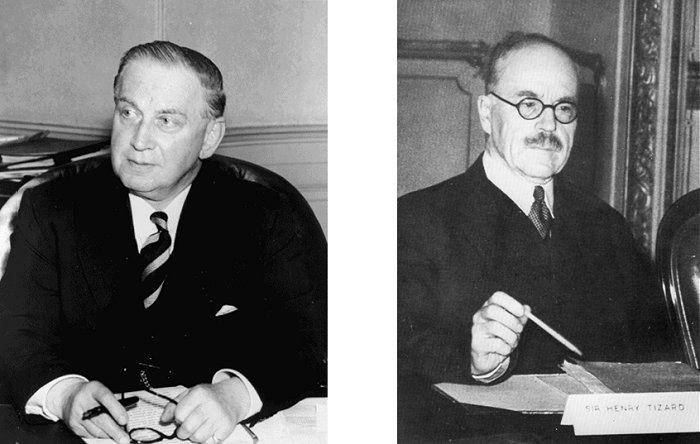

Figure 2.1 left: Sir Edward Victor Appleton (1892-1965), right: Sir Henry Tizard (1885-1959).

Radar had been "in the works" in Germany as early as 1933. Not long after that also England, France, Holland, Italy, Russia, and the United States started research projects along the same lines. Only England however, really pushed Radar and its practical use, and integrated it into their fighter command network. By the time the Nazis were ready to start the blitz of England in July 1940, England had 29 Radar stations making an invisible curtain along its southern and eastern coasts. According to Bowen, this was largely due to the vision of one man, Sir Henry Tizard.

Tizard was a chemist by training and he had spend a year working in Nernst’s laboratory in Berlin in 1908. As such he knew the German people and he had a first-hand experience of that country preparing to go to war. During World War I Tizard served in the Royal Flying Corps and in 1917 he was in charge of the scientific work of the Aeroplane and Armaments Experimental Station. Between the wars Tizard held a variety of governmental posts, perhaps the most important of which was Secretary of the Department of Scientific and Industrial Research. As such Tizard was very much aware of the length of time which must elapse between initiating something at a research level and its practical application.

In 1934 Tizard was the rector of Imperial College. Towards the end of 1934 he began to think about the problems of air defense and what could be done about it. He realized that in a few years’ time, Britain would be subjected to a devastating air attack and, as things stood, the country was defenseless against it. Most likely on initiative of Tizard himself a committee was formed to consider this problem. The committee consisted of P.M.S. Blackett [5], A.V. Hill [6] and H.E. Wimperis, with Tizard as Chairman. It became known as the “Tizard Committee.”

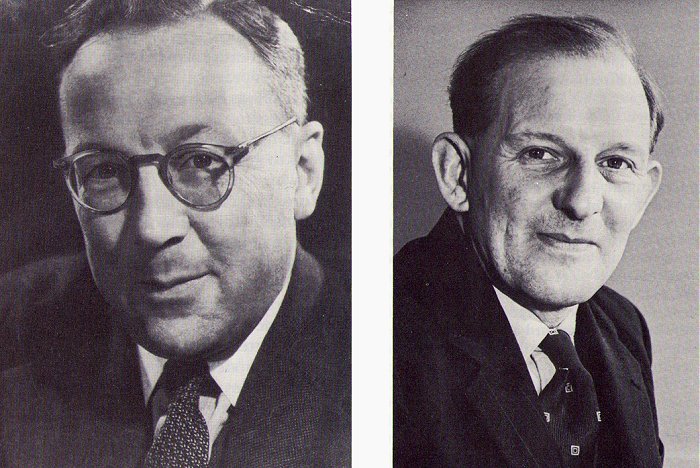

Figure 2.2 left: Sir Robert Watson-Watt (1912-1973), right: Arnold F. Wilkins.

There were at that time numerous rumors that Germany had developed a “Death ray.” Engines would stop and animals and people would drop death when subjected to such a death ray. To assess the truth of these rumors the Tizard committee decided to consult Watson-Watt. Watson-Watt was at that time the Superintendent of the National Physical Laboratory (NPL). As a physicist Watson-Watt had worked on the detection of dangerous thunderstorms. To do this he had designed an elementary radio direction finder which on a cathode-ray tube gave the direction of thunderstorm activity. Watson-Watt passed the “death ray” question on to Arnold Wilkins, and asked him to calculate how much energy would be required to damage an aircraft or adversely affect the crew. The answer came out at an impossibly high figure. However, in the course of making his calculations, Wilkins realized that if radio waves were sent in the direction of an approaching aircraft, while no damage would be done, there was a possibility of something quite different, namely detection of radio waves reflected back from that aircraft.

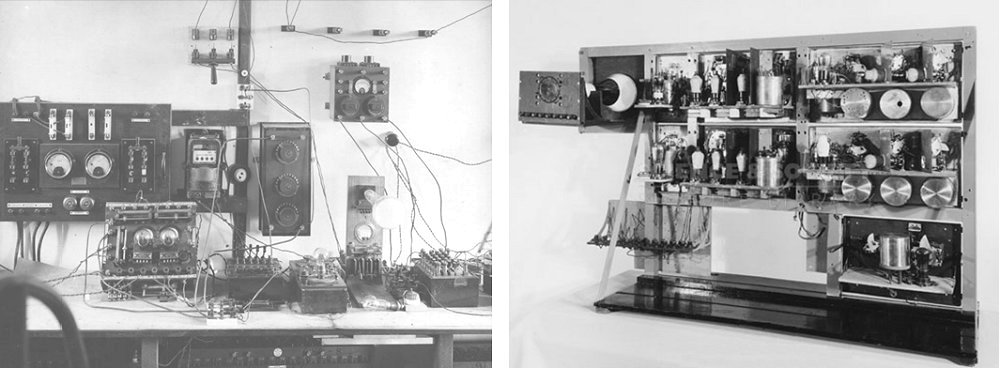

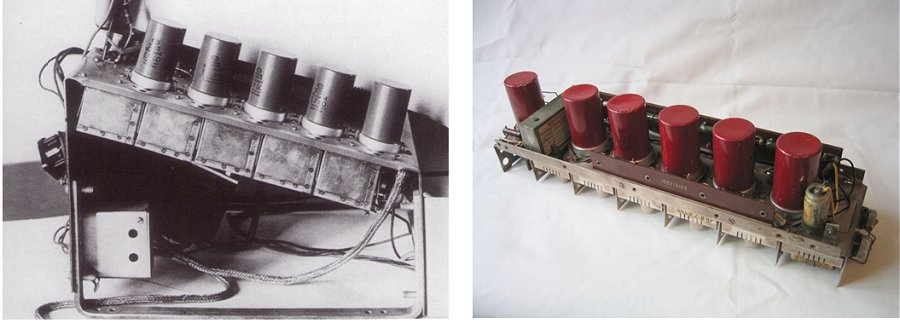

Figure 2.3 left: Watson-Watt’s apparatus for studying waveforms of ionospherics (ca. 1924), right: The original equipment used by Watson-Watt and Wilkens in 1935 to demonstrate the principle of Radar.

This proposal was put forward in the famous memorandum “Detection and Location of Aircraft by Radio Methods” which Watson-Watt submitted to the Air Ministry on the 12th of February 1935 [7]. By a happy coincidence, the Air Member for Research and Development at that time was the legendary Air Vice-Marshal Sir Hugh Dowding, the man who was destined to play a vital role as Commander-in-Chief during the Battle of Britain. In his gruff way, his first reaction to Watson-Watt’s memorandum was that he was not much impressed by calculations, but if a practical demonstration were given he might be convinced. It remains an almost unbelievable coincidence that on the very same day that Hitler signed a secret document ordering the organization of the Reich Luftwaffe with Goering in command, the 26th February 1935, A.F. Wilkins demonstrated from a small wooden van which had hurriedly been loaded with equipment the reflection of radio-waves originating from the BBC short-wave transmitter at Daventry, using a Heyford bomber as target. It is completely to the credit and vision of Hugh Dowding that he granted the initial sum of £ 10000 for initial work, and in this way secured the victory of Britain in the upcoming war. It was at this point that Taffy Bowen came into the picture as the most junior of the three scientists assigned to the task: Wilkins, Bainbridge-Bell and Bowen.

Figure 2.4 From left to right: Air Vice-Marshal Sir Hugh Dowding, the RAF Heyford bomber of the type that was the first Radar target in England in February 1935, Arnold Wilkins in the radio van that was used in the first Radar demonstration.

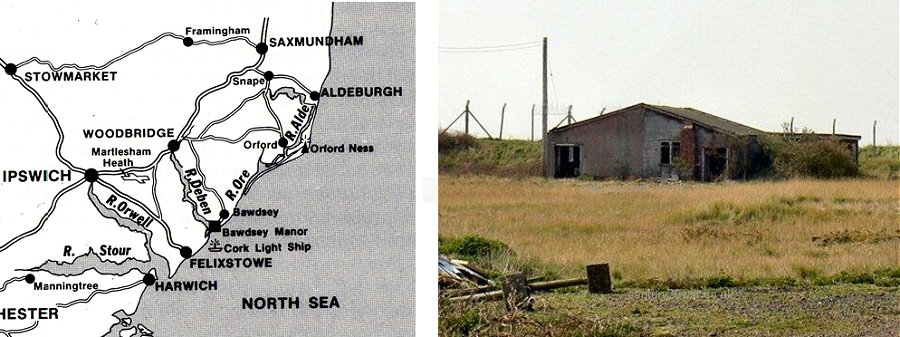

In order to preserve secrecy it was decided to erect the first Radar system not at Slough, but at a remote site at Orfordness. This was a remote split of salt marsh, already owned by the Air Ministry that could be reached by boat from Orford. The group of three complimented by George Willis - the technical assistant of Bainbridge-Bell - arrived at Orfordness on the 13th of May 1935. During the first weeks this small group worked like slaves to have the first system installed. The receiver and the cahode-ray indicator were basically identical to the set-up for detecting thunderstorms at Slough and were assembled by Wilkins and Bainbridge-Bell. The transmitter was of a completely new design and the responsibility of Bowen. It was basically a couple of NT46 valves, the highest transmitting power valves used by the British Navy, used in a push-pull arrangement. With the filament consuming some 20 amps at 20 volts and the anode voltage pushed to 12000 volts, the transmitter eventually reached an output power of 200 kilowatts. Within a month on Monday the 17th of June the first echo’s from a Scapa flying boat were received from a distance of 17 miles.

Figure 2.5 The NT46, the transmitter tube used in the first Radar experiments in Orfordness in May 1935. The valve measures 500x105 mm and nominally draws 40A of filament current at 15V and is rated at a maximum anode voltage of 10000V.

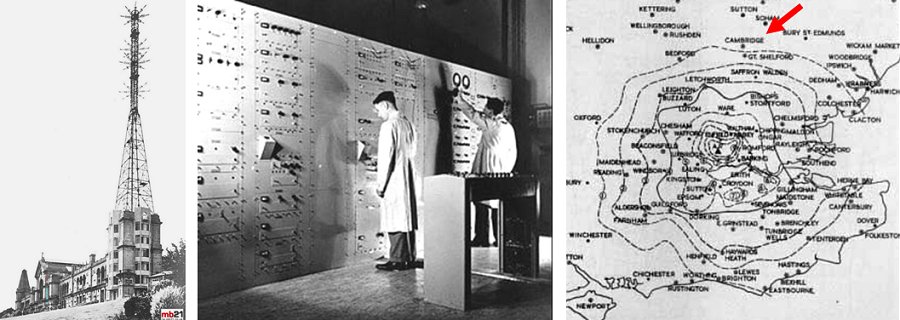

From that moment the progress was very rapid. Martlesham airbase assumed responsibility for the test flights for the new Radar system. With such flights on a daily basis, the performance of the equipment rapidly improved until it reached more than 100 miles in the early months of 1936. The successes in Orfordness prompted the Air Staff to ask for a set off five stations to provide air warning over the Thames estuary at the expense of a sum of £ 1000000. It was clear that this task was far beyond the capacity of the small staff at Orfordness so it was decided to increase the staff and to move to a more favorable site. Bawdsey Manor located not far from Orfordness at a location on the coast some 30 meters above sea level proved to be the ideal place. The Manor was purchased by the Air Ministry and in March 1936 the Radar group gradually took possession of the estate.

Figure 2.6 Map showing the Orfordness, Bawdsey and Martlesham area as it was in 1935. On the right, the receiver hut on Orfordness now.

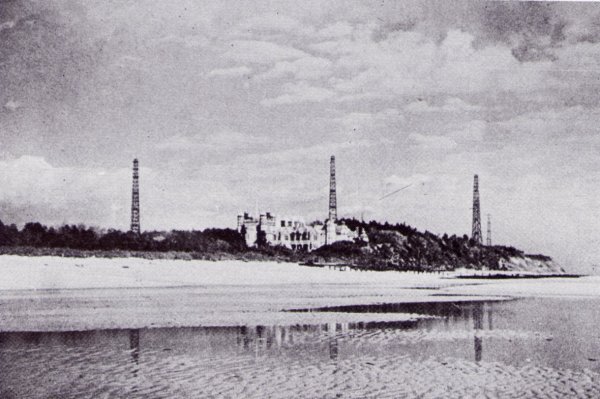

Bawdsey Manor became an exceedingly busy place. The fast growing staff worked hard, often well after midnight. But there was also time for a swim before lunch or a game of cricket before dinner. The stimulating atmosphere has been compared to that of Oxford or Cambridge. Enormous 80 meter high antennas were erected and the white tower was converted in a laboratory. As the construction of the Radar stations proceeded, another vital component was added to the Radar scheme. The Tizard Committee, alert as always of the problems at hand, pointed out that it was not sufficient just to get a warning of approach of enemy aircraft. There was a need to coordinate the information coming from different stations, for decisions to be taken on which squadrons should be deployed against the enemy, and for precise instructions to be given to the fighters. When the final air defence system came into being it was as a result - in contrast the Radar systems in other countries - a fully integrated one. It consisted of the air warning network, a filtering process for assessing and collating the data and an efficient communications system for alerting the fighters and guiding them to their targets. The performance of the stations was so good that before the end of 1936 plans were made to extend the air warning network to a chain of 19 stations along the whole of the east coast, later to be extended by another 6 stations to cover the South Coast. The Battle of Britain could never have been won without “Home Chain” as the Radar system was called by then. It was a tribute to the genius of Tizard who foresaw the problem, and to Watson-Watt who provided the solution.

Figure 2.7 Bawdsey Manor, the headquarters of Radar research in Britain from 1936 until the outbreak of the war in 1939.

| to top of page | back to homepage |

The success of the integrated Home Chain Radar system prompted Tizard and his committee to start thinking about the next steps to be taken. Tizar argued that as soon as the RAF would have a better chance of repelling the German Bombers at daytime, they would undoubtedly increase their night bombing efforts. At night, the Home Chain Radar system was much less effective: the range at which an enemy aircraft could be seen was less than 300 m, and it was clearly beyond the capability of the Home Chain system to guide a fighter that accurate to its target. What was required was a Radar small enough to be installed in a night fighter, which would enable the pilot to close a range of 4 or 5 miles down to the required 150 to 300 m on his own initiative.

Figure 3.1 Left, Bawdsey Manor anno 2008 the red tower with the white tower behind it. Right, the transmitter towers at Bawdsey of the Home Chain system during World War II.

No one was very optimistic about the feasibility of such a miniature Radar system at that time. The original wavelength of the Radar system during the first trials in Orfordness was 50 meters (6 MHz). Watson-Watt had chosen this wavelength on the assumption that the best reflected signals from an aircraft would be on the wavelength at which the wing span acted as a dipole resonator. Since many bombers of that period had a wing span of about 25 meters, they would thus resonate at 50 meters wavelength. Due to interference with commercial traffic this wavelength was later reduced to 26 meters, and again later to the final wavelength of 10 to 13 meters. To achieve a reasonable antenna size for airborne systems however, the operating wavelength would have to be reduced to one or two meters (150-300 MHz), which was clearly beyond what was possible at that time. In addition, the pulse width had to be reduced from 20 to 1 microsecond, which was strictly unknown territory. On top of that the size and weight of the system had to be such that it would fit into an airplane.

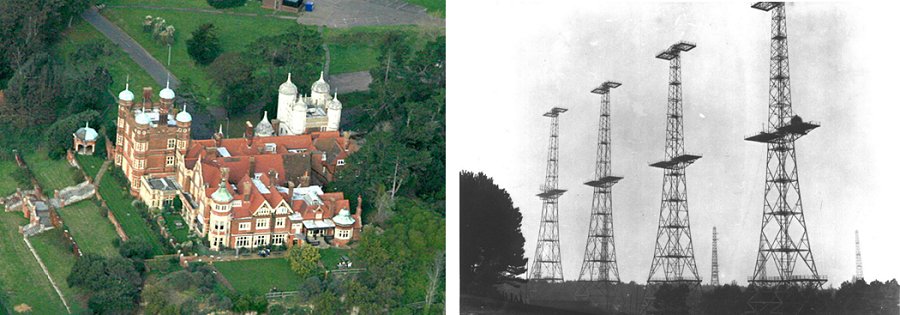

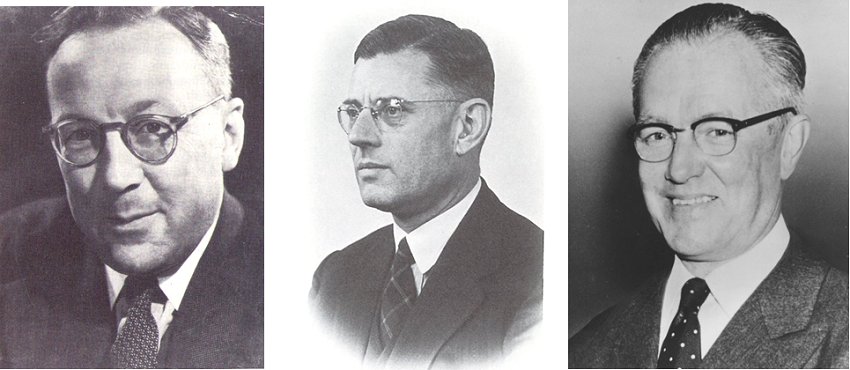

Figure 3.2 Left A.G. Touch, middle ‘Perc’ Hibbert and right Keith Wood members of the original airborne Radar team.

Despite all the obvious difficulties Bowen managed to persuade Watson-Watt to embark on the airborne project around mid-1936. A small team was formed consisting of Bowen, Gerald Touch, Sidney Jefferson and Perc Hibberd (Fig. 3.2). One of the most important designs restrictions for the airborne Radar system was that the antenna should not cause too much aerodynamic drag, eliminating any type of long wire antenna. The most that could be tolerated was a stub antenna, half a meter or so in length, demanding a wavelength of about a meter (300MHz). This was on edge of what was possible in 1936. In his book “Radar Days” Bowen recollects a striking story from this period:

| ‘About this time, we stumbled on a gem beyond price; it was a tuned radio frequency (TRF) receiver designed by EMI for their projected television service from Alexandra Palace. It operated on a frequency of 45 megacycles per second or a wavelength of 6.7 meters and had a bandwidth of 1 MHz. It had 7 or 8 valves on a chassis about 3 inches wide by 15 or 18 inches long. I cannot quote the sensitivity, but it was far and away better than anything which had been achieved in Britain up to that time. This receiver formed the basis of our whole airborne Radar experimental programme for the next two years. I have never discovered exactly how we came by that particular set, but I suspect it came through the back door of the EMI Company; they had no idea of the use to which it was being put. During the next few years we made strenuous efforts to obtain additional receivers of the same design; but although the negotiations were conducted by Watson-Watt himself, he failed to produce another chassis. This account being written some 50 years later and it is difficult to believe that until the end of 1938, when we had two Ansons and the Battles as experimental aircraft and at least a number of Radar transmitters to share between them, we only had the one receiver chassis which was switched from one aircraft to the other as occasion demanded!’ |

Figure 3.3 Left, the Western Electric 316A “giant Acorn” or “door-knob” valve that was used in the first 6.7 meter airborne Radar transmitter. Middle, the 4304 CB (alias NT58, VT62, CV2761). Right, an RCA Acorn tube that was used in the down converter of the first 1.5 meter Radar system.

Rapid progress was being made in the airborne group however, and by March 1937 Perc Hibbert had built a 6.7 meters transmitter using two Western Electric 316A “giant Acorn” or “door-knob” valves as they were called. Although the output power could not have exceeded a few hundreds of Watt at a pulse length of 2 to 3 microseconds and a repetition frequency of a 1000Hz, it enabled the first fully airborne Radar system with a detection range of three to four miles. The system was installed in the Heyford, and in March 1937 the first ground objects were detected during a trial flight. This success generated considerable enthusiasm and Bowen and his team were given free choice for an aircraft especially devoted to the airborne Radar program. They selected an Anson, and much to their surprise they were allocated not one, but two aircraft.

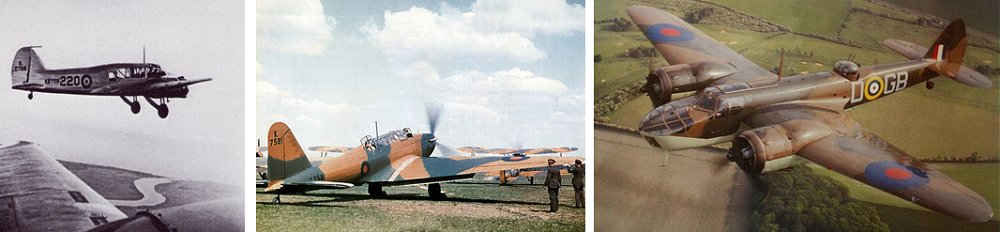

Figure 3.4 Left, the Avro Anson K8758 aircraft acting as target during the initial airborne Radar experiments photographed from the Radar equipped K6260. Middle, a Fairey Battle. Right, the Blenheim MK IV.

During the summer of 1937 Bowen and his team worked hard getting the wavelength of the airborne Radar system down. By converting the transmitter to push-pull operation using two 316As, they managed to reduce the wavelength to 1.25 meters at a pulse width of one microsecond. Below 1.25 meters the output power of the transmitter dropped sharply. Touch rebuilt the receiver to operate at 1.25 meter by converting it to a super-heterodyne, using acorn valves from RCA in a mixer stage ahead of the one and only EMI chassis. The latter became the IF-amplifier, still on its design frequency of 45 MHz. It is interesting to note that in this way the transmit frequency of the original Alexandra Palace television system of 45 MHz became the standard IF frequency for all airborne and many other Radar systems for the remainder of the war, and probably a long time afterwards! The 1.25 meters system was installed in one of the Ansons and on the first flight targets were detected. It was soon found that a small increase in wavelength to 1.5 meters (200 MHz) greatly increased the sensitivity. This was the moment that the 200 MHz Radar was born, which was to remain the most widely used frequency band for airborne, ship borne and ground based Radar during the whole of the war [8].

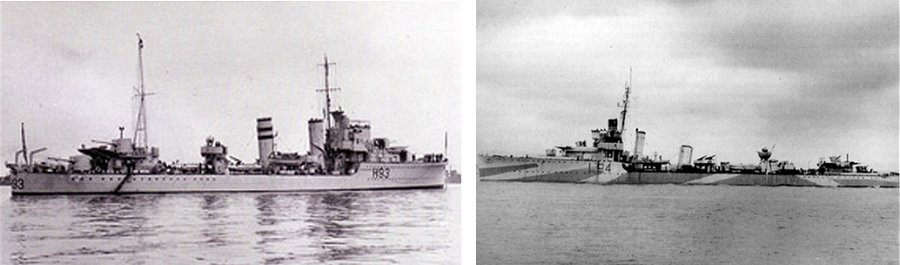

A few days after the successful demonstration of the 1.5 meter system, Bowen and his team were invited to take part in an exercise that was planned starting on the 4th of September (1937). The goal of the exercise was that Coastal Command would search for the British Fleet in the North Sea. The fleet would follow a zigzag coarse and, naturally would try to avoid discovery. A total of 48 aircraft, none equipped with Radar of course, since that was obviously still in development and highly secret, were scheduled to search for them. Bowen and his team in the Radar equipped Anson managed to find the fleet within a few hours. They were then overtaken by bad weather. With the help of their Radar they managed to find their way back safely. When they returned they learned that they indeed had spotted the fleet in the right location but also that the exercise had been cancelled due to bad weather. It was something of a landmark in the history of airborne Radar. They had found the fleet under conditions which had grounded Coastal Command, they had detected other aircraft for the first time with a self-contained Radar and, simply by returning home in one piece, had demonstrated some of its navigational capabilities. From then on their path was much easier and they were besieged for flight demonstrations, none the least for Sir Henry Tizard, for whom this was a particular nostalgic occasion.

Klick here to hear Keith Wood’s verbal account of the exercise.

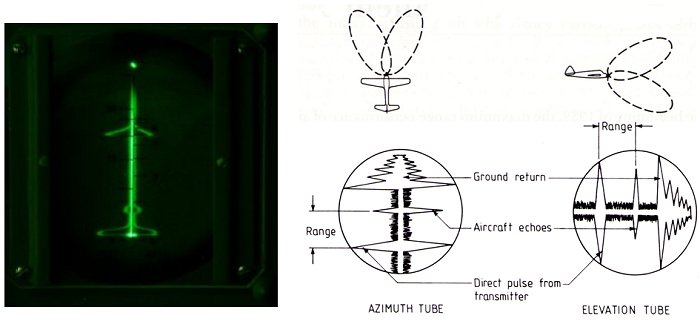

Figure 3.5 In the first Air Interception Radar systems, the location of the bearing and the elevation of the enemy plane was indicated on two separate oscilloscope screens.

By the end of 1937 the team worked on two projects – Air to Surface Vessel (ASV) and Air Interception (AI). Much of 1938 was actually spent on the development of the ASV system. During 1938, the principal instrumental improvement in the airborne Radar system was the substitution of Western Electric 4304 valves for the ‘giant acorns’ in the transmitter. They gave an increase in peak power to 1 or 2 kilowatts. In the course of 1938 the Anson aircrafts, which were becoming rapidly obsolete, were replaced by two Fairy Battles. Towards the end of 1938 it became clear that AI and ASV would soon come into service and the problem of how to supply them with electrical power became an important consideration. The standard RAF generator at that time was a 500 watt, 25 DC machine. Most of this power was taken up by the existing aircraft equipment and on top of that the Radar equipment was going to require such a variety of voltages that an alternating supply was essential. A way out was to fit an AC generator on the spare generator shaft of the second engine. The story how this generator came into service is an excellent example of prewar decisiveness and pragmatic engineering [10].

Towards the beginning of 1939 it became clear that the ranging performance of the air-to-air Radar was more or less adequate. The most urgent task therefore was to add directional information in azimuth and elevation. After considering a number of alternatives it was decided to indicate bearing and elevation in the way depicted in Fig. 3.5. In total four antennas were used, two with overlapping antenna patterns for azimuth and two for elevation. The data was represented on two CRT tubes. The image on the CRT tubes showed the direct pulse from the transmitter and, at the far end, the reflection from the ground (the so called Xmas tree). The simulation on the left gives an impression of how an approaching aircraft would be observed by the Radar operator. A mechanical switch designed by Touch was used to multiplex the receiver and transmitter over the four antennas of the aircraft.

Towards the beginning of 1939 it became clear that the ranging performance of the air-to-air Radar was more or less adequate. The most urgent task therefore was to add directional information in azimuth and elevation. After considering a number of alternatives it was decided to indicate bearing and elevation in the way depicted in Fig. 3.5. In total four antennas were used, two with overlapping antenna patterns for azimuth and two for elevation. The data was represented on two CRT tubes. The image on the CRT tubes showed the direct pulse from the transmitter and, at the far end, the reflection from the ground (the so called Xmas tree). The simulation on the left gives an impression of how an approaching aircraft would be observed by the Radar operator. A mechanical switch designed by Touch was used to multiplex the receiver and transmitter over the four antennas of the aircraft.

Following the Air Ministries decision to adopt the Benheim as a night fighter, an extensive series of flight trials using Blenheims K7033 and K7034 as night fighter and target respectively was began. In July 1939 things were rapidly coming to a head in Europe, and Bowen and his team had to start thinking about producing airborne Radars in quantities. Vickers was selected as a contractor for the transmitter but the receiver possed to be a greater problem. Unbelievably, Bowen and his men at that time still only had one receiver: the original 45 MHz EMI chassis. The most logical choice for a contractor would obviously have been EMI but Bowen was under some kind of restraint not to talk to them. Instead Cossor, who had built receivers for the Home Chain system, was asked to produce some 45 MHz receiver samples. They turned out to be a complete failure. They did not come within a tenth of the required sensitivity, and their weight was astronomical, weighing more than their complete system at that time. The receiver was rapidly becoming a problem!

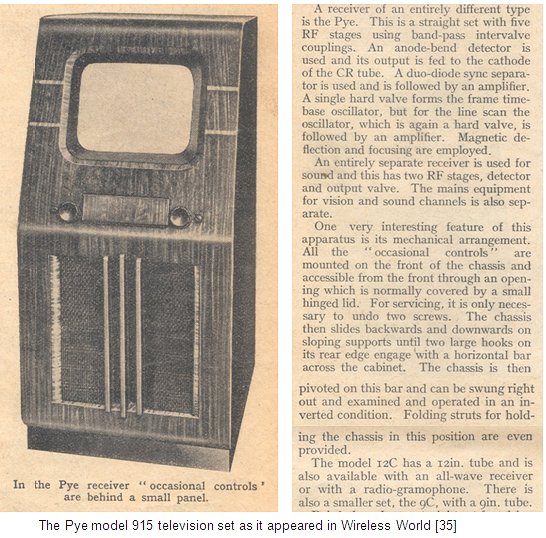

Quite by chance in April or May of 1939, Bowen heard some encouraging news from Edward Appleton, his old Professor at King’s College and now the Jacksonian Professor of Physics at Cambridge. He told Bowen that the Pye company, still hoping that there would be a television industry in Britain, had set up a production line for 45 MHz chassis and had actually made a trial run! Bowen immediately went to Cambridge to see B.J. Edwards, the Technical Director of Pye, and was rewarded with a remarkable sight – he had scores of TRF chassis of just the type that they were looking for! The chassis was built around a revolutionary new tube, the EF50.

| to top of page | back to homepage |

What makes the EF50 special is that it was the first all-glass valve that was designed in such a way that it could be produced in very high volumes at low-costs. People have talked about the “invention of the EF50,” but invention is not really the correct term to be used here. The EF50 was merely one of the milestones in the development process of radio tubes that started in the mid thirties, and eventually ended in the miniature Noval radio tubes we are all so familiar with. After the invention of the triode, the manufacturers of incandescent light bulbs were the obvious candidates to take this new invention into mass production. Like the incandescent light bulb, the radio tube also required a vacuum glass envelope, a filament and wires sealed into the glass envelope. By the end twenties highly automated production lines for the production of incandescent light bulbs had been developed, and it was only natural that those machines and techniques were adopted for the fabrication of radio valves.

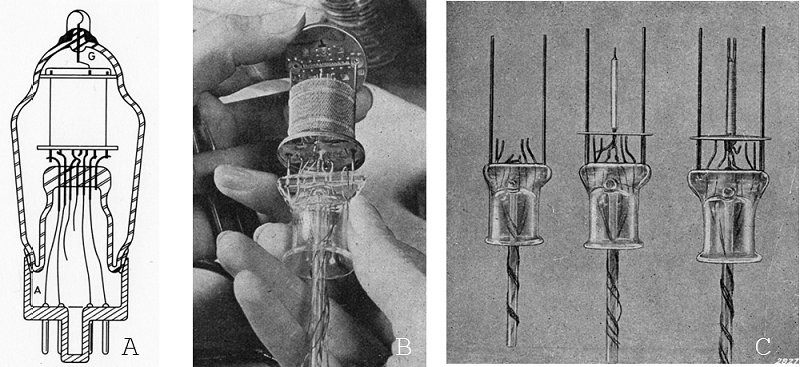

Figure 4.1 The glass pinch which formed the base for tubes developed in the twenties and thirties.

These early radio valves were all based on what is called “a pinch.” The pinch is the central part of the tube were the lead-in wires are fed through and which mechanically supports the electrode system. Figure 4.1 schematically shows a cross-section of a valve manufactured in a pinch based technology and it shows some photographs of glass pinches together with the glass exhaust tube.

The fabrication sequence of the pinch based tubes starts with the cutting of pieces of glass tube. On one side of the glass tube a small collar is formed by heating the edge and pressing the tube against a conical shape (Fig. 4.2b). Next the other side of the glass tube is turned into a more or less rectangular opening by heating it and opening it with a V-shaped pair of pliers (Fig. 4.2e).

Next the electrode bases and the rods that support the electrode assembly, together with the glass exhaust tube are placed in a fixture/mold which exactly positions these parts with respect to each other (Fig. 4.3a). The lead-in wires are already attached to the electrode bases at this point. The pre-formed glass pinch is placed, top side down, over this assembly. The glass pinch is heated at the narrowest point, and closed by pressing with an anvil (Fig. 4.3c). A small opening to the exhaust tube is formed by heating the glass pinch with an extremely sharp pointed flame, while at the same time some compressed air is applied to the exhaust tube (Fig. 4.3d). This will form a glass bubble which at a certain point will burst open forming the opening (Fig. 4.3e). The whole fabrication sequence is beautifully recorded for posterity by OSRAM.

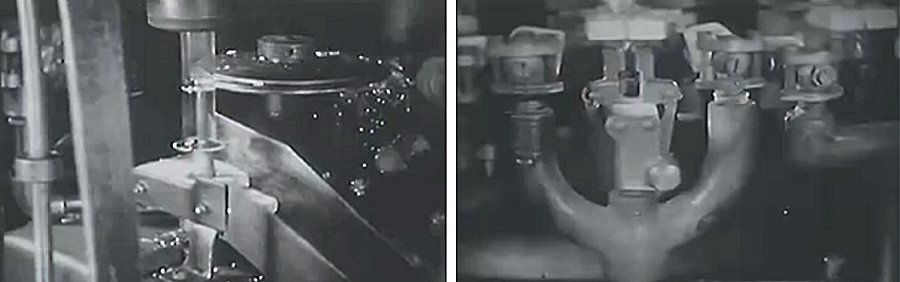

Figure 4.4 Cutting of glass tubes for the pinch (left) and sealing of the electrode wires in the pinch with the anvil (right).

The pictures are stills from the OSRAM movie Manufacture of Modern Radio valves, 1930.

The pinch technology, borrowed from incandescent light bulb manufacturing, made it possible that radio could be taken quickly into high volume production. However, within a few years also the limitations of the pinch technology became apparent:

Figure 4.5 Metal valve envelopes developed in the thirties as an alternative for pinch based valves.

Figure 4.5 Metal valve envelopes developed in the thirties as an alternative for pinch based valves.

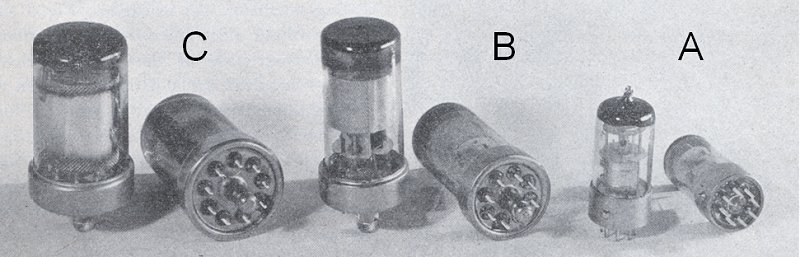

To find a way to make radio valves better suitable for high frequency operation, valve manufacturers in the thirties came up with the concept of the metal valve. The first one in this series was the CATKIN (diminutive of Cooled Anode Transmitter). It was developed by G.E.C. in Britain and was derived from metal transmitter tubes, in which the metal envelope was used as the anode connection (Fig. 4.5A). The CATKIN was expensive to manufacture and it was not a success. The CATKIN was only manufactured for a few years.

In 1934 G.E.C. in the US introduced another metal tube concept (Fig. 4.5B). It consisted of a metal base plate (the heather) into which “Fernico” (iron-nickel-cobalt) eyelets, each one containing a hard-glass bead with a lead-in wire, were welded. The lead-in wires were welded to pins which were pressed in a Bakelite bottom plate in octal-base configuration. After the electrode system was mounted, the iron envelope was welded to the header by means of a very heavy projection welder. Klaas Rodenhuis vividly remembers the enormous “bang” produced by these welding machines when they welded the envelope to the header. The tube was exhausted through a metal tube welded to the header. Philips second-sourced these valves in high volumes for the foreign market straight through the war. The valve did have lower parasitic capacitances and inductances, but was also expensive to manufacture.

In 1935 R.C.A. developed a variant of this model of which it was hoped that it would be less expensive as the construction described in the previous section. In this tube the metal header was replaced by a glass plate with sealed-in lead wires (Fig. 4.5C). Both this tube, as well as the previous tube used a top control-grid connection. Everybody was so used to the top grid connection that another construction was simply not considered. Telefunken surprises everybody, when in 1937 they introduce a single ended all-metal valve, the so called “Stahlröhre” (Fig. 4.5D). In this valve all connections were located on the bottom side of the tube, which obviously meant a big advantage for set-makers. The electrode system in this tube was horizontally, which implied a better mechanical stability, and less microphony. It did however imply a rather large tube diameter which reduced the inter-electrode capacitances, but didn’t help in reducing the size of receivers. In inter-electrode capacitances were further reduced by the way the pins were grouped (in groups of 3 and 5 opposite of each other) and by the placement of metal screens between the electrodes in the tube. Technically the tube was superior, but the implementation was again expensive because of the use of “Fernico” eyelets.

| to top of page | back to homepage |

Philips entered the radio-tube arena relatively late. In most European Countries the First World War had been a driving force behind the development of a solid industrial base for these new components. But, since Holland was neutral during the First World War, Philips had deployed little or no initiatives in that direction. Gerard Philips, the founder of Philips, didn’t think much of these new gadgets. As far as he was concerned, they were a plaything for the military and the post offices,

and they held no promise for high volume production, and that was just the thing Philips had specialized in.

and they held no promise for high volume production, and that was just the thing Philips had specialized in.

Philips was founded by Gerard Philips in 1891. Gerard came from a family of entrepreneurs. His father was a banker, but he also ran a tobacco trading company, a coffee roasting company a cotton mill and he owned a gas factory! Gerard’s interest was however more in technology. In 1883 he graduated from the faculty of Mechanical Engineering in Delft, and a few years later supervised the installation of electrical light on the Dutch steamer “Prince Willem of Orange” in Glasgow. During this trip to Scotland he came into contact with the famous physicist Thomson. He stayed with Thomson for a year, and during that period learned everything there was to learn about electricity. Back in Holland, Gerard developed

his own technology for making light-bulbs. With financial support from his father he bought a small factory in the picturesque country village of Eindhoven, and in 1891 the private partnership “Philips & Co” is founded.

his own technology for making light-bulbs. With financial support from his father he bought a small factory in the picturesque country village of Eindhoven, and in 1891 the private partnership “Philips & Co” is founded.

The first years are not easy for Philips. Fierce competition amongst light-bulb manufacturers forces Gerard to lower prices and increase production. Gerard then makes a clever move, being himself more an engineer than a business man, he makes his younger brother Anton a co-director responsible for the business aspects of the company. Together they form a golden pair in which Anton tries to sell more lamps than his brother can produce and vice versa. Business thrives, and across the road of the old factory new immense buildings are erected and Philips grows at an enormous pace. In 1900, less than 10 years after its foundation, production reaches 3 million light bulbs a year, making Philips one of the largest light-bulb manufacturers in the world!

By 1910 the number of employees has reached 2000. Philips is now the largest private employer in Holland. Then, an unexpected event upsets the otherwise so peaceful life of the two brothers. Within a time frame of a few years, General Electric introduces two innovations: ductile “pulled” tungsten filaments and gas filed light bulbs. The engineers in Eindhoven are completely taken by surprise, and Philips is forced to buy the required equipment and licenses. The technology is quickly introduced, and within no time the Philips Argon filled lamps even prove superior over the lamps of G.E.

Gerard and Anton realize that the innovations from General Electric were the result of fundamental physical research. In the mean time, the number of employees of Philips has grown to over 3500, and the company is about to celebrate its 25th anniversary. The brothers recognize that for the future of the company it is vital that Philips embarks on its own fundamental research program, so an advertisement for a scientist with a PhD in Physics is placed in the newspapers. The scientist will be responsible for the setting up of a research organization that will make Philips less dependent on patents from others, and that will generate new ideas for products.

Among the applications they receive is one from Gilles Holst. Holst did his PhD under professor Kamerlingh Ohnes, who ran the low temperature lab in Leiden. Ohnes was the first to liquefy Helium and to discovere super conductivity in mercury for which he received the Nobel Prize for Physics in 1913. After a short interview Holst is hired, and he sets about organizing his lab. In 1914 Philips Research, or the “NatLab” as it is known in Eindhoven, is founded. “NatLab” being an abbreviation for “Natuurkundig Laboratorium,” or Physics Laboratory.

Among the applications they receive is one from Gilles Holst. Holst did his PhD under professor Kamerlingh Ohnes, who ran the low temperature lab in Leiden. Ohnes was the first to liquefy Helium and to discovere super conductivity in mercury for which he received the Nobel Prize for Physics in 1913. After a short interview Holst is hired, and he sets about organizing his lab. In 1914 Philips Research, or the “NatLab” as it is known in Eindhoven, is founded. “NatLab” being an abbreviation for “Natuurkundig Laboratorium,” or Physics Laboratory.

Holst starts his new job by investigating the state-of-the-art in electrical lighting and all of the aspects related to it. The results of his study are published in a small book titled “Lichtbronnen en hare eigenschappen” (“electrical light sources and their properties”). He concludes that it was already too late to carry out fundamental research on incandescent light. The time was ripe to work on a new source of electrical light: the discharge tube. Discharge tubes were still something very new and fancy in 1914. Even the glow discharge itself was a phenomenon which was still poorly understood at that time. Philips Research would play an enormous role in the understanding and application of gas-discharges. The Tungsten Arc Lamp, the high pressure mercury and sodium lamps, the fluorescent light tube, cathode sputtering, impurity gettering, the theory on discharges in gas mixtures are but a few of the innovations originating from Philips Research in the period between the two World-Wars.

Then, on a quiet summer evening in august 1917, in the middle of the First World war, a small German Seaplane makes an emergency landing in Dutch territorial waters in the north of Holland. When the Dutch military officials salvaged the plane, they discovered something that surprised them: a radio receiver. As it turned out, it was quite an advanced radio because it used two EVN 94 vacuum tubes from Telefunken, switched in cascade! Understanding the potential of it for modern warfare, and facing an uneasy post-war relation with Belgium, the military officials commissioned Captain De Blauw to construct a number of similar radio sets. For the necessary radio tubes Captain De Blauw naturally turned to the largest light-bulb manufacturer in Europe, Philips. So Captain De Blauw sets about to make an appointment with Gillest Holst. As it happens, this is the start of a remarkable chain of events. Holst politely receives him in Eindhoven and listens to his story and request for help in the fabrication of radio tube samples. Undoubtedly, Holst must have been fascinated by these new gadgets and the physics that made them work. However, Holst also knew that Gerard Philips considered radio and radio-tubes a plaything for the military, and something with little practical and commercial value! Holst finds it difficult to do something that might upset his boss only three years after being appointed, and although tempted, he reluctantly turns down Captain De Blauw’s request for help. Disappointed, Captain De Blauw turns to one of the dozen or so other light-bulb manufacturers in Holland: “de Metaaldraadlampenfabriek” in Utrecht. They are quite willing to help him, and a few weeks later the first radio-tubes manufactured in Holland are delivered to Captain De Blauw.

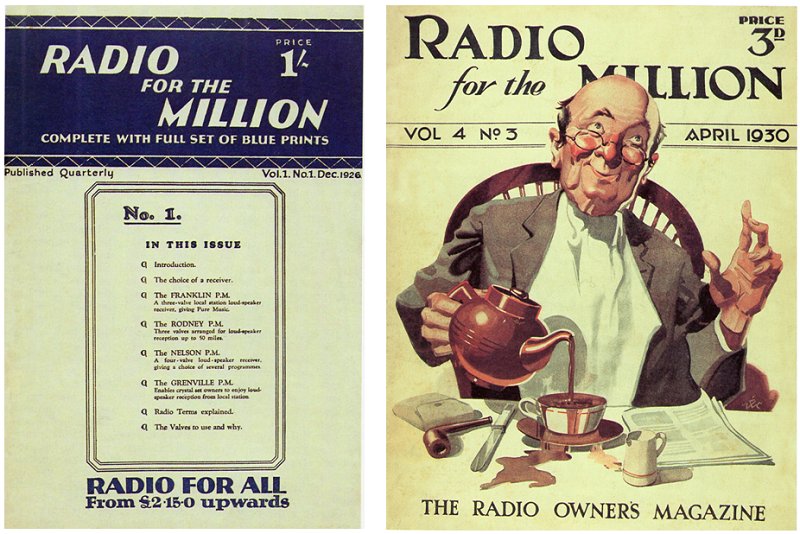

In the development of radio into something as we know it today, radio amateurs played an important role. The ending of the War, during which listening to radio was forbidden, gave an enormous impulse to the popularity of radio amateurism. But what to listen to? Most radio transmissions where in Morse code originating from post offices, news agencies and of course the odd spy. Transmission of speech, let alone music, was practically unheard of. This was something that troubled the

Dutch radio pioneer “Hanso Henricus Schotanus à Steringa Idzerda,” a long and difficult to pronounce name, even to Dutch standards. Idzerda, was an electrotechnical engineer and a keen radio amateur. Already during the war Idzerda run a small wireless instruments and consultancy agency from The Hague, mainly servicing the military. After the war, Idzerda changed the name of his company to “Nederlandsche Radio-Industrie.” It is his dream to build and sell radio receivers to ordinary civilians. Since there was basically nothing to listen to, he intends to provide the buyers of his radio sets with interesting programs consisting of news, music and radio plays transmitted from his company in The Hague.

Dutch radio pioneer “Hanso Henricus Schotanus à Steringa Idzerda,” a long and difficult to pronounce name, even to Dutch standards. Idzerda, was an electrotechnical engineer and a keen radio amateur. Already during the war Idzerda run a small wireless instruments and consultancy agency from The Hague, mainly servicing the military. After the war, Idzerda changed the name of his company to “Nederlandsche Radio-Industrie.” It is his dream to build and sell radio receivers to ordinary civilians. Since there was basically nothing to listen to, he intends to provide the buyers of his radio sets with interesting programs consisting of news, music and radio plays transmitted from his company in The Hague.

To realize his ambition, Idzerda needs a steady supply of radio tubes. So naturally he first turns to the “Metaaldraadlampenfabriek” in Utrecht, who a year earlier had provided Captain De Blauw with radio tubes. They are however unable to supply him the tubes because they have signed a “contract of secrecy” with the Ministry of War. Idzerda now turns his hope to Philips. One way or the other, he is able to convince Gerard Philips himself of the economical significance of his vision, because Gerard orders Holst and his staff to fabricate the tubes according to Idzerda’s specifications. The tubes are advertised under the name “IDEEZET-lamps,” and in an advertisement in “Radio Nieuws” of January 1919, Idzerda proudly announces that already 1450 tubes have been sold.

Following instructions from Idzerda, Philips also manufactures several transmission lamps. In August that year the first transmissions take

place from Idzerda’s radio station, which transmits with less than 20

watts of RF power, and is heard within a radius of 60 km around “The Hague.” On the 5th of November 1919, Idzerda places an advertisement in the news papers, announcing a “Soirée-Musicale” for the following Thursday between eight and eleven. It is a world-premiere, since it is the first radio broadcast which is preceded by an announcement of the program in the news papers. The event is internationally recognized as the birth of public radio broadcast.

watts of RF power, and is heard within a radius of 60 km around “The Hague.” On the 5th of November 1919, Idzerda places an advertisement in the news papers, announcing a “Soirée-Musicale” for the following Thursday between eight and eleven. It is a world-premiere, since it is the first radio broadcast which is preceded by an announcement of the program in the news papers. The event is internationally recognized as the birth of public radio broadcast.

In the following years, the fabrication of receiver tubes remains a relatively insignificant activity compared to the fabrication of light-bulbs. This is however not the case for X-ray tubes and transmission tubes. There, a stroke of luck places Philips in ideal position. In the early years of 1920, Holst visites one of the glass-blowing factories where light-bulbs are being fabricated. He notices that some of the glass-blowers have more difficulty in removing the light-bulb from their blow-pipe than others. He finds this intriguing, and decides to investigate the cause. He discovers that when the blow-pipes are made from a particular chromium-iron alloy, they have an almost perfect adhesion and thermal match to the glass. The story goes that Holst after founding the cause, immediately rushed to the patent department and got the discovery patented. The patent indeed proved of immense value to Philips. It allowed them to make powerful transmission tubes with a water cooled anode and the so called “METALLIX” X-ray tube which was partly made from metal to reduce stray radiation.

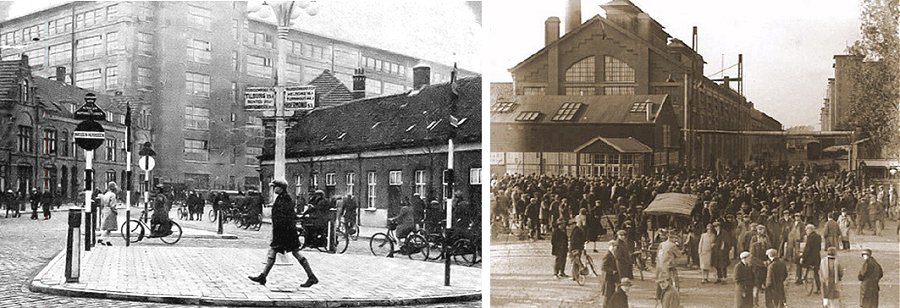

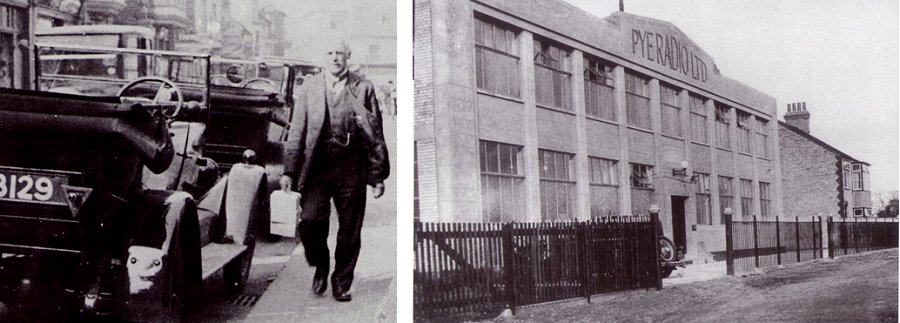

Finally, in 1923 the idea of public radio broadcasts really sets of and the demand for radio tubes explodes. Tube manufacturers are hardly able to supply the demand, and Philips quickly changes gears. After the fabrication of light-bulbs was moved to a location just outside the center of Eindhoven, the huge plant on “de Emmasingel” (Fig. 6.2) became available for the production of radio tubes. Whereas in 1921 only 320 radio tubes were fabricated in total, in 1923 the production had increased to 1000 tubes a day!

In 1922 Gilest Holst hires the Dutch Scientist “Balthasar van der Pol” to head the research and development of radio tubes. Van der Pol who had worked under Thomson and

Fleming in England was a brilliant scientist who already in 1917 in “Wireless World” had featured in an article “Personalities of the Wireless World.” Van der Pol’s first job was to work on oxide coated filaments. So far just normal tungsten filaments had been used in radio tubes. To get sufficient electron emission, these filaments had to be

heated white hot, so that these tubes were cold “hel branders” or “bright burners.” In fact the radios in those days gave as much light as sound. To save batteries and tubes, van der Pol and his staff developed barium and thorium coated filaments. The low work function of these materials strongly increases the electron emission of the filaments, so that they could burn at lower temperatures. Philips successfully introduced these tubes in 1924 under the brand name “Miniwatt.” At that moment already 9 out of the 16 researchers at Philips were working on radio tubes.

heated white hot, so that these tubes were cold “hel branders” or “bright burners.” In fact the radios in those days gave as much light as sound. To save batteries and tubes, van der Pol and his staff developed barium and thorium coated filaments. The low work function of these materials strongly increases the electron emission of the filaments, so that they could burn at lower temperatures. Philips successfully introduced these tubes in 1924 under the brand name “Miniwatt.” At that moment already 9 out of the 16 researchers at Philips were working on radio tubes.

In 1924 Bernard Tellegen joins the radio tube research group of van der Pol. He is then 24 years of age and has only just graduated. He was put on a very practical problem: due to new safety regulations, the anode voltage in radio receivers was limited to less than 250V. At these low

voltages it was difficult to generate enough output power for a loud speaker with a simple triode. The triode had namely two serious drawbacks. First of all it didn’t behave like a current source, in other words, the anode current not only increased with increasing grid voltage, but also with increasing anode voltage. This seriously limited the maximum amplification and the output power of the tube. At the same time there was a strong capacitive coupling between the anode and the grid. This Miller capacitance limited the high frequency operation. In 1915 a remedy to these drawbacks was found by Walter Schottky. By inserting a screen grid in between the control grid and the anode, which was held at a constant high potential, the anode potential is effectively screened from the control grid. In its hybrid form this arrangement is of course still widely used, and is known as a cascode. The tetrode as is was called, represented an enormous improvement, but in its turn also had a drawback. Electrons accelerated by the high potential on the screen grid bombarded the anode and generated secondary electrons. Unfortunately, in operating conditions where the anode voltage is low compared to the screen grid, these secondary electrons are accelerated to the screen grid, causing a current flow in the opposite direction. The result is a kink in the anode current characteristics. The problem especially occurred in output stages where the output voltage would swing between supply voltage and almost zero. Tellegen studied the problem, and came up with a very simply solution. He simply inserted a third grid between the screen grid and the anode. This brake- or suppressor grid was

voltages it was difficult to generate enough output power for a loud speaker with a simple triode. The triode had namely two serious drawbacks. First of all it didn’t behave like a current source, in other words, the anode current not only increased with increasing grid voltage, but also with increasing anode voltage. This seriously limited the maximum amplification and the output power of the tube. At the same time there was a strong capacitive coupling between the anode and the grid. This Miller capacitance limited the high frequency operation. In 1915 a remedy to these drawbacks was found by Walter Schottky. By inserting a screen grid in between the control grid and the anode, which was held at a constant high potential, the anode potential is effectively screened from the control grid. In its hybrid form this arrangement is of course still widely used, and is known as a cascode. The tetrode as is was called, represented an enormous improvement, but in its turn also had a drawback. Electrons accelerated by the high potential on the screen grid bombarded the anode and generated secondary electrons. Unfortunately, in operating conditions where the anode voltage is low compared to the screen grid, these secondary electrons are accelerated to the screen grid, causing a current flow in the opposite direction. The result is a kink in the anode current characteristics. The problem especially occurred in output stages where the output voltage would swing between supply voltage and almost zero. Tellegen studied the problem, and came up with a very simply solution. He simply inserted a third grid between the screen grid and the anode. This brake- or suppressor grid was

connected to a low potential e.g. the cathode. The suppressor grid simply pushed the secondary electrons back to the anode and all at once the disadvantages of the tetrode had disappeared. The pentode was a near ideal amplifying device with very high amplification and capable of delivering high output powers at relatively low voltages. Tellegen and Holst immediately applied for a patent on the 14th of December 1926. It turned out to be perhaps the most valuable patent of Philips ever. In 1932, little more than 10 years after the first samples were made in the research lab, Philips produced its 100 millionth’s radio tube.

connected to a low potential e.g. the cathode. The suppressor grid simply pushed the secondary electrons back to the anode and all at once the disadvantages of the tetrode had disappeared. The pentode was a near ideal amplifying device with very high amplification and capable of delivering high output powers at relatively low voltages. Tellegen and Holst immediately applied for a patent on the 14th of December 1926. It turned out to be perhaps the most valuable patent of Philips ever. In 1932, little more than 10 years after the first samples were made in the research lab, Philips produced its 100 millionth’s radio tube.

The popularity of radio increased explosively, and it had not remained unnoticed by Anton Philips that, whereas the price of a radio tube on average was 10 guilders, the price of a complete radio was about 200 guilders. So obviously making radio sets was a very profitable business. This, combined with the fact that Philips now had their hands on a superior radio tube, the pentode, made them feel confident enough to start thinking about producing radio’s themselves. For Philips in 1926 this was something of a revolution. So far Philips had been a component manufacturer. A radio was a system, and manufacturing a system would require a completely different approach! From the onset it was clear that the receiver had to be suitable for mass-production, it should be reliable, easy to use, of high quality and reasonably priced. Holst discussed the issue with Van der Pol. Van der Pol personally had no interest in the development of domestic receivers, although some members of his group were very active in such development. Holst understood the situation and rather than putting pressure on Van der Pol to turn his attention to something he disliked and possibly even despised, Holst asked Ekko Oosterhuis to ensure that a commercial radio set was developed

quickly. So Oosterhuis set up a “practical radio group” which got on with the job. The solution of Holst was exemplary for the style of management at Philips Research which was always aimed at creating a working atmosphere that would get the best out of people. For a time the group of Oosterhuis was in competition with the group of Van der Pol. The group of Oosterhuis concentrated on so called “Straight Receivers,” while Van de Pol’s group concentrated on “Heterodyne Receiver” configurations. Visits were paid to RCA in the US to study mass production. A thorough study was made on how something so complex as a radio could be made on a large scale with a high accuracy and yield by unskilled hands. The result was the 2501, in Holland nick-named “the loaf of bread.” Because of the high gain of the pentode, only three radio tubes were needed compared to four in radios from competitors. It was an enormous success. In 1927, 6000 receivers were built; in 1930 the production had already increased to half a million radios a year.

quickly. So Oosterhuis set up a “practical radio group” which got on with the job. The solution of Holst was exemplary for the style of management at Philips Research which was always aimed at creating a working atmosphere that would get the best out of people. For a time the group of Oosterhuis was in competition with the group of Van der Pol. The group of Oosterhuis concentrated on so called “Straight Receivers,” while Van de Pol’s group concentrated on “Heterodyne Receiver” configurations. Visits were paid to RCA in the US to study mass production. A thorough study was made on how something so complex as a radio could be made on a large scale with a high accuracy and yield by unskilled hands. The result was the 2501, in Holland nick-named “the loaf of bread.” Because of the high gain of the pentode, only three radio tubes were needed compared to four in radios from competitors. It was an enormous success. In 1927, 6000 receivers were built; in 1930 the production had already increased to half a million radios a year.

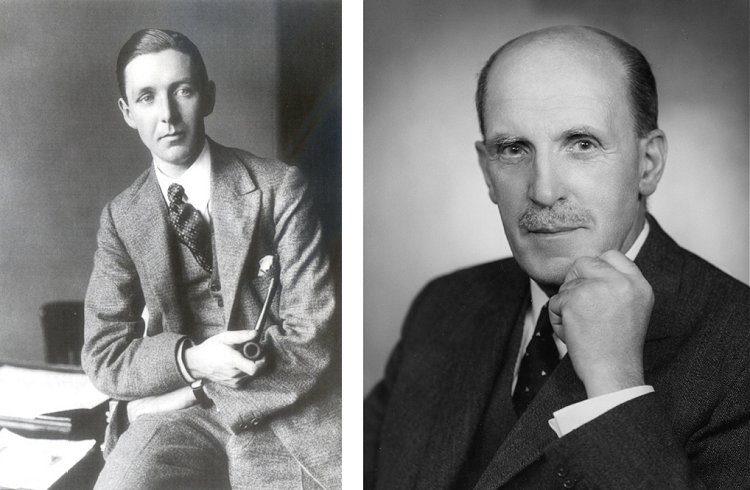

Johan Lodewijk (Hans) Jonker was born the 19th of March 1901 in The Hague. He studied electrical engeneering in Delft. For several years he headed the radio tube development group at Splendor, one of the smaller radio-tube manufacturers in Holland.

In January 1930 Jonker joins the radio research group of Ekko Oosterhuis at Philips Research. His fellow group members include: Tellegen, the theoreticians Strutt and Aldert van der Ziel who became famous because of his work on noise. By the time Jonkers joined Philips, the development and

production of radio tubes had grown to such an extent, that it was felt necessary to organize a separate radio tube development and application laboratory close to the production site. In this way the research groups could concentrate on more fundamental issues. Jonker is assigned to the task to organize this Lab, and on the first of November 1931 he leaves

Philips Research to found and organize “the Jonker Lab (Radio IV)” on the fourth floor of the radio tube production plant on the Emmasingel. This lab, which later became known as the “buizenlab” (the tube-lab), would become the birthplace of virtually all the tubes which would make Philips the largest tube manufacturer in Europe. On the 19th of September 1936 Jonkers returns to Philips Research to head the radio tube research group.

In January 1930 Jonker joins the radio research group of Ekko Oosterhuis at Philips Research. His fellow group members include: Tellegen, the theoreticians Strutt and Aldert van der Ziel who became famous because of his work on noise. By the time Jonkers joined Philips, the development and

production of radio tubes had grown to such an extent, that it was felt necessary to organize a separate radio tube development and application laboratory close to the production site. In this way the research groups could concentrate on more fundamental issues. Jonker is assigned to the task to organize this Lab, and on the first of November 1931 he leaves

Philips Research to found and organize “the Jonker Lab (Radio IV)” on the fourth floor of the radio tube production plant on the Emmasingel. This lab, which later became known as the “buizenlab” (the tube-lab), would become the birthplace of virtually all the tubes which would make Philips the largest tube manufacturer in Europe. On the 19th of September 1936 Jonkers returns to Philips Research to head the radio tube research group.

So the research and development of radio tubes took place on two places: the research lab at the Kastanjelaan and the tube-lab on the Emmasingel. Besides these, there were smaller development centers at the production sites. The group in the Research Lab concentrated on more fundamental

issues, such as secondary emission and the calculation of electron trajectories. Sometimes this resulted in innovative new tubes and concepts such as the EE50 secondary emission television tube and the

remarkable E1T Counting Tube,

which were not necessarily always a commercial success. In any case the research group was equipped with all the manufacturability capabilities to make their own radio tube samples. Especially the glass blowing and crafting capabilities were renowned. This department was headed by the eccentric Lemmens who contributed to many inventions, such as the powder glass tube bases, the L-cathode and high pressure gass-discharge tubes.

issues, such as secondary emission and the calculation of electron trajectories. Sometimes this resulted in innovative new tubes and concepts such as the EE50 secondary emission television tube and the

remarkable E1T Counting Tube,

which were not necessarily always a commercial success. In any case the research group was equipped with all the manufacturability capabilities to make their own radio tube samples. Especially the glass blowing and crafting capabilities were renowned. This department was headed by the eccentric Lemmens who contributed to many inventions, such as the powder glass tube bases, the L-cathode and high pressure gass-discharge tubes.

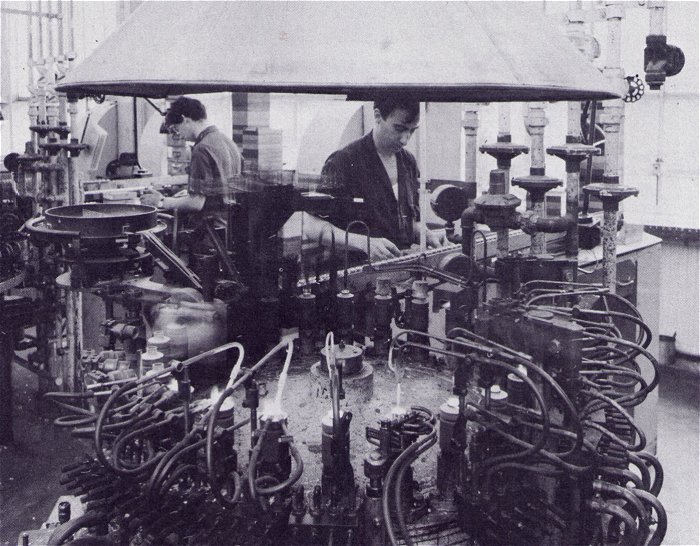

The tube-lab on the Emmasingel mainly consisted of two groups: the “Samples Department” (

Proefafdeling) of Dr. Frits Prakke and the “Electrical Laboratory” of ir. Gerrit Alma. The samples department could manufacture all the parts

necessary to make tubes, as well as small series of complete tubes. The department also developed new processes and provided assistance in

solving problems with fabrication processes. Cathode poisoning was such a reoccurring problem. After much research it was found that small contaminations, specifically traces of chlorine could “poison” cathodes, resulting in early failure. An interesting anecdote is that this knowledge was used to sabotage the production of tubes for the Germans during the Second World-War. A small cylinder of chlorine gas, hidden on the roof of the building, was used to add minute and undetectable traces of chlorine to the vacuum of the tube. Although these tubes tested ok when they left the factory, they failed after a short period of use. The scheme was never discovered by the Germans. In the electrical laboratory of Gerrit Alma, designs for new tubes were made which were subsequently fabricated by the sample department. When the tubes samples came back they were tested and evaluated. The electrical laboratory was also responsible for the development of the required test equipment and procedures. From early 1939 onward all development and manufacturing of radio tubes fell under Dr. Tromp, who played an important role in the flight of the EF50 to Brittain.

solving problems with fabrication processes. Cathode poisoning was such a reoccurring problem. After much research it was found that small contaminations, specifically traces of chlorine could “poison” cathodes, resulting in early failure. An interesting anecdote is that this knowledge was used to sabotage the production of tubes for the Germans during the Second World-War. A small cylinder of chlorine gas, hidden on the roof of the building, was used to add minute and undetectable traces of chlorine to the vacuum of the tube. Although these tubes tested ok when they left the factory, they failed after a short period of use. The scheme was never discovered by the Germans. In the electrical laboratory of Gerrit Alma, designs for new tubes were made which were subsequently fabricated by the sample department. When the tubes samples came back they were tested and evaluated. The electrical laboratory was also responsible for the development of the required test equipment and procedures. From early 1939 onward all development and manufacturing of radio tubes fell under Dr. Tromp, who played an important role in the flight of the EF50 to Brittain.

The fact that the samples department of Dr. Prakke and the electrical laboratory of ir. Alma were two separate organizations, resulted in many misunderstandings, frictions and delays. An example is the development of

the all-glass valve (see next section).

Shortly after the war Prakke was promoted to head the television picture tube development, and both departments are united under Alma. The sample department, now called the technology group was led by van Tol, a former production chief, who leads this group very skillfully.

Shortly after the war Prakke was promoted to head the television picture tube development, and both departments are united under Alma. The sample department, now called the technology group was led by van Tol, a former production chief, who leads this group very skillfully.

Again a few years later, the electrical laboratory is split into what we what now would call consumer devices: “Radio Receiver Tubes” (Radio Ontvangbuizen) headed by Dr. Dammers, and the group “Professional Receiver

Tubes” which was trusted to ir. Rodenhuis. In subsequent further reorganizations more groups were added to the radio lab of ir. Alma. Rodenhuis remembers Alma as a very pleasant and skillful boss. Later when Rodenhuis had become the director of the Philips tube division in Hamburg “Valvo”, he realized how much Alma had shielded his groupleaders from administrative burdens.

Tubes” which was trusted to ir. Rodenhuis. In subsequent further reorganizations more groups were added to the radio lab of ir. Alma. Rodenhuis remembers Alma as a very pleasant and skillful boss. Later when Rodenhuis had become the director of the Philips tube division in Hamburg “Valvo”, he realized how much Alma had shielded his groupleaders from administrative burdens.

The Professional Tube group of Rodenhuis was in a sense a continuation of the “short-wave” group he had led earlier. The group had in the mean time developed a triode that could generate signals up to 1 GHz (EC80, EC81). A new task for the group was the development of receiver tubes with an improved reliability and expectancy for industrial applications. After an analysis of the factors which

determine the reliability and life of normal tubes, the construction, materials and production processes were optimized resulting in significantly more reliable components. In particular it was found that small particles negatively influenced the reliability, so Rodenhuis was the first to introduce glove boxes for the production of tubes. These

Special Quality tubes can easily be recognized from the tube designation: E90CC and E82M are e.g. the Special Quality variants of the ECC90 and EM82. These tubes were used in measurement equipment, computers (e.g. for IBM who was their biggest customer) and transmitters. An example is the famous EC56 “lighthouse triode” which contained the L-cathode invented by Lemmens which was used in most of the European microwave link

transmitters and which was so robust that there was virtually no replacement market.

transmitters and which was so robust that there was virtually no replacement market.

The Radio Tube Application lab was at that time headed by Dr. Dammers, and was often referred to as the ‘Dammers Lab”. Dr Dammers who joined Philips in 1945, was the author of several books on radio tubes. His exceptional insight into radio tubes is legendary, and he was the father of many radio and television circuits. The tube application lab designed and tested application circuits for the tubes that Philips manufactured. In this way it bridged the gap between the tube development and production division and the television and radio set-makers, both in and outside Philips. Ir. Hoefgeest remembers how during a presentation in

Scandinavia of the Application Lab not less than 49 television set makers from Scandinavia alone attended (39 in Spain)! In 1963 the name was changed to CAB (Central Applications Laboratory Building blocks) when the Electron Tube and ICOMA Industriele COmponenten en MAterialen = Industrial COmponents and Materials) divisions were merged to become the ELCOMA (Electronic Components and Materials) division. Contacts with internal customers was intensive from the very beginning. The RGT (Radio, Gramophone and Television) Division, now part of Consumer Electronics, was one of the biggest customers. The arrival of the transistor and the IC shifted, to a large extend, the focus to the design of television ICs. In 1967 the Application Lab was relocated from the building on the Emma Singel to building BA at the “Beatrix Site” also in Eindhoven, where it remained until July 2002, when it was moved to buildings A320 and A410 on the High-Tech Campus in Eindhoven.

| to top of page | back to homepage |

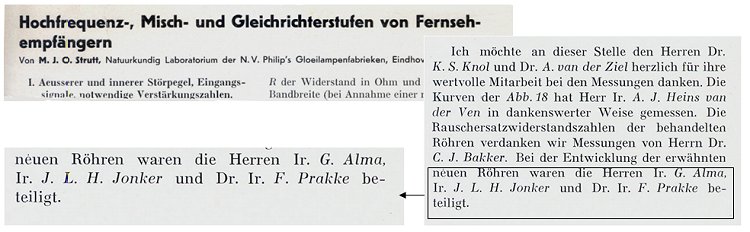

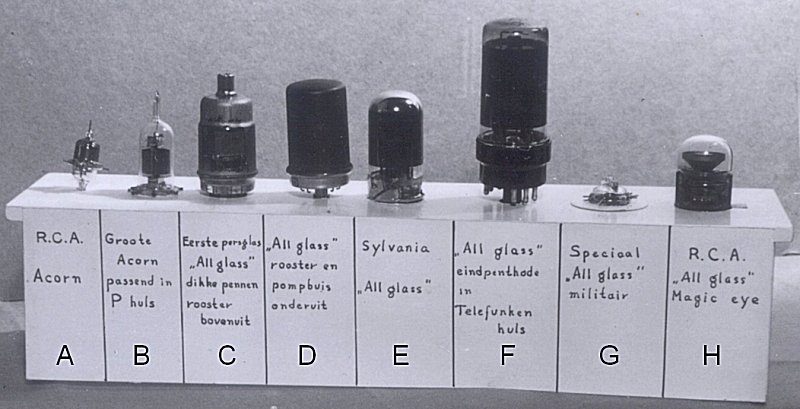

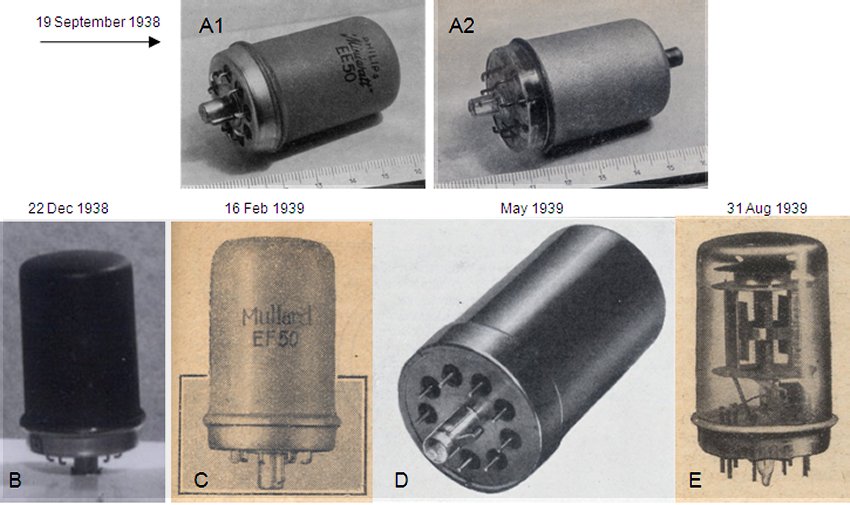

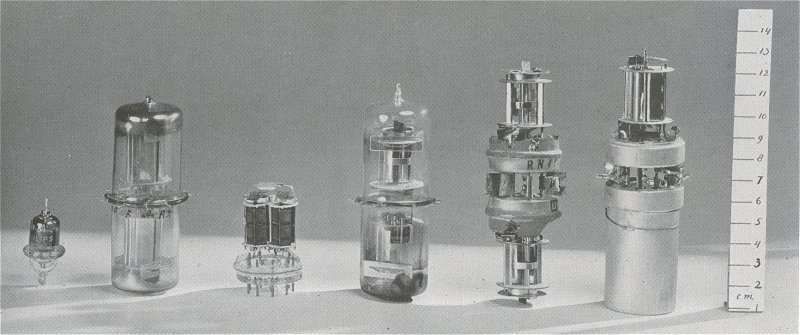

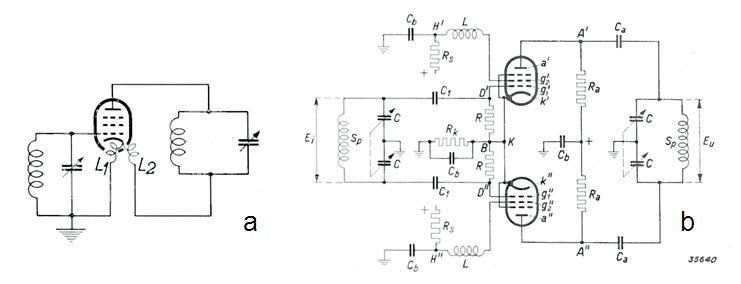

The first publication known to me refering to the new all-glass tubes was a conference proceeding by M.J.O. Strutt from the tube development group at Philips Research [25]. The presentation was given at the first “Internationale Fernseh-Tagung in Zürich” (international television conference in Zürich) held from 19 to the 21th of September 1938. The paper discusses several aspects of “straight” receivers for television. To illustrate the latest developments in the design and fabrication of high performance radio tubes, Strutt included a few photographs of the new all-glass Philips valves (the EE50 secondary emission tube in this case) (Fig. 6.4 A1 and A2) and a photo of a Telefunken “Stahlrohre.” Interestingly, in the acknowledgements Strutt specifically mentions the principle people involved in the development of these new tubes: G. Alma, J.L.H. Jonker and F. Prakke (Fig. 6.1).

Figure 6.1 First publication with a reference to the new all-glass tubes under development at Philips [25]. In the acknowledgements the men behind the development are identified.

A few months later, Jonker publishes an internal Philips Research Technical Note, Titled: “New radio Tube Constructions.” [21] (The original Dutch text of this report is available for download, as well as a translation of the relevant section into English). Indeed Jonker’s role in the development of the all-glass valve is confirmed by the head of radio valve manufacturing and development of Philips at that time: Th.P. Tromp. In a letter of Th.P.Tromp, head of the Radio Valve Department, to Mr. Bell dated 16th of Jan 1979 he writes [20]:

| The facts are these: Prof. Dr. Jonker (head of development lab of electronic valves in the mid thirties) was the originator of the EF50 and this development started already as far back as 1934/1935. It was indeed developed in view of possible television application. |

Figure 6.2 The two locations were the development of the all-glass valve took place: The tube development lab on the Emmasingel (left), and the glass factory on the “Glaslaan” (right) both locations are in Eindhoven.

Jonker’s Technical Note gives a summary of recent radio valve developments [21]. Section two of the document briefly summarizes the first steps at Philips towards the all-glass valve:

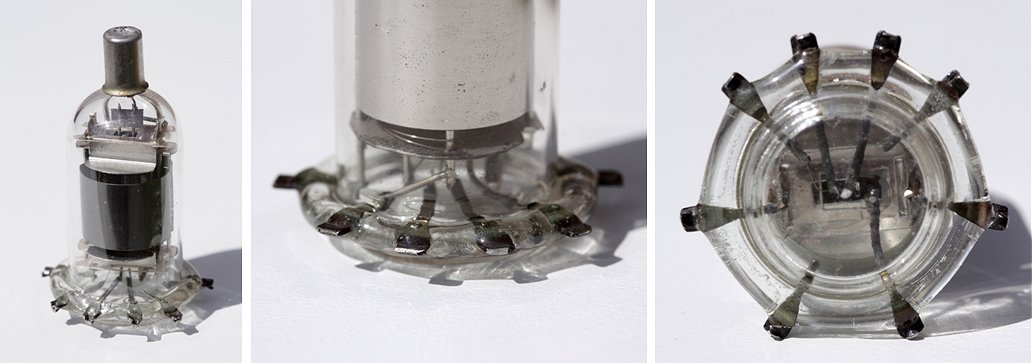

| The introduction of the familiar “acorn” or “button” valve was at that time reason for us to revive an old idea, namely to try to eliminate the pinch in our old glass valves, since the length of the pinch often amounts to more than half of the total length of the valve. Since we had to accommodate the normal E-system in this new tube, we made a large type of button valve that would fit into a P-base [Ct8 base]. The grid was connected to the top of the tube through the exhaust tube to which a metal cap was cemented. |

Figure 6.3 Detail from a photograph in the Technical Note by Jonker. Translation of the text: B. Large Acorn in P socket, C. First Press-Glass “All-glass” Thick pins and grid top connection, D. “All-glass” grid and exhaust tube on the bottom, E. Sylvania “All-glass”, F. “All-glass” power pentode in Telefunken socket, G. Special “All-glass” military. The original photograph is kept at the Philips Company Archive. Klick here for a full scan of the photographs.

Very interesting is the reference and photograph (Fig. 6.3 B) in Jonkers Technical Note to the “large acorn” with P-base (also known as Ct8 base).

Due to manufacturing difficulties, this tube was never commercialized.

I had personally given up all hope of finding more information about this all-glass P-base until I received an email from Adri de Keijzer after the publication of this page. On a open air booth-sale some 15 years ago he actually found several all-glass P-base development samples in a box full of ordinary (Philips) tubes (Fig. 6.4). What a treasure to find!

Figure 6.4 Development samples of the all-glass P-base tube. The pictures are by Adri de Keijzer who owns there rare samples.

Click here for more detailed photographs and a description.

The P-base was a typical Philips/Mullard base, and although it was in use for more than a decade, was not a technical success. The reliability of the contact of the tube to the socket was bad as well as the socket itself. This pushed the development in the direction of the pressed-glass valve base. Jonker:

|

Pressed glass is cheap, and if we could succeed in mechanically pressing the leads into the glass base, this would result in a cheap solution. After many experiments in the glass factory it appeared that thick Chrome-iron pins that could be directly inserted into a tube socket resulted in many problems. The bases cracked, or leaked. The lead-in wires had to be thinner and after some experiments the familiar bend pins that we know today were developed. This construction became possible after we decided to use a spigot which had been so successful in the American Octal Base valves. In this way the pins were protected against bending. When in the mean time all-metal valves were fabricated with all connections on one [bottom] side, we also investigated if something similar would be possible in the all-glass valve. Although this did not seem likely because of the thick glass bottom plate (capacitances), it nevertheless appeared to be possible by using effective screening. With the elimination of the top connection, it was no longer possible to hide the exhaust tube underneath the metal cap. We looked for a construction method whereby the exhaust tube could be fabricated on the bottom side. A method was found whereby a hole was made in the glass bottom plate onto which a glass exhaust tube could be molted. By placing a small metal box around the bottom part of the valve, on the base called “the metal trouser,” the exhaust tube could be neatly concealed, while the pins protruded through openings in this box. |

Figure 6.5 The earliest known photographs of the EF50/EE50 tubes using an all-glass envelop: A, Internat. Fernseh-Tagung Zurich 19 September 1938 [25], B. Philips Research Technical Note No. 1350 22 Dec 1938, C. The Wireless World February 16th 1938 [17], D. The Wireless Engineer May 1939 [18], E. The Wireless World 31st August 1939 [19].

The development of the final all-glass envelope clearly went through a number of stages. By reviewing the early publications and reports, it becomes possible to reconstruct the development states of the pressed- all-glass base (at Philips):

too much pressure on the thin pins. The appearance of the spigot with the rim resembled a key, and hence these tubes were nicknamed “sleutelbuizen” (keytubes). In the mean time the competition had started to introduce so

called “single-ended” tubes, e.g. tubes with all connections on the bottom side, eliminating the need for a top-contact.

The relatively large distance between the pins in combination with the carful placement of metal screens inside the tube made it possible to relocate the grid to the bottom side without introducing additional feedback capacitance. Since the top contact had also been used to hide the exhaust tube, it was decided to relocate the exhaust tube to a position at the bottom of the tube where it would be protected by the “metal trouser.” The tubes in this state have thin bended pins and have either the exhaust tube or the grid contact at the top of the tube (Fig. 6.5 A2)

too much pressure on the thin pins. The appearance of the spigot with the rim resembled a key, and hence these tubes were nicknamed “sleutelbuizen” (keytubes). In the mean time the competition had started to introduce so

called “single-ended” tubes, e.g. tubes with all connections on the bottom side, eliminating the need for a top-contact.

The relatively large distance between the pins in combination with the carful placement of metal screens inside the tube made it possible to relocate the grid to the bottom side without introducing additional feedback capacitance. Since the top contact had also been used to hide the exhaust tube, it was decided to relocate the exhaust tube to a position at the bottom of the tube where it would be protected by the “metal trouser.” The tubes in this state have thin bended pins and have either the exhaust tube or the grid contact at the top of the tube (Fig. 6.5 A2)

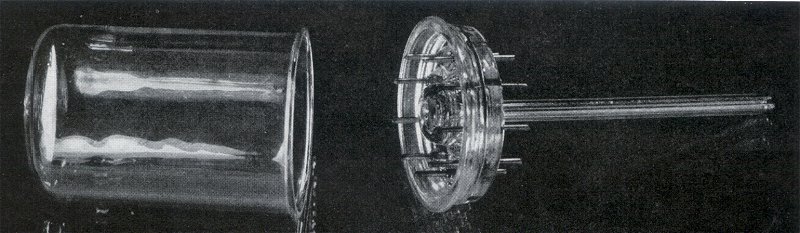

Figure 6.6 The balloon and the pressed glass base of the first all-glass valves (C-technique / Loctal-9 / B9G).

| Mid 1937, during a meeting with the board of directors, I have pointed out that there was something fundamentally wrong with the development of radio tubes. In particular the pace of development was too slow, and there was a lack of new innovative ideas which inevitably would result in losing our leading position. Two and a half years later, near the end of 1939, in a similar meeting I reminded the board of the previous meeting and I pointed out that in the mean time the organization had not changed, and that the situation was exactly the same as in 1937, only that now indeed we had lost our leading position. It is a fact, that since the invention of the pentode not a single new idea of any significance has been taken into production, and that any new idea of any significance lost its value because of the suffocating slow pace of development. The most notorious example is the development of the all-glass tube which, although it no doubt originated from Philips, took no less than 5 years. By that time others had preceded us. The situation had became so problematic that we can say in retrospect that outbreak of the war has saved us for a very painful situation. Telefunken had developed a metal tube of very high quality in a single-ended version while our all-glass tube was not yet ready for mass production as would have been necessary in normal circumstances. |

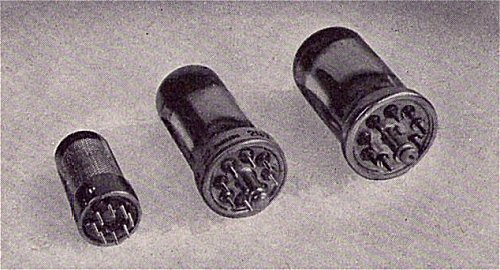

Figure 6.7 From left to right a tube made in A-technique (Rimlock), B-technique (Loctal-8 / B8G), and in C-technique (Key-tube / Loctal-9 / B9G).

Be it as it may, the all-glass envelope was there and it was going to stay. Already in 1938 the use of the all-glass envelope for radio is planned as can be read from Jonker’s Technical Note:

| The development of the all-glass valve has now advanced to such a state that several special valves for television have been introduced, while the introduction next year, of the normal valve series [for radio] in this envelope is seriously being contemplated. In order to gain some experience with the all-glass valve, one receiver type in Holland will be equipped with a single all-glass valve. In order to convince Telefunken of the possibilities of pressed glass, they have fabricated amplifier tubes and rectifiers with a pressed-glass base, underneath which still a normal socket was cemented. It is expected that the all-glass valves will be significant cheaper than the traditional glass valves and metal valves. Additionally, they have better properties for short waves. |

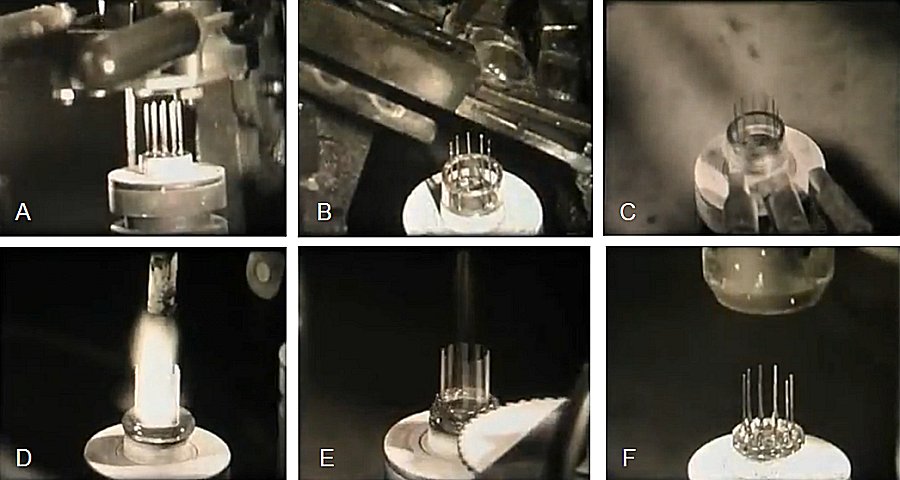

Figure 6.8 Fabrication of a pressed-glass base for Noval tubes. The pictures are stills from the documentary “the Blackburn Story” which shows in great detail the fabrication of an EF80 including pressed-glass base. The fabrication of the pressed-glass base is shown in part 4.

A vital part of the all-glass envelope was the pressed-glass base. It is surprising how little information is still around on the actual fabrication technology of this crucial component. Very illustrative however is a movie which was made in the fifties or sixties at Philips-Mullard showing the fabrication of radio tubes. The movie shows in detail the fabrication of a Noval tube and takes the EF80 as an example. The movie also shows how the pressed glass base for Noval tubes was made. It seems reasonable to assume that the fabrication of the pressed-glass base for the C-technique tubes was quite similar.

To start with the nine pins are placed in a heat resistant template (Fig. 6.8 A). In the case of the C and B-technique valves, these pins were made out of the famous Chromium-Iron alloy. After the pins are placed in the template, a simple glass ring is placed around them (Fig. 6.8 B). The glass ring is intensely heated (Fig. 6.8 C,D). When the glass has sufficiently softened a toothed wheel presses the molted glass in between the pins (Fig. 6.8 E). Finally, a mold is pressed over the pins and the molded glass to press the glass into a disk which seals the pins (Fig. 6.8 F).

Figure 6.9 A machine for the fully automated fabrication of pressed-glass bases for Noval tubes. Machines like this could spit out up to 2500 tube bases per hours.

Obviously, most of the development work was done at the tube lab in the building on the Emmasingel. However, Klaas Rodenhuis, who was responsible for the professional tube development, clearly remembers how he used to visit the glass factory near the “Glaspoort” (Fig. 6.2 right) in conjunction with the development of pressed-glass (Noval) bases with gold pated pins. So very likely a large part of the development work was carried out at that location.